Classification of hoods by the type of material from which they were made

Wooden

Such caps are very easy and simple to make with your own hands, while having an elementary set of carpentry tools, but they have the least low quality indicators and service life. It is impossible to protect the pillars from damage for a long time with such an overlap.

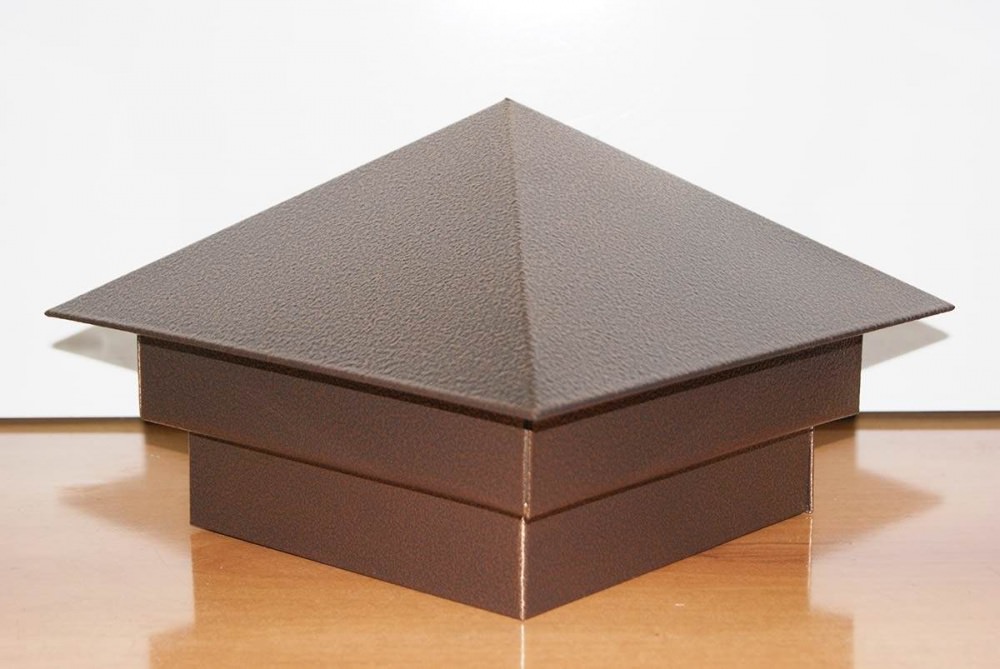

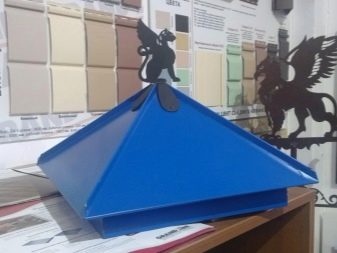

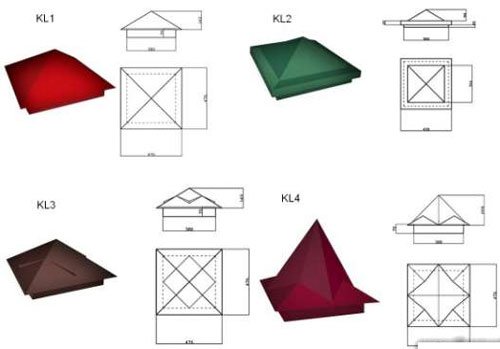

Metallic

They have good resistance to weather conditions and mechanical stress. Most often they

used for a fence made of stone, wood, brick or wrought iron fence. Such visors can be purchased or made by hand in all RAL colors, for this you only need to select a color and make a drawing according to the individual size of the bearing support.

Concrete

These are fairly inexpensive items that are very often used due to their availability. You can also easily make them with your own hands, for this you only need cement and a metal mold in order to pour out the concrete cover. The form is made individually according to the size, having previously measured the pillar, and its bends are the wishes and intentions of the owner.

Ceramic

Such decorative elements are very easy to install with your own hands - they are best fixed with tile adhesive, and ordinary ceramic or paving slabs can serve as the material for use. The only caveat is that they perform only a protective function, and decorative finishing is impossible, since this element turns out to be invisible (it is flat).

