Sealant Gun Operating Instructions

First, a little advice. If at the right time the gun was suddenly not at hand, then in order to knock out the sealant from the cartridge, you can use any tool at hand. For example, a hammer.

And in order to use the pistol successfully, follow these steps, which we have illustrated with pictures.

Step 1. Take personal protection first - at least wear gloves.

Step 2. Next, prepare the surface to apply the sealant. In this case, we cannot advise anything specific, since everything depends on the instructions of the manufacturer of the cartridge. Everything should be written on the back of the latter. Use a sharp knife or triangular scraper to remove the previous coating. Remove the remaining crumbs with a brush or use a vacuum cleaner.

In addition, the work surface must be degreased without fail.

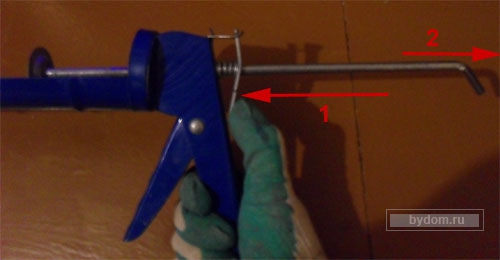

Step 3. Next, remove the delimiters. If we are talking about a half-body or skeletal pistol, then this procedure will happen quickly. First, make sure that there is no special limiter on the tube. And if it is still present, then delete it.

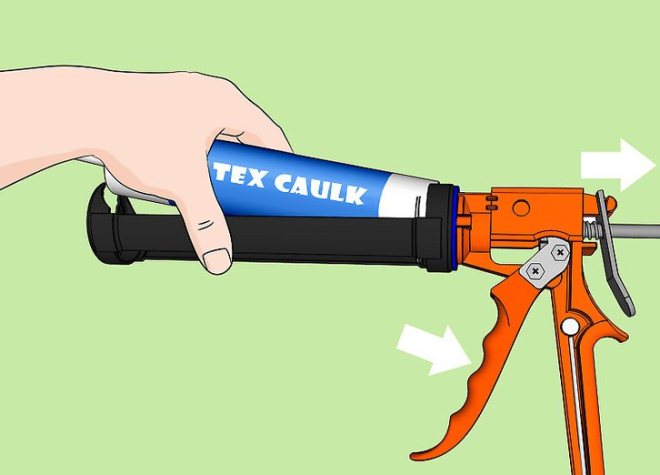

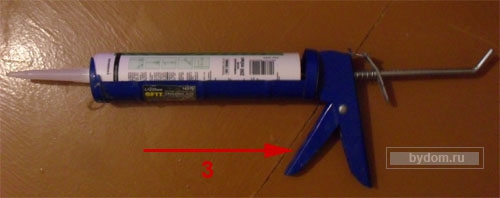

Step 4. Let's figure out how to use a sealant gun. Then pull out the stem in the device. To this end, press down on the lever and remove the part. In the place that was freed after the rod, place the cartridge and make several gentle pressure on the hook in order to finally strengthen the container.

Installing a cartridge in a skeletal sealant gun (photo)

Step 5. Next, make a hole in the container through which the sealant will be supplied to the cone, which, in fact, provides a uniform and even line.

Note! In most cases, these cones are sealed. And if you also have it sealed, then you will have to cut off the end of the cone in order to form the required seam diameter

In this case, it is important that the dimensions of the cut are smaller than required for work. But if you decide to use a tubular or syringe tool for work, then you should use it in a slightly different way.

But if you decide to use a tubular or syringe tool for work, then you should use it in a slightly different way.

