How to bend glass?

On the net today, you can find a lot of tips on the correct finish of plexiglass and even watch the guide on the video. But to organize the information, it is better to first read our instructions. If you want to bend polymer glass at home, then this will require the following tools and equipment.

Necessary equipment and methods of bending

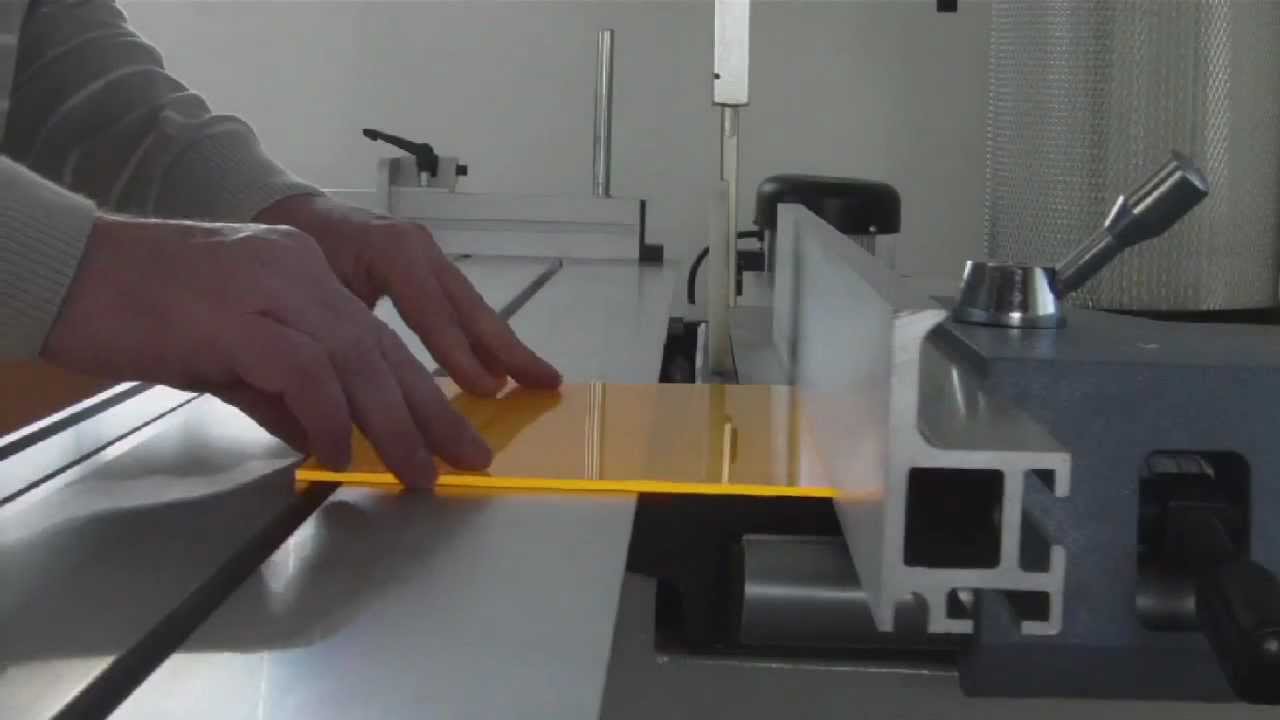

Before working with plexiglass, you need to cut out the finished part or product, its edges. It is better to take bent plexiglass with heat-resistant gloves.

In order to bend the glass at home, you need to heat it up. And this means you need to find a device that can quickly warm up the required area. For heating glass, various devices are suitable, from candles to a soldering iron. It all depends on the heating area, for example, small pieces of plexiglass can be heated by simply boiling them in water, for larger parts you cannot do without a tool. Let's consider the most simple and convenient ones.

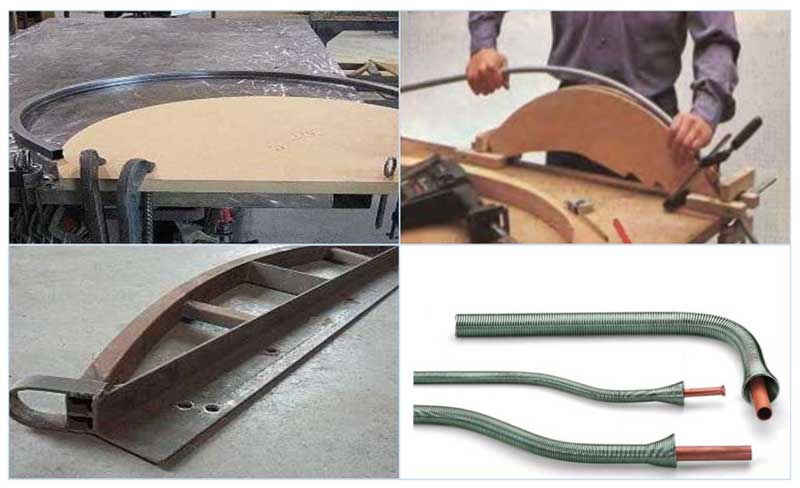

- Heating glass can be done with a building hair dryer. If your material exceeds 5 mm, then we will heat it from both sides. Before heating the glass, you need to prepare some kind of template for bending, a machine made of wood, or we will simply bend it, for example, against the surface of the edge of a table. So, we direct the hair dryer to the area needed for heating. After making sure that our material has become softer, we immediately give it a shape, without waiting for it to cool. It is necessary to bend in the opposite direction from the heated side. And if you are heating both sides, then the outer corner should be bent last. After the polymer glass is bent, you need to leave it to the side for a while to cool.

