What it is

Kleimer is a specially shaped metal bracket to which the cladding material (plastic, wood) is attached. In turn, the kleimer is installed in the crate with nails or self-tapping screws (depending on the material of the frame). You can choose clamps according to the type of coating, the thickness of the lining and based on the material of this fastener. Mainly, the staples are made of alloy steel or iron coated with a zinc layer.

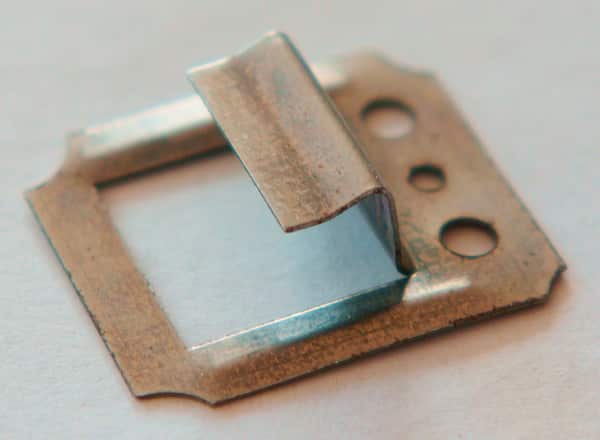

Photo - kleimer for chipboard

Photo - kleimer for chipboard

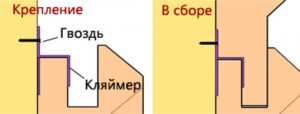

Mainly fastening lining with clamps is produced for in order to hide the installation site. When fastening, a small recess is cut into the board, which is inserted into the protrusion of the bracket. This is a great alternative to classic self-tapping screws, which cannot always be used to install Euro lining or MDF sheets on walls.

Photo - installation example

Photo - installation example

This fastener has many advantages:

- Safety of wood and plastic building material. MDF and chipboard panels can begin to crumble when installing self-tapping screws, while the tongue protects them from destruction;

- Installation can be carried out on any surface and in any room (sauna, kitchen, terrace);

- The fasteners are completely invisible. This is very convenient, because after the end of the installation work, you will not have to paint over the joints, as when working with self-tapping screws;

- If necessary, the casing can be easily dismantled.

Separately, it must be said about the service life. On average, brackets made of steel and galvanized iron will last from 20 to 40 years, the service depends on the characteristics of the room (moisture level, condensation, temperature changes). The disadvantages of fastening include the relatively high cost of the elements. The prices of clapboard clamps can be two to three times higher than the cost of standard screws and nails.

# 1. Features of the installation of the lining

The lining is recommended to be mounted on a pre-installed frame. If the walls or ceiling have a perfectly flat surface, it is allowed to install the lining without constructing a frame, but the lathing still helps to extend the service life of the base surface and allows you to create an additional layer in the space between the lining and the main surface for laying heat-insulating material.

The lathing is fastened in 50-60 cm increments, it is imperative to use a level to achieve a perfectly flat surface and compensate for unevenness in the base ceiling or wall. The frame can be made of a metal profile or a bar. When it comes to wooden lining, it is better to stop the choice on a bar. It's all about the ability of wood to absorb and release moisture, changing in volume. The lining and timber will react in a similar way, but the metal in the volume does not change, and if the profile is rigidly fixed to the surface, the lining can lead. Of course, this risk persists when using a wooden frame, but still to a lesser extent.

Between the bars of the lathing, you can lay heat-insulating material, which is important not only for residential buildings, but especially for baths and saunas.

You can mount the lining in one of the following ways:

- horizontally. This is probably one of the most popular lining installation options. Some types of material (quarter paneling and "American") can only be mounted in this way. If we are talking about arranging a steam room, then it is necessary to place the slats with the thorn up. Only in this way will condensate and water slide freely along the wall. In this case, the installation of the lining begins from the ceiling;

- vertically. This arrangement allows you to visually raise the ceiling in the room, it is often used in baths.The installation of the lamellas begins from any angle, the first element is installed with the groove outward. When fixing the lining to the ceiling, it is recommended to work in a direction away from the light in order to avoid the appearance of shadows between the boards;

- diagonally. This is a decorative styling option that is often used when decorating walls and ceilings in living rooms;

- combined and patterned laying involves the installation of lamella lamellas in different directions, due to which you can get an original drawing. Unlike all the others, this installation option requires proper skill and preparation, so it is not suitable for beginners.

