Peculiarities

A facade board called planken can successfully replace a bar, lining or block house. This material is widely used in various construction and finishing works. Of course, there are tasks for which planken is best suited. For example, installing a planken on the facades of buildings will add warmth and a chic look to them.

You can make a wonderful fence, playground, pieces of furniture from it. It should be noted that the material is resistant to water and various pests. And also it is often used in the construction of open verandas, gazebos, terraces, for finishing ceilings and railings.

For the manufacture of planken, larch, pine or polymer composite is most often taken. Of course, in terms of characteristics, larch will be better than others. A strong and durable material is obtained from it, which also provides noise damping. Pine contains substances that prevent the spread of rot and fungi.

Plankening of buildings requires that the surface is first treated with antiseptic drugs.

And it is also important for the reliability of fastening to make the frame correctly. Moreover, under it you can lay materials for insulation and sound insulation.

Experts recommend laying the boards horizontally in order to reduce material consumption, and this will also help to make the surface look as aesthetically pleasing as possible.

There are several types of planken.

Straight, which is also called classic. Differs in straight edges

It is important to mount it with a technological gap.

Beveled, in which the edges are rounded and cut at a certain angle (35-70 degrees).

With grooves, which are overlapped.

Mounting

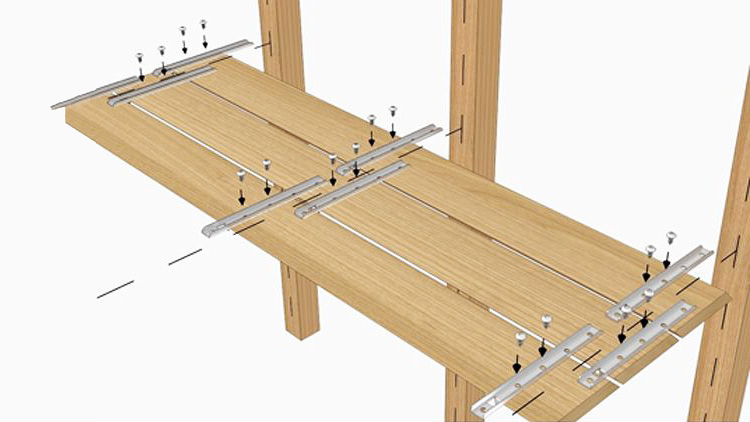

There is a certain instruction, the sequence of actions which must be followed in order to carry out the fastening with the "snake" fastener correctly, creating a strong and sealed connection.

Installation is carried out as follows:

- at the first stage, you need to prepare self-tapping screws, a screwdriver, planken and the fasteners themselves;

- the strips are mixed in such a way that their reverse side is on top;

- fastening of the fixing part is carried out - you need to fasten it so that it protrudes beyond the planken board by about 1–2 cm;

- it is installed at all points where the planking board intersects with the crate;

- then the plank board is turned over and attached to the crate;

- after the joint, all subsequent boards are mounted and attached to the joint.

"Snake"