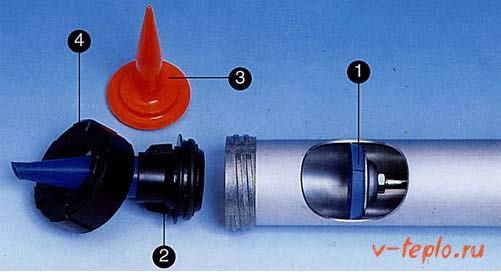

Installing a cartridge in a tubular (syringe) sealant gun

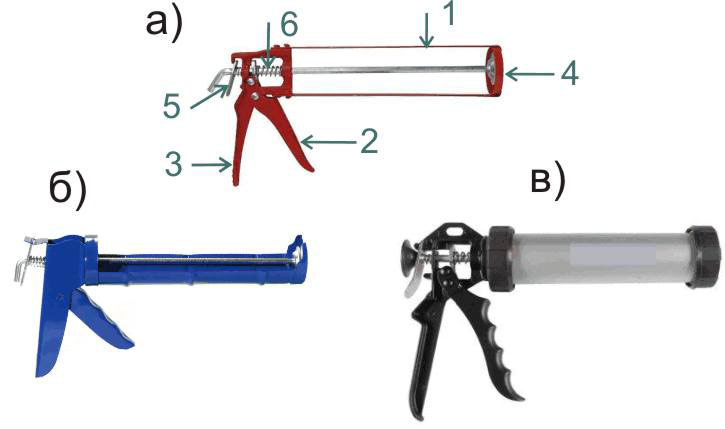

Photo - diagram of a tubular pistol

Step 1. First, make a hole in the sealant tube. If you use pre-packaged material, or "sausage", then cut off one corner / end with the utmost care so that the mixture can easily come out of the bag.

Step 2. Next, put the prepared container with the material into the tool itself, but so that it is the cut end of the container that comes out to the tip, through which, in fact, the strip of material will be squeezed out.

Step 3. Of course, before that it is necessary to remove the stem - do this in the same way as with a skeletal type device.

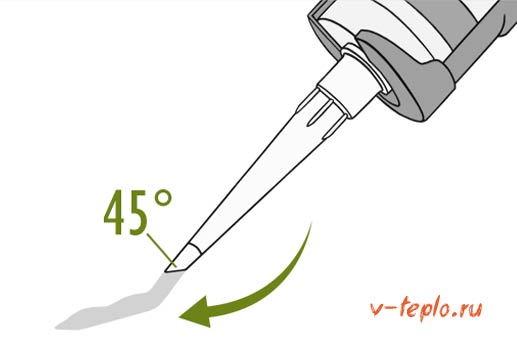

Step 4. Often, guns are equipped with several nozzles with such tips. Select one of them and spin the cylinder with it. If you notice that there is no hole on it (tip), then take a clerical knife and cut the tip, but strictly at an angle of 45 degrees. Of course, in this case, you must also guess with the dimensions of the future hole in order to get a seam of the required diameter.

Be that as it may, if you have a sealant gun on hand, then there must be a manufacturer's instruction. Do not be lazy to familiarize yourself with it, since manufacturers often complete tools with some improvements and developments that are not provided for in standard models.

You might be interested in this

Previously, we considered the characteristics of self-adhesive foam, which is very often used for warming rooms. We advise you to see this article

Pistol Models

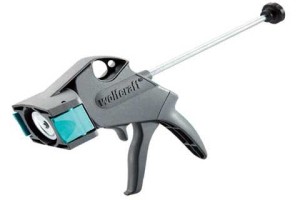

Such an apparatus cannot be considered complicated in any way.Its principle of operation is to squeeze the sealant out of the appropriate container. But, as in any business, there are subtleties here. To begin with, their assortment is so wide that everyone can choose for themselves according to their material capabilities, but how not to be mistaken.

Devices for sealing materials are divided according to the following indicators:

- type of compartments for tubes;

- design features;

- material feeding system.

By the type of compartments, they are divided into sheet and frame, and the latter are more in demand, since they hold the tube much stronger.

According to the sealant supply system, the gun is of several types - each with its own pros and cons.