The direction of the lathing bars will be perpendicular to the direction of the lining, this goes without saying.

How to attach the lining to the clamps

When the lining and the type of fastening are selected, the question usually arises of how to fasten the lining with clamps. This process is quite simple, but to make it easier, you can watch special training videos.

Carriage panels can be installed both horizontally and vertically, everything will depend on personal wishes. Vertical panels, for example, will visually enlarge the room, and horizontal ones will visually make the narrow one a little wider. And the method of installation will already be selected depending on the type of fastening of the lining.

When the vertical mount is selected, the first plank is mounted in a corner, leveling it with a level. On the middle of the carriage panel, in a special groove, a bracket is fixed, which is attached to the frame with nails or screws. The third part, which it grabs, is cut off from the next bar and fastened under the first. The element that remains is mounted in the groove to the first panel.

On each carriage rail, fasteners for the clapboard are installed, about 4 pieces. All of them must be screwed to the frame, in order to avoid deformation of the entire coating in the future.

The second and subsequent carriage panels are inserted into the grooves to the already installed ones, and from the reverse side, they are mounted with special fasteners to the crate.

When it is customary to sheathe the walls with panels horizontally, then the attachment of the planks must be made up with thorns. This will contribute to better ventilation, and therefore mold and mildew will be less dangerous, as well as prevent the collection of water or dust between the carriages. Carriage panels are mounted with horizontal cladding from bottom to top. On the bottom row, the brackets should be fixed a couple of millimeters above the floor. And the outer panel is cut in such a way that the remaining distance is completely covered.

This work is quite painstaking, so there is no need to rush here. And in order for the wall cladding to turn out perfectly flat, it is necessary to regularly check with the level how all the cladding elements are laid.

How to choose the right kleimers

It is possible to choose cleats for installing lining and plastic according to the dimensions of the panels and their materials. The staples are classified by the size of the tab or tongue that is used to support the locating sheet. There are such types:

- For installing chipboard. The thickness of the elements is 4 mm;

- For the installation of plastic lining and MDF. Up to 2 mm;

- For fastening panels made of Euro lining, brackets up to 4 mm thick are used;

- For classic wooden lining, 5 mm fasteners are used;

Also, in some cases, the dimensions of the sheet are selected individually, depending on the thickness and material of the panels, as well as on the place of their installation. It is most convenient to buy fasteners in bulk at once, this will significantly save your time and money.

In hardware stores, the classification of kleimers is carried out by numbers. For example, when installing aspen panels, brackets 5 and 6 are used for the ceiling, and for Euro lining 4. Check the information directly with the seller so as not to confuse the fasteners.

Photo - steel kleimer

In the process of choosing clearers, a prerequisite is that you need to take into account the thickness of the material used in finishing work.

It is very important to use only those clapboard brackets that correspond to the dimensions of the product that you plan to use for cladding a particular structure

If we talk about the consumption of these fasteners, then you will need about 20 pieces to finish one square meter. Claymers have a relatively low cost, so you can safely purchase these parts with a margin - in any case, it will cost you less than buying other types of hardware.

The main requirement when choosing cleats for lining is dimensions. It is from the parameters of your panels and the type of material that you determine the appropriate option for fasteners so that they provide the expected reliability of the coating, but are invisible upon completion of all finishing work.

Having decided where to buy clays for lining, consider the following recommendations for the purpose:

- staples up to 2 mm - the optimal solution for assembling structures from plastic panels and MDF-type plates;

- 3 and 4 mm fasteners are purchased when clamps are needed for euro lining or chipboard;

- 5 mm fasteners - to solve the question of how to fix the lining made of wood, especially of such species as aspen, linden;

- 6mm products are used for the blockhouse.

-

strength of steel;

-

the integrity of the galvanized;

-

consistency of dimensional parameters of the entire batch.

The described fasteners for lining are so common among consumers today for a variety of reasons. Among others, we can highlight the possibility of carrying out installation work in a room, the conditions of which are characterized by a high level of air humidity. Among other things, such fasteners are quite simple to use, even an employee who does not have enough experience can perform manipulations.

The main requirement when choosing cleats for lining is dimensions.

Specifically from the characteristics of your panels and type, determine a suitable option for fasteners so that they provide the expected reliability of the coating, but are invisible upon completion of all finishing work.

