Dependence of consumption on the type of tile

The consumption of this material directly depends on the size of the tile: the larger the tile, the thicker the layer and vice versa. So, a tile with a side of 20-30 cm is laid on 2 ... 4 mm of an adhesive layer, with a side of 30 to 50 cm, it is kept on glue, the thickness of which is 3.5 ... 4.5 mm, with large sizes the layer increases to 5 mm.

In addition to the size of the tile, the material from which it is made also affects the consumption of material. The tile is very porous and absorbs a lot of glue. Porcelain stoneware absorbs glue in much smaller quantities, therefore, for laying (especially large tiles), it is necessary to apply glue to the back side - with a layer of 1 mm.

The flatness of the back also plays a role. Absolutely flat tiles are laid on a thinner layer than with deeply grooved surfaces.

Dependence of consumption on the quality of the base

The quality and material of the base on which the tiles will be laid play an important role in calculating the glue consumption. Brick absorbs glue several times more than concrete or drywall.

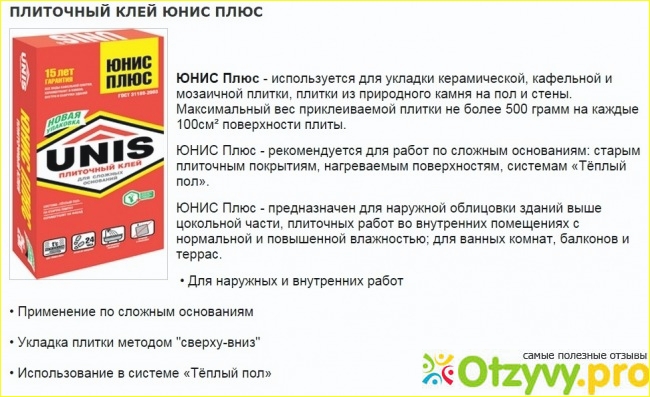

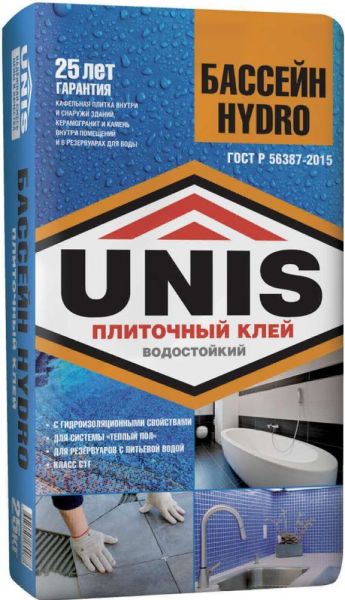

What is good about Eunice glue

The use of modern fillers makes it possible to improve resistance to moisture, cold weather, and to increase the adhesion strength of the product to the base. The glue holds well not only tiles, but also heavy natural stones. At the same time, masonry can be performed on a wide variety of surfaces - from brick and concrete to plastered walls.

You can knead the glue not only by mechanized methods, but also manually, which makes it possible to use it at home. It takes about 180 minutes to use the solution, which is quite enough for laying material in rooms of different sizes. The product is delivered in convenient packages that are easy to transport by any car.