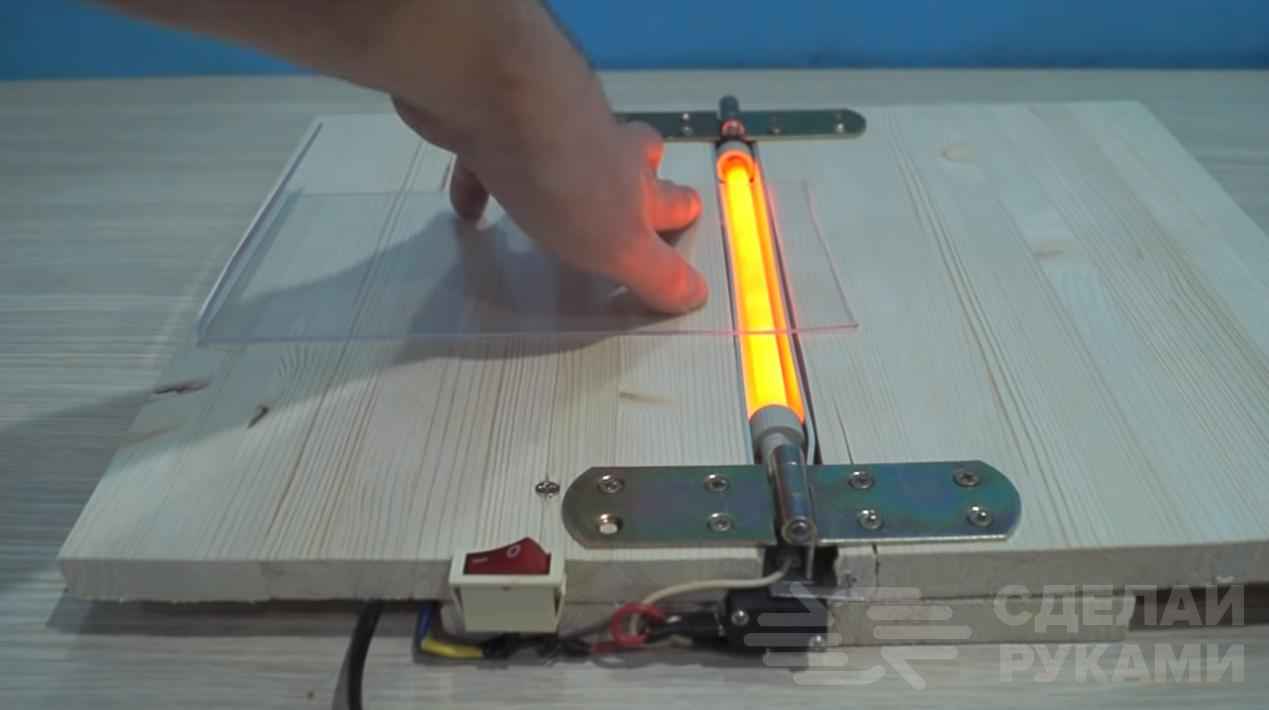

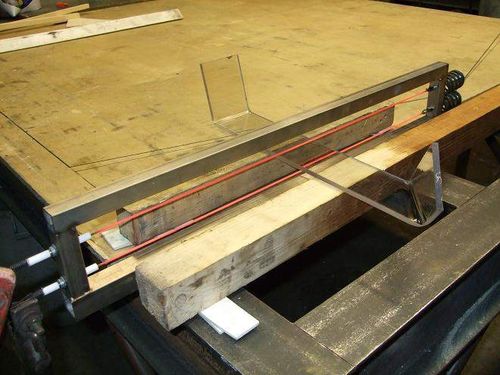

- Nichrome wire can be used to heat the glass surface. For such a process, you need to fix the glass on the edge of the workbench or table, and under it lay a wire from the sheet by 5 mm. - we get a homemade bending machine. Nichrome is connected to the transformer and heats up, after heating the wire, the polymer glass will begin to sag. It is not necessary to "help" the glass to bend, it threatens the emergence of internal stresses.

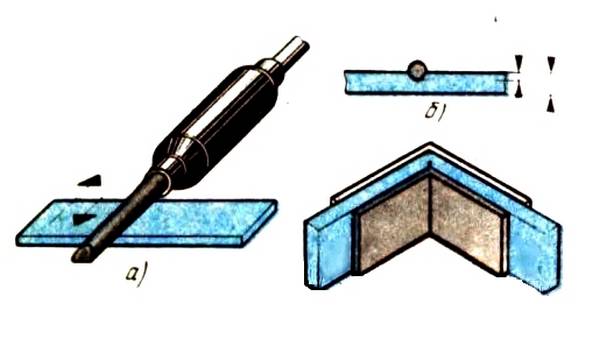

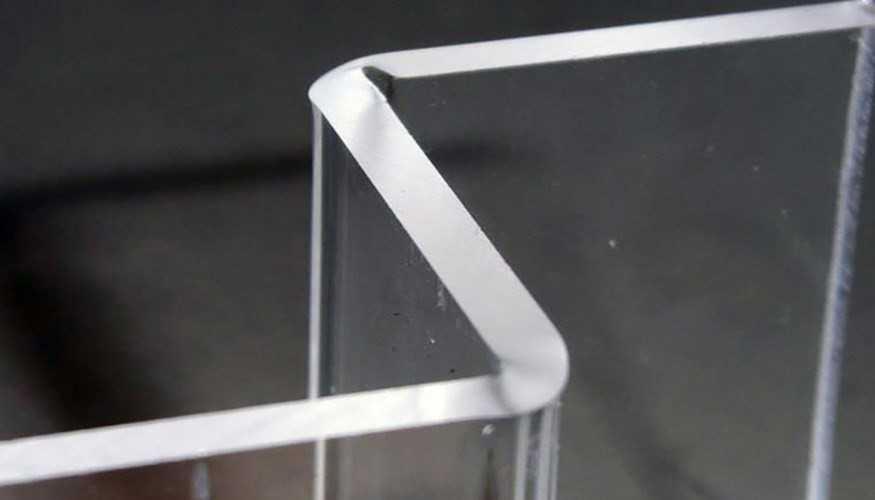

- Sometimes the bend does not have to occur along the entire perimeter plane, or the glass needs to be bent 90 degrees. In this case, you can use a soldering iron. We mark the area with a pencil and draw the soldering irons over it, slightly melting the surface. It is necessary to bend the glass until it cools.

- Sometimes glass is required not only to bend, but to give it a rounded shape. For such purposes, you will need a certain remainder of the pipe around which our material will be twisted. In this case, it is better to use a blowtorch.

In the event that you need to bend a significant area of artificial glass, then the masters advise you to practice in a small area. With the help of any folding technology, you can decorate your home with beautiful plexiglass crafts.

Those of the novice craftsmen who have to work with organic glass are wondering how to bend plexiglass at home without deteriorating its technical characteristics.

Plexiglass is a popular material for indoor and furniture finishing.

Plexiglass is a popular material for indoor and furniture finishing. Using this material, you can give uniqueness to any interior.You can easily make photo frames and transparent cases for various devices from plexiglass at home.

The use of this material is due to the fact that it has a whole range of advantages over ordinary glass. The main ones are as follows:

- low density compared to silicate glass;

- the material is less brittle due to the presence of an amorphous structure;

- high resistance to weathering;

- high impact resistance;

- the polymer is shatterproof;

- high transparency rate;

- the ability to change the shape of the workpiece.

All these properties have determined the wide popularity in the use of this material both in everyday life and in industry.

Bending plexiglass

Observe the temperature regime depending on the desired result. If you are going to bend glass, you need a temperature of 150 degrees. Plexiglass is melted at a temperature of 170 degrees.

There are several heating methods to bend plexiglass. You can use an electric stove. This method is good for shaping glass sheets that are not too thick.

Heating plexiglass with a building hair dryer

Small parts can be "welded" simply by holding them in boiling water for a while. After sufficient heating, use heat resistant gloves to shape the parts to the desired shape.

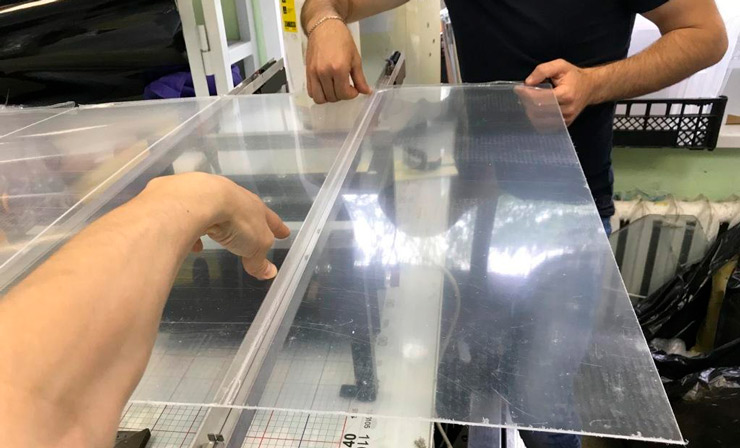

To work with large sheets, with a greater thickness, it is most convenient to use a construction hairdryer.

Let's take a closer look at how to do this using a hairdryer:

- The first thing to remember when bending plexiglass is to bend the material in the opposite direction to the heated side.

- If you bend a sheet that is more than 5 millimeters thick, it must be heated alternately on both sides, with the outer corner warming up last.

- After making sure that the polymer has reached the required temperature and has become sufficiently plastic, it is necessary to immediately give it the desired shape, without waiting for it to cool, otherwise turbidity may form in the place of the fold, a sign of microcracks in the material. If you do not follow these measures, the glass will simply break at the bend.