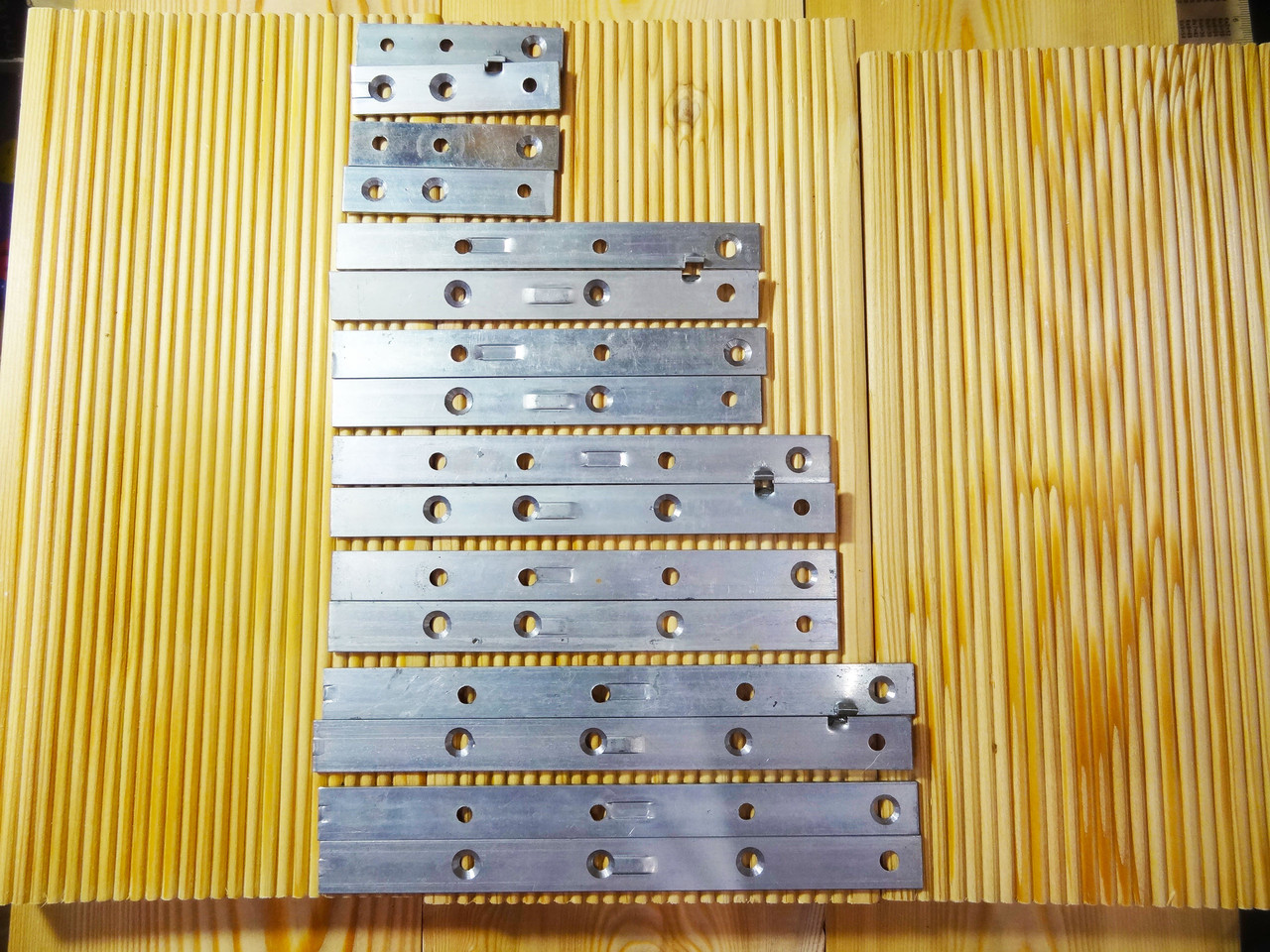

This option is clearly used for the oblique planken, as the only possible one, but it can also be used on a straight board. The name was formed due to the characteristic mounting of the fastening strips, reminiscent of the movement of a snake: the plates alternately criss-cross at the junction, like a wave. The length of the plank depends on the width of the board: up to 110 mm, a 145 mm plate is used, and over 110 mm - a 190 mm plate. At the same time, the width remains standard - 15 mm.

Fastening for planken type "snake"

Fastening for planken type "snake"

Along the length of the plate there are holes for fixing with self-tapping screws to the board. The main features of the "snake" wiring diagram are:

- The plate protrudes 10 mm beyond both edges of the board. The hole for fixing with a self-tapping screw on the crate is located on the top. The lower part is wound up behind the bar of the previously laid board - in this way a wave is formed;

- To provide the necessary clearance, each plank has a flange - a curved tendril of standard width, against which the ends of the plank abut;

- Before starting work on the back side of planken boards, laying and marking of fasteners is carried out;

- Since on one batten of the lathing there must be two docked strips at the same time (the width of each is 15 mm), then its optimal width should be at least 40 mm.

