Cold Welding Tips

In private life, the method is most often used for auto repair and repair of heating facilities. A leaky and sealed muffler or gas tank will last for many years without requiring replacement.

Unfortunately, in this way, the radiator can only be temporarily patched up in order to get to the service on its own. It will not be possible to use it constantly. If it is not possible to establish the leak, then you can lower the radiator into a bath of water. Escaping bubbles will indicate the location of the leak.

For muffler repair, select a high temperature grade. If the instructions indicate the room temperature of use, then wait for the part to cool before starting the repair work.

If you are repairing a heating system, then you should choose a composition that can withstand prolonged contact with water. It should be remembered that the method is suitable for repairing small holes. If the damage is significant, it is better to use hot welding.

You should not try to replace a brand designed for a specific material with one that is at hand. The filler must exactly match the materials to be glued, otherwise you can forget about the strength of the seam.

How to connect linoleum with cold welding

One of the most popular queries in Yandex and Google is the rule for gluing linoleum using cold welding. Floor linoleum is popular, and therefore, when laying it in large rooms, it becomes necessary to glue the seams. For this, special cold welding is used for linoleum, and the process of gluing two sheets is carried out according to the following scheme:

- First, you need to ensure the perfect joining of two sheets of linoleum. This is achieved by overlapping two parts, with a protrusion of at least 5 cm. This protrusion is needed so that the junction does not have free space. The place of the overlap must be glued with masking tape, and then, using a sharp construction knife, remove the upper and lower parts of the linoleum projections. It is not necessary to glue it with masking tape, but it is recommended, since this will not move the joint. In this simple way, a high precision of the connection is achieved.

- In the next step, you also need to use masking tape, and glue the joint on both sides from the bottom and from the top. It is also not necessary to glue the lower part, but this will prevent the linoleum from sticking to the moisture-proof film. On top, gluing with masking tape is performed in order to exclude the ingress of cold welding on the decorative part of the material

- At the joining site, you need to cut a line in the tape through which cold welding will be introduced

- Pick up a tube of special glue for linoleum, and apply it to the junction with a thin needle twisted onto the tube. If the glue will go beyond the connection, then it should be promptly removed with a swab.

- In addition to this method, there is another, which consists in the fact that a uniform layer of glue is applied to one end part of the linoleum, and then it is laid and connected to the second sheet. This method is suitable if the joint has an almost imperceptible seam, which does not allow a thin needle to be drawn along it.

The glue curing time is at least 2 hours, therefore it is recommended to withstand this time, and only after that to remove the masking tape. If there is a glue protrusion at the seam site, then it can be removed with a utility knife or spatula.

It is interesting! It is recommended to clean the seam not earlier than after 5 hours, until the glue has completely hardened.

Principle of operation, advantages and disadvantages

What is the cold method of joining metal with a special composition, what are the compositions and what are the nuances of preparation and use? At its core, it is a glue specially created for joining parts of metal blanks or repairing parts that have a broken surface or tightness. It contains the following components:

- epoxy resin;

- filler;

- additives for various purposes, contributing to adhesion, obtaining the required degree of strength, heat resistance and the formation of appearance.

All together, they bind materials to each other, participate in the formation of interatomic bonds, without which it is impossible to obtain a strong connection. The composition has an increased degree of adhesion to metals, destroys the oxide film and hardens quickly. Special additives in epoxy glue release heat, forming a substance that can bind metals. The composition can be liquid or plastic-like (pasty). The cold method is intended for gluing parts and structures made of different metals and their combinations. Repair and restoration of surfaces of metal parts can be carried out even by a beginner

The advantages of cold welding of metals with special glue include the following factors:

- the ability to create a strong and reliable connection in the shortest possible time (the time of complete hardening is indicated on the packaging and in the manufacturer's instructions: approximately from 30 minutes to 5 hours);

- there is no need to use special equipment (energy costs are excluded);

- profitability (a small amount of composition is spent);

- wastelessness (no need for disposal);

- aesthetics (the junction has an attractive appearance, it can be machined and painted);

- the composition of the adhesive does not affect the structure of the metal (it remains the same as it was before gluing);

- it is possible to connect and repair in places with difficult access and at the place of installation of parts and structures;

- you can repair structures and parts for which heating is contraindicated, and even in fire-hazardous rooms;

- availability (you can buy at any store that sells construction and welding materials).