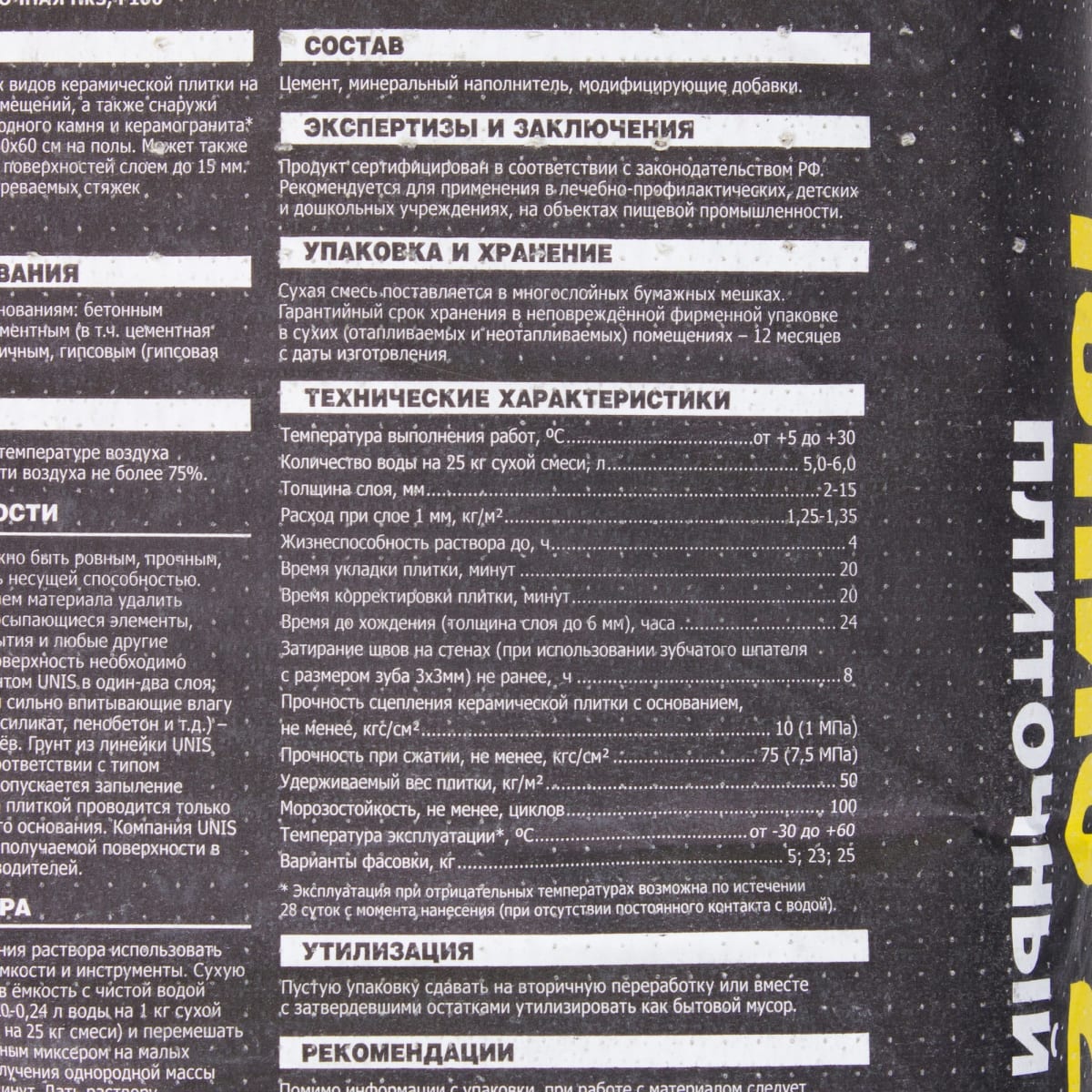

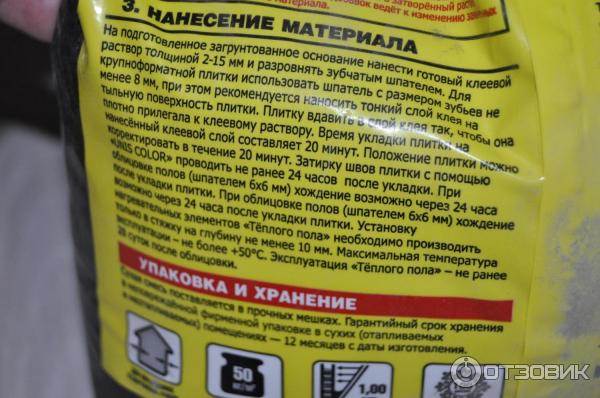

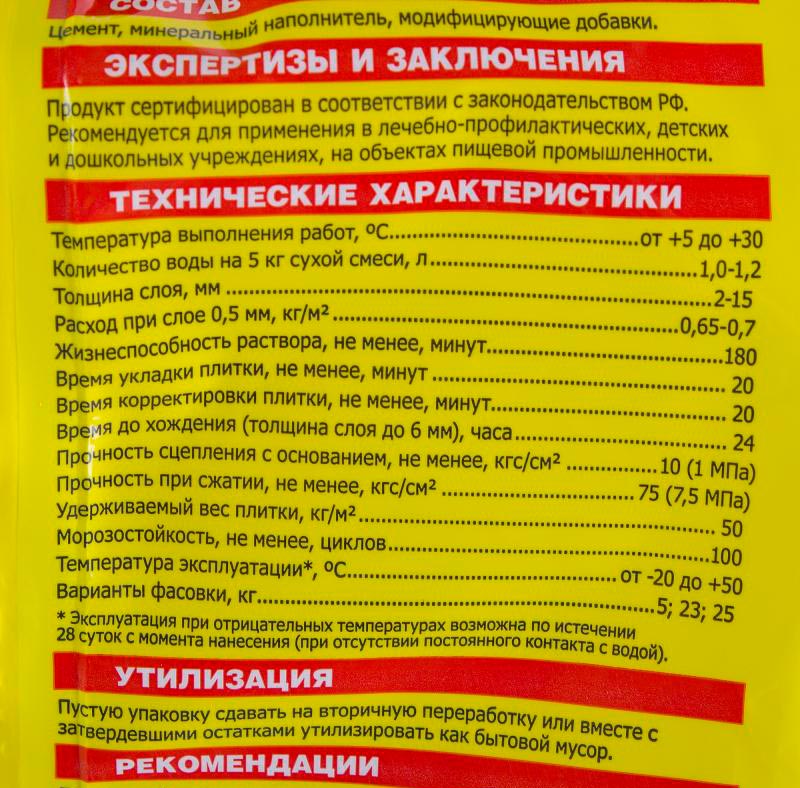

Main characteristics

- The composition can hold a tile weighing one hundred kilograms per square meter.

- The pot life of the glue is about three hours, twenty minutes are given for laying the tiles, and ten minutes for adjusting it. The composition will freeze after a day, and you can safely move on the tiles.

To dilute the product, packaged in a 25 kg bag, you will need 4-6 liters of water. In this case, laying can be performed at temperatures from + 5C to + 30C. If you apply a layer of glue of 3-15 mm, the consumption of the product will be about four kilograms per square meter.

It is not accidental that these adhesives are used to work with complex surfaces. They give a high adhesion strength, so laying can even be done "from top to bottom".

Adhesives can also be used on heated surfaces, for example, on "warm floors" heated to a temperature of 40C.

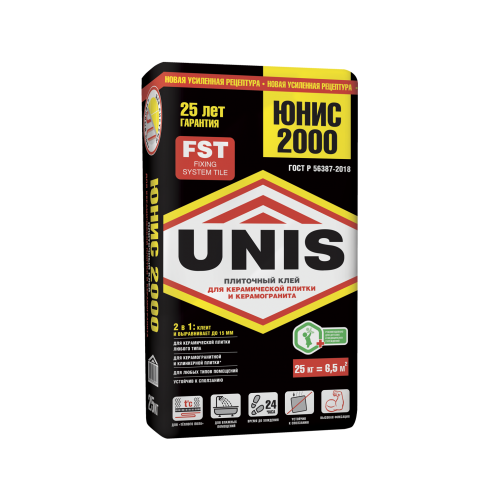

Clay Eunice 2000

The purchased glue in the original packaging can be stored for one year, observing the manufacturer's requirements for humidity and ambient temperature.

In terms of the combination of price and characteristics, Eunice adhesives are deservedly considered one of the best on the building materials market.

