Features of use for wooden products

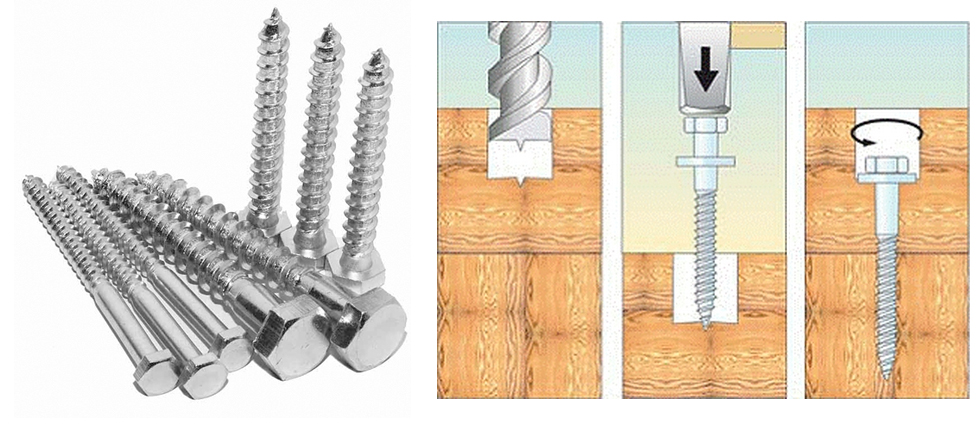

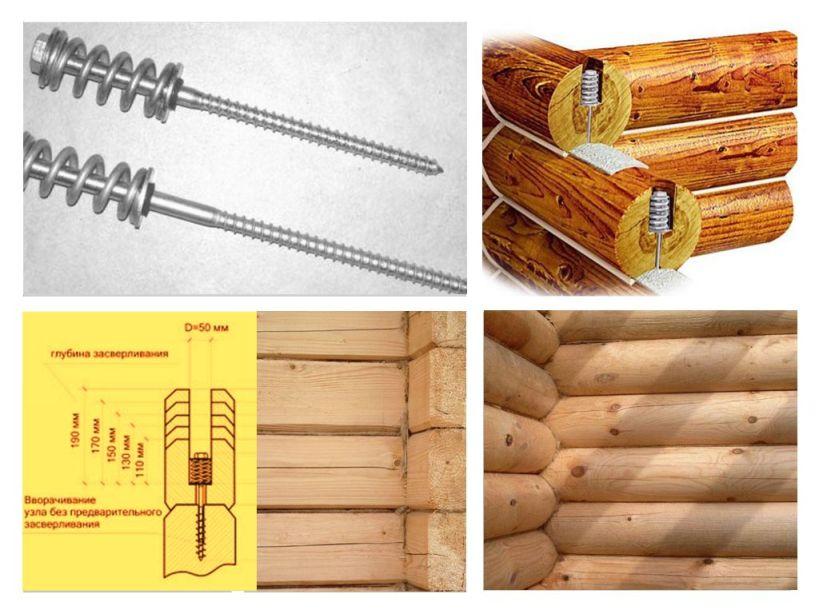

If work is carried out with wooden structures and the wood of the products is not too hard, and the wood grouse has a small diameter, then it can be screwed in without preliminary drilling.

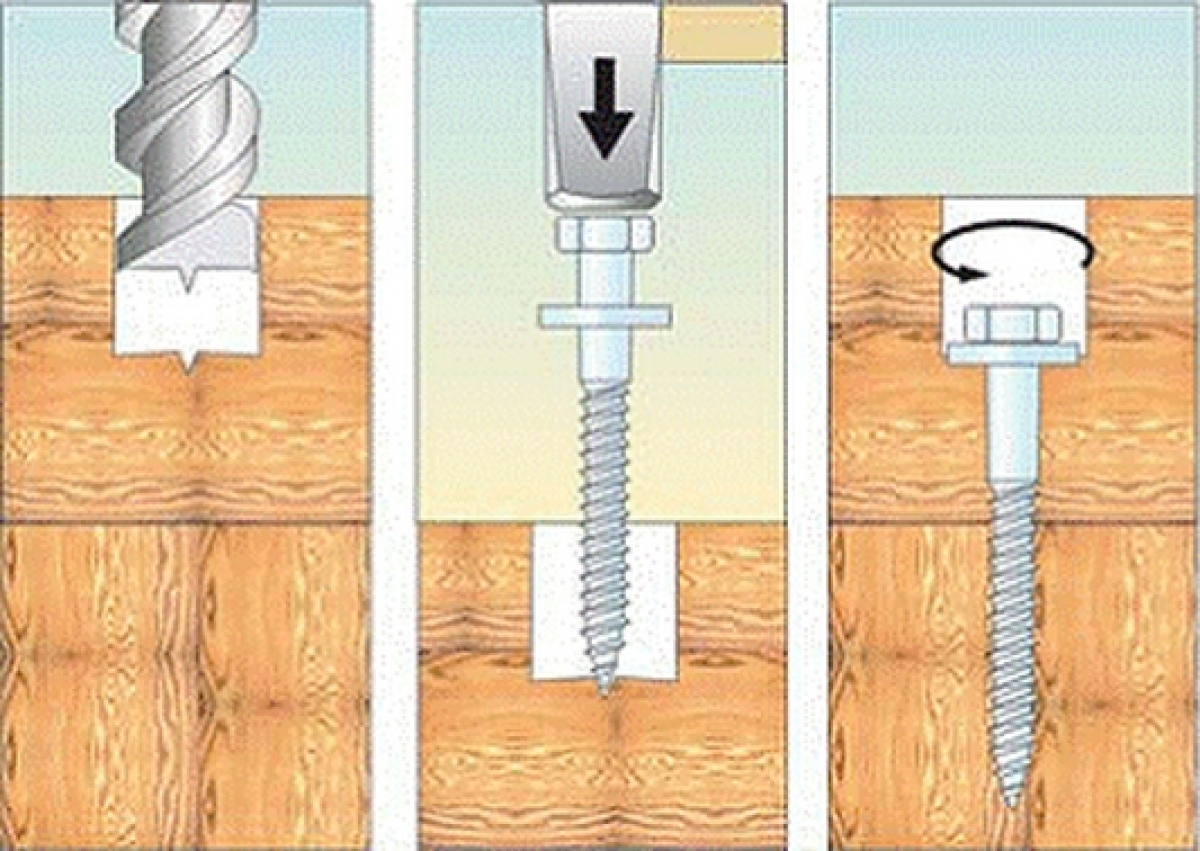

If the wood is hard and the bolt is large in diameter, then a hole must be drilled before starting the screwing process. To do this, take a drill of a smaller diameter, about 70% of the diameter of the bolt, and drill a hole to a depth slightly greater than the wood grouse, by about 10 mm. This is done so that the thread does not break off under strong pressure during screwing in.