Mechanical manual

Such a model is the most affordable version of the tool, although, unfortunately, not very durable. They are great for household jobs when you only need a couple of cartridges. But imagine what it will be like to squeeze out the masses only due to the physical effort of the hands on a large object.

Pneumatic

The gun works thanks to the compressed air pressure (3–6 atm). This model is very common when performing medium-sized construction work, since it is quite simple to use this type of pistol. This is facilitated by the various limiters and regulators that manufacturers equip them with. The pneumatic tool allows you to get an even seam of the sealant of the required thickness. The tool is equipped with a special valve through which excess material is dumped, that is, there is practically no loss of sealant. Another plus is the ability to use it for different capacities. Considering that these models run on compressed air, their bodies are often made of metal.

The gun works thanks to the compressed air pressure (3–6 atm). This model is very common when performing medium-sized construction work, since it is quite simple to use this type of pistol. This is facilitated by the various limiters and regulators that manufacturers equip them with. The pneumatic tool allows you to get an even seam of the sealant of the required thickness. The tool is equipped with a special valve through which excess material is dumped, that is, there is practically no loss of sealant. Another plus is the ability to use it for different capacities. Considering that these models run on compressed air, their bodies are often made of metal.

Rechargeable

These models are distinguished by their autonomy, since they are equipped with a battery pack, usually lithium-ion. The sealing paste is squeezed out with a pen having sufficient pressure sensitivity. In fact, the speed and accuracy with which the sealant is dispensed is controlled by the pressure on the same handle.

These models are distinguished by their autonomy, since they are equipped with a battery pack, usually lithium-ion. The sealing paste is squeezed out with a pen having sufficient pressure sensitivity. In fact, the speed and accuracy with which the sealant is dispensed is controlled by the pressure on the same handle.

Electrical

The electric version and the previous one differ only in the power source - the electric ones are powered from the mains. They provide speed and accuracy, and a high level of economy. Different types of containers are suitable for them. It must be understood that these professional devices are not cheap, but for simple repair, in fact, such a model is simply not needed.

Self-contained guns are equipped with a pressure regulator that allows you to adjust the flow rate of the sealing material. Moreover, the "auto-reverse" function eliminates its residual extrusion: when the work is finished, the stem moves back and reduces the pressure.

And, finally, according to the characteristics of the device, the devices are divided into:

And, finally, according to the characteristics of the device, the devices are divided into:

- half-body - works with a tube volume of 310 ml, have a simple mechanism consisting of a stem and a cartridge holder, therefore they fail quickly enough - they are only enough for 2-3 tubes. The instrument of this type is not comfortable enough in work - it is difficult to hold it in the hands;

- skeletal - designed for work with the same volume, but differs in a more complex mechanism, consists of a stem and three stiffeners. They are more expensive than semi-hulls, but also more durable;

- tubular (closed) - more versatile and adapted to work with different volumes of acrylic and silicone compounds, 600-1600 ml, so it needs to be refilled much less frequently. By design, it consists of a cylinder serving as a cartridge and a rod.

Precautionary measures

There is a list of actions that are mandatory and, conversely, completely contraindicated. A craftsman who follows these recommendations is not in danger of a quick equipment failure.

Twisting the adjustment is a stage that cannot be forgotten after the end of the work.

It is categorically not recommended to clean the nozzle with any metal objects, the consequence may be its depressurization.

After removing the cylinder, it is imperative to clean the pistol not only from the outside, but also from the inside. A tool left in the foam will quickly fail.

A cold bottle (15-20 °) cannot be used. They heat it in warm, but not hot water. Its optimum temperature is from 30 to 40 °.

The thermal cover, put on the container, is a mandatory attribute when working on the street in adverse conditions

Precaution is needed both in the heat and in the cold.

When unscrewing the balloon in which the foam remains, you must be careful: if the valve is faulty, an uncontrolled "eruption" of foam is possible.

Hand and eye protection is a must: always use glasses and gloves. Small unventilated rooms are a reason to purchase a respirator.