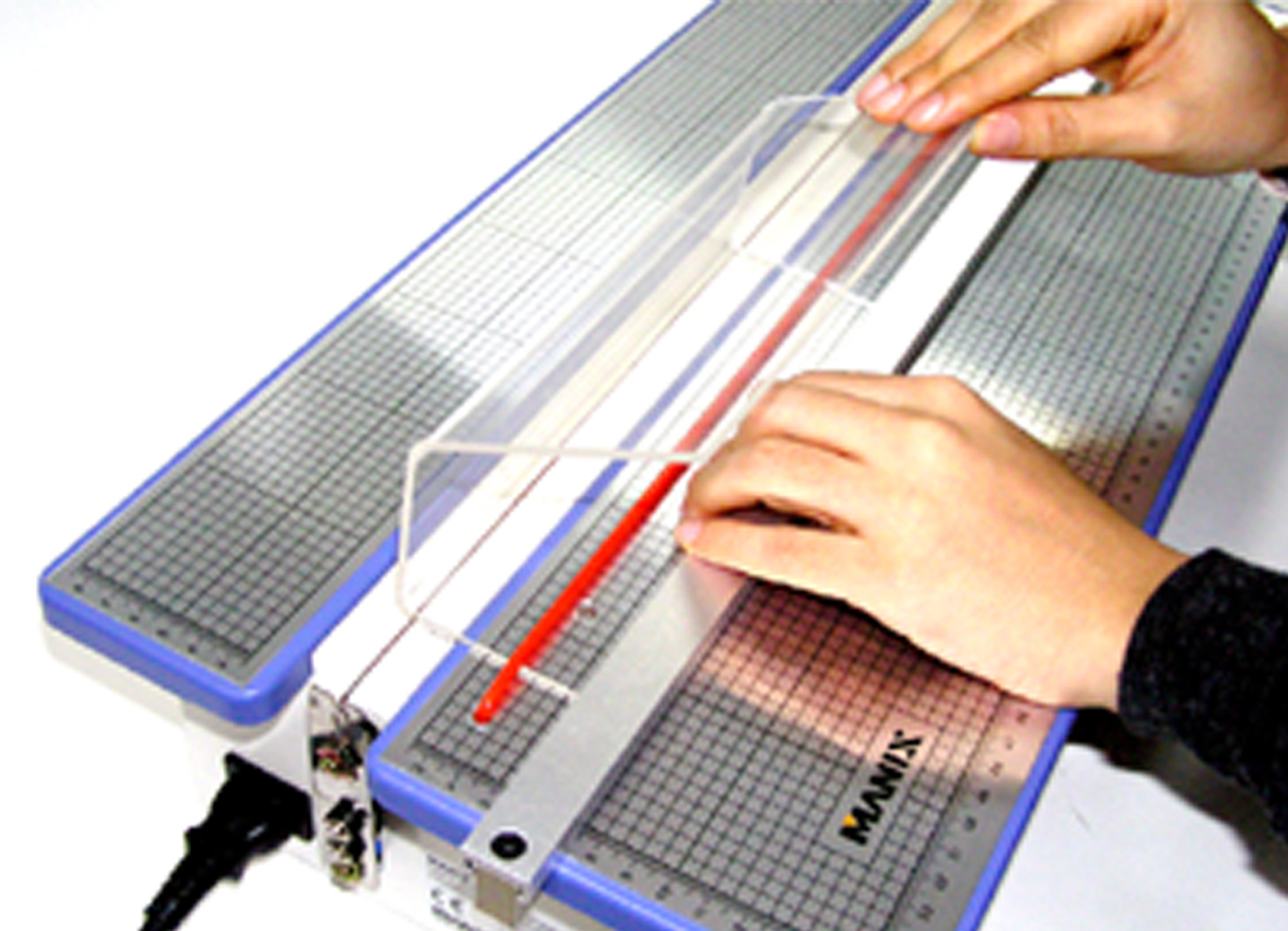

Before starting the process of bending the plexiglass with a hair dryer, prepare a shape or template for bending.

This can be a tabletop, a piece of pipe, a piece of wood, or some other surface that you want to shape the glass. Heat the area you want to bend, then shape as desired. Next, the plexiglass product must be properly cooled. Do not expose the glass to sudden temperature changes, as this can lead to cracking or the formation of other defects. Just leave it to cool at room temperature for a while.

Bending plexiglass according to the template

When the part has cooled down enough, process the edges of the product. This can be done both mechanically (using sandpaper) and thermally. For rough processing, you need sandpaper, and for finer sanding, abrasive pastes are used, for example, GOI paste, as well as toothpastes and powders. When machining edges mechanically, remember to cool the glass surface with water.

Your product is ready, now you know how to bend plexiglass at home. We hope that with the help of this article you will be able to decorate your interior with a large number of beautiful and unique decor items.