After that, you need to take a small brush and clean the hole, removing the remains of the wood from there. Sawdust can clog the passage and the screw will not be fully screwed in. In the absence of a brush, you can take a thin long screw and run it back and forth in the hole several times.

In order for the wood grouse self-tapping screw to hold firmly, it is necessary to use washers with it, corresponding in diameter. Their outer diameter should be equal to three inner ones. Washers DIN 9021 are well suited. Before starting screwing, you need to string a washer on the shank, and then start work.

Peculiarities

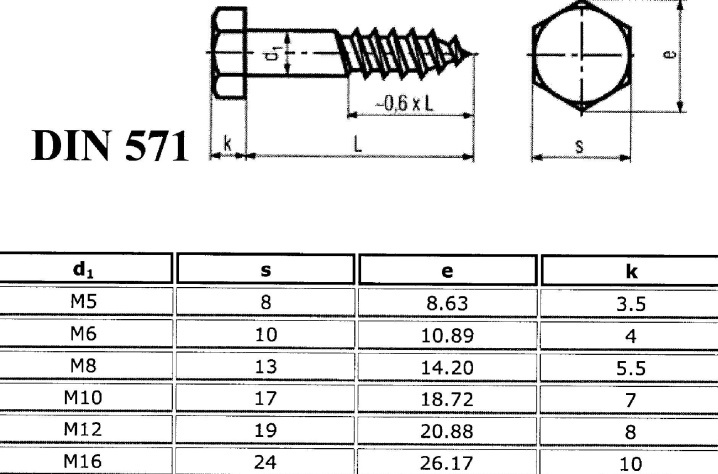

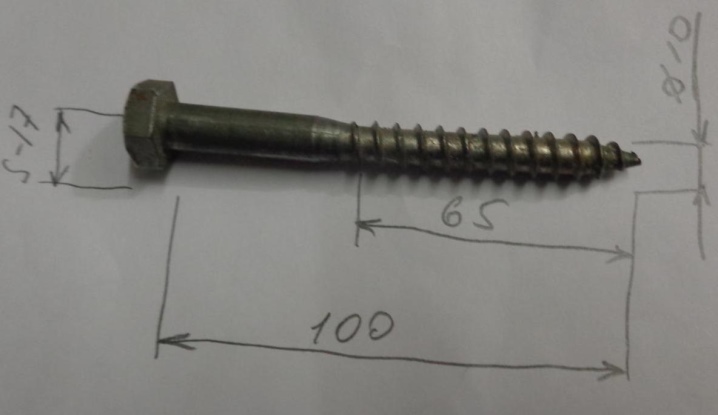

If we consider a self-tapping screw for a hexagon, then outwardly it looks more like a bolt with several external signs.

- Screw threads are infrequent.

- The sharp end is not too sharpened and hardly stands out.

Its scope of application is quite wide due to how original its design is. If a hex head screw is used simultaneously with a dowel, then, for fastening large parts to a tree, you can use this self-tapping screw to fasten the necessary parts even to concrete. The only caveat is that the dowel in diameter should be exactly twice as large as the head for reliable fastening.

For work, you will need keys of 10, 13 or 17 mm, depending on the type of bolt that the master plans to use. Also, such fasteners are sometimes called "wood grouse", because it tightly secures almost any object to the surface with the right approach. When the socket head bolt is used to organize the roof, its design also has a number of features.

- A hard and sharp tip, similar in shape to a drill.

- Hex head bolt.

- Rubber washer.

The latter serves as a kind of insulator that reliably protects the bolt from moisture ingress. Accordingly, in this case, there is less risk of rust and moisture. In addition, the washer makes the connection to the screw much tighter than under normal conditions. In terms of their diameter, such fasteners can be from 8 to 10 mm inclusive. And the length can be up to 100 mm, so you can pick up a screw for literally any roofing material, with any level of load, depending on the need and need.

Anti-vandal self-tapping screws that cannot be turned out without the use of special tools are also popular among hexagonal or multi-sided screws.

Their very design outwardly already attracts a lot of attention, and the rigid fastening eliminates the risk of any kind of structural damage, which is very useful in public facilities, especially if you pay attention to the name of the screws

Self-tapping screws with a press washer in the design, they can also have six faces, but in this case there is one important nuance. The area of their cap is much larger, which is suitable for attaching metal sheets. Most often they do not have any characteristic color; outwardly, they resemble ordinary silver bolts.

Another option, when it comes to the design features of specialized screws, is self-tapping screws for the production of furniture. They are distinguished by a blunt tip and are tightened with a special hex wrench. Their diameter is generally the same for the entire length, but towards the head the bolt itself becomes a little thicker.

Prehistory of unique wood fasteners

The size of nails for joining wood materials ranged from fifty millimeters to one hundred and fifty. Slate, roofing felt, roofing felt were attached to the roof lathing with special nails with a much larger head - up to 18 mm with five millimeters on others

This is because the material there is soft or brittle and it is important to prevent wind breaks.

Before the advent of self-tapping screws, a hammer was the only tool. The hardware industry has given rise to a new, electrical, toolkit - screwdrivers. They have been so improved that you no longer need to buy holders for screws, you should not be afraid that you will screw them deeper than you should.

The innovation "one click" is applied on imported similar drills. It will automatically adjust the flush wrapping depth. That is, flush with the base (floor, slate, and so on).

What it is?

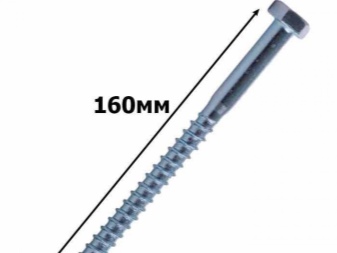

During repair work and construction, it is often necessary to install wooden structures with high bearing loads. In order for the fasteners to be carried out correctly, the craftsmen recommend using wood grouse screws, which may have a square or hexagon head. This product is made of high quality galvanized coated stainless steel.

A plumbing bolt can have different rod lengths and head shapes. This self-tapping screw has a stamp with information about the manufacturer and the characteristics of the product. The rod consists of 2 parts:

- smooth, in the form of a cylinder;

- with external thread.