Care is also needed when flushing the gun, this liquid is flammable

There are exceptions: these are fire fighting types.

Experienced people often share the secrets of a long but effective operation of any equipment. The foam gun is no exception. The extension tube adapter will keep the barrel and nozzle clean. They always wear it, and take it off only after the completion of the work. With this "innovative" method, the foam solidifies only in the extension, and remains liquid in the barrel tip. The set mass is removed from the nozzle tube with a long, thin self-tapping screw.

Types and features of the device

The principle of operation of a sealant gun resembles a medical syringe, in which a thick mass is squeezed out by a piston rod through a hole in the tip. By the type of device, these devices can be divided into three classes:

- Skeletal. The simplest and most inexpensive model designed to work with ready-made tubes. For the manufacture of this type of device, strong steel is used, therefore, despite the apparent fragility, the structure can last quite a long time.

- Semi-hull. In these construction devices, the bottom of the cylinder is closed, which allows you to securely hold the tube. Half-body pistols are durable and easy to use.

- Closed tubular. The mixture prepared just before use is charged into a closed tubular device. Such a device is usually found in professional models powered by a battery or electrical network.

In addition, pistols differ in the way the sealant mixture is squeezed out. Each type of tool has its own pros and cons, which must be considered when choosing.

- Rechargeable. The device operates from an autonomous power source (battery). In everyday life, it is used extremely rarely, since it is expensive and requires special training from the employee. The pistol can be filled with both ready-made tubes and the mixture diluted from dry packaging. The design provides for the possibility of pre-setting the power of the mixture supply.

- Electrical. The device is powered by an electrical network. With this tool, the sealant is applied quickly, accurately and economically. Recommended for professional use.

- Pneumatic. It is most popular because it does not require special skills and physical effort, is easy to use and is inexpensive. The device squeezes out the sealing mixture due to the air pressure created by pressing the handle. The ergonomic design is equipped with all kinds of restraints and regulators for uniform sealant delivery. It is used in cases where the speed of work is not too important.

- Mechanical. The hand gun is the most affordable and short-lived, used when you need to quickly close up a sprawling seam on a pipe or walk with a sealant between the tiles in the bathroom. The mixture is squeezed out with the help of physical effort of the hands, which negatively affects the speed and quality of work.

Which tool to choose, everyone decides independently, depending on the amount of repair work, the specifics of the sealing material and financial capabilities. If two or three seams need to be closed, a cheap skeletal device can be dispensed with. When the work requires precision and speed, an electric gun is indispensable.

Tips for a beginner

If the tool in question was correctly equipped, then there should be no difficulties with its use. If you succeed in putting the cartridge into the device, then halfway has already been passed. All that remains to be done is to slowly pull the trigger and squeeze the mixture onto the desired surface.

There are a few tips to help you get the job done as well as possible.

- If a skeletal or half-body gun is selected, it may take several taps for the sealant to come out of the hole. Remember to press gently to ensure that the product is squeezed out evenly.

- If a model is used that is powered by electricity or a battery, then by pressing the trigger, you can control the intensity of the mixture supply.

- When working with this device for the first time, it is recommended to practice on unobtrusive places or on separate objects. To do the job well, you need to learn a little about how to use the tool.

- If in the process of work it will be necessary to trim any area or add sealant into a narrow gap, then you can do this with your fingers. The only thing is that you need to wet them with soapy water. This will help keep the sealant from sticking to your hands.

It should be noted that the sealant does not require additional drying. If it is in the fresh air, it will acquire the necessary strength in a few hours.

As soon as you have finished working with the sealant gun, be sure to rinse the mechanism well under warm soapy water.

- For a beautiful seam, it is best to use masking tape. They need to glue the surface on both sides, leaving only the area that should be covered with sealant free. You will need to remove it immediately after applying the layer.