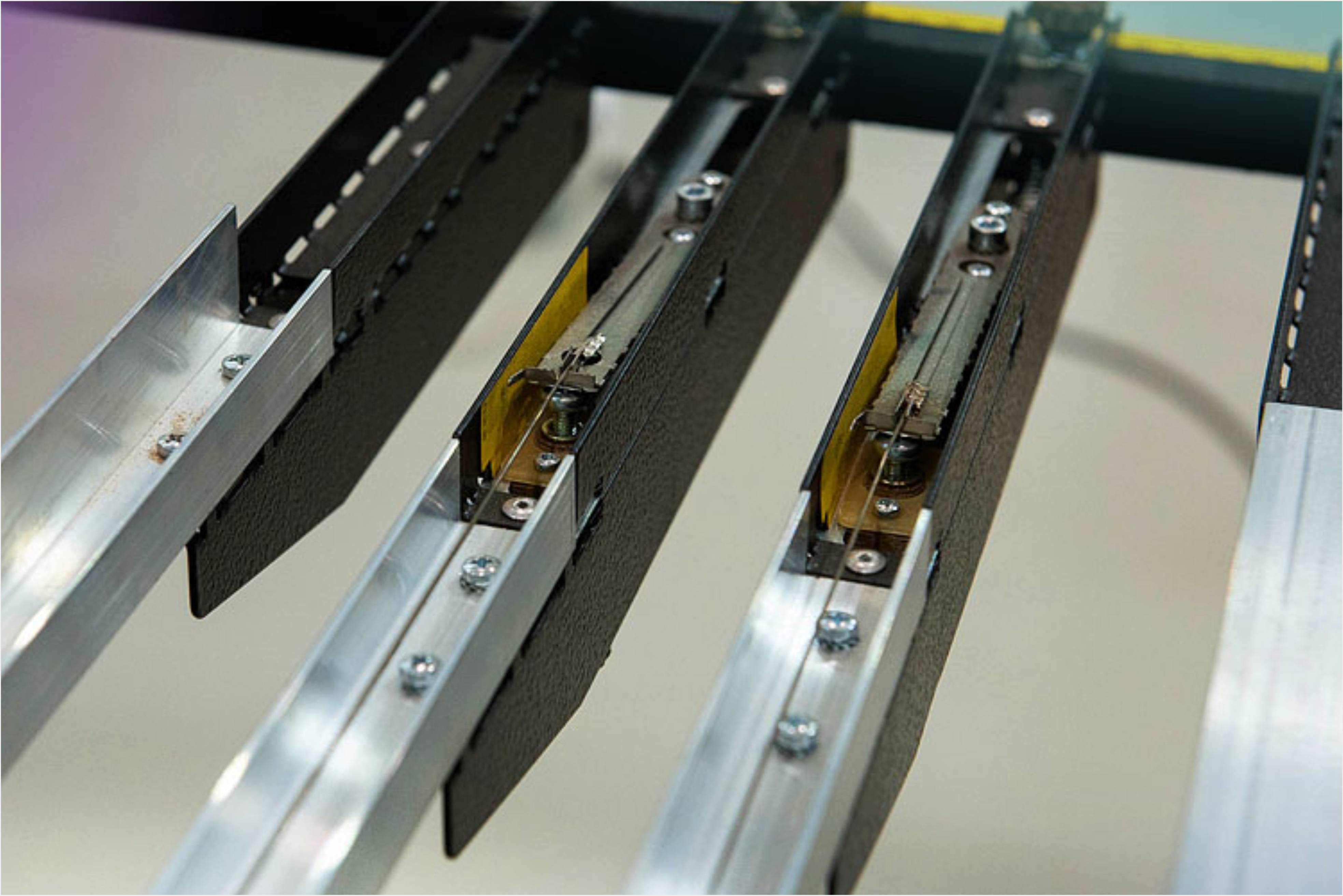

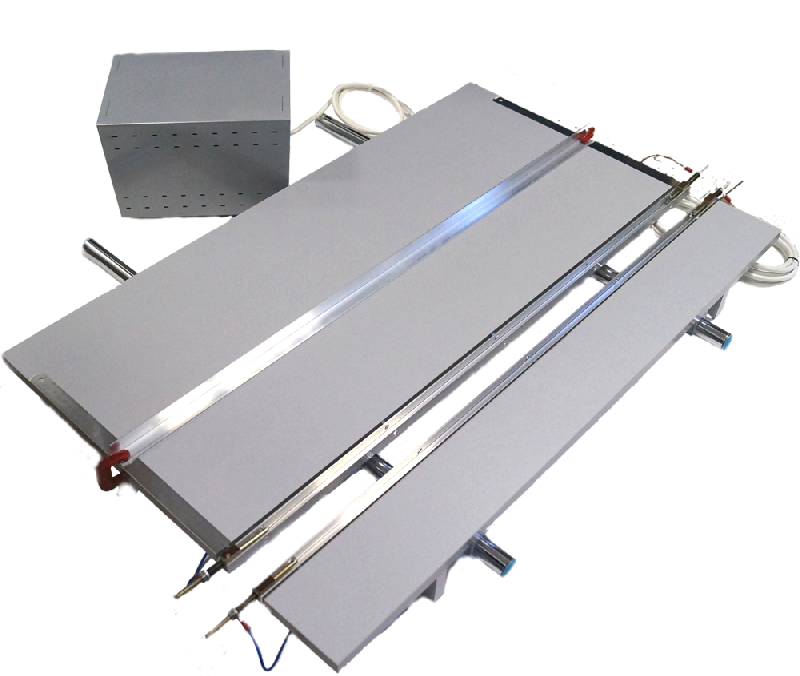

The advantages of using the machine

Bending machine plexiglass has many advantages in comparison with manual flexible:

- high productivity due to the possibility of increasing the number of working lines;

- use of 220 volt voltage, economical power consumption;

- individual adjustment of each heating line;

- the possibility of heating the surface of the material from both sides;

- ease of control, the presence of a timer with sound and light signaling;

- the heating mode is gentle, lengthens the operating time of the device and improves the quality of the products;

- the ability to customize the operating parameters taking into account individual requirements.

Other methods

At home, a plexiglass sheet can be shaped with your own hands. There are various ways of performing bending work, thanks to which you can bend a sheet on a nichrome string along a radius of 90 degrees, or squeeze a hemisphere out of thin acrylic. You can process organic glass using various tools.

With a hairdryer

This method of processing acrylic is applicable in cases where it is necessary to bend a very large piece of organic glass. To warm up the working field with high quality, you will need a rather powerful tool, which is a building hair dryer. This high-power device blows out a stream of air heated to the required temperature. The flexion process is carried out in several stages:

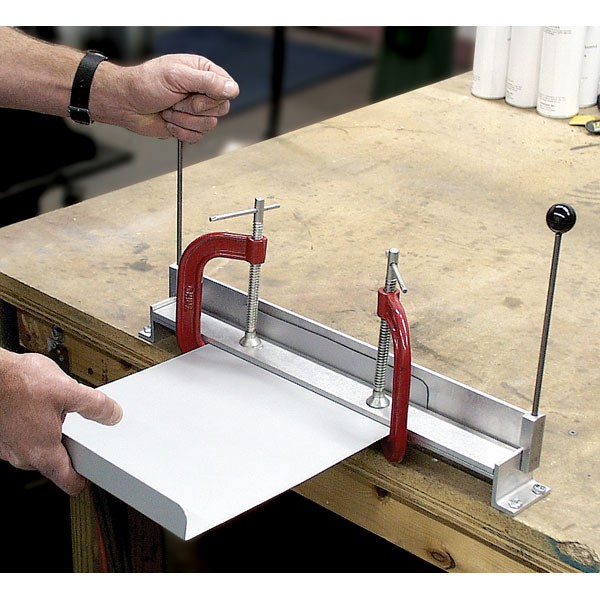

- a sheet of organic glass is firmly fixed on the desktop with the help of carpentry clamps;

- take measurements and outline a line for performing bending of the material;

- the fold area is treated with hot air supplied from a building hair dryer;

- the material is treated with hot air until softening;

- the softened sheet is bent at the required angle;

- the finished product is cooled at room temperature.

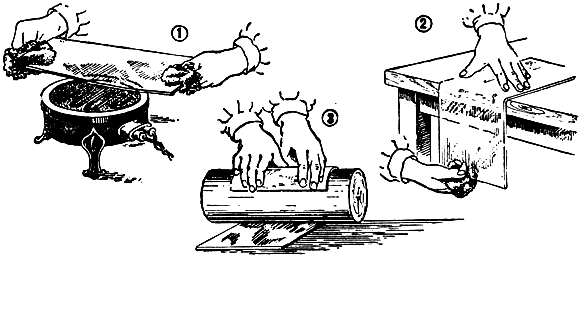

In hot water

Bending a small-sized plexiglass at home can be done using a fairly simple method, which is considered the least energy-consuming and quickest - you will need water to complete it. The process includes a number of steps:

- choose a container so that the workpiece to be processed can enter it, and water is poured;

- bring it to a boil;

- into boiling liquid for 5 minutes. lower the workpiece from acrylic - the exposure time also depends on the thickness of the plexiglass;

- the workpiece is heated under the influence of hot water, then it is removed from the container;

- the workpiece is bent to the desired configuration.

The disadvantage of this method is that the acrylic has to be bent on a hot workpiece, so it is necessary to provide for the presence of cotton gloves so as not to burn your hands while working.