Bituminous, PVC

Such caps are the most practical, lightweight and durable. The option using bituminous shingles will become a very individual decoration of the entire estate, since there are no samples of hoods made of such material on the market. Most often they can be found in people who have recently blocked the roof of a house, and the roofing material was not in full demand and they create their own little masterpieces with their own hands. You can also find the option of covering the pillars with liquid rubber.

Such caps are the most practical, lightweight and durable. The option using bituminous shingles will become a very individual decoration of the entire estate, since there are no samples of hoods made of such material on the market. Most often they can be found in people who have recently blocked the roof of a house, and the roofing material was not in full demand and they create their own little masterpieces with their own hands. You can also find the option of covering the pillars with liquid rubber.

Most often, such additional elements as caps are either bought on the market or made to order by experienced craftsmen or manufacturers based on their own measurements and designs. Making with your own hands is possible, but only the tools and devices for carrying out all the stages are not available in every owner, and their acquisition is sometimes very expensive, which is irrelevant for personal use. For example, decorative forging - not every person knows how to make it, and even repeat some of his fantasies and wishes.

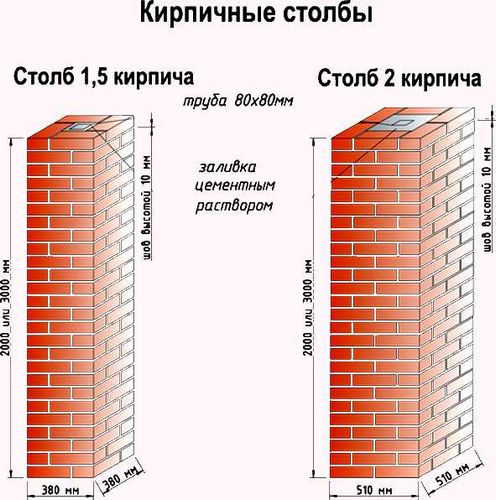

Brickwork fence posts

To install fence posts, two types of masonry are usually used - one and a half or two bricks. When using standard brick sizes, a pillar of one and a half elements will have dimensions of 38 by 38 cm.Masonry in two bricks is 51 by 51 cm, respectively.

If there is a metal pipe inside the brick pillar, in no case should it be left hollow. All gaps, as well as the space inside the pipe, must be filled with mortar.

After waterproofing is done, one centimeter of cement mortar is applied. Bricks are laid on it, which were previously supported in water for several seconds. Bricks must be leveled using a building level. If the bricks are unevenly positioned, you can slightly trim their position using a rubber mallet.

The second and subsequent rows can be laid out using several technologies. For the construction of brick fence posts, masonry is used for a bar and a standard masonry with a ladder.

Brickwork for a bar

This method is a simplified version of the classic brickwork. If the pillar is being built by a beginner, it is very difficult to maintain the same space for the joints, and also to cover with mortar so that it does not spread. For these purposes, they came up with a brickwork for a bar.

Brickwork for a bar

Brickwork for a bar

The rods are located along the perimeter of the brick support. As a result, the thickness of the mortar coincides with the thickness of the rods, and they also do not allow to go beyond the boundaries of the seam.

For masonry, a metal bar is used, the side of which is 1 cm. It may be more or less by a few millimeters. You need four rods that are 10 cm longer than the post. After the first row of the structure has been laid, the rods are laid out. Next, the bricks are covered with mortar, the layer near the pipe should be slightly larger than on the edge. With the help of a trowel, the excess solution is removed, the bar is cleaned. Next, they put a brick of the second row and level it using a building level. The vertical seam rod is installed along the brick poke. After that, excess solution is removed again. The bar should be removed while holding the seam with a trowel. The rods are rearranged with the erection of each row.

Standard brickwork for fence posts

Usually, for the construction of fence posts, bricks are laid out with a ladder, that is, the seams of each subsequent row should not coincide. This method is called bandaging and is done to strengthen the structure.

Since there are no metal rods in this method, after each row, the dimensions of the masonry are checked using a tape measure. There should be no discrepancies even by a few millimeters. To eliminate the displacement, it is necessary to tap on the butt side of the brick, bringing it closer to another brick block.

Laying brick pillars for a fence is a rather laborious process, but you can cope with it even with a lack of experience in construction work.

General information

The main reasons to put covers on the fence posts:

- A fence plug is required to protect the brick post. The caps protect the supporting structures from the negative effects of rain and icing.

- Decorative function of the cap. Brick posts look ugly without installing covers on the fence.