The end of the self-tapping screw is represented by a sharp tip, thanks to which the hardware easily enters the wood. Capercaillies have found their application when it is necessary to fasten structures made of wood with high bearing capacity. These hardware fasten slats, boards, bars to a brick and concrete base. It is difficult to do without hexagons when installing plumbing fixtures on a wall or concrete floor. In addition, this fastening connection is used in mechanical engineering, when working with rails and concrete pillars.

Installation technology

Fastening hexagons consists of several basic steps:

- first of all, prepare a hole suitable for the screw diameter;

- carefully remove the debris formed after drilling;

- insert a dowel into the resulting hole (they are often sold with screws);

- fix the screw with a special wrench (since the wood grouse has a hex head, a simple screwdriver will not work for work);

- after installation, the product begins to twist in the clockwise direction. To protect the base from damage and increase the strength of the structure, it is recommended to place enlarged washers under the screw head. Also, hardware can be closed with decorative caps.

When installing a wood grouse screw into soft woods, you can do without drilling, the pointed end will easily enter the base

However, it is very important to insert the head nut straight and screw it in carefully, otherwise the bolt can go crookedly and damage fragile wood.

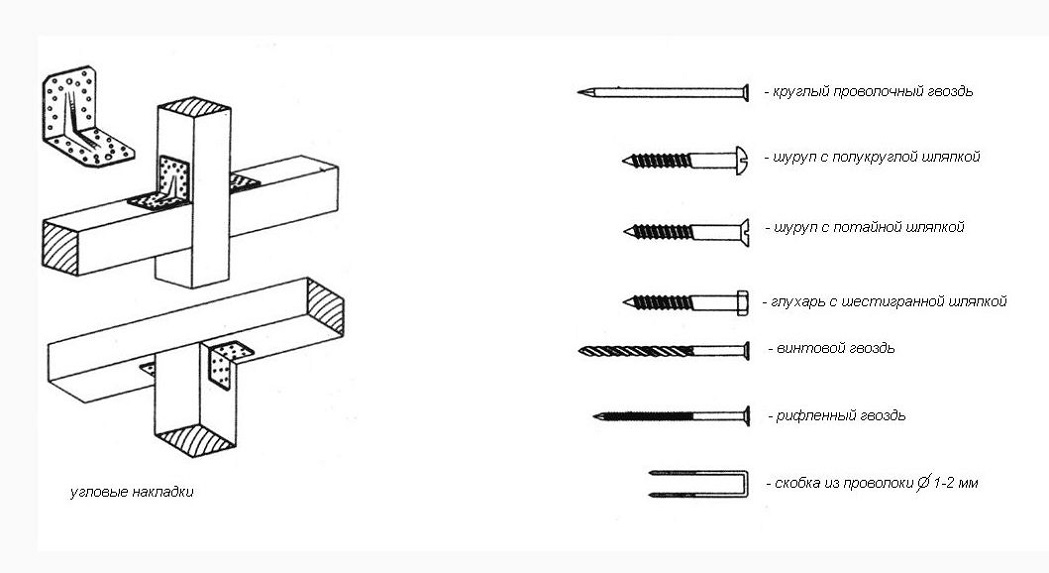

Wood screws

Connections made with screws are more durable and stronger than nails. The spiral thread adheres perfectly to the material and prevents the fasteners from slipping out.

For the construction of houses, wood screws are often chosen with a length of 40 to 320 mm and a diameter of 0.5 to 6 mm.

As for the types of this construction fasteners, a wide variety of screws can be used. The most popular among developers are self-drilling screws, since they do not require any preparatory work: you just need to get them out of the packaging and screw them into the tree with a screwdriver.This is possible thanks to the specially designed spitz.

Traditional screws are cheaper, but when choosing them, keep in mind that you have to drill a hole before you start screwing them into the wood. It should be slightly smaller than the diameter of the auger.

There are also construction screws with partial threads. In them, as a rule, the thread is only on a small surface and at a certain angle. These fasteners come in handy if you plan to fasten wood to other materials, as they have up to 67% more tensile force than traditional screws.

Many developers prefer to fasten rafters, beams and other wooden elements of the house with screws. However, it should be borne in mind that this is a more time-consuming task than nails. To make it easier to fix the screw in hard wood, its threads can be pre-lubricated with colorless oil, stearin or rubbed with soap.

However, unlike nails, fastening with wood screws often looks more aesthetically pleasing. In addition, they almost do not rust, as they are protected from corrosion by chrome plating or brass. Of course, this does not give a 100% guarantee.

If you want to completely avoid rusting, you should choose stainless steel screws. Of course, they will cost more. However, such fasteners come in handy if you plan to work with wooden structures that may be exposed to frequent exposure to water or in conditions of high salinity (houses built on coastal areas).

How to tighten the screws correctly?

The screwing technology depends on the shape of the screw. The easiest way, of course, is to work with self-tightening screws with a traditional thread. Somewhat more difficult - with fasteners in which the thread is applied only partially or with the so-called screws with a threadless section.

When working with the latter, you will need to drill holes in the wood. This is done in two steps. First, a hole is made with a narrow drill, and then with a drill with a diameter similar to the threaded part of the screw. The principle of double drilling does not apply to screws with a wider thread than a threadless one.

Do I need to pre-drill the holes if we are dealing with traditional full-length screws? There are no special rules here: if they twist like this, then there is no need to drill the tree. However, if you are dealing with hardwood planks, be prepared to drill every time.

In addition, if you plan on screwing in at the edges of the board, experts strongly recommend pre-drilling the hole to avoid damaging the wood. Remember that the hole for the screw should always be not only narrower than its diameter, including the thread, but also about 1/3 shorter than it.

Supermets: safer and more durable

Everything is relative. Another feature of the difference between metal products (hardware). Nails were made from the simplest, low-carbon, steel, and not covered with anything on top, which received the name - nail wire.

The current fasteners are an order of magnitude better and even more aesthetically pleasing than nails. Self-tapping screws are available in a large assortment and many subgroups - for any type of material for its connection. For metal and for roofing, self-tapping screws for wood and drywall for gypsum fiber sheets and plastic sheeting, and so on.

Varieties of self-tapping screws for their coating:

- black wood screws, so named because of their phosphating or oxidation.

- yellow and white, in addition to this protective coating, differ from black ones also by frequent carvings and its steep corners. Suitable for joining hardwood and chipboard.

- "Wood grouses" - large sizes with a hexagon head for wrenches. Basic for assembling furniture.

Oxidized hardware, in comparison with other coatings, is somewhat limited in application - only in dry places.

Yellows and whites, which are more attractive due to their color, and zinc-coated have better protection against corrosion. They are also suitable for roofing work. But builders prefer black screws. The reason lies in their budgetary cost.

