Main properties and features

These products are excellent for filling / sealing defects on vertical and horizontal surfaces. One of the important advantages is fast polymerization on contact with moisture in the air. This allows the rubber sealants to cure after being squeezed out of the tube. High performance one- and two-component formulations can be found on the market.

The polymerization process is fast enough, but it allows you to create / correct the seal. The resulting seam has a rubber-like structure: moderately elastic and durable. UV resistance is a key feature of modern synthetic rubber based sealants. Due to her, these funds are suitable for outdoor work.

Other properties of rubber sealants include:

- increased resistance to mechanical stress (the hardened seam is difficult to damage with anything, it retains its elasticity over a long period of operation);

- insensitivity to weathering (a wide temperature range makes rubber sealants insensitive to seasonal changes, as well as to atmospheric precipitation);

- good adhesion (thanks to this property, sealants acquire high adhesion to various surfaces);

- frost resistance (these funds retain their qualities even with frosts down to -50 degrees Celsius).

Full curing of rubber sealants takes on average 1–2 days, depending on the composition. In general, these funds are very similar in properties to silicone compositions, but they have many advantages over them.

The most commonly used sealant is black. The dark color is acquired by a chemical reaction between the base components. There are also products of other colors: red, white, brown.

Peculiarities

The main component of any rubber sealant is synthetic rubber. Like mixtures based on modified bitumen, such substances are very resistant to moisture. Thanks to such valuable properties, they can be used for sealing roofs and facades, as well as for interior work, even in the wettest rooms.

Sealants that protect the surface from water adhere well to the surface of a variety of materials, including rubber. They can be used to repair an inflatable boat, wading boots and much more. Roofing material and other roofing products are glued on top of the sealing layer.

The main advantages of rubber sealants:

- good level of elasticity;

- the working temperature range is at least -50 degrees and a maximum of +150 degrees;

- the ability to paint the sealant after application in any suitable tone;

- immunity to ultraviolet radiation;

- the possibility of using up to two decades.

Peculiarities

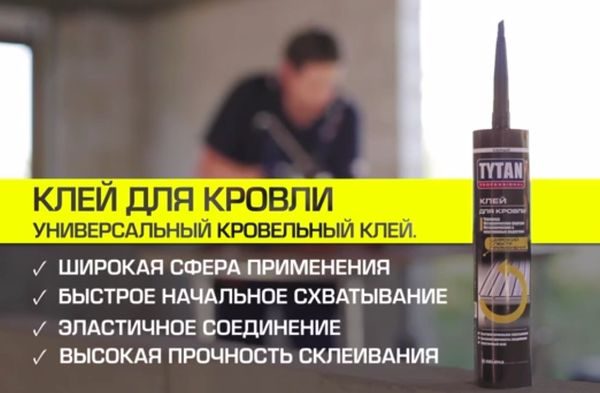

In practice, sealants are not always used neat. Mixed reagents are often used, such as "Titan", formed by combining rubber with resin, bitumen, synthesized fibers and even a solvent. Such a composition has proven itself perfectly when performing roofing work. Judging by the assessments of professional and amateur builders, this sealant is distinguished by its high viscosity and perfectly tolerates harmful atmospheric influences.

Basically, such a mixture is needed for the following purposes:

- closing of the docking points of the blocks;

- elimination of gaps;

- updating of previously formed joints;

- fight against leaking places;

- increasing the rigidity of gutters and roof windows.

The classic rubber-based sealant, along with bituminous analogs, is used in the following:

- in the repair of rooms and utility rooms with excessive moisture;

- when holes appear in inflatable boats and rubber boots;

- when restoring the integrity of roofing materials;

- for fixing roofing material and other bitumen coatings;

- for attaching expanded polystyrene or polyurethane to any base.

Questions

The recommended application temperature is from -10 to +40. Clean the surfaces to be connected from dust and solid particles. Non-porous surfaces may be damp, porous surfaces should be dry. The surfaces to be joined may be slightly oily.

Place cartridge in gun and apply sealant. After application, smooth out the sealant immediately with a damp spatula.

Storage: at temperatures from +5 ºС to +25 ºС.

The main task of a rubber sealant is to fill gaps, dents, chips, cracks and other defects. With its special composition, this tool allows you to create a sealing seam that prevents moisture and dust from entering.

Popular rubber sealants

It was noted above that the variety of these funds is great. This opens up great opportunities for choosing a composition, taking into account the nature of the task at hand.