- Security function of the cap. Only one kind of tip on the fence support - in the form of a lance - will be able to scare away uninvited guests trying to climb over the fence.

- The topping on the fence is a good basis for installing lanterns and other decorative elements.

Particularly protection is required for fence columns made of stone. This is a porous material, because it is much more susceptible to negative environmental factors.

The photo shows a fence of a private house with brick pillars.

Types of protective covers for poles

Even the simplest tops for support pillars have a number of parameters that must be taken into account when choosing them. They can be made in different shapes:

- Simple - in the form of a cone.

- Pitched roof strips.

- In the form of a pyramid.

- In the form of a hemisphere.

- Decorative designs, decorated with different elements, for example, forging.

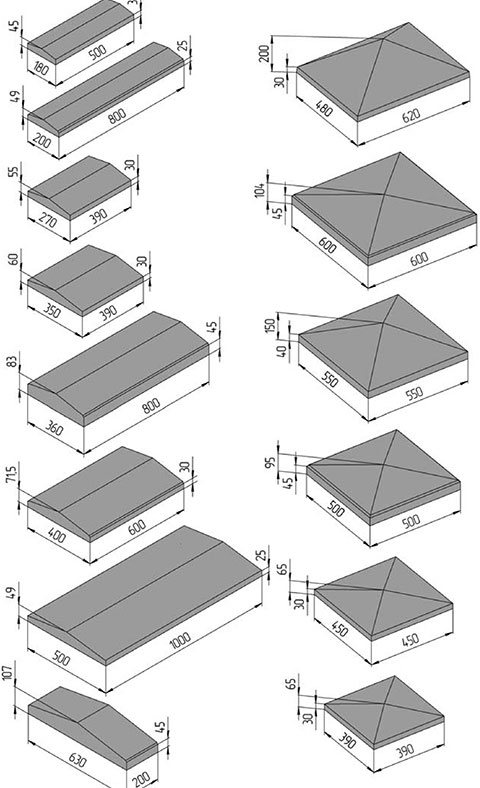

Popular sizes of products for brick fence posts: 38x38, 40x40, 40x60, 50x50, 60x60, 60x80, 70x70, 80x80 cm.

For greater protection of the supports and to give an original look, you can install a special parapet from above around the entire perimeter of the fence.

Taking into account the material, the caps for brick fence posts are of the following types:

- plastic;

- fiberglass (ABS glass);

- metal (usually tin, stainless steel, galvanized profiled sheet are used);

- ceramic;

- wooden;

- stone;

- concrete.

Moreover, a large number of colors will delight any consumer. The most popular colors are brown (RAL 8017), to match the brick or tile, and green, under the bushes planted near the fence.

The surfaces of the protective covers for the fence are matte and glossy.It should be borne in mind that any cap on a brick pillar must correspond to the general composition of the installed fence.

To make it easier to mount the metal hats on a brick support, they are made hollow inside. This reduces their cost, and also allows them to operate in any weather conditions. The void does not degrade the quality of the product and does not make the caps fragile and unreliable.

The cost of a metal cover for fence brick posts includes the cost of manufacturing the product and the price of the material itself. Therefore, brick fence plugs made of stainless steel are inexpensive. In addition, they are easy to transport by simply stowing them in the trunk of your car.

Luminaires can be installed in protective caps on the fence. This will help you organize your street lighting and decorate your fence.

When choosing a cap for a fence post, attention should be paid not only to aesthetic indicators, but also to the parameters of the future cap. Before buying a product, you need to determine the size and material of manufacture

If there is no suitable model among the large selection of popular manufacturers (for example, "Grandline"), then you can make hats and a visor for a brick fence to order according to your own drawing.

The photo shows a beautiful cap for a brick support.

Features of choice

The design of the protective covers for the fence posts is very simple. Each contains only two main elements that serve their intended purpose:

- the lower part - fasteners that allow you to hold the cap on the chimney or brick support on the fence;

- the upper part plays a decorative and protective role.

To choose the right protective cover for brick fence supports, you can use a few simple rules. They will allow you to check the main structural details and fasteners, as well as determine the quality of the product:

Take a close look at the headband from all sides

Determine its symmetry and proportions.

Look at the eaves - it should be tightly closed.

Ask the store for tools that allow you to determine the correspondence of the actual angles of the product and those declared by the manufacturer.