Hardware from the second named subgroup is twenty percent more expensive. And it is not always better than black ones, and not only because of the coating, but in coarse carvings. They are used in prominent places for aesthetics.

The price of wood screws depends on the color and size. For black ones with a countersunk head with a length of 70 to 102 mm, prices range from 230 to 250 rubles per kilogram. Yellow and white are both more expensive and cheaper - competition forces you to vary the price.

Nails

Of course, the first thing a private house developer should take care of is to purchase a sufficient number of nails. This is the main type of fastener that comes in handy for connecting wooden structures to each other.

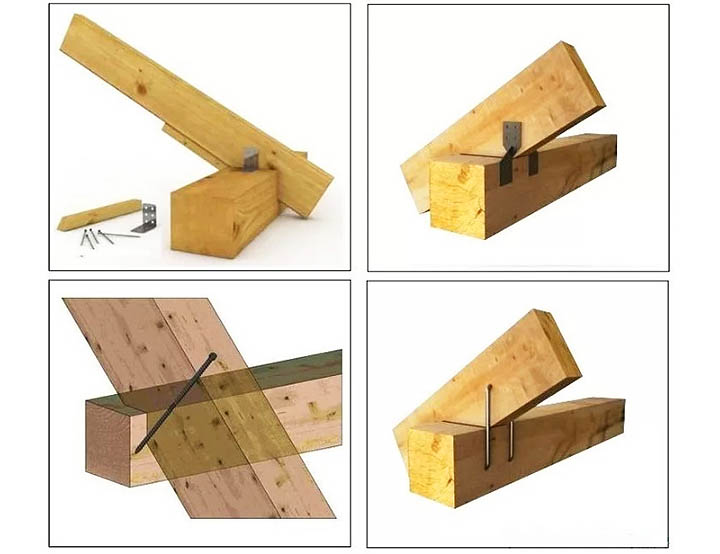

Of course, nails will not work everywhere. With the help of them, simple flat boards can be nailed to each other, but it is better to fasten more complex structural elements with screws. The long screws with special threads and a small head are ideal for mounting solid beams and rafters. For even more complex work, special construction accessories will come in handy.

Nails are considered the most primitive fastener. They are also the cheapest. They are easy enough to hammer into a tree, and also to pull out. Another undoubted plus of nails is the possibility of their reusability. It is easy enough to pull them out of the wood with pliers or the back of the hammer head and use them again.

However, working with this seemingly simple fastener also requires some experience. An improperly driven nail can damage the wood or bulge out, impairing its appearance. In addition, it should be borne in mind that it is better to buy stainless steel nails. Yes, of course, they are more expensive than ordinary steel ones, but the latter quickly rust, which will ruin the appearance of the structure and may even lead to a change in the color of the wood.

Types of nails for wood

Today, most often, for rafter and carpentry work, they use:

- Smooth galvanized hardened steel nails with round cross section and flat heads. Typically, they are 2.5 to 30 cm long and 2 to 9 mm thick. Smaller nails are practically not used in construction; as a rule, they are bought only for some auxiliary tasks;

- Hidden nails (no head). They are called hidden, because after clogging they are practically invisible;

- Corrugated nails are a cross between a screw and a traditional nail. They wedge better into wood, but are more difficult to pull out. It is recommended to choose such fasteners for fastening floor boards, so that over time the seams do not loosen and the floor does not begin to creak.

In addition, nails are selected based on the thickness of the wood. The optimal ratio of nail thickness to material thickness should be 1 to 5. For dry or hard wood, you can choose 1 to 10.

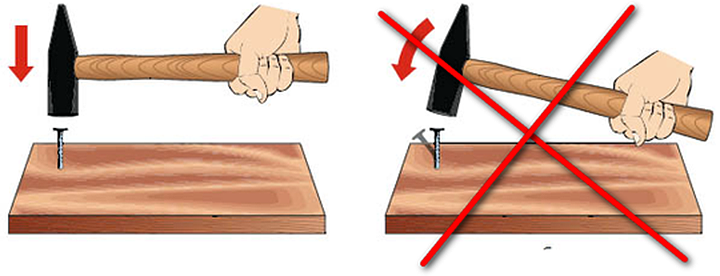

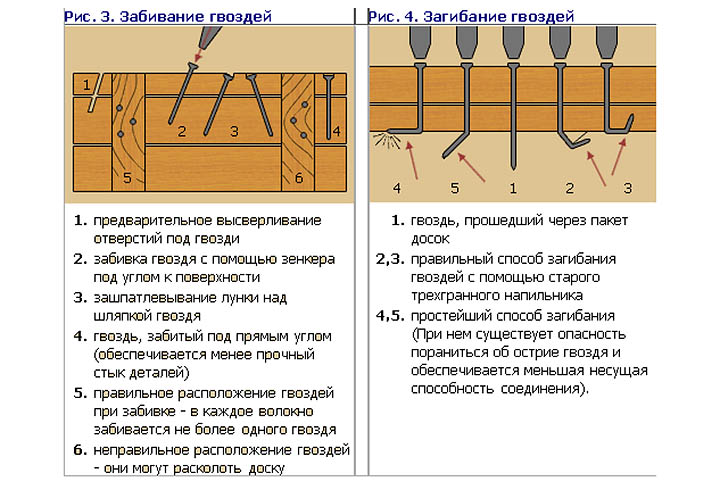

How to drive nails correctly?

The head of the nail should be completely sunk into the wood, but not too deep (so that you can feel it by running your hand over it). When working with particularly hard parts of wood, you can make a thin hole with a drill before hammering in the nail.

Be aware that hammering a nail into previously made seams can weaken them. It is better to use a screw or bolt in this place. Also keep in mind that the nail holds best when it is driven perpendicularly into the plane of the tree along which the fibers are running (along the trunk). If it is not possible to hammer in a nail in this way, to further strengthen the connection, you can hammer in nails at a slight angle - up to 15 degrees.

There is also another rule among carpenters: there must be at least 4 nails for each connection. This does not apply to structures with small cross-sections. If a nail goes through such an element, you can bend it with a hammer, cut off the protruding part with a metal saw, or grind it. Of course, in this case, a bend may appear, but this way the fastening will be more reliable.