The construction / hardware stores receive imported and domestic sealants. It is recommended to choose the product that has passed the technical control and meets the current norms and standards (there must be a corresponding mark on the packaging).

To make the selection of a rubber sealant as easy and fast as possible, we provide a useful overview of leading manufacturers and well-known products.

Rubber Roof Sealant Tytan

The products of this brand are well known and loved in our country, as it has proven itself well. Tytan creates a reliable waterproof connection that can withstand ambient temperatures ranging from –55 to +100 degrees Celsius.

Resistance to fungi and mold is an important feature of this composition. This allows you not to be afraid of the development of microorganisms in hard-to-reach places (joints between tiles, cracks between the bathroom and the wall). The sealant is indispensable for processing:

- roof ridge;

- roof windows;

- sewer hatches;

- gutters;

- stormwater systems;

- ventilation.

For ease of use, Tytan rubber sealant is available in 310 ml tubes. It is curious that the product can withstand up to four freezing cycles, while maintaining its consumer qualities.

This sealant should be applied at a positive air temperature. The curing rate is approximately 2 mm per day.

Penosil Premium All Weather Sealant

The main advantage of this sealant is its excellent adhesion to the surface combined with a viscous consistency. The product does not drain even from vertical panels and partitions, adhering to them and hardening gradually.

Penosil sealant is indispensable when working with brick / masonry, monolithic concrete surfaces, glass, wood and metal. In addition, he is not so aggressive towards plastic. Complete hardening occurs 20 minutes after removal from the cartridge.

Like the previous composition, this sealant is resistant to mold. An important difference is application even at a temperature of -5 degrees Celsius, which expands the possibilities for using the product.

Body 920

Thick consistency, stability on the surface, protection against cracking - these are the main advantages of the one-component rubber sealant Body 920. It is non-aggressive to plastic, has good adhesion to metal parts and perfectly adheres / seals joint joints.

Due to its availability, this composition is actively used in the treatment of air conditioning systems. It is used in the construction of small ships made of metal and wood, as well as for the sealing of sea containers and the processing of automotive body parts.

Rubber sealant MasterTeks Liquid rubber

This tool is good because it is suitable for work in any season and regardless of weather conditions. Based on butyl acetate and synthetic rubber, this sealant is used to restore roof coverings and protect rafter systems from the damaging effects of moisture.

The composition has a narrower operating temperature range (from –40 to +90 degrees Celsius), but it can be applied even at 10 degrees below zero. Liquid rubber is excellent for working in rooms with high humidity and is very often used to seal building facades.

TechnoNIKOL No. 45

Another equally popular butyl rubber sealant that has become famous for:

- cold curing;

- low gas permeability;

- elasticity of the seam;

- application at a temperature of –20 degrees Celsius.

This sealant has a neutral white color and is well suited for overpainting. It is durable. Complete drying occurs one hour after application. For ease of use, the product is available in buckets weighing up to 16 kg.

The given sealants have passed technical control and a number of tests, and most importantly, have been tested in practice. These funds are available not only for professional builders, but also for ordinary consumers, which is reflected in the growth of their popularity.

Rubber sealant tytan professional for a roof colorless 310 ml in Sevastopol

Tytan Professional sealant bitumen-rubber for roofing black 310ml, art.99963 ty99963

Rubber roofing sealant TYTAN Professional brown Permanently elastic sealant based on synthetic rubber.

Tytan Professional silicone sealant sanitary colorless 310ml, art.19649 ty19649

Tytan Professional sealant acrylic frost-resistant white 310 ml art.11510 / 51791

Rubber sealant for roofs and facades Grover R100 transparent 300ml Properties: sealant based on synthetic rubber.

Professional one-component, fast-curing sealant, forms a very strong, aging-resistant joint. Free of isocyanates, silicone and solvents. Safe for the environment. Odorless.

ORDER - goods for home and garden

Tytan Professional sanitary silicone sealant white 310ml, art.19663 ty19663

Tytan Professional silicone sealant universal white 310ml, art.20041 ty20041

A high quality acidic silicone sealant designed for a wide range of construction and renovation applications.

ORDER - goods for home and garden

Sealant polyurethane TYTAN INDUSTRY PU40 black 600 ml One-component, high modulus, elastic sealant based on polyurethane. Designed for sealing during the construction and repair of roads, silo pits, automobile construction.