Before making a purchase, you need to make sure once again that the chosen product is well combined with other elements of the fence and everything that is around.

Attention should be paid to the quality of the packaging material, this is important during transportation.

Compliance with the described points will allow you to choose and purchase caps for the pillar of the model that suits your own wishes.

The photo shows a fence with brick pillars in the country.

Views

Intake hoods are diverse and can be classified according to manufacturing methods, configuration and material from which they are made.

The shape is chosen depending on the style of the fence and the preferences of the owner. It can be domed, with four slopes, cone-shaped, in the form of a pyramid or an eastern pagoda.

Sometimes they are decorated with a spire, lamp, sculptural figures. All of these elements must be made of durable materials that can withstand the weather.

The overhead construction consists of an upper and a lower part. The fastening is the bottom of the cap (skirt), it is rather tightly planted on the post and becomes almost invisible under the upper part. The hood itself is sealed, has an attractive appearance, its design ends downward with slopes and grooves to remove moisture.

Technically, caps are produced in different ways - by casting, stamping, they can be made by welding, bending in different ways, or forged products.

The linings are even more diverse in terms of the composition of the material from which they are made.

Metallic

Some owners make their own plugs from tin. Caps made with the participation of forging look spectacular.The industry produces nozzles made of stainless steel, copper, brass, galvanized. To avoid corrosion, polymer coatings are applied to the caps, it can be plastisol or polyester. Copper and brass products can last for over a century without replacement.

Metal plates are made curly, they become a kind of decoration of the fence.

The sheet metal is often lightweight and should not be installed in areas with strong winds. It is necessary to take into account the sounds that metal makes from the impact of raindrops or hail and should not be placed near the windows of a residential building.

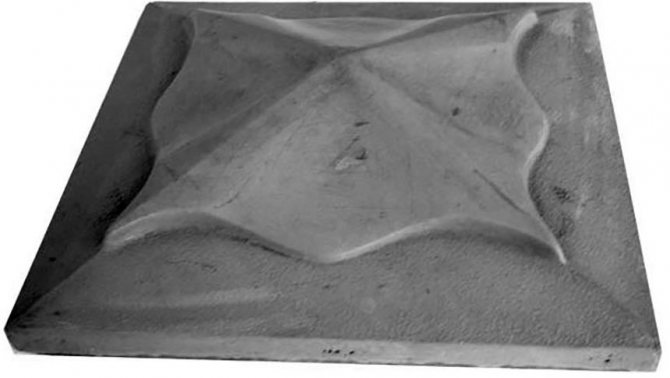

Concrete

They weigh up to 20 kg, they will not be blown away even by a strong wind, but its constant effect on concrete over time will have a negative effect, this should be taken into account when installing such products in windy places. Concrete pads are cast in any shape and are well bonded with mortar. They are installed on brick pillars if the fence is made of stone, concrete or brick. Such caps are not suitable for other types of fences.

Concrete overlays are made in a color that repeats the shade of a brick pillar or enters into contrast with it. This product looks reliable, presentable and if it is made with high quality, it is. Poor-quality concrete caps, according to the owners, take on the appearance of a shapeless lump in a year.

Stone

Products are made of natural and artificial stone. Natural stone looks great, has special strength and durability, but it weighs a lot and is expensive to the owner. A product of artificial manufacture is much cheaper, in quality it cannot compete with natural stone, but it will provide a solid, majestic view to the structure.

Ceramic

This is a beautiful mosaic type of overlays that looks exquisite and expensive. It really costs a lot. This material should be handled with care due to its fragile structure.

Polymer-sand (composite)

The latest development, which has already been appreciated and chosen by consumers for its durability, affordability and impeccable appearance. They are made from sand, polymers and various modifiers. They have a wide range of colors, imitate natural stone, tiles, and are transparent for setting internal lighting.

Composite-based material can not only cover the pillars, but also the brick fence itself.

Cheap lightweight material is not durable. Used for temporary protection of pillars.

Wooden

Such caps are easy to make with your own hands, they are in good harmony with the garden landscape. They can have various forms, up to sculptural. Meet the specific styles and intentions of the designer.

Bituminous

Created from soft tiles. For the formation of the hoods, trimming of the building material after roofing works is suitable. Liquid rubber serves as a waterproofing agent.