Photo of wood grouse screws on wood

We also recommend viewing:

- Crab system for shaped pipes

- What is a lifting shackle

- What is foundation bolt

- Why do you need a grover washer

- Dowel-clamp for cable fastening

- Lifting crane hook

- How to choose cable clamps

- Features of furniture fasteners

- Which toilet mount is better to choose

- Fasteners for timber structures

- Fasteners for plastic windows

- Advantages and Disadvantages of Screw Nails

- Best plastic dowels

- How to choose a threaded rod

- Self-tapping screw with drill

- How to choose self-tapping screws for metal

- How to choose a drywall dowel

- The most reliable pipe fittings

- The best screws for concrete

- How to choose pipe brackets

- High Strength Bolt Parameters

- Hex bolt

- Varieties of anchor bolts

- Construction nails

- How to use the drop-in anchor

- How to select and install a wedge anchor

- Features of dowel screws

- Hammer-in metal dowel

- What is a dowel-nail

- How to choose and apply a chemical anchor

- Sink bracket

- Types of brackets and fasteners for shelves

- How to choose a steel chain

- Choosing a bracket for the cornice

- Brackets for satellite dishes

- Choosing the best plastic clamps

- What is a construction bracket

- The best roofing screws

- Expansion dowel

- What are wood screws

- How to choose a wall mount for your TV

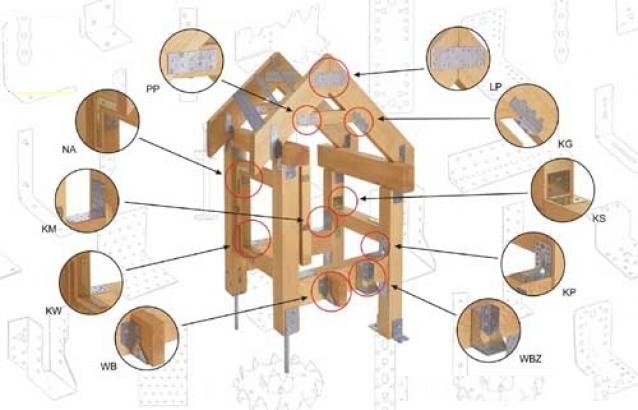

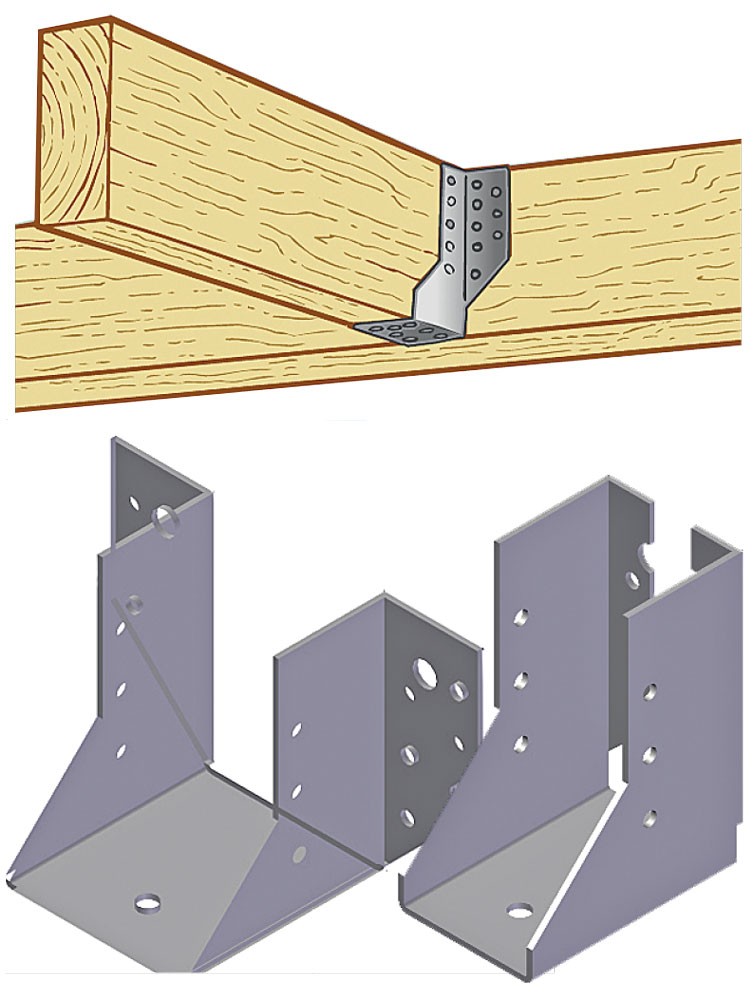

The essence of mounting supports

The main material used in the construction of wooden buildings is classic timber.

Traditionally, it is in demand in the manufacture of the following elements of an erected structure:

- wooden logs used for laying (laying) floors;

- floor beams;

- elements of frame-panel structures.