Silicone sealant universal black 310ml

Silicone Red high temperature titanium 310ml Poland (00843/19380

The sealant is intended for sealing joints exposed to high temperatures.

ORDER - goods for home and garden

Colorless universal silicone sealant PUTECH 280 ML Scope: for sealing joints of adjoining floorings, split systems, awnings, windows, doors.

Silicone sealant Kraftool transparent, universal, 300 ml.

Silicone sealant Bison expert white, neutral, 280 ml.

Stayer MASTER neutral silicone, white, 260 ml.

Sealant for ventilation ducts 310ml

Stayer MASTER, neutral silicone, transparent, 260 ml.

TYTAN rubber sealant Packaging: 310 ml, 12 pcs in a box Color: colorless, black, brown, white Shelf life: 24 months Description: TYTAN rubber sealant is a high quality, one-component synthetic rubber based sealant designed for deformation.

TYTAN rubber roofing sealant Packing: 310 ml, 12 pcs in a box Color: black Shelf life: 24 months Description: TYTAN rubber roofing sealant is a permanently elastic sealant based on synthetic rubber designed for reconstruction and repair of deformation.

Manufacturers and versions

The bulk of Russian companies producing rubber and other sealants concentrated their production in the Nizhny Novgorod region. Accordingly, almost all products from other regions of the Russian Federation are not an independent product, but just the result of re-sticking labels.

The Greek material of the Body brand is considered by experts to be almost the best solution for metal surfaces and joints of metal parts. Unfortunately, the resulting coating is quickly destroyed by ultraviolet rays. To apply the mixture, you need a hand or air gun.

Titan sealant can be considered a versatile finishing and building material. It is used for metal, wood, and concrete.

You need to choose this option if you need:

- close a small gap;

- seal the roof;

- mount plumbing fixtures;

- glue glass and ceramics together.

No other material is capable of providing such elasticity, protection from contact with water, from the effects of vibration vibrations as Titan sealant. Drying time depends on humidity and air temperature. On average, complete drying takes 24 to 48 hours.

For information on how to choose a sealant, see the next video.

Rubber sealants: description and characteristics

Closing holes, cracks, eliminating various cavities is very often necessary during repair and construction. Even exclusively for domestic purposes, such processing is practiced by many people. This means that you need to thoroughly study what a rubber sealant is and how to use it correctly.

Peculiarities

In practice, sealants are not always used neat. Mixed reagents are often used, such as "Titan", formed by combining rubber with resin, bitumen, synthesized fibers and even a solvent. Such a composition has proven itself perfectly when performing roofing work. Judging by the assessments of professional and amateur builders, this sealant is distinguished by its high viscosity and perfectly tolerates harmful atmospheric influences.

Basically, such a mixture is needed for the following purposes:

- closure of the docking points of the blocks,

- elimination of gaps,

- renewal of previously formed joints,

- fight against leaking places,

- increasing the rigidity of gutters and roof windows.

The classic rubber-based sealant, along with bituminous analogues, is used in the following:

- in the repair of rooms and utility rooms with excessive moisture,

- when holes appear in inflatable boats and rubber boots,

- when restoring the integrity of roofing materials,

- for fixing roofing material and other bitumen coatings,

- for attaching expanded polystyrene or polyurethane to any base.

Usage

Rubber sealants are required to be used only at positive temperatures. No other type of sealing compounds allows you to refuse to clean the surface to be finished. And rubber, thanks to its exceptional adhesion, makes it possible to get rid of this tedious procedure. When the composition is applied, it quickly hardens, becoming insensitive to weather changes.

If necessary, the sealed surface can be repainted in a short time to match the tone of the surrounding material.

Positive and negative sides

Reviews of rubber sealants suggest that they have properties such as:

- extremely elastic

- adhere perfectly to almost any building material,

- prevent corrosion,

- can be operated in a frost of -50 degrees,

- stable even when heated to +150 degrees,

- will last up to 20 years,

- easily tolerate wind, rain, hail, snow, dew.

But you have to put up with certain restrictions. So, rubber sealants are incompatible with a number of plastics, because there is a risk of material destruction.The sealing layer, in turn, can be damaged by mineral oils.