Fiberglass

Thanks to innovative production, beautiful, lightweight and durable hoods have appeared that can withstand temperature fluctuations from minus forty to plus ninety degrees. The density of the product is guaranteed by the content of polycarbonate with acrylic and quartz glass. They cannot be scratched and are easy to assemble.

The illuminated overlays look fantastic.

Fence post laying: basic technologies

Usually, the pillars are 1.5-2 m high and 38 × 38 cm or 51 × 51 cm wide (for three-meter supports). Strength is achieved by the way the bricks are laid. The seam between the bricks (8-10 cm) of the lower row should be overlapped by the surface of the upper brick. Such a masonry scheme ensures that the rows are linked to each other.

Operating procedure

To correctly fold a brick post on your own, you need to perform the following work procedure.

- Laying waterproofing under the support so that it is not saturated with moisture. The wet brick starts to deteriorate. For insulation, roofing material or special insulation with bitumen ("Gidroizol") and mastic are used.

- Each layer is checked with a level. Use the handle of the trowel by tapping it on the masonry. It is necessary to have other devices for laying brick posts - a hammer with a rubber tip and others.

- It happens that a badly rubbed solution drips onto the brick. The material is recommended to be slightly moistened with water. This one makes it easier to clean the bricks.

- After laying out several layers, measurements are taken. By tapping with a hammer, the displacement is straightened (even 1-2 mm). The vertical gaps are filled with the solution.

- The voids between the pipe and the masonry are poured with a solution, if it is large, rubble with sand is interfered with, poured into the voids and fixed with a solution.

Brick pillars for bars

Masonry with rods allows the bricklayer to make beautiful seams, since usually excess mixture crawls out onto the plane of the brick, and the seams are made uneven. The bar (side - from 8 to 10 mm) is cut into pieces that are 10-15 cm larger than the pillar. The first row is laid, then the rod is laid along the edge. A layer of mortar and bricks of the second row are applied. Metal prevents them from sinking. A trowel is led along the bar, cleaning off the excess. Bricks are checked by level. The same method is used when laying the bar on its side. The solution is applied with a trowel, the excess is also removed, a level is applied, the workpiece is removed. The bar is removed, the seam is adhered to with a trowel.

Installation of mortgages for fastening the intake sections

The master often overlooks the detail - what to attach the fence to. For fastening to the pipes in the middle of the pillar, mortgages (corner, pins and others) are welded at the same height so that the crossbars are level. For a solid brick wall, wire loops 8 cm thick are used for every fourth row. In the case of profiled sheet and wood, a cut is made in the brick and metal plates are attached that can withstand the weight of the canvas. Logs are welded onto the mortgages for fastening the fence.

The choice of bricks for pillars

Usually, four types of products are used for the construction of brick pillars:

- ceramic brick;

- clinker brick;

- silicate brick;

- hyper-pressed brick.

And in order to accurately determine which of the bricks is of a sufficiently high quality, you can simply carry out a banal check right in the store.

- The easiest way to identify flaws in the material is to examine it for various defects. If cracks are found on the surface of the brick, then, of course, it is better not to buy such material. You can use a metal object to check the quality of the brick. If you knock this object on the surface of the building material, then by the nature of the sound emitted it is easy to determine the quality. If the sound is sonorous, then the material can be bought. If the sound when hitting a metal object on the surface is deaf, then it is better not to purchase such a brick. A dull sound emitted indicates that the material was poorly processed during the production phase.

- Another way to test the quality of a brick is to throw it on the asphalt from about a meter in height. If it splits into several pieces, it means that the requirements were poorly followed during its production. Naturally, then you don't need to buy it. When buying a brick, be sure to ask the seller to show a passport confirming the quality of the product. This document must be mandatory, but if it is not there, then it will be easy to understand what quality the material has. Therefore, it is better not to buy a brick without a passport.

Varieties of hoods made from other materials

For the manufacture of hoods, not only concrete is used, but also other materials.

- metal;

- plastic;

- stone.

Let's dwell on the features of each option.

Metal plugs are made using various technologies

- by stamping;

- bending method;

- welding method.

For exclusive options, forging is used by hand or on presses.