How to breed and work with Eunice tile adhesive

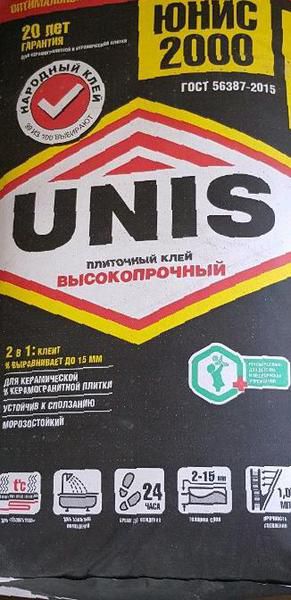

The preparation of the Eunice 2000 tile adhesive solution is carried out in accordance with the manufacturer's recommendations, which are stated on the product packaging. Use only clean containers and tools.

Stages of dilution and use of Eunice glue:

1.Pour the dry mixture into a prepared container with clean water and mix until a homogeneous mass is obtained for 3-5 minutes.

2.We stand for 3-5 minutes and mix again. While stirring, do not add dry mixture or water to the composition.

3. The resulting solution must be used within 180 minutes.

Important information:

- Adhesives should be used for lining durable non-deformable substrates. Works should be carried out in dry conditions at an air and base temperature from + 5C to + 30C and a relative humidity of no more than 75%.

- When performing external cladding, direct sunlight is not allowed on the cladding surfaces.

4. On the prepared primed base or work surface, using a trowel or a spatula, apply the prepared adhesive solution with a thickness of 3 to 15 mm and level it with a notched trowel. For large-format ceramic tiles, a trowel with a notch size of at least 8 mm is used.