- To create a beautiful, excellent fillet weld, you must first moisten the sides with soapy water. In advance, you should find a stick made of plastic or wood. On the one hand, it must be cut so that it can be used to set the shape of the seam. This is a very simple and convenient technique, thanks to which you can get a beautiful seam. There is no need to look for special attachments for this, since an ordinary stick will save the situation.

If you overdo it with the sealant, then you should not worry about this. This situation can be easily remedied. It will be necessary to dry the seam well. A regular hair dryer can help with this. Next, you will need to remove the remnants of the material. This can be done with a stick that was previously soaked in soapy water.

It is important to note that with this solution you can remove various contaminants, but you should still try to work as carefully as possible.

There is a situation when a sealant gun is not available, but it is necessary for the job. In this case, you can use the tools at hand to "knock out" the sealant

This is far from the most convenient option, but it will help save the situation.

Based on the above, it becomes clear that loading and using a sealant gun is not that difficult. All it takes is choosing the right tool, choosing a quality sealant, and some practice on how to prime it quickly.

For how to use a sealant gun, see the next video.

Types of assembly guns and their purpose

Each construction gun belongs to one of the types, depending on:

- Energy source:

Gas

Powerful nailer suitable for thin metal and sturdy concrete.

To use it, you need a special disposable gas cylinder, which is quite expensive.

It is used, as a rule, by professional builders on large objects.

For household use, buying a tool is impractical, since it will pay off for several years.

The principle of operation resembles an internal combustion engine - the gas from the can enters the combustion chamber, where, after pressing the button of the pistol, it ignites.

The increased pressure pushes the piston mechanism, which in turn pushes the fastener out.

Among the minuses, it should be noted that the gas often comes out through the seal, so once having charged the cylinder, it is better to use it to the end.

Pneumatic nailer

Among such a tool, it is the most budgetary option, but a compressor with a receiver is required to use it.

Due to its average power, it copes with a wide range of tasks, except for working with reinforced concrete, stone or thick metal.

Air from the compressor receiver is fed into the gun through a hose, where, after pressing the trigger, the piston is abruptly pushed out under pressure, firing the fasteners.

It has a low cost of a shot, and only requires a compressor and the dowels to operate.

Such a pneumatic gun does not have recoil and by itself works quite quietly, and among the minuses - a hose that interferes with the work, the need for electricity, the periodic constant noise of the compressor.

Powder nailer

the most powerful option, capable of piercing surfaces of any hardness.

In addition, both the tool itself and its consumables are expensive.

The principle of operation is similar to that of a firearm.

Fasteners are inserted into the pistol nose, and a special blank cartridge is inserted into the rear part.

After the shot, the powder gases, expanding, push the piston acting on the dowel-nail.

Due to the risk of injury and lethality, like a small-caliber weapon, the use of a tool requires a special permit.

There are single-shot and multi-shot options, and they can be combined with each other, for example, if the pistol is designed to use fasteners in the tape, but at the same time it must be loaded with a new cartridge after each shot.

Although this fact reduces the speed of work, it still remains higher than when using a hammer drill.

Requires strict adherence to safety precautions.

Electric gun

Electric models are produced in two types: network and battery.

The cost of this tool is extremely high; not even every professional in his field can purchase it.

It makes sense to buy this option only if you work with it on a daily basis.

They are suitable for working with different materials from wood to brick.

The cordless gun has a number of advantages, in particular, independence from the presence of an electrical network, ease of use, etc.

- Type of fasteners:

Nailing

Better known as nailer.

Often used because of its high speed.

It is used both in construction and in furniture assembly.

In addition, unlike the manual method of hammering in nails, the nailer is capable of punching through hard materials such as bricks.

For these purposes, there is a reinforced fastener.

How to apply silicone sealant

The most common is silicone acriplast. Silicone sealant is easy to use. It can withstand sudden changes in temperature, high humidity, therefore it is often used for sealing works in the bathroom. In addition, it contains special antiseptics that prevent the spread of fungal formations and mold.