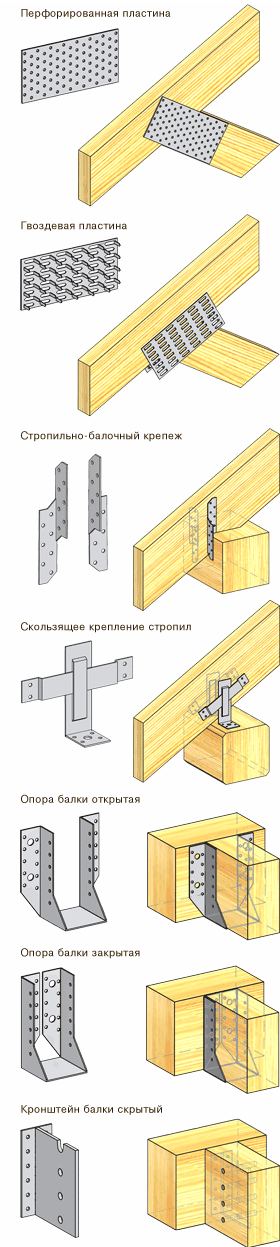

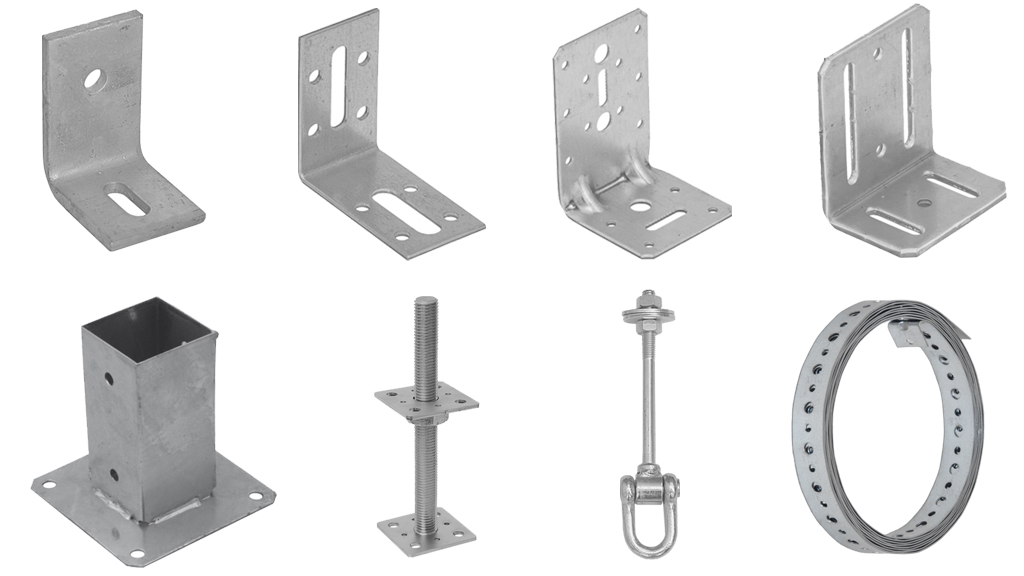

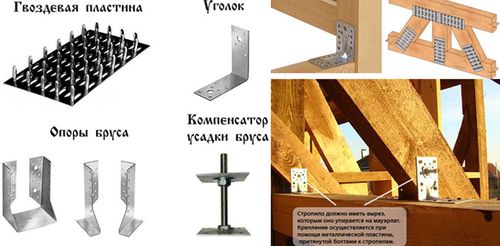

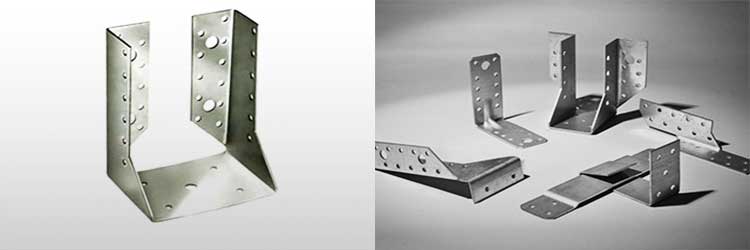

The material has long been used in the construction of houses. In any case, its use is possible only if there are special embedded supports for the timber. Parts are usually made in the form of perforated fastening steel blanks.

When constructing outdoor sheds, as a rule, concrete foundations are used. In the process of their arrangement, the embedded support parts are pre-poured with concrete and only after that they are used for their intended purpose.

Advantages and disadvantages

The advantages of using steel supports for timber blanks include:

- increased strength of the formed joints and low consumption of starting material;

- low cost of the metal used;

- versatility of fastening blanks;

- the presence of a special galvanized coating that reliably protects building elements from rust and significantly extends the service life.

The disadvantages of supporting structures include the complication of the assembly scheme, which reduces the speed of installation. In this case, you will need hardware of suitable size.