Concrete cover for brick fence post

The production of metal plugs is carried out from various types of metal

- galvanized steel. Finished products must be immediately painted to protect against rust;

- of stainless steel. Such heads are not afraid of corrosion;

- painted black metal. The cost of painted covers is much lower than the price of galvanized or stainless steel products;

- roofing sheet. The material bends easily, the tips are cheaper, but susceptible to deformation.

You can use plastic covers that look harmonious with the fixtures.

Main advantages

- reduced price;

- reduced weight;

- acceptable strength;

- moisture resistance.

Fence masonry: technology

In most cases, the posts for the fence are made in 1.5 or 2 bricks, the section is 380 * 380 mm and 510 * 510 mm, respectively, the height is up to 3 meters.

The laying is carried out with a bandaging (offset) - the seam of the lower row is overlapped by the "body" of the brick lying on top. The seam is standard - 8-10 mm. The scheme of laying posts in one and a half and two bricks in the photo below.

Brick pillars in 1.5 and 2 bricks

Laying pillars: order of work

Cut-off waterproofing is spread on the finished foundation. It can be roofing material in two layers, but waterproofing on bituminous mastic is better. This layer is necessary so that the brick does not "pull" moisture from the soil. If wet brick freezes, it quickly begins to crack and crumble. Therefore, waterproofing is necessary.

According to the dimensions of the pillar, a solution is applied to the waterproofing with a layer of a little more than 1 cm.According to the scheme, bricks are laid on it. They are leveled vertically and horizontally by tapping with a special rubber mallet. Craftsmen can use the handle of the trowel, but in this case, the remains of the mortar can fly off the plane of the trowel, staining the hands and brick, and it is not wiped off the cement well.

Ceramic brick absorbs moisture very quickly, so if you hesitate a little, it will be difficult for you to "put" it in place. In order for the mortar to retain its plasticity longer, the brick is dipped in water for a few seconds before laying. The same maneuver makes it easier to wipe off the solution from the surface (it is removed immediately with a dry cloth).

Hammer down

The second row is also placed: a solution is spread on the bricks, bricks are placed on it, but with a dressing - unfolding so that the seam is blocked. Level again. Then they take a tape measure and check the dimensions of the stacked rows. Even a small offset of 1-2 mm is eliminated. They tap on the end of the brick (called a "poke"), moving the bricks closer. Then, if the side edges were not coated, the vertical seams are filled. All subsequent rows are laid in the same way.

If between the inner pipe reinforcement and masonry there is a void, it is being filled. If the distance is small, you can use a masonry mortar, if the void is significant, to save space, you can fill it up with rubble, tamp it, then spill it with a liquid cement-sand mortar.

Bar masonry

Such a laying of pillars has long been tested, but for beginners, it is difficult to maintain an even seam when self-made. Another problem - the solution crawls out of the seam, staining the surface. It turns out not very nice. To facilitate the work, they came up with a masonry for a bar. Take a square metal bar with a side of 8-10 mm, cut it into pieces, 10-15 cm longer than the size of the post.

Bar layout

Having laid the first row, a bar is laid on it along the edge of the brick. The site is filled with a solution with a small margin, and closer to the pipe, the layer is made larger. Then, leading with a trowel along the bar, remove the excess, cleaning the bar from the solution. But at the same time, the slope of the solution remains. They put a brick, level it. At the same time, the bar does not allow it to settle strongly, and the position of the other end is controlled by the level.

Apply the solution to the side face under the bar.

Then they take a short piece of a bar of about 10 cm (for a vertical seam), put it along the butt, apply the mortar with a trowel to the side of the laid brick, also removing the excess along the bar. The second brick is placed and leveled. After the level is set, the seam is pressed from above with a trowel, and the vertical bar is removed.

We take out the bar, holding the seam with a trowel

This is how all the bricks in a row are laid out. Then the rods are taken out, proceed to the next row. This technology of laying brick posts allows you to control the seams and make them neat. Even a novice amateur bricklayer can fold a pillar with his own hands.

It is only important in the process to control the parameters of each row.

Video lessons

A more complex version of a brick pillar - twisted with a screw

Features of working with ceramic bricks

Installation of strip foundations on the ground

First, wooden pegs are installed around the perimeter of the construction and the length of the fence is measured with an accuracy of a centimeter. After that, they begin to calculate the number of pillars, taking into account the size of the gates and wickets. Depending on the filling of the body of the fence, the distance between the posts may be different. It ranges from 2.5 to 3 meters. If the soil allows you to avoid the installation of formwork, concrete is poured directly into the ground.