You can learn more clearly about the installation method using the snake fastener from the following video:

Planken mount: general installation nuances

When considering modern facing materials, many contractors forget to mention to the customer about the possibility of facing the house with planken. Mounting the plank on the wall does not take much time, but the result is ready, striking in its excellent appearance.

This siding is a set of wood planks fixed to the facade of a building or indoors. Planks come with rounded, square and oblique edges, it all depends on the imagination of the interior designer and the wishes of the customer.

General installation nuances

In order for the finished result to meet expectations, and a beautiful result pleasing to the eye for a long time, it is necessary that the mount for the planken be correctly selected (Snake, Key, Planfix, Crab, etc.), and the work is done by professionals. In addition, the veneering result is influenced by:

- board - type, profile, quantity, type of wood;

- processing - varnish, enamel, anti-corrosion and other compounds;

- wall - the working surface is important and must be prepared, it must also be opened with protective equipment, if necessary, heat-insulating (waterproofing) materials are laid before the frame is installed.

- frame - the fasteners must be correctly selected for the desired end result, the board is always a board, and the desired decorative result is achieved precisely by the correct selection of the type of frame and its competent installation.

Mounting options

There are two types of plank fastening: hidden and open. Open fastening means fixing the plank elements to the frame with screws or self-tapping screws, in the case of a metal lathing.

But this approach has several drawbacks: the caps are visible, the screws violate the physical integrity of the wood, accelerate corrosion, promote the development of fungus, in addition, some types of wood (for example, larch) simply crack.

Concealed fasteners

This topic is extensive, because for such a fastening many types of special hardware are used: "Wave" ("Snake"), "Crab" and others. The choice of fastening depends on the required pattern and the type of elements (straight, beveled or a system of grooves).

A straight profile is the easiest to install, but it has one significant drawback, namely the need for a technological gap, which slightly spoils the aesthetic part of such a cladding.

Beveled profile - the boards are attached, going behind the adjacent one, completely covering the frame, therefore it is considered the most highly aesthetic and popular.

A profile with grooves is an imitation of a bar, this type of plank is sometimes called clapboard, and the boards have a thorn-groove design, the fastening is hidden and completely covers the frame.

General settlement rules

In addition to the attractive appearance, hidden fastening systems have a number of technical advantages that make the industry of such frame fasteners so developed and diverse.

Only hidden fasteners can fix hard (iron wood, oak) and fragile (larch) wood species, make the fastening invisible, so that the structure will look whole and neat.

As a general rule, calculations of the consumption of fasteners are made according to the formula:

K = S / (W + Z) / L

Where abbreviations mean the following points:

K is the estimated consumption of fasteners;

S is the area of the required siding;

W is the width of the planken beam;

З - gap width (for straight profile);

L is the distance between the details of the lathing.

Block quote: "The simplest and most reliable calculation method for a specific fastening system is a calculator on the manufacturer's website."

Fastening systems

Before proceeding with the purchase of materials, it is necessary to accurately determine the question: "how to fix the planken?" The modern market offers a lot of options for hidden mounts, and many companies offer their product.

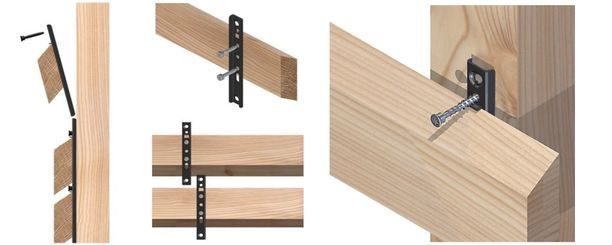

PLANfix

This fastener is designed for a rectangular profile that does not have grooves. The fittings are plates with a 90-degree bend; the plate has mounting holes and a fixing spike.