Most attractive variety

Liquid rubber Masterteks is famous for its excellent adhesion on wet and oily substrates. It is compatible with bitumen and adheres well to bricks. The positive results of using liquid rubber when connecting the railings to the wall or plaster were noted. This material allows copper window sills to be glued to oak slopes, to seal the bonds between wood and copper, stone surfaces and sheet glass. Such characteristics make it possible to use the sealant when closing the borders of decorative panels, in the installation of plumbing and air conditioners, PVC and aluminum double-glazed windows.

Liquid rubber can confidently replace compounds based on polyurethane, silicone, polymers and other actively used sealing agents. The resulting layer is mechanically strong, but elastic at the same time. Curing occurs as a result of a reaction initiated by the moisture in the air. Therefore, the sealant must be carefully protected from moisture and only opened for use. Subject to the proprietary processing technology, even contact with salty ocean water or exposure to ultraviolet radiation will not pose any threat.

Advantages and disadvantages

Rubber compounds have many advantages. A distinctive feature is a long service life of up to 20 years. This reduces the cost of rebuilding and maintaining the sealing joints.

Sealants adhere well to most known materials. They are indispensable in large and small construction, when carrying out repair and restoration and installation work. Other benefits include:

resistance to corrosion and a high level of protection of surfaces against rust;

the possibility of staining, which makes the seam more attractive;

elasticity that prevents the sealing seam from cracking over time;

moisture resistance, which is especially important when carrying out outdoor work;

use even on wet surfaces.

Rubber sealants are so practical and effective that they do not need to be pre-cleaned. Despite this, they have a number of disadvantages. These compounds are not recommended for use when working with plastics: aggressive components of the sealant can lead to damage to parts and surfaces.

Softening on contact with oils is another disadvantage

This applies directly to automotive rubber sealants, so care must be taken when handling them.

Sealants: types and applications

Sealant - a material based on oligomers or polymers, provides reliable insulation and protection of the base from external factors. Sealants are indispensable in the field of construction, most often they are used to process connecting seams and joints. There are quick-drying and non-drying (viscous-flow) sealants, they are available in the form of a paste.

The main types of sealants

Acrylic sealant

The mixture contains derivatives of acrylic acid. Does not withstand severe frost and heat, constant contact with water: it can flake off from the joint. Before applying, the surface must be prepared, the material will polymerize for 10-15 days.

The pluses include:

- Good adhesion.

- Lack of odors.

- Possibility of additional surface treatment (painting, pasting).

Cons - not suitable for rooms with high humidity.

Polyurethane sealant

It can be one- and two-component (mixed with a catalyst in a certain proportion). It is a rubbery mass that is highly elastic and elongates by 400% at the moment of breaking. The main area of application is household and construction.

The benefits include:

- Fast drying.

- Resistance to external factors.

- The ability to apply at temperatures up to minus 10 degrees.

- Excellent adhesion.

- You can paint the resulting seam.

Of the minuses: they contain caustic substances, so you need to work with gloves and a mask, they are not stored for a long time.

Silicone sealant

The pluses include:

- Durability.

- Resistance to external factors.

- Excellent adhesion.

- Plastic.

Cons: the impossibility of applying on wet surfaces, it is impossible to additionally process the sealed seam, low adhesion to plastic and silicone.

Thiokol sealant

The polymerizing substance is polysulfide rubber, there are two- and three-component sealants (hardener, sealant and accelerator). Scope of application - reinforced concrete and concrete structures, the surface is cleaned and primed before application.

- High strength and durability.

- Resistance to acids, alkalis, external factors.

- Excellent adhesion.

- Long service life.

Cons: ready-made formulations are not stored for a long time, they can only be applied with gloves.

Rubber, bituminous sealant

Despite the different basis, both materials are used in the same field: for roofing repairs, rubber products, bituminous coatings and insulating building materials. You can work only at positive temperatures, the surface can be left without preparation.

Advantages:

- Adhesion, elasticity.

- Anti-corrosion properties.

- Further surface treatment is possible.

- Long service life.

Cons: incompatible with some plastics, mineral oils.

Butyl rubber sealant

Its main constituents are isoprene and isobutylene, an uncured sealant that is often used in the installation and repair of roofing materials and joints. In fact, applying sealant does not seem to work like double-sided tape. After removing the protective film, we attach one side to the repaired product, the other to the base. It is possible to grow the tape with an overlap, paste-like ones can be applied more abundantly.

- Excellent flexibility.

- Resistant to deformation.

- Compatible with most materials.

- Reliability.

Cons: low elongation index, shrinkage.