This is possible for clayey, rocky soils, which may not crumble for several days in good weather without rain. If the ground is sandy, formwork must be installed to the full height of the base. For formwork, boards, plywood, flat slate are used. If the house is on a slope, then the fence foundation will have to be made stepwise.

Photo: foundation with pillars installed on a slope

Benefits of using buta

Foundations for a fence made of rubble stone with brick pillars in terms of bearing capacity are in no way inferior to concrete ones. Any stone material of suitable size is used to fill the trench. Large stones are split with a chisel or an old ax. To do this, they are laid on the ground and with strong blows they first cut a long furrow in them, and then split them. Tie the stones together with a solution of the brand of at least M200.

There should be no gaps and cavities between the elements that are not filled with cement mortar. If water gets into the cavity in winter and freezes, there is a risk of rupture of the foundation and the fence may tilt. When the bottom of the foundation is tilted a few centimeters, the top of the fence will go 5-10 cm to the side and everything will have to be redone.

Photo: buta laying

Foundation with glasses and reinforced concrete beam

This is the most cost-effective option for building foundations for brick fences. After breaking down the plan, holes are dug under the fence and concrete glasses are poured into the formwork. At the top of the glass, a recess is left for the thickness of the beam. Reinforced concrete beams, which play the role of a base, can be cast in one place, and after hardening, transported to the fence and installed. An expansion joint should be provided between the beams and glasses.

Foundation on screw piles

Steel screw pile supports can be used to construct foundations in soils with low bearing capacity. They have steel caps, on which a concrete grillage is formed under the load-bearing beams.

It should be taken into account that the screw pile supports for houses have a closed contour and are a rectangle or square in the plan

Fences can be long, and in order to reduce the effect of positive or negative temperatures, it will be necessary to make expansion joints at regular intervals. The advantage of steel screw supports is that there is no need to use earth-moving equipment during their construction. In fact, the body of the foundation is above the ground.

Advice:

- Choose welded piles for low density soils or cast piles for heavier soils.However, keep in mind: cast piles are much more expensive, although more durable.

- The internal cavities of the piles are filled with concrete of a grade not lower than M200.

- For fences with a large windage, with filling with corrugated board, you will have to make a calculation for the wind load.

Arrangement of strip-and-column foundations

This type of foundation is used for brick fences with solid brick filling between posts on unstable soils in climatic zones with a freezing depth of more than 1 meter or in permafrost areas. A very costly way of arranging such bases. This requires the use of special machines and mechanisms: excavators, drilling rigs.

The pillars are concreted in special metal formwork and, after hardening, are treated with bituminous compounds for waterproofing. Waterproofing serves as a lubricant for heaving soils when temperatures drop to -30 ° C and below. The entire body of the foundation with pillars is reinforced with steel reinforcement.

Do you need mortgages?

There is no unequivocal answer to this question. If it is decided to weld them in advance, the installation site should be carefully marked. For the wicket I provide two of them, for the gate leaves - three. Brick laying is performed in such a way that the mortgages are located directly in the seam being formed, are symmetrically relative to the top and bottom of the supports. In this case, all work must be done very carefully. Only individual people can cope with such a task.

Mortgage in a brick pillar

An alternative option is to weld the elements directly during the masonry process. For this, the bricks are stacked to the desired height, and then the mortgage is attached in any convenient way. This can be done using bots, a clamp, or simply weld the element to the support.

This version of the sash device allows you to do everything not only very accurately, but also very beautifully, which is important for finishing the supports, which many decide to do on their own. Subsequently, it will be possible to paint the protruding elements with paint of the same color as the brick in order to hide the traces of installation work

Attachment option to a ready-made post

If the support is installed and the brick is laid, then the support can be fixed in two ways:

- Through the clamp. In this case, the completely finished post is "encircled" by a clamp frame welded from the corner. Sometimes it is placed in the form of three rings, placed at an equal distance relative to each other along the entire length of the support;

- To reinforcement rods. To do this, using a perforator, sufficiently deep holes are drilled, the diameter of which is slightly larger than the transverse dimensions of the reinforcement. They begin to work from a point located on the seam of the brickwork. Then they move downward, placing the drill at a certain angle. Reinforcement is driven into the holes prepared in this way.