The disadvantages include the need for thorough preparation of surfaces and edges for the implementation of the connection or repair work, the impossibility of sealing large defective areas and the not very high strength of the resulting seam. Compared to conventional welding, by melting or by combining melting and pressure, the strength is still lower. Responsible structures should not be cold-welded using an adhesive composition: they can only be temporarily fixed in this way.

More clearly about cold welding in the video:

Examples of gluing surfaces by cold welding. What can be glued.

Cold welding can be used to fix and repair many different elements, such as:

p, blockquote 17,0,0,0,0 ->

- Metal parts, pipes, brackets, etc.

- Various plastic products. But remember that cold welding eats away at polyethylene products.

- Products made of natural and artificial stone.

- Glass objects.

- Mixed materials. For example, you can glue glass to stone or plastic.

- Ceramics of various types.

- Linoleum.

In principle, my personal opinion is that this is more glue than welding, and such a name is just some kind of PR move that manufacturers skillfully spin in the vastness of our vast homeland.

p, blockquote 18,0,0,0,0 ->

p, blockquote 19,0,0,0,0 ->

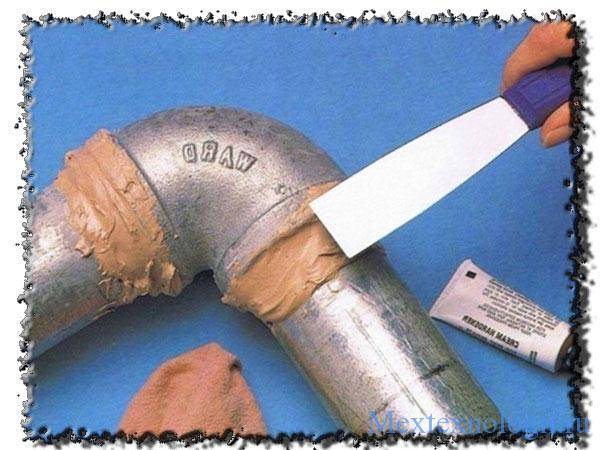

In this photo you can see how with the help of this miracle of glue the holes in the water pipe are repaired. Dry all surfaces thoroughly before doing this. Otherwise, such a connection will not be strong.

p, blockquote 20,0,0,0,0 ->

p, blockquote 21,0,0,0,0 ->

Here we see how the rod and the hemispherical surface were connected. This is possible only if in the future this structure will not experience serious bending and fracture loads. Although this application of cold welding is quite rare.

p, blockquote 22,0,0,1,0 ->

p, blockquote 23,0,0,0,0 ->

Attaching the part of the bracket that was broken off as a result of the impact was not difficult. Well, here we rather see not a broken off part, but a crack that was sealed with glue. And do not even hesitate such a seal will withstand a sufficiently high pressure.

p, blockquote 24,0,0,0,0 ->

Conclusion.

By the way, I began to practice this topic. You can send me your article by mail and if it is of good enough quality, I will publish it on my blog. And I will definitely indicate a link to your project and authorship of the article. Here is such an idea. So, I will be glad to cooperate with you.

p, blockquote 26,0,0,0,0 ->

p, blockquote 27,0,0,0,0 ->

On this I say goodbye to you and finally recommend that you watch a video about 20 different and very cool types of welding. I recommend a very informative video with pleasant music.