Support for timber

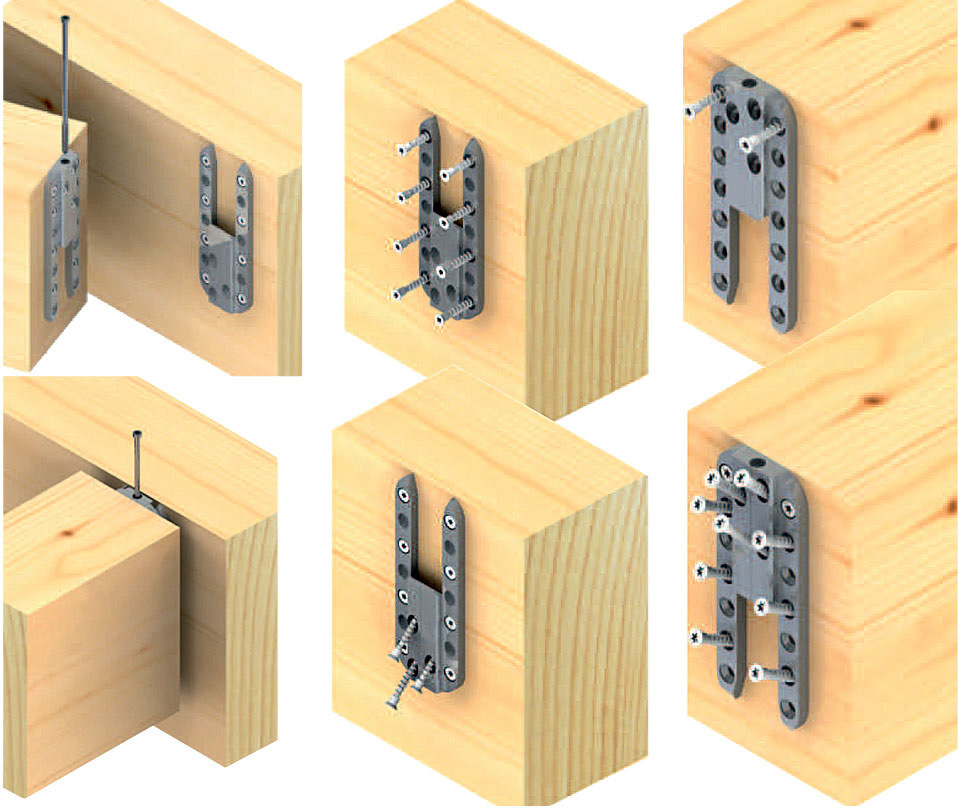

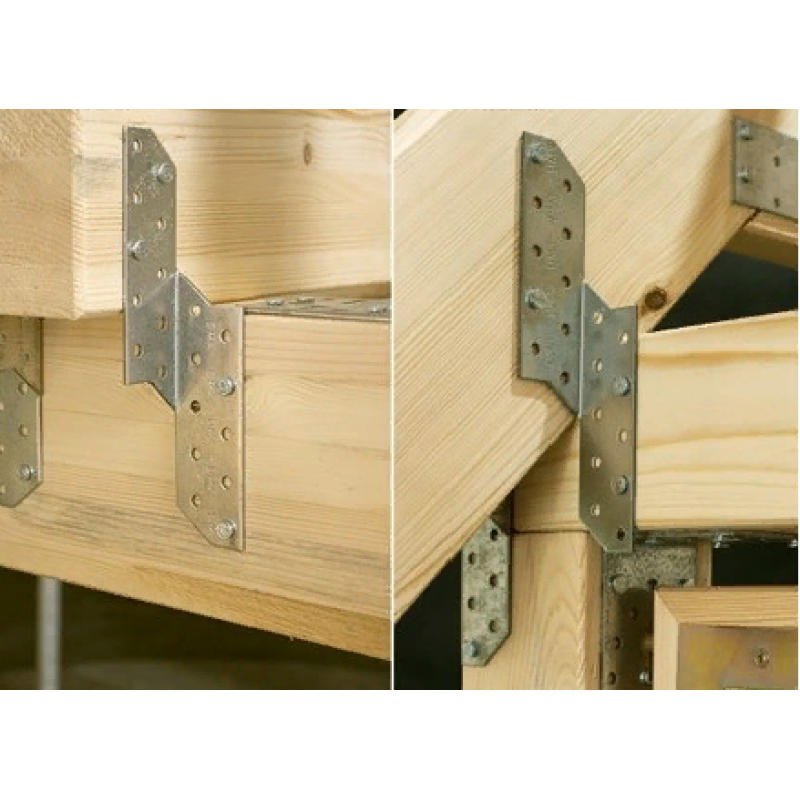

To fasten the floor beams, rafter legs to the base and other similar units, an open support of the beam is used. It allows you to make support both on a wooden base and on a stone and concrete wall using screws, nails without preliminary drilling, reliably and quickly. Since the lug ears are pointing in different directions, they can be opened to any angle, not just 90 °.

Another type of this fastener is a closed beam support. Its distinctive feature: the mounting ears, which are attached to the wall, are turned towards each other in such a way that the product becomes almost invisible in the working position. It is used for the same installation purposes as open. Moreover, you can reliably fix not only a rectangular bar, but also a different shape.

The open and closed support are used for the same purpose, but the closed ones are considered more reliable - when the bar is attached, the ears are additionally clamped, the connection turns out to be strong and almost invisible.

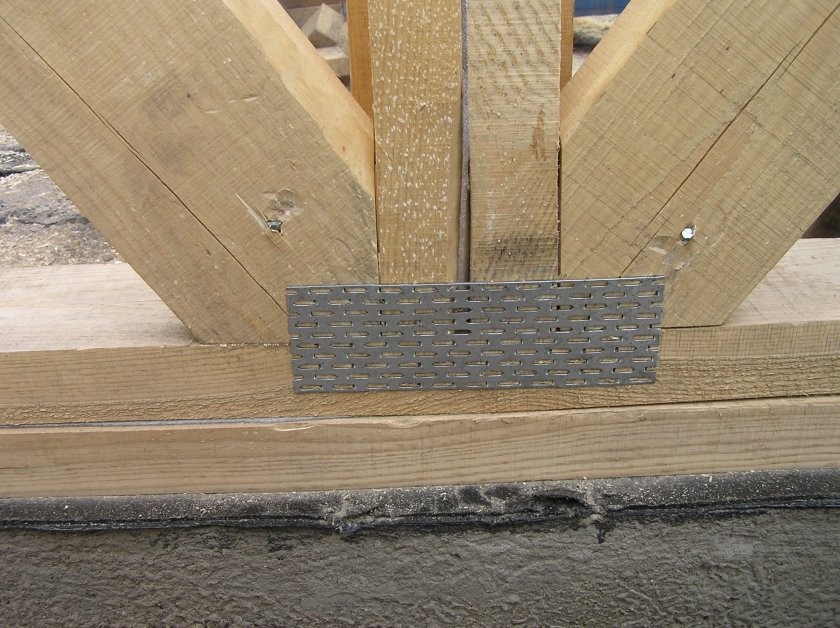

Perforated fasteners

The main material of the mounting elements is galvanized steel. The geometry of the structures can be different. A common feature is the presence of many holes. Perforation makes it possible to select the desired attachment point in the tree. Self-tapping screws are screwed in through it or screw nails are driven in. The advantages of this type of fastener:

- Saving time for connecting structural elements made of wood.

- Small amount of waste when performing fastening of knots.

- The ability to install several hardware in one plane. This increases the load-bearing capacity of the attachment point.

- Variety of types of assembly products. Allows you to choose the optimal solution for evenly distributing the load on the wooden components of a building or structure.

- Versatility. Suitable for all lumber.

Types:

- plates;

- corners;

- holders for beams;

- slats are three-dimensional;

- mounting tape.

Plate

Planks with multiple holes are used to hold timber together in one plane. In the plan, parts can be of different shapes (for example, in the form of the letters T, Z). Plates are made of steel with a thickness of 1-3 mm or more.

The parts are easy to bend, which is convenient when joining wood at an angle of 90 ° or more. Plates can be cut with metal scissors.

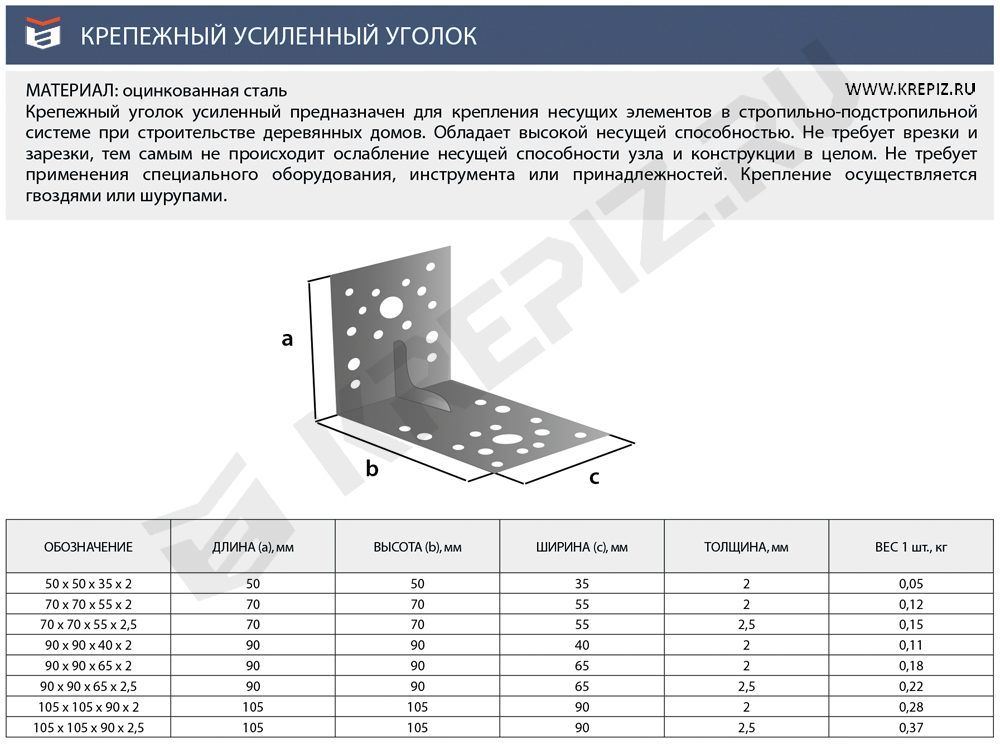

Corners

To connect wooden structures at right angles, equilateral, reinforced, with double reinforcement, anchor metal corners are used. There are more complex products: Z-shaped, sliding, other modifications.