Having decided where to buy clapboards for lining, consider the following tips for appointment:

- staples up to 2 mm middle solution for assembling structures made of plastic panels and MDF boards;

- 3 and 4 mm fasteners are received when clamps are needed for Euro lining or chipboard;

- 5 mm fasteners to solve the question, how to fix the lining made of wood, especially of such species as aspen, linden;

- 6mm products are used for the blockhouse.

-

strength of steel;

-

the integrity of the galvanized;

-

consistency of dimensional characteristics of the entire batch.

Rules for calculating the stamps and their application for fastening

The experience of using kleimers shows that to securely and firmly fix one square meter, it is quite enough to pick up about ten pieces.

- For a more accurate calculation, you need to measure the length of one panel. After that, we measure the pitch of the sheathing frame. Typically, this distance ranges from 40 to 60 centimeters. We divide the length of the panel by the lathing step and add one. We multiply this result by the number of panels. This will be the right amount for fastening.

- When choosing the type of product used for fixing panels, it is necessary to take into account that each element must be fastened with two or three self-tapping screws. It is not worth saving on their quantity, as this can affect the reliability and quality of installation in general. For the fastening of heavy panels, thicker reinforced elements with a large number of points of their fastening are used.

- After calculating the number of clippers, you can start installing the panels. The wall on which the installation is planned is pre-treated with special antiseptic solutions to eliminate the possibility of fungus formation.In the future, clamps are installed on the wall or installed crate with nails or self-tapping screws. In this case, nails are used only in the case of using a lathing.

- Since the use of lining requires a flat surface, in the presence of uneven walls, it is necessary to calculate how best to align them. Perhaps leveling the wall surface with a special mortar or installing the lathing.

- Very often, in such cases, a crate is used, which is quickly installed on the wall surface, and you can immediately install it on it. Usually, the lathing is made of a wooden bar of the same thickness, which is fixed at a distance of about one meter from each other. When installing a wooden lining, this distance is slightly less, and is about 50-60 cm.

- When installing the lathing beam, you need to constantly monitor the plane of the resulting surface, which should be flat. If necessary, to obtain a flat surface, plates of the required thickness are placed under the bars.

- The use of leveling solutions takes a long time, after which time is also needed for them to dry. Therefore, this option is used much less often and if necessary to carry out such work.

- Having installed the fasteners for the first panel, proceed to its installation and the subsequent fastening of the clamps for the next one. The first board is tightly inserted into the hooks of the kleimers, the rest are mounted in the same way. This method ensures an accurate and secure fit of each panel to each other.

- To ensure high-quality installation with natural further ventilation, it is necessary to take into account that the boards should not touch the wall surface. Otherwise, it will lead to limited ventilation, moisture accumulation, mold and mildew formation.

- When working with clapboard and cleats, it should be noted that work should be carried out at an ambient temperature of at least 10 degrees, since at lower temperatures deformation of the panels can occur. Kleimers must be made of stainless materials and are treated with a special protective coating, since rust can spread over the surface of the lining.

- You cannot use liquid sealant at the joints of wooden panels, but it is better to choose a moisture-proof film for this. Its use in case of temperature extremes can lead to cracking of the panels. After the installation is completed, the surface of the lining should be treated with special protective antiseptic materials that increase its resistance to precipitation and ultraviolet radiation.

- Taking into account all the requirements for the selection of clamps for lining will provide reliable and durable installation, as well as a long service life of the installed coating.

For information on how to attach clamps for lining, see the next video.

Subtleties of installation

Installation of cleats is carried out using a screwdriver, a building level, a tape measure, a square, a hammer, a screwdriver and a marker. The first stage of work should be the preparation of the working base by leveling the surface or, if necessary, installing the lathing. The evenness of the base is determined using a laser or a building level. All protruding parts must be removed, and large cracks, chips and deformations must be eliminated using a cement-sand mixture.

After that, you should make an antiseptic treatment of the base and wait until the surface is completely dry. Then you can start marking the installation locations of the cleats. It should be borne in mind that with the vertical arrangement of the rails, the installation of hardware should be planned at a distance of the width of the board from the adjacent wall. With a horizontal arrangement, 2-3 mm should be retreated from the floor, necessary for screwing in the self-tapping screw

Particular attention should be paid to the clarity of the location of the first element, since the correct installation of all subsequent strips and the appearance of the cladding as a whole will depend on it.