p, blockquote 28,0,0,0,0 ->

p, blockquote 29,0,0,0,0 -> p, blockquote 30,0,0,0,1 ->

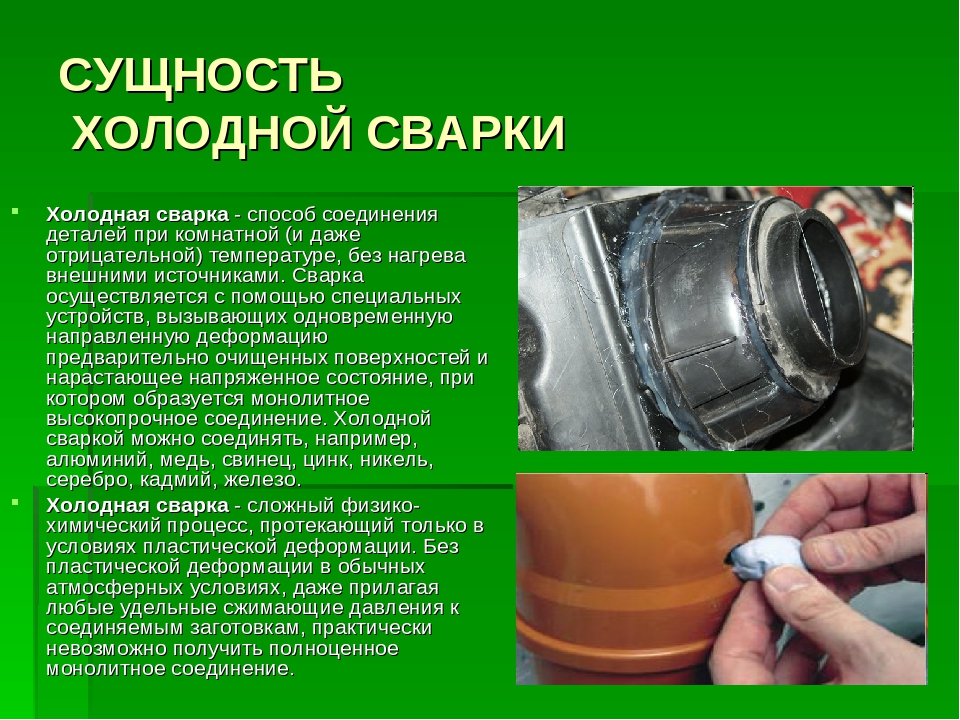

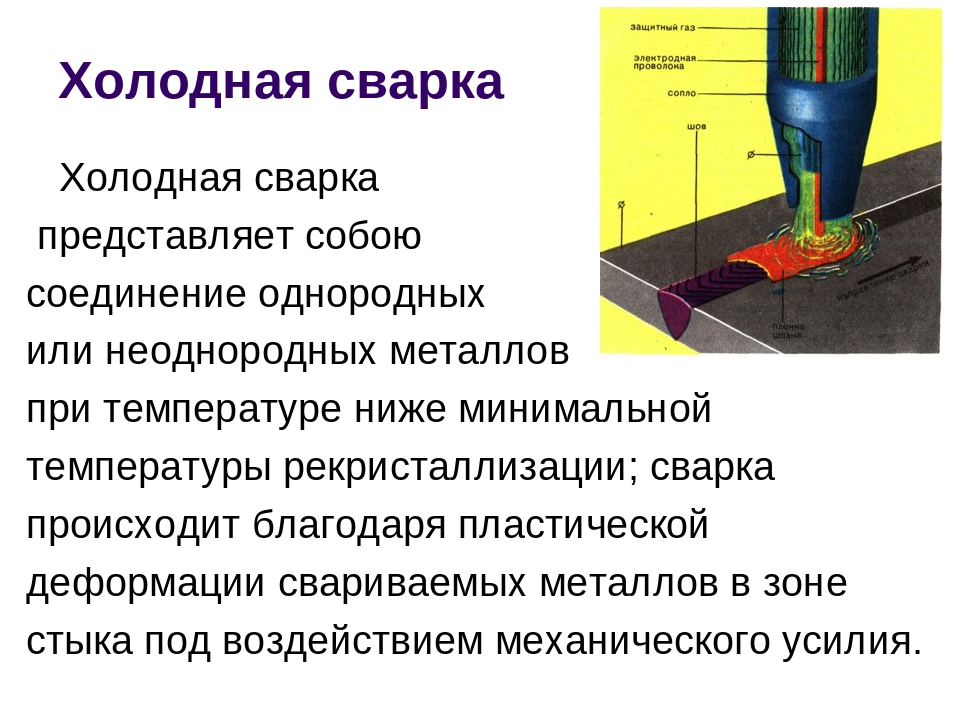

The gluing process occurs due to the interpenetration of the mass of the composition and the surfaces to be glued. Cold welding is easy to use; it does not require any special fixtures or equipment.

This type of bonding in its action is pressure welding, and a continuous weld seam occurs during penetrating plastic deformation, which initiates the destruction of the oxide film on the planes to be joined, and brings the distance between them closer to the dimensions of the crystal lattice. The concentration of the energetic interaction of atoms on the planes being welded contributes to the establishment of chemical bonds.

Cold welding for metal - the instruction allows you to glue products from any metals: silver and copper, iron and lead, zinc and aluminum. This method is a good solution for repairing heat-sensitive metal parts. It can be used to weld dissimilar metals: casing aluminum wires with copper bushings.