Advantages:

- mounted on the side of the board, so you can fix the plank, up to 18 mm thick;

- technical clearance provides effective ventilation;

- can be fixed without electrical appliances.

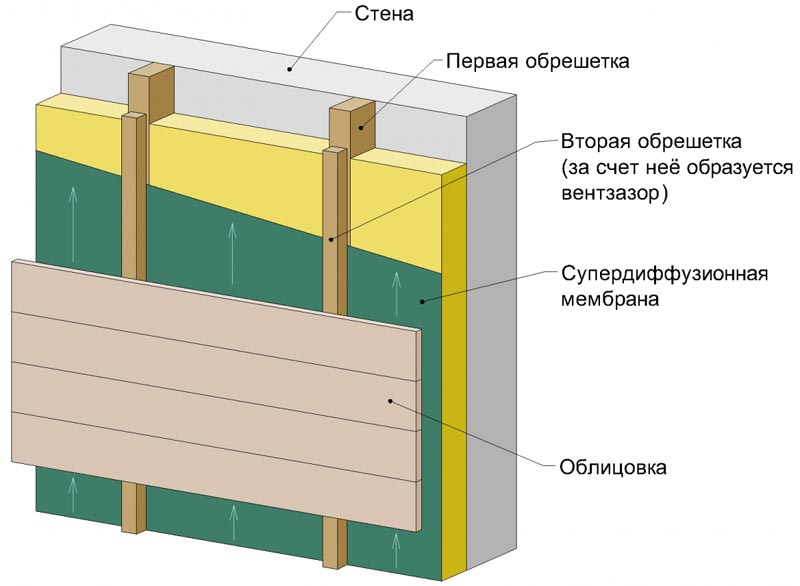

Facade construction and material installation

Facade finishing with planken is carried out in three stages:

- Arrangement of the lathing.

- Laying the heat-insulating layer.

- Installation of cladding.

Such a system will be a ventilated façade that allows air currents to dry out the walls and their cladding.

The dimensions of the battens for installing the planken depend on the width of the heat insulator plates. All varieties of mineral wool are usually 60 cm wide.For this size, the distance between the frame slats should be 58 cm.

General diagram of the device of a ventilated facade for installation of a facade board

In any case, this distance is chosen so that the insulation fits tightly between the slats. The thickness of the battens must always be greater than the thickness of the insulation. If this condition was not initially met, the problem can be corrected by sewing on additional slats - thus, you have a mandatory ventilated space of 20-30 mm in size.

After complete installation of the crate, a heater is installed between its slats, which is covered with a waterproofer and a wind barrier.

Before installation, it is most convenient to mark and fix the fasteners on the ground.

In principle, a fairly dense cellophane film can also play their role. After its installation, the entire “pie” is fixed with dowels directly through the insulation. These fasteners are installed by pre-drilling the holes. As the drill goes into the rock wool, you may find that the material is wrapped around it.

To prevent winding, a plastic or metal hollow tube is needed. Its diameter should be such that the drill fits into it. This tube is threaded through the cotton wool, and drilling takes place through it.

Variety of material and its fasteners

Planken is a wooden board designed for wall cladding, floor and ceiling decoration, which is laid in a vertical or horizontal position. Its width is from 70 to 140 mm, and its thickness is from 15 to 20 mm. Finishing material is made from different types of wood, but larch is considered the best.

Planken is of three types:

- A straight planken in cross section looks like a rectangle. Install it on the Snake or Key mounts;

- A straight planken with grooves has a similar shape, only its sides are equipped with special locks for fastening. Install it on the Crab or Bridge fasteners;

- The beveled shape has oblique edges that hide the technological gaps during installation and provide ventilation for the cladding of the house. Concealed installation is performed only with a Snake.

- straight with grooves

- straight planken

- beveled shape