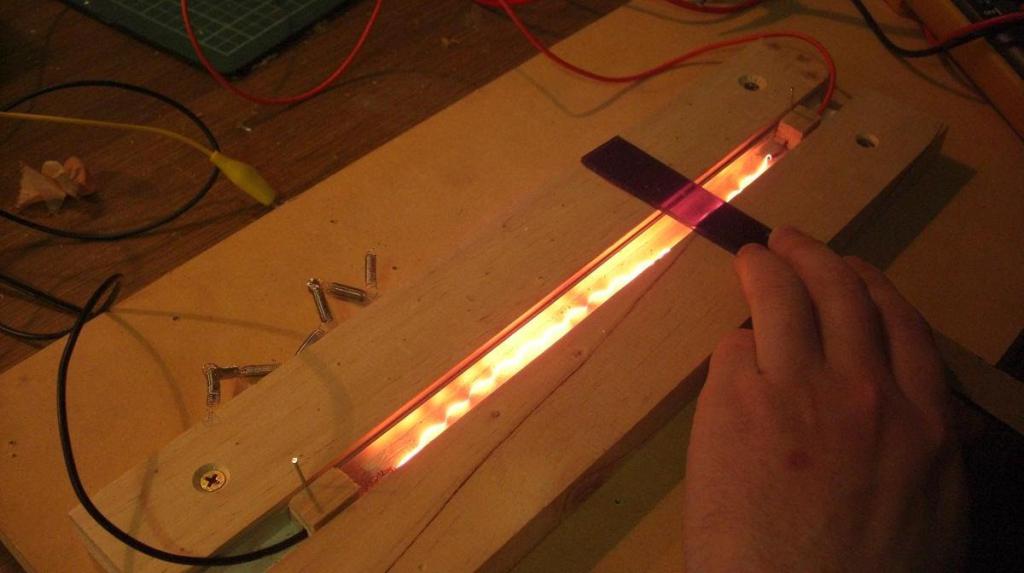

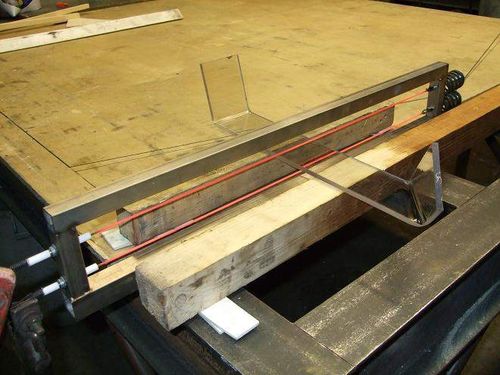

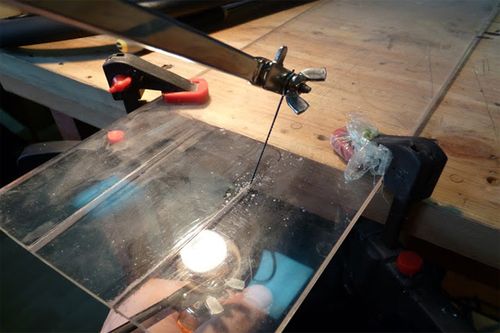

Special nichrome wire

You can perform high-quality bending of plexiglass using a nichrome thread. The procedure looks like this:

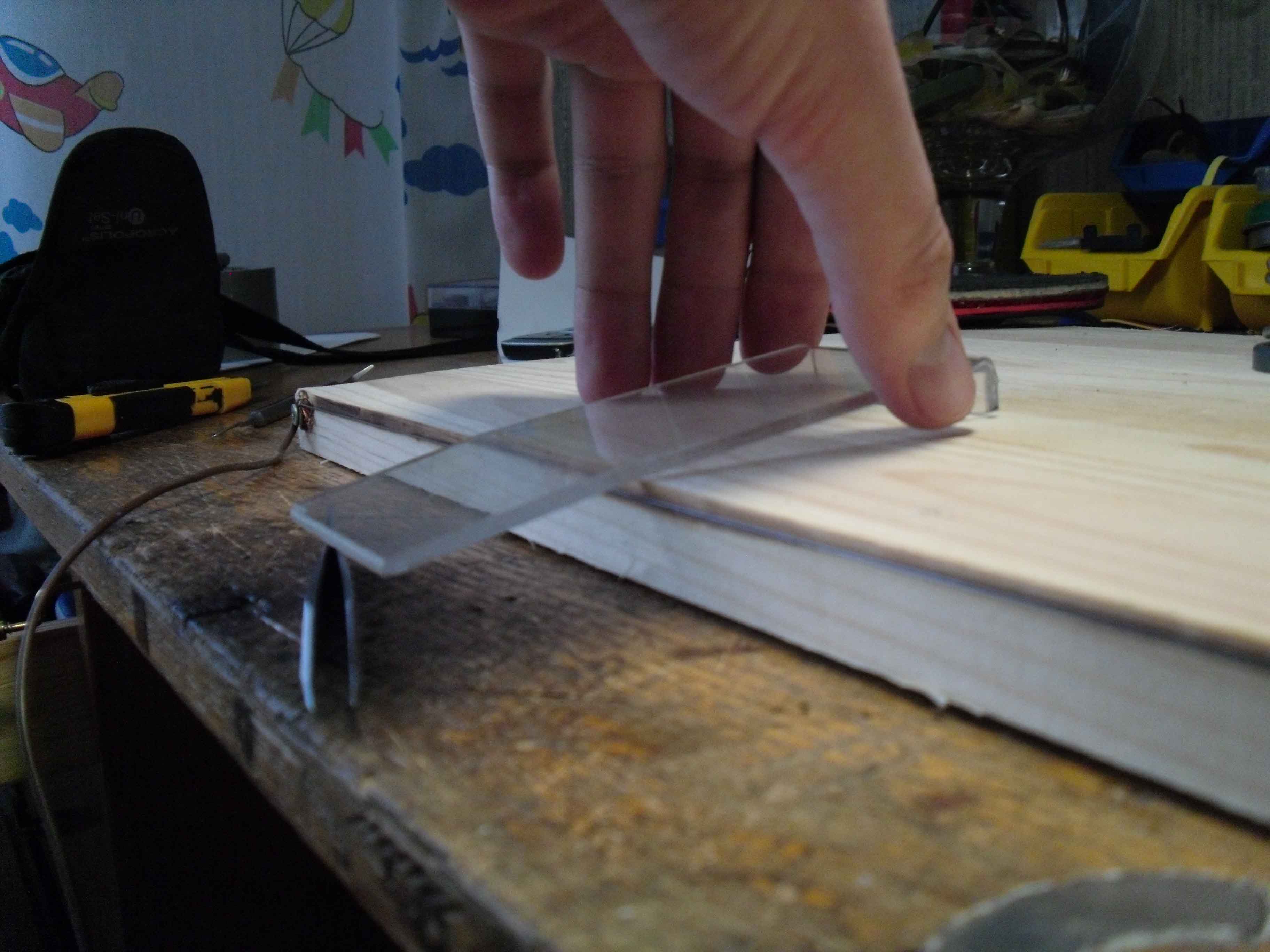

- a plexiglass sheet is fixed on the desktop with clamps, allowing the free edge at the bend to hang freely;

- a nichrome wire is pulled over the table at a distance of no more than 5 mm from the surface of the sheet;

- the wire is connected to a 24 V transformer;

- the transformer heats up the nichrome filament, and after it is very hot, the glass will slowly bend under the influence of heat and its own weight.

When bending glass, do not speed up the procedure by helping it with your hands - this can lead to cracks or deformation of the material.