The installation of cleats and lining strips occurs alternately, so the main thing is to strictly observe the installation order and monitor the parallel arrangement of the elements. The use of nails as fixing elements for the bracket is permissible only in the case of installation on a wooden crate. In all other cases, self-tapping screws or dowels should be used, depending on the size of the bracket and the weight of the wooden planks. Then you should proceed with the installation of the cleats, while it is necessary to ensure that the board lies flat: without shifting to the side and violating the general order of laying.

In order to facilitate screwing in the screws, you should first mark the necessary places with dots. After installing the first brackets, it is necessary to proceed with the installation of the lining, simultaneously fixing the following brackets. The first lamella is inserted into the hook of the staple, and then the subsequent lamellas are slotted into the ridge. The next bracket should not be fixed until the absolutely level position of the first panel has been determined. The end part of the lamella, equipped with a ridge, must be pressed tightly to the base, and at this time, insert the clearer into the groove from the back side and fix it with self-tapping screws.

Following this installation technique, you need to complete the installation of the material, periodically checking the readings of the building level. After installing the last board, it is required to close the metal fastening elements with a wooden side.

Kleimers as a type of hidden panel mounting

Kleimers are one of the options for installing the finishing of hidden-type premises. They are special shaped brackets that are installed on a wall surface or other base using ordinary self-tapping screws, as well as nails. A special shaped hook protrusion on the clearer serves for further fastening of panels to it.

They are used for fastening different materials.

- Curtain wall elements made of stone or tiles up to 14 mm thick. For the installation of natural stones, reinforced products are made, designed for a thickness of up to 40 mm.

- Facade cladding with large aluminum elements.

- Flooring elements such as decking.

- Skirting boards.

- Various panels in different sizes inside the building.

- Lining of various profiles and materials.

Cleamers are made on special equipment by stamping from ordinary and special strip steel, as well as from aluminum. After that, they are covered with an anti-corrosion coating, most often zinc.

The use of cleats for installation has a number of specific advantages and benefits.

- There is absolutely no possibility of damage to the material of the panels during their installation. This is due to the fact that when using them, holes do not appear. While when fixing lining panels with nails and screws, there are always holes from which cracks can form in the future, moisture can get into them and cause rotting of the material.

- Cleamers are hidden fasteners that cannot be seen from the outside. This improves the appearance of the room, and the walls look beautiful and stylish, as a whole, without nail heads and screws.

- This is a very easy-to-use type of installation that does not require special tools.

- The staple made of durable metal is very reliable and will last for many years.

When choosing cleats, it should be borne in mind that they are available in various thicknesses.

, which is chosen, taking into account the weight of the structures to be fixed. So, the usual, most common, has a thickness of about 0.5 mm, and the reinforced version is about 1 mm or more.When intending to use clamps for fastening, it should be noted that in this case the panels to be fixed must have a margin in the thickness of the gap, calculated taking into account the thickness of the fastening used. Otherwise, it will not be possible to use it.

To do this, you need to take panels from different packs, insert them into each other together with the kleimer. In this case, everything must fit tightly, without unnecessary gaps, otherwise the installation configuration will change.

How to fix it?

The installation of the cladding begins with the fastening of the lathing on the desired surface. Even if the surface of the wall, ceiling or floor is fairly flat, the lathing allows you to create a level and verified plane, allows for ventilation, and also provides space in which a variety of cables and insulation can fit. The lathing can be made from wooden bars, or you can assemble a metal one, as for fixing drywall. For the installation of wooden lining, a lath made of wood is better, especially in a bathhouse and a sauna, since the wooden lathing "plays" with the wall and prevents the wood material from cracking when it dries and swells, depending on humidity and atmospheric conditions.

You need to decide in advance on the direction of the wall cladding. There are 4 options with which you can fix the panels on the crate: horizontal, vertical, diagonal, combined. It should be noted that the direction of the strips of the lathing should be perpendicular to the direction of the lamellas of the used finishing material. For horizontal installation, the first plate must be fixed horizontally with self-tapping screws or nails at a distance of 1-2 mm from the floor or ceiling.

This attachment will later cover the ceiling or floor skirting board. We install the kleimer tongue in the groove of this board, and fasten its base with self-tapping screws or nail it to the crate. All the following panels are inserted with grooves into the ridge of the previous one and securely fixed to the lathing bars.