Application will not be difficult, since silicone sealants are on sale in convenient tubes. They should be placed in a syringe or applied directly from a balloon.

Application rules are the same as for other products. But some features should be taken into account.

Complete drying of the composition occurs after two days (the indicator depends on the thickness, depth of the seam). Although the surface appears to be dry after an hour, putting it into operation is prohibited. During drying, there should be no direct contact with water.

Before starting work, the old sealing compound is removed from the surface. To do this, you should use a spatula, special washes.

If the filling of the space has occurred unevenly, then it is worthwhile to start forming the seam immediately. For smoothing, a spatula, a knife soaked in soapy water or a moistened finger are suitable. Seam forming process:

- The selected tool is moistened with soapy water.

- A spatula is pressed to the far point, without strong pressure, a uniform movement is made towards you.

- The line is drawn without interruption, if this did not work out, then the process is repeated anew.

- The tool is washed under running water.

There are pistols on sale that immediately form the shape of the roller. But for a one-time application, it is impractical to purchase them.

It is worth buying a high-quality composition, where the fourth part is a silicone polymer, 5% rubber mastic, 3% thiokol, 2% epoxy, 0.5% cement component.

If the composition includes antiseptics, then such agents are not used on surfaces that may be in contact with food. This mass is not suitable for aquariums.

Silicone masses are universal, you can pick up for any purpose, surfaces. We recommend a video on the topic:

What is glued with a heat gun

The main function of the heat gun is a quick hot glue connection.

The final hardening occurs within 5 minutes, and not after 24 hours, like most analogs in tubes. In comparison with instant - the probability of "making friends" fingers is reduced to zero. Almost any natural and synthetic materials can be glued:

- wood;

- metal;

- stone;

- cardboard;

- glass;

- ceramics;

- cork;

- skin;

- plastic.

How does this miracle work? The gun contains a thermal heater. A round glue stick - a rod touches it through the feeder. Another name is the cartridge: after all, it is with them that pistols are loaded. When the device is plugged into a 220 W network, a temperature of 105 o –210 o C. is created in the thermal heater. The glue melts and, when the trigger is pressed, flows through the nozzle.

Hot melt gun components

Glue application with a gun tips and tricks

Before squeezing the substance onto the materials to be glued, it is recommended to figure out how to do this correctly. If you plan to glue large and heavy parts, such as ceramic tiles or gypsum structures, then it is better to apply the glue in a continuous manner in the form of a snake or mesh. This will increase the bonding area and also ensure a secure connection.

The setting speed of liquid nails is from 1 to 2 minutes, depending on the materials to be glued. After applying the substance, it is necessary to press them tightly together, and hold for at least 1 minute, and preferably 2 minutes, which will be more reliable. A press can be used whenever possible, especially when joining wooden structures.

It is interesting!The more substance is applied to the joint materials, the longer it takes for them to cure.

How to care for a foam gun?

Proper handling of the tool will allow even an inexpensive gun to “cope” with a large number of polyurethane foam cylinders. This simple device, with flawless operation, will not require either complete disassembly or external intervention. In order to guarantee the long life of the equipment, certain rules must be followed.

- The foam cylinder is removed from the gun only in one case: if the container needs to be replaced. A container that is "successfully" emptied at the end of the work does not need to be removed.

- After blowing out the joints, only the shutoff valve and nozzle are cleaned from the sealant.

- Flushing the adapter when changing the container is mandatory. The foam is removed with a solvent.

- If the hardened sealant interferes with disassembly, then acetone or inexpensive solvent 646 can be used to soften and remove it.

A pistol that refuses to work due to unexplained problems is not yet a reason to send it to the landfill. The tool is simple, so in most cases you can find the cause of the breakdown and then fix it. The broken part is replaced with a new one, the parts are lubricated. These simple steps will extend the useful life of your equipment.