Both options allow you to slightly increase the strength of the mounted structure. However, in this case, the appearance of the structure to be mounted is significantly deteriorated. This can be avoided solely by adhering to the technology for installing supporting elements.

For which poles is it advisable to operate?

Concrete covers are an excellent option for a protective structure made of bricks, Besser, natural and artificial stone. Concrete products for posts are very easy to select according to the size of the structure and the preferred shape.

As you already understood, you can install such products on almost any support, since concrete goes well with any material. The only thing is that concrete covers are rarely mounted on a metal fence. Other caps are made for him.

The video shows caps for fences of various types:

Due to their low price, ease of material handling and easy installation, such products have become very popular among consumers. They are characterized by:

- hydrophobicity;

- opposition to the rays of the sun;

- resistance to chemical components.

Most owners install on the luminaire pole caps. For these purposes, holes are made in them for a cable that comes from a source of electrical energy and passes through the cavity of the column. The connection of the lamp to the cover must be carefully sealed.

Fence caps

A variety of caps are used to complete the look of the fence. They decorate the fence, but besides this, hand-made caps protect the pillars from precipitation.

Almost every hood design is highly resistant, they are not afraid of any climatic conditions, the hoods are never covered with rust. The material of the hoods is stainless steel, which has a wide variety of coatings:

- Polyester;

- Pural;

- Plastisol;

- Powder paint.

Fence caps come in many different shapes. Their cost always depends on the material, dimensions and shape of the structure.

The caps are painted in a variety of colors, sometimes decorated with decorative details. This allows you to choose a cap that matches the future fencing at an acceptable cost. These covers can be installed on fences made of a wide variety of materials.

Diagram of the device of various intake hoods

They protect the brick pillars and keep moisture out.

Brick pillars are especially in need of covers, since the brick quickly collapses from moisture, and, remaining unprotected, it will begin to crack, which leads to the destruction of the brick pillar. The cost of repairing such a pillar will require large financial investments.

There are several main types of caps:

- metal;

- concrete;

- forged.

Concrete

This design has several advantages. First of all, concrete never rusts, it always retains its original appearance. To achieve a beautiful design, such caps can be painted in any color using special dyes.

A hood made of concrete can have any shape, but only if two main conditions are met. Its dimensions must necessarily be equal to the dimensions of the post, and the cap must have a streamlined shape.

For the manufacture of concrete caps, special forms are used, which for do-it-yourself work can be made to order. The finished product can have a monolithic or prefabricated structure. I must say that the prefabricated structure has several layers, which are connected with a special adhesive. This makes it possible to realize the most original design fantasies.

The finished cap can be in the form of a platform, in which the top layer is made as a complex geometric figure. Thus, you can get a product that looks like a gingerbread house. To obtain especially complex shapes, parts glued together are used. For example, pyramids decorated with round balls. Simple concrete caps simply mimic the roof.

Metallic

These products are distinguished by a simple shape. Most often, the cap looks like a pyramid with a square base. For manufacturing, thin sheet metal coated with a dye is used.

This is what metal caps installed on the fence look like.

In most cases, the metal cap is made by hand, however, it looks like a factory stamping. The discreet style and the dark color make it possible to achieve the level of fashionable European design. The cost of such caps suits different segments of the population the most. Thanks to the varied range of colors of oil paints, you can choose the color of the part that will harmoniously fit into the surrounding landscape.

Tin caps differ in their technological features. The main one is the fold of the seams. They are assembled by hand, and if there is a very complex structure, special equipment is used. Such caps are decorated with forged details, which adds sophistication to them.

Schemes of various metal caps

Wrought iron

This type of caps makes it possible to implement design ideas, as well as demonstrate the consistency of the owner of the fence. The cost of such a product is quite high, since the work is performed by a professional craftsman who is engaged in artistic forging.

Forged products are maximally resistant to a wide variety of influences. They never wrinkle or chip. They can be operated for a long time. When a brick fence is being built, on which forged products are installed, it is possible to show the smallest details that require very delicate work.

An example of a forged fence hood

I must say that the cost of caps strongly depends on the type of design and its complexity. Tinted products look more attractive, which can turn into a highlight of the entire design.

Brick pillars, combined with forged details, become the decoration of the entire fence. For completeness of the design, forged caps are well combined with the lighting details that are attached to the fence.