For wall cladding, the weight of large tiles must not exceed the weight indicated on the package.

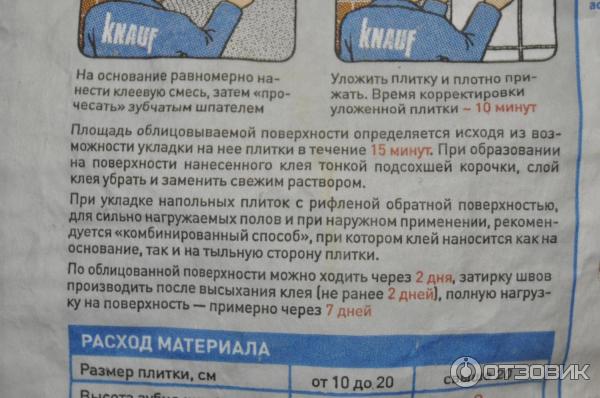

5. Lay the tiles on a layer of glue and press down. Its inner surface should adhere tightly to the adhesive solution. When applying glue to substrates, the mortar mixture should be applied to an area that can be tiled within 10 minutes.

We control the laying by level. If necessary, the adjustment of the position of the tiles can be carried out within 10 minutes after laying. During the same period, the surface of the tiles and seams should be cleaned from excess glue.

Subsequent grouting of wall and floor tiles with Eunice Color is allowed 24 hours after tiling.

Instructions for use

Carrying out works is permissible at air temperatures from +5 to +30 ° C and relative humidity less than 75%.

Surface preparation

Before starting work, it is necessary to carry out the traditional preparation of the base:

Laying on flat walls and floors will be faster and better

Remove old finish, old peeling plaster or screed.

Level the base. Height differences of 1 mm per 1 meter are permissible. Cracks and defects with a depth of more than 10 mm must be leveled with plaster. The manufacturer recommends using Eunice "Silin", "Teplon" or "Standard" plaster, depending on the situation.

When laying on old tiles, to improve adhesion, notches are made on the old cladding every 5 cm in a checkerboard pattern.

Dry and degrease the surface.

In damp and basements, it is recommended to apply waterproofing coating using UNIS HYDROPLAST.

To improve adhesion, the surface should be primed 1-2 times with UNIS primer. Highly absorbent surfaces (gas silicate, foam concrete) should be treated especially carefully.

It is not necessary to wet the base or tile beforehand.

On an uneven base, the layer of glue will be uneven, which means it will set and shrink at different times. This can cause peeling or cracking in the tiles.

Mixing the solution

Stir until smooth without lumps

To mix the solution, use a clean tool and container.

The dry mixture is poured into a container with clean water in the specified proportions (see the table of technical characteristics or instructions on the package). The solution must be mixed until a homogeneous consistency is obtained for 3-5 minutes.

The solution should ripen in a calm state for 3-5 minutes, after which it must be mixed again.

Mixing can be done by hand or using a construction mixer / drill with a nozzle at low speed. When manually mixing, the portion of the mixture should not exceed 1 kg by weight.

The prepared solution must be used within 180 minutes (300 minutes for the HiTech mixture). If the mixture thickens within this time, it must be stirred without adding water.

If the specified proportions are not observed when mixing or adding other components, the properties of the glue may deteriorate.

Glue application

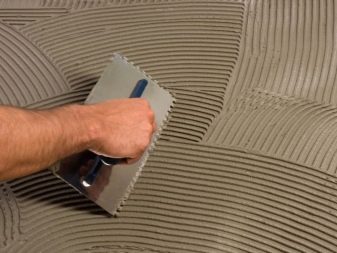

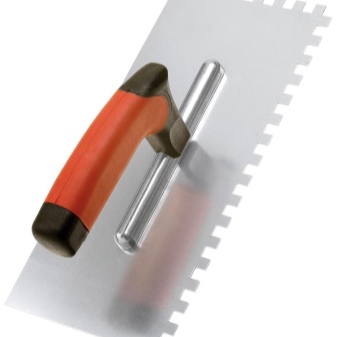

Application of glue with a comb

- On the prepared surface, using a trowel or an ordinary spatula, the prepared mortar is applied with a layer of 3-15 mm and leveled with a notched trowel or a trowel-comb.

- For large tiles and porcelain stoneware, the teeth must be at least 8 mm.The weight of large tiles should not exceed the maximum allowable weight.