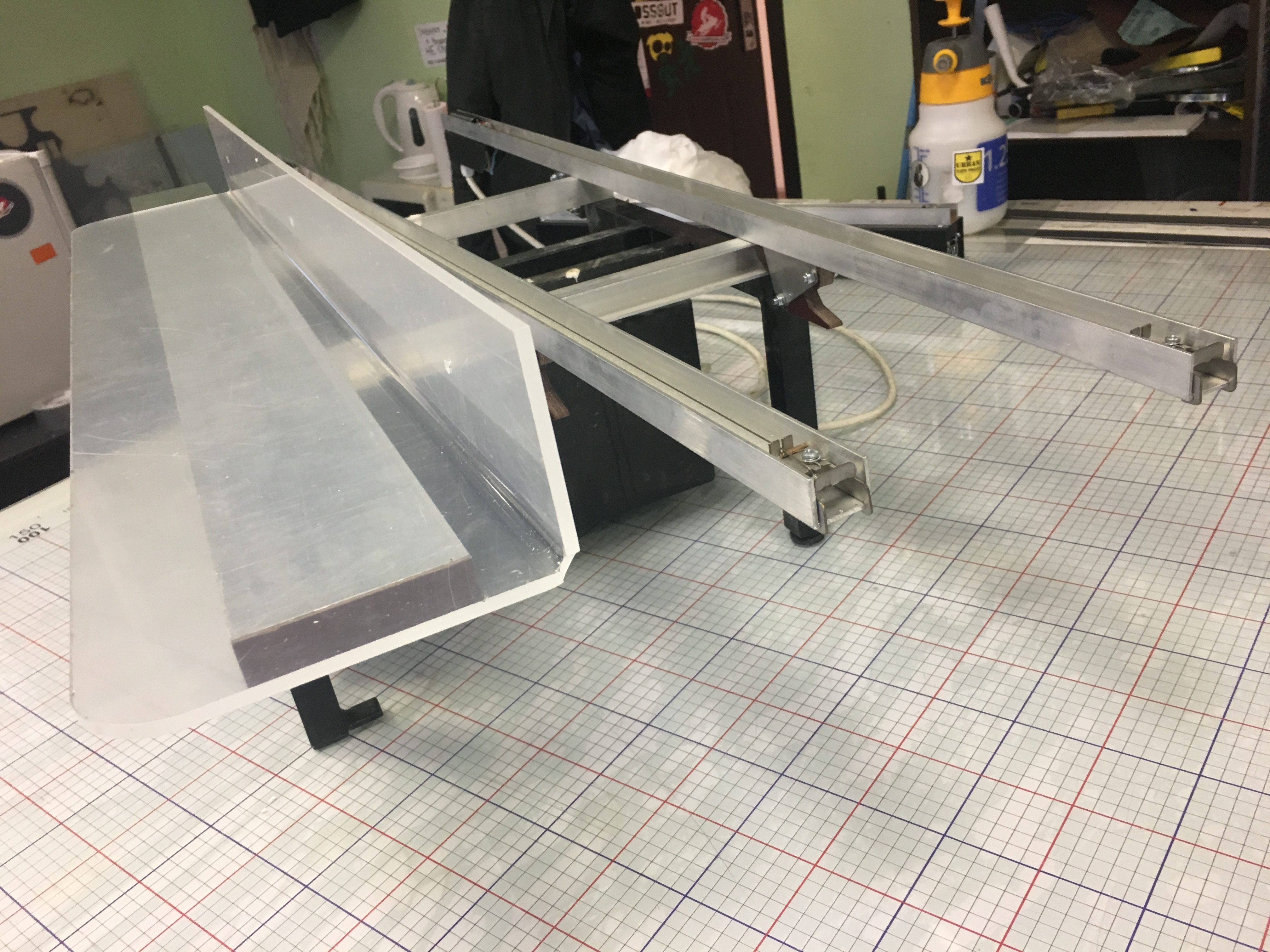

Metal pipe

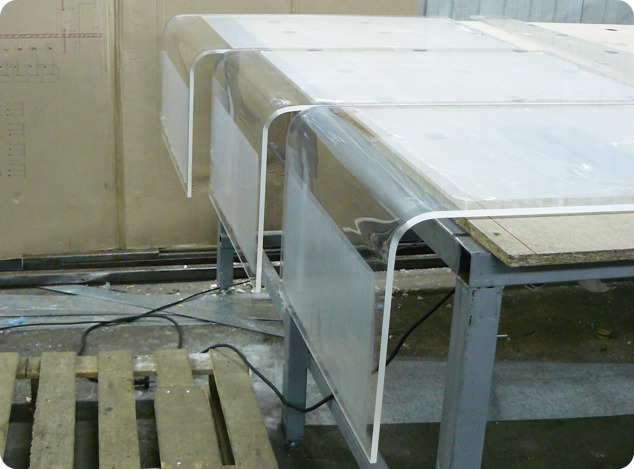

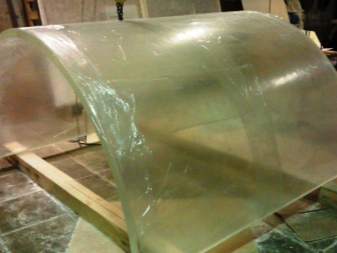

To give the acrylic workpiece a certain radius of curvature, the method of bending the plexiglass on a metal pipe is used. To perform this procedure at home, you can heat either the material itself or the pipe. A blowtorch is used to warm up the pipe.

The flexion procedure is performed in the following sequence:

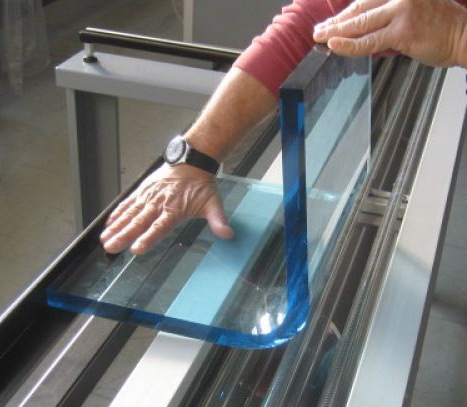

- a sheet of cold acrylic is applied to a pipe, the diameter of which is equal to the bending radius;

- with a blowtorch or a construction hairdryer, they warm up the folded area of the sheet;

- when the organic glass is warmed up and acquires plasticity, turn the sheet over the surface of the pipe with your hands;

- the procedure is repeated until the acrylic sheet is sufficiently folded.

A hemisphere can be extruded from the acrylic material.To do this, take a thin sheet of plexiglass (3-5 mm), a punch and a plywood matrix, in which a hole of the diameter you need is made. The diameter of the hole needs to be made a little larger, taking into account the allowance equal to the thickness of the organic glass.

In order to prevent the wood grain pattern from being printed on an acrylic blank, the punch and the surface of the plywood matrix are lubricated with casein glue, and then, when it dries, the film is sanded with sandpaper.

A sheet of organic glass is heated until softened - this can be done with a gas burner, working in cotton gloves so as not to burn your hands. After the material is well heated, it must be placed on top of the matrix. Next, a hemispherical punch is installed on top of the acrylic. With this tool, the acrylic sheet is pressed, then held for 10 minutes. the entire structure until it hardens. Thus, the plexiglass acquires a semicircular configuration. A similar technology can be used to extrude any other shape, depending on the shapes of the stencil and punch.

How to bend plexiglass, see below.

Processing methods

Several options have been developed that allow the plexiglass to be folded. The operation is performed using:

- construction hair dryer;

- boiling water;

- nichrome wire;

- metal pipe.

The work is done in two steps. First, preparation is carried out (we described this earlier), then bending is carried out.

Now let's get acquainted with all the methods in more detail.

Boiling the plexiglass allows you to clean the material and raise its temperature, which will make it easy to bend

Boiling

This option is simple and effective; amateurs and specialists resort to it. It is carried out in several stages:

- A container is selected in which the workpiece can fit without problems. Water is poured inside.

- The water in the container is heated to a boil.

- A plexiglass workpiece is lowered into boiling water and held for five minutes (the thicker the plexiglass, the longer it will take to hold).

- After heating, the material acquires a plastic shape, it is removed and given the desired shape.

Before getting started, keep in mind that you will have to deal with boiling water and a heated part. Take the necessary measures to avoid burning yourself.

Using a building hair dryer

This technique is suitable for cases where an overly bulky piece of plexiglass has to be processed. In this case, a professional high-power hair dryer used in construction is used to heat it to the desired temperature.

To heat plexiglass, you should choose a powerful building hair dryer.

Bending is done as follows:

- A piece of plexiglass is fixed motionlessly on the tabletop (in a vice or with the help of clamps).

- Measure and mark the future bend line.

- The entire targeted area is heated with a stream of hot air, gradually softening it.

- Bending is smoothly carried out to the required angle.

- The curved part is cooled naturally.

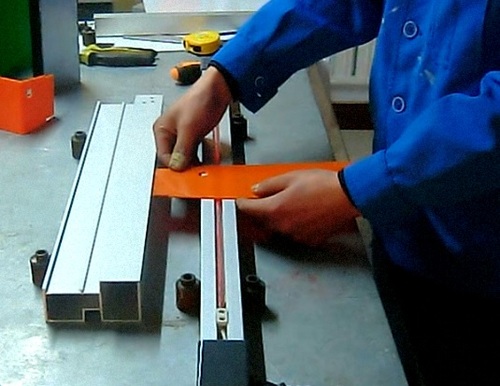

Wire fold

For work, you will need a special nichrome wire connected to a constant voltage source. The intensity of the source should be sufficient to heat the wire.