For a more reliable connection, you can fix the sheathing by attaching the boards to each other more tightly, lightly driving them into the grooves using a mallet and a tamping board. The last plank, if necessary, cut to size to the required width. When laying the panels horizontally in a steam bath, they begin to be installed from the ceiling so that the lining spike is directed up the wall, and the groove down. This is necessary so that condensation does not accumulate in the lining, but flows freely down the wall.

With vertical installation, the starting board is nailed vertically from the beginning of the sheathing, placing it close to the crate and hammering a nail into the crest of the lining. The nail heads on the first board can be removed with a side cutter or covered with decorative strips. Clips must be installed in the groove of the first board and fixed with nails or self-tapping screws on the crate. Place the comb of the next board into the groove of the previous one.

We use a rubber hammer to fit the lining panels more tightly into each other. And then, with the help of clamps, we install all the finishing materials. The last panel is also cut to size. With such an installation, the correct vertical of the installation must be checked using a plumb line every 7-10 panels. Vertical cladding is suitable for rooms with high humidity - saunas, baths, verandas, for upholstery from the street, as it does not allow moisture to accumulate in the grooves of the lining.

With diagonal and combined laying, sufficient skill and professionalism is required, therefore it is better to entrust such a cladding to a specialist with sufficient experience. This type of cladding is most often used for interior walls and ceilings.

All types of cleats, what they are used for and how they are attached, see the video.

Mounting on self-tapping screws

Through fastening on self-tapping screws through the entire board, and not through a groove, is the simplest, rather reliable, but not the best solution for a wooden lining.With this method, the integrity of the material is violated, so the holes must be regularly treated with special protective mastics in order to prevent the destruction and rotting of the wood. Despite all efforts, over time, the installation locations of the fasteners can become noticeable, which significantly impairs the aesthetics of the decorative finish. Usually, the first and last panels are mounted this way for reliability, and for the rest they use fastening on finishing studs or clamps.

What is a kleimer

Cleamers are staples for attaching finishing materials such as wall clapboard, MDF panels and plastic plates. They are made of galvanized metal (to prevent corrosion). These hardware are attached to the surface with nails or self-tapping screws. As a rule, decorative materials are attached with their help to the crate, less often directly to the wall.

Advantages of cleats over other mounts

This is an affordable fastener sold at any hardware store. It is recommended to buy them in specialized establishments to avoid purchasing low-quality materials.

If you calculate the cost of these hardware, then their purchase will cost more than screws or nails, which also often act as the main fastening of the lining. The savings will lie elsewhere. Fastening with staples is more economical, due to the fact that chips or cracks do not appear on the panels themselves. With nails and screws, the opposite is true, and often you have to buy spare lining panels to replace damaged ones.

They are attached to the wall or lathing, and then the lining strip is inserted into special grooves. The advantages of this material include:

- Installation takes place several times faster;

- During the use of clamps, the lining panel is almost impossible to damage;

- They can be installed in a room with high humidity due to a special coating that prevents corrosion;

- Varieties of hardware, which differ from each other in size, allow you to choose an option for concealed installation of panels of any size;

- Thanks to reliable fixation, the lining will not begin to move and deform over time;

- Claymers are highly durable and not subject to breakage.

But why do many people prefer fastening the lining with clamps? Unlike nails and screws, as mentioned above, they significantly reduce the chance of ruining the lining and do not lead to additional waste. They are more practical and convenient to use and allow for seamless installation.

What are kleimers, their advantages

The high consumer demand and popularity of kleimers are due to the many indisputable advantages of this type of fastener.

- The simplicity of the design and the uncomplicated installation process allow you to independently perform the facing of the room without resorting to the services of specialists, and the exact observance of the installation technology will significantly reduce the time of work.

- The use of staples eliminates drilling, nailing and other mechanical impact on the lamellas of the lining, due to which the appearance of cracks and chips becomes impossible. This is one of the advantages of using fastening clamps over installation, carried out using self-tapping screws, nails and screws.

- A large size range of models allows you to form a neat seamless coating even when using the technique of combining the lining with other finishing materials.

- Reliable fixation, which is achieved with the help of clamps, completely eliminates the risk of deformation and shear of the coating.

- Kleimers are highly resistant to aggressive environmental influences and high humidity, so they can be used both in freezing temperatures and when decorating baths and saunas.

- Comfortable cost. The price of kleimers compares favorably with the price of other types of hardware.