- The tile is pressed onto the layer of glue. The glue should be evenly distributed underneath, avoiding voids. To do this, you can press the tile in wave-like movements, or tap it with a rubber hammer. After pressing, the adhesive thickness must not exceed the maximum permissible value (see table of characteristics).

- Apply the glue to the area that you will have time to veneer during the pot life of the solution (10-20 minutes). Thereafter, adhesion will deteriorate.

Press down firmly on the tile to distribute the grout

For outdoor work or for fixing marble slabs, light limestone, large tiles or with different thicknesses and reliefs, the mixture must be additionally applied to the working surface of the tile.

After laying, there is another 10-20 minutes for adjusting the position of the tiles. Level its plane. Use plastic crosses to maintain uniform seams.

After 24 hours, you can start walking on the tiles and start grouting with UNIS COLOR colored grout mixes.

The underfloor heating system can only be used 28 days after tiling.

comments powered by HyperComments

How to apply?

After the surface is prepared and the glue looks like a uniform consistency, you can start applying it to the wall or floor.

This process requires a spatula. With the help of it, an even layer of the composition with a thickness of 3 to 15 millimeters is applied; one must not forget to level it with a special grater or a spatula with teeth. If the squares of the tiles are large, then the teeth should be from 8 millimeters.

It is important to keep an even distribution of the adhesive mass. The voids will turn into unpleasant consequences in the future, so it is better to press the tiles a little to the surface.

After the material is laid, it can still be corrected within twenty minutes. The glue dries exactly one day. Then you can move freely on the tile (if the finishing work was carried out on the floor) .After the completion of the work, you need to remove the excess adhesive mass that remained on the front of the tile and grout joints. If the excess composition remains in the seam, then a number of problems may arise when grouting begins.

Possible consequences.

- If you apply grout to an unrefined seam, then in the future it will begin to crack, because it will be thin.

- Another reason to remove glue residues is for aesthetics. If a sticky mass peeps through the grout, then no matter how beautiful the tile is, its appearance will be spoiled.

- The use of colored grout on the joint with glue residues will result in the fact that after drying it will differ in color from the rest of the grout. The thing is that in this place it will be thin and not so strong. The result will be sloppy.

To avoid these unpleasant consequences, you need to remove the remnants of the glue while it is soft, otherwise it will be much more difficult to do this later. You will need a knife for the procedure. Using its blade, it is easy to remove the remnants of the adhesive mass from the edges of the tiles.

If the mixture has already frozen, then here you need to use a special knife, which is designed for the grouting seam. First, make a cut in the center of the joint and scrape dry glue off the edge of each tile with a knife. If necessary, you can clean the tiles with an abrasive trowel. And at the end of the procedure, the seams are cleaned with a vacuum cleaner so that not a single small particle remains of the glue.

additional information

Unis is a Russian manufacturer of dry building mixes, which have been in demand for over two decades. The company's products are among the three most demanded products. Unis 2000 glue can be used for marble, limestone and granite tiles, but not thicker than 1 cm. When working with such materials, you can use both notched and ordinary spatulas or trowels.In the first case, grooves of a given size are obtained, and in the second, the thickness of the coating being created can be increased.

The maximum adhesive layer thickness is used when it is required to smooth out the most powerful height differences. If the base is so chaotic, sometimes it is more advisable to resort to leveling with plaster or screed in order to save time and increase the reliability of tile laying. Remember that the smallest layer of adhesive in a particular case is equal to or greater than the thickness of the tiles.

When mixing dry material, it is advisable to use a mixer, achieving the final disappearance of the smallest lumps. The set of strength, like all cement-based compounds, takes 28 days, and during the first 14 days it is undesirable to grind the seams. Do not use glue on top of a warm floor. Having familiarized yourself with the properties of the mixture, it is easy to understand that it satisfies even the most stringent technological requirements, provided that the manufacturer's recommendations are followed.

For more information on tiling using Unis 2000 glue, see the video.

Quantitative ratio

Tile adhesive is packed in bags

The link describes which adhesive to choose for laying tiles in the bathroom. For outdoor use, frost-resistant tile adhesive is suitable.

To determine the consumption of tile adhesive, several options are used:

- The first method of calculation is advisable to apply to those who have already bought glue again and know how to work with it. If you trust the same manufacturer, you can go to its website and calculate the consumption thanks to the “Online calculator” function available there. The program only requires you to enter the tile size, room area, and glue type. After that, you will get the value, which will be expressed in kg.