The process is carried out in several steps:

- The plexiglass part is carefully dried (water bubbles can reduce the quality of work).

- The workpiece is clamped on a workbench, a section of the future bend is marked with a pencil or marker without using a dye.

- At a height of 5 mm above the intended area, the wire is pulled.

- A current is passed through the wire, its strength is gradually increased - the heating temperature should reach 150 ° C.

- Under the influence of heating, the area under the wire becomes plastic, the sheet begins to bend under its own weight.

- We give the plexiglass the required shape.

- Upon completion, the workpiece is cooled naturally.

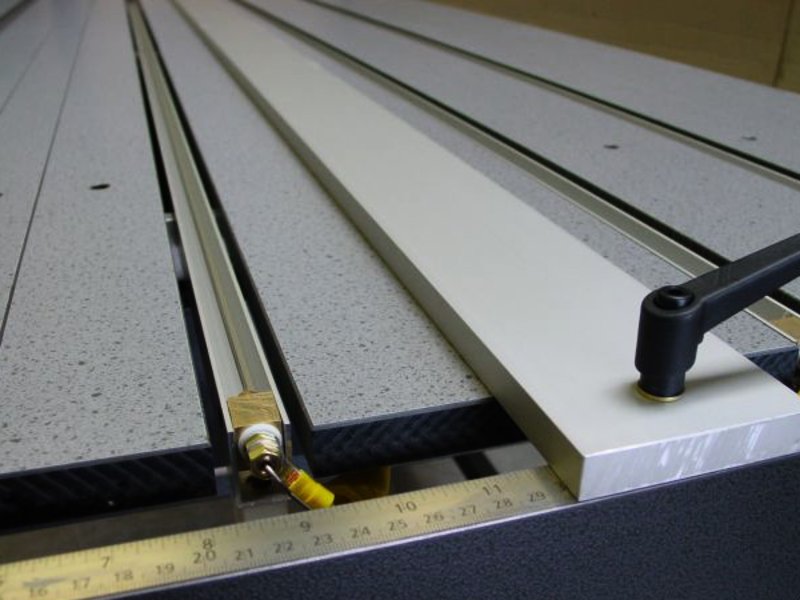

Metal pipe application

Sometimes it is desirable not just to bend a plexiglass part, but to give it a special radius of curvature. You will have to use a metal pipe, heating it or the bend section. A powerful soldering iron or blowtorch is suitable for heating.

The sequence of action is as follows:

- The prepared pipe of a suitable diameter is fixed in space.

- A cold plexiglass panel is placed on top of the pipe, the site of the future bend is outlined.

- The bending area begins to warm up with the selected tool.

- Bringing the material to a plastic state, they smoothly begin to bend it along the pipe, achieving a bend of the required diameter.

With the help of a metal pipe, you can give the plexiglass a rounded shape

If a soldering iron with a wide tip is used, then the workpiece itself should be heated. You can understand that the moment has come by the characteristic crackling, which begins to publish the material, changing its properties.

Whichever way you prefer to bend plexiglass at home, be sure to take care of observing all safety measures. You will have to work with hot tools, boiling water or heating devices - protect yourself from burns.

The second danger is that in case of insufficient heating, the material can break, causing the scattering of fragments. Competent observance of safety precautions will protect you from injury.

The main features of working with organic glass

To achieve good results when working with the bending of organic glass, you should take into account its features. They will allow you to get rid of possible waste and waste of material. Bending plexiglass at home is not a complicated operation.

Plexiglass in decor

First of all, it is necessary to correctly calculate the dimensions of the future part, taking into account the bending radius. If experience is not enough, it is advisable to make a mock-up of the future part from cardboard or thick paper (if the part is not large).

When choosing a material, it is necessary to clean the workpiece, it is better to rinse it with clean water and remove all small particles that are on the surface. This is due to the formation of an electrical charge on the surface. It is necessary to avoid the use of any abrasive materials, even the smallest fractions. This will lead to a significant decrease in the transparency of the future part. After rinsing, professionals let the organic glass dry for 24 hours, preferably at room temperature. If time is limited, you can use a construction hairdryer. In this case, it is necessary to observe the thermal regime. The temperature of the directed air flow should not exceed 80 ° C. To obtain a good result, use an empirical approach that allows you to calculate the drying time. According to this approach, it is necessary to spend one hour for every millimeter of glass thickness. Therefore, if the glass is 3 mm thick, it must be dried for at least three hours.

After drying, you can start production of work. However, it should be remembered that it is more expedient to heat the required area from the opposite side of the fold surface. If it is necessary to obtain a given inner angle, the outer side of the glass is heated.

Plexiglass details

The heating temperature must be taken into account. Plexiglass, like a material made from organic compounds, can not only heat up, but melt and even catch fire. Professionals advise keeping the heating temperature at about 150 ° C. If, in addition to the task of changing the surface configuration, it becomes necessary to fill a certain shape with organic glass, it must be heated to a temperature of more than 170 ° C.

An important feature is the need to warm up such an area of organic glass, which is three times the thickness of the glass. When bending a glass with a thickness of 4 mm, a strip with a width of 12 mm should be heated

For material with a thickness of more than 5 mm, it is necessary to warm up on both sides along the line of the planned bend.

After completion of the work, it is necessary to cool the part, without using fast cooling methods (flow of cold water or air). Such a rush can lead to the formation of internal cracks, bubbles, deformation. Therefore, to obtain the required bending angle, it is necessary to carefully follow the technological sequence.

Bending plexiglass

Attention! To avoid burns when heating the plexiglass, use heat-insulating gloves or silicone gloves. Depending on the desired result, observe the temperature regime

If you are going to bend glass, you need a temperature of 150 degrees. Plexiglass is melted at a temperature of 170 degrees

Observe the temperature regime depending on the desired result. If you are going to bend glass, you need a temperature of 150 degrees. Plexiglass is melted at a temperature of 170 degrees.

Attention! If you decide to melt the resin and mold something out of it, make sure the mold is clean. An insufficiently clean shape can lead to defects on the surface of the product.

There are several heating methods to bend plexiglass. You can use an electric stove. This method is good for shaping glass sheets that are not too thick.

Heating plexiglass with a building hair dryer

Small parts can be "welded" simply by holding them in boiling water for a while. After sufficient heating, use heat resistant gloves to shape the parts to the desired shape.

To work with large sheets, with a greater thickness, it is most convenient to use a construction hairdryer.

Let's take a closer look at how to do this using a hairdryer:

- The first thing to remember when bending plexiglass is to bend the material in the opposite direction to the heated side.

- If you bend a sheet that is more than 5 millimeters thick, it must be heated alternately on both sides, with the outer corner warming up last.

- After making sure that the polymer has reached the required temperature and has become sufficiently plastic, it is necessary to immediately give it the desired shape, without waiting for it to cool, otherwise turbidity may form in the place of the fold, a sign of microcracks in the material. If you do not follow these measures, the glass will simply break at the bend.

Before starting the process of bending the plexiglass with a hair dryer, prepare a shape or template for bending.

This can be a tabletop, a piece of pipe, a piece of wood, or some other surface that you want to shape the glass. Heat the area you want to bend, then shape as desired. Next, the plexiglass product must be properly cooled. Do not expose the glass to sudden temperature changes, as this can lead to cracking or the formation of other defects. Just leave it to cool at room temperature for a while.

Bending plexiglass according to the template

When the part is cool enough, process the edges of the product. This can be done both mechanically (using sandpaper) and thermally. For rough processing, you need sandpaper, and for finer sanding, abrasive pastes are used, for example, GOI paste, as well as toothpastes and powders. When machining edges mechanically, remember to cool the glass surface with water.