- The versatility of the design allows the use of brackets when installing the lining on any rough surfaces, including wood, concrete, cinder block, cement bases and lathing.

The disadvantages of clapboards for lining include insufficient reliability under the influence of increased loads or foundation vibrations.

Kleimers are made of galvanized iron or spring steel. They are special brackets for fixing the lining, which are installed on a wall or lathing using self-tapping screws or nails. Cleamers are also used for fixing plastic boards and fixing MDF panels.

Clamps for fixing the lining are easy to purchase at any hardware store, and the low price is another advantage. Of course, buying nails and screws is a little more profitable, but the practicality of use and ease of installation with their help fully justify these costs. But besides this, there are a number of other advantages:

- The construction process is 2-3 times faster;

- Installation using cleats completely eliminates damage to the finishing material (cracks and chips), due to the fact that the panel itself does not need to be drilled or nailed to fix it;

- Such a fastener is not afraid of constant exposure to high humidity. And it is best suited for indoor use like a bath;

- Ease of installation: even an inexperienced person can master the technology of using clearers;

- There is a wide selection of cleats that differ in size, and this will allow you to choose a fastener that will facilitate fastening in a hidden way and without seams;

- Reliable fixation of trim panels, without possible shift in the future;

- Cleamers are very reliable, they are not subject to corrosion and destruction, and are highly durable.

Preparation of the base

A perfectly flat surface is necessary so that the plastic or wood material is correctly mounted, and there are no gaps, depressions or protrusions between the panels.

A perfectly flat surface is necessary so that the plastic or wood material is correctly mounted, and there are no gaps, depressions or protrusions between the panels.

Therefore, the installation of the frame is a necessary stage in such finishing work.

It can be assembled from wooden bars, a metal profile and special plastic guides, in which grooves for fastening the cleats have already been made.

The step between the bars of any kind of lathing should not exceed 60 centimeters. And the distance between them can, if necessary, be filled with heat-insulating material. The simplest material for assembling the frame, of course, is wood (except for rooms with high humidity, such as a bathroom, bathhouse, sauna).

But it should be remembered that wooden blocks can eventually rot, so it is advisable to cover them in advance with a special antiseptic that will protect them from biological damage for many years.

Installation

Depending on how to attach the lining to the clamps, vertically or horizontally, the installation method is also selected.

Depending on how to attach the lining to the clamps, vertically or horizontally, the installation method is also selected.

In the vertical position of the cladding, the first panel is installed in a corner and leveled with a level. In the middle of the lining, a bracket is installed in the groove and attached to the lathing with nails.

With a vertical installation method, 3-4 clamps for lining are screwed onto one panel. Each of them must be fixed on several nails to the lathing bars in order to avoid deformation of the structure in the future.

The next finishing board is inserted into the groove of the one that is already installed, and on the other hand it is installed with fasteners to the frame.

Video - editing using this technology:

Sauna finished horizontally

In the event that the cladding is mounted horizontally, then the plates are fastened with spikes upward, which improves ventilation and prevents the accumulation of water and dirt between the grooves of the panels.

The installation of the horizontal Euro lining is carried out from the bottom up, and the brackets of the first row are fastened a few millimeters from the floor.In this case, fastening to the cleats of all panels should be made to each bar.

The last board or plastic panel should be cut to close the remaining gap.

Conclusion

Clamp mounting has a number of advantages and is a modern alternative to fixing with finishing nails or a stapler. In the event that the surface cladding is carried out in compliance with all the rules and instructions, then it does not present any difficulties and is available even to a non-professional builder.

Important points

When attaching the lining to such brackets, you must keep in mind some details:

- there should be some space between the lining panels and the wall for ventilation. That is, it is impossible to firmly fasten the bar to some surface, otherwise harmful microorganisms may settle there,

- if the lining is attached to a wall on which there are sockets, then at first the entire wall is closed with strips, and only then the corresponding holes are cut out with the help of a saw,

- when the entire surface is sheathed with clapboard, at the joints, at the bottom and at the top, small gaps remain, which are masked with special skirting boards that are suitable in texture to the finishing material.

Using a clapboard as a fastener, you can get a number of advantages, since this modern technology is the safest for surface cladding. If you strictly follow all the rules, as well as adhere to the prescribed instructions, then there will be no problems with such a mount, and even a non-professional master can handle it.