- The second option is more complicated, because here you will have to carry out a number of calculations. Let's consider this using a cement-based adhesive as an example. Let the installation process be carried out under favorable conditions. Accepts a consumption of 1.3 kg glue. Now it is worth multiplying this figure by the layer thickness (if you use a 30x30 cm tile, then the layer thickness will be 4 mm). The result is 5.2 kg / m2. If you lay 10 m2 tiles, then the consumption will be 52 kg. Tiles with other dimensions have their own layer thickness. But even this result cannot be called accurate, because everyone can use their own glue with certain properties. This way you will be able to get an approximate result.

- The third option should be used by those who want to urgently get data on the consumption of tile adhesive. For these purposes, it is necessary to take into account such parameters as ½ the thickness of the tiles, the average consumption of the glue used. By multiplying these indicators, you will get the desired result. But this option is one of the most inaccurate, because even porcelain stoneware tiles from the same batch can have different thicknesses.

What affects the consumption of tile glue

tile size - a thicker layer is required for larger tiles. The thickness is regulated by the height of the spatula teeth, most manufacturers are guided by this indicator, and indicate the corresponding information on the container. For example, for tiles 15 * 15 cm, the recommended layer thickness is 6 mm.

technique and skill level - an inexperienced craftsman has a slightly higher mix consumption than a professional stacker. A beginner will not be able to estimate the real amount that is needed for one batch, and there will also be a lot of excess grout. Part of the solution dries out, or is not used for its intended purpose. evenness of the base - with a perfectly flat base, with maximum differences within 3-5 mm, a minimum amount of glue is used. But if there are significant irregularities in the room that have not been corrected with self-leveling solutions, then it is worth expecting that the flow rate will increase significantly.

What affects consumption

There are a lot of factors on which the rate of consumption of glue for tiles per 1 m2 depends.And if calculating the squares of surface area themselves is not difficult, then calculating the consumption of glue will require the collection of some data. For the most accurate and correct calculation, it is necessary to take into account all of them as objectively and correctly as possible:

The type and size of tiles or tiles chosen for finishing. Each material has a different degree of porosity and density

More porous tiles will absorb more adhesive. Dense material, such as porcelain stoneware, practically does not absorb moisture due to its high density. But matte tiles are the most expensive in terms of the amount of adhesive solution per 1 m2.

The size of the tile plates also plays a big role. The larger the tile, the greater its mass. Therefore, you will need to apply more glue to better adhere the tile to the surface.

Features of the surface to be laid. As is the case with the back of the tile itself, the amount of adhesive applied depends on the degree of uniformity and evenness of the wall or floor surface. Differences, protrusions, cracks will require additional consumption of the composition. If the relief of the wall or floor is significantly heterogeneous, it is advisable to carry out work to level the surface before laying the facing material.

The secret lies in the correct positioning of the trowel relative to the surface. The larger the angle, the more excess glue will be applied. The optimum trowel angle is approximately 40-45 degrees.

External conditions during work. This factor is especially important under changeable weather conditions, if work is carried out outdoors. If in the room in most cases it is quite possible to maintain constant and optimal conditions for carrying out work, then when working with the facade you will have to adjust to external factors that do not depend on the master.

It should also be borne in mind that a concrete surface will need much less glue than a more porous brick base or plastered surface. The PVC surface is also very costly in terms of the amount of glue. When calculating the consumption of adhesive solution, you will need to take into account this feature.

- Method and technology for laying ceramic tiles or tiles. If the facing material is laid in straight rows, the cost of glue will be significantly lower. When laying panels, mosaics, patterns, the consumption of the adhesive composition increases.

- Adhesive application technology. Experienced craftsmen are well versed in the most economical in terms of glue consumption techniques for applying a solution. Moreover, the reduction in consumption does not occur to the detriment of the strength of the fastening of the tile itself.

It is impossible to carry out styling at temperatures below +5 degrees. High humidity also affects the quality of work. Too hot temperatures are also unacceptable. The maximum threshold at which it is possible to produce high-quality cladding is +35 degrees.

If these recommendations are not followed, for example, when working in rainy, cold weather, or, on the contrary, under the scorching sun, there is an almost one hundred percent chance that the glue will simply lose its properties. High-quality fixing of tiles to a surface, especially a vertical one, will be impossible. If the temperature is too high, the glue begins to harden even before application, the time for using the ready-made solution is significantly reduced.

At low temperatures and excessive humidity indoors or outdoors, important properties such as the viscosity and speed of glue set are affected. If a large tile of a large size, for example, clinker, is chosen for cladding, it will be almost impossible to fix it on a vertical surface under such conditions.