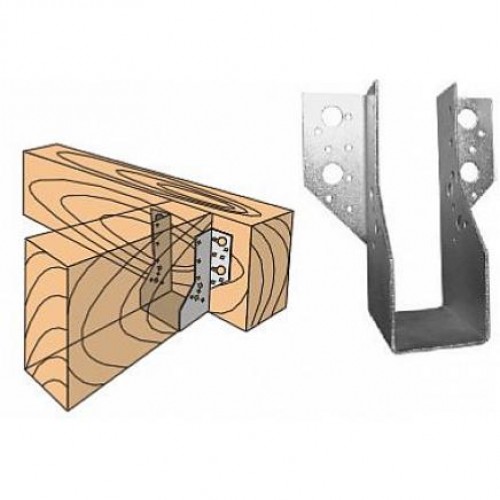

Holders for beams

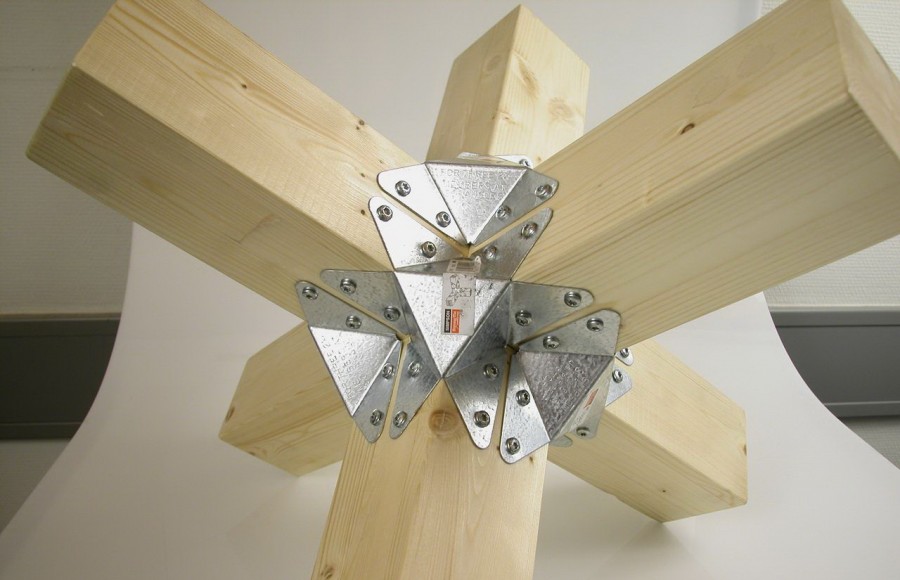

The product allows you to connect a beam and beams. The mount is installed on self-tapping screws or screws. The supporting part of the beam is fixed from the sides and from the bottom. The perpendicular planes of the steel part are fixed to the transverse beam. The photo shows one of the holder options.

Reiki three-dimensional

They come in different lengths. The design feature is that the connection elements fix the tree in three planes. The slats form a strong and reliable bond in the knots. Metal longitudinal slats perform two functions: they tie the wood into a single system, they are load-bearing beams that take on a significant part of the vertical load.

Fasteners - T-profile made of durable steel alloy. They are produced by the Italian company Alumidi. The slats are selected based on the cross-section of the connected elements, the level of dynamic and static loads.

Mounting tape

Perforated galvanized steel tape is used as an auxiliary fixation when making complex assemblies in wooden structures. It is easy to cut into pieces. It is also used as an attachment of non-metallic products to wood.

Varieties of staples

To mount the brackets, a gun is used, which is connected to a special compressor device. The gun greatly simplifies the installation process, it is quite simple to use it.

The following types of construction brackets are presented on the market:

- standard type;

- hardened.

If typical popular wood species are used in the work, then it is advisable to use standard staples. The hardened modification is more suitable for fastening materials in the form of plates - chipboard or fiberboard. This solution is due to the possibility of deformation of standard brackets until the moment of punching the plate material.

Common pistol models are suitable for both conventional and hardened fasteners, as can be seen in the photo of the construction bracket.

Drive in standard fasteners carefully, since their fragility can lead not only to deformation, but also to breakage. At the same time, the wave bends of the reinforcing metal sometimes cause damage to the wood blank. Along the length of such a bar, protrusions are also located - they are located at opposite ends.

We recommend reading:

Alternative energy and heating systems for a private house

All about country life and real estate

Where is Moscow expanding? And what does this threaten summer residents? 294265

Will the Central Ring Road be able to relieve the highways near Moscow? 163312

What metro stations will be built in the Moscow region? 155012

What areas of the Moscow region are the cleanest and dirtiest in terms of ecology? 140065

The best cottage settlements of the Moscow region 106846

Where is the best place to live in the suburbs? Neighborhood ranking 82935

How much does it cost to connect a house and a plot to communications? 79441

How many acres of land do you need to build a house? 72106

Districts of New Moscow. What are their advantages and disadvantages? 68760

How to calculate hundreds of square meters of land? 65390

Construction norms and rules for the development of land plots 64414

What are the exhibitions of ready-made houses in Moscow and the Moscow region? 62492

What houses are currently on sale in the Moscow region? 60956

What are land plots without a contract? 58012

What are the restrictions on construction near rivers and water bodies? 55623

Are the basement and basement considered floors? 51221

What taxes do I need to pay for a house, garage, sauna and other buildings? 51086

Which house heating is more profitable: gas or electric? 48237

Is it profitable to build a house for sale? 44774

The best places for fishing in the Moscow region 43577

Arrangement of the site from scratch. Where to begin? 43110

Pitfalls when buying a house

What should you pay attention to? 42219

What is the right way to bargain for a house? 42096

Can I get out of SNT? 42017

Where will the gas be available soon? Gasification plan for settlements in the Moscow region 37860

Life in a cottage community. Pros and cons 37039

Do I need to get a permit to build a house on my site? 34080

The largest and most expensive cottages in Russia 33652

How much does it cost to build your house? 32879

Is it worth buying a house in SNT for permanent residence? 32261

What is the best way to build a house for permanent residence? 31142