Your product is ready, now you know how to bend plexiglass at home. We hope that with the help of this article you will be able to decorate your interior with a large number of beautiful and unique decor items.

We bring to your attention a video that shows how to bend plexiglass correctly and what points you need to pay attention to.The following video illustrates the process of bending transparent plexiglass by heating it with a gas burner.

The following video illustrates the process of bending transparent plexiglass by heating it with a gas burner.

Plexiglass is a unique material with many useful characteristics. It is nowadays used in many areas of industry. For example, in the production of modern original souvenirs. This is not to say that they began to use plexiglass in ancient times. On the horizon, this material appeared only in the 20s of the twentieth century, because it is a synthetic product.

Plexiglass or simply plexiglass is a more functional material than ordinary glass, it is much easier for processing and various mechanical operations. Quite often, it becomes necessary to change the shape of the plexiglass. On the one hand, this is an easy task, but on the other, there are certain rules for its flexibility. Professionals will be happy to share their experience with you and tell you how to bend plexiglass at home.

Other ways to bend organic glass

To bend organic glass, it is immersed in boiling water for 1 minute. Then they take out the material and immediately bend it, putting on silicone gloves on their hands. There are also many other ways to bend glass at home, using improvised means:

- Gas-burner. With the help of a burner, it is very easy to make a fold; you just need to heat the organic glass in a certain place. In order for the heat to get exclusively to the place of the bend, a tin can should be attached to the gas burner, at the bottom of which a slot-like hole should be cut.

- Soldering iron. Using a soldering iron to bend organic glass, you can get a high-quality and accurate bend. But before starting the main work, you need to practice.

- Hot pipe. Before bending the glass with a hot pipe, it must first be prepared and wiped with a soda solution.

When working with plexiglass, it is necessary to learn one important rule: in order to bend this material, it must be softened in a certain place. Any heat source can be used for this.

The shape of the material changes just as easily, you need to make a little effort, and an unremarkable strip of plexiglass will turn into a real work of art, you just need to warm it up to the required temperature.

Now you know what this material looks like, what it is and what characteristics it differs in, which means that you will be able to cope with the task by figuring out how to bend plexiglass.

Plexiglas is a hard synthetic transparent material made from organic polymers. Plexiglas is used for the construction of aquariums and shelves, as well as glazing for greenhouses, doors and decorative finishes. Since this material belongs to thermoplastics, it becomes plastic when exposed to high temperatures. It is thanks to this property that the plexiglass is flexible.

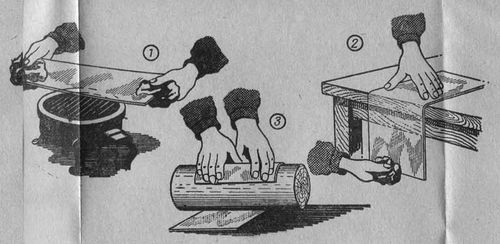

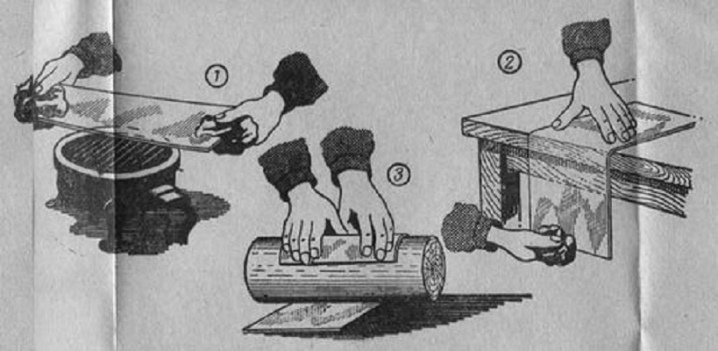

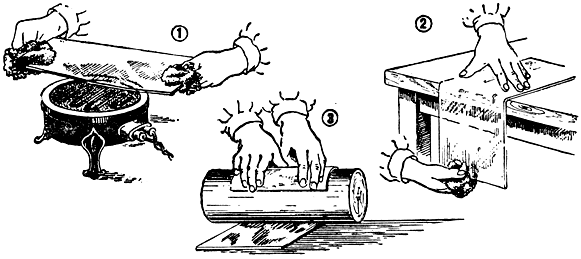

The process of bending organic glass: 1 - warming up, 2 - bending at a right angle, 3 - bending into a tube.

Plexiglass properties

Plexiglas contains various polymers. It is they who give the glass strength; polymer glass is even stronger than silicate glass. Plexiglas is a lightweight material, therefore, when it is used in structures, for example, roofs, awnings, solid supports are not required.

In everyday life, polymer glass can be found in a variety of options, just look at the photo with polymer products: aquariums, decorative design elements, shelves, TV stand, coffee table. Artificial glass has excellent transparency, so you can make interior doors and partitions from it.Probably the only drawback of plexiglass is flammability and thermoplasticity, but the latter drawback can be just turned into an advantage, because sometimes artificial glass has to be bent at home.

How to bend glass?

On the net today, you can find a lot of tips on the correct finish of plexiglass and even watch the guide on the video. But to organize the information, it is better to first read our instructions. If you want to bend polymer glass at home, then this will require the following tools and equipment.

Necessary equipment and methods of bending

Before working with plexiglass, you need to cut out the finished part or product, its edges. It is better to take bent plexiglass with heat-resistant gloves.

In order to bend the glass at home, you need to heat it up. And this means you need to find a device that can quickly warm up the required area. For heating glass, various devices are suitable, from candles to a soldering iron. It all depends on the heating area, for example, small pieces of plexiglass can be heated by simply boiling them in water, for larger parts you cannot do without a tool. Let's consider the most simple and convenient ones.

- Heating glass can be done with a building hair dryer. If your material exceeds 5 mm, then we will heat it from both sides. Before heating the glass, you need to prepare some kind of template for bending, a machine made of wood, or we will simply bend it, for example, against the surface of the edge of a table. So, we direct the hair dryer to the area needed for heating. After making sure that our material has become softer, we immediately give it a shape, without waiting for it to cool. It is necessary to bend in the opposite direction from the heated side. And if you are heating both sides, then the outer corner should be bent last. After the polymer glass is bent, you need to leave it to the side for a while to cool.

- Nichrome wire can be used to heat the glass surface. For such a process, you need to fix the glass on the edge of the workbench or table, and under it lay a wire from the sheet by 5 mm. - we get a homemade bending machine. Nichrome is connected to the transformer and heats up, after heating the wire, the polymer glass will begin to sag. It is not necessary to "help" the glass to bend, it threatens the emergence of internal stresses.

- Sometimes the bend does not have to occur along the entire perimeter plane, or the glass needs to be bent 90 degrees. In this case, you can use a soldering iron. We mark the area with a pencil and draw the soldering irons over it, slightly melting the surface. It is necessary to bend the glass until it cools.

- Sometimes glass is required not only to bend, but to give it a rounded shape. For such purposes, you will need a certain remainder of the pipe around which our material will be twisted. In this case, it is better to use a blowtorch.

In the event that you need to bend a significant area of artificial glass, then the masters advise you to practice in a small area. With the help of any folding technology, you can decorate your home with beautiful plexiglass crafts.

Often the desire to make their home even more attractive and interesting prompts the owners to use very rare and intricate materials in their work. Previously, vinyl records and metal alloys, matchboxes and burnt wood, textiles and leatherette, and also much more were used for decoration: an experienced craftsman will find use for everything. Today, polymer plexiglass has gained wide popularity, which can be used both for decorative purposes and as a material for creating intricate household appliances.Thanks to creativity, skillful hands and a certain knowledge of organic glass, you can create truly unique objects that will later become your pride and home decoration.