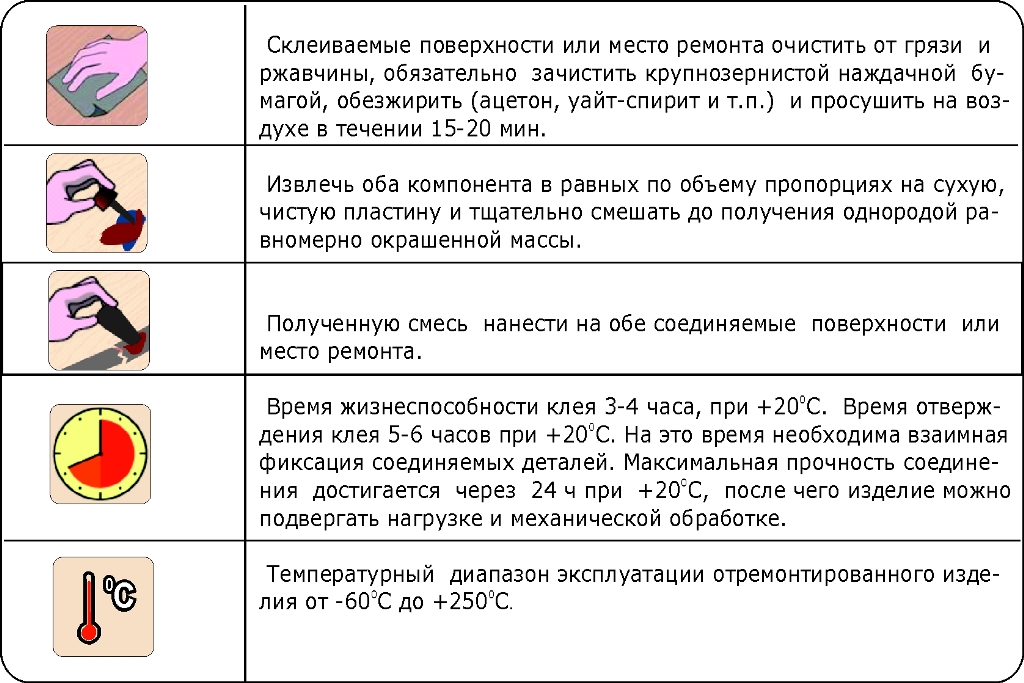

Operating procedure

How to use cold welding? To work with it, you do not need to have qualifications and special equipment and accessories. Cold welding for metal - instructions for use will help everyone to cope with the work. To bond metals, in addition to welding glue, you will need:

- abrasive for cleaning surfaces - emery cloth or sanding paper;

- surface degreasers - acetone, alcohol, any technical solvent;

- if necessary, a clamp or clamps, a vice.

Sequence of operations:

- first of all, we prepare the surfaces of the elements to be glued - we clean with an abrasive and wipe with a technical solvent (degrease), dry. The strength of the welding directly depends on the quality of surface preparation;

- working with a clay-like composition, so that the welding mass does not stick to the palms when kneading, it is necessary to periodically moisten them with water;

- when working with a flowing two-component glue, it is necessary to mix the resin with a hardener in the required proportion, during mixing, the mixture heats up, the ready glue should be applied no longer than three minutes;

- having connected the planes covered with the welding mass, they must be fixed with a vice or clamps;

- the bonding time depends on the adhesive composition and can be up to eight hours, after which the restored product can be putty, primed and painted.

Some areas of application

It is often used when carrying out repairs of the heating system and car elements. For example, a gas tank cannot be repaired in the traditional way, but cold welding can be done, and thereby save money on buying a new tank.Car radiator repair is another frequently used area. To detect leaks in the radiator, it is placed in water and blown with compressed air - air bubbles will go through the leaks. Such repairs are used as a temporary measure; the radiator cannot withstand long-term operation. The muffler of a car can also be patched with welding glue with a maximum temperature of 260 degrees.

This method can also be used for the temporary repair of intra-apartment communications: heating and water supply pipelines, sewerage, including PVC pipes. In this case, the welding glue must be waterproof. The damage to the piping should be small. In the future, it is better to make repairs with traditional welding.

Cold welding is not applicable if the load on the parts is significant, the weld seam does not work well for tearing. You should not use glue intended for gluing metals in gluing wood, if the glue has a filler - metal powder, then it will not glue the wood. When choosing welding, look at the temperature limit of the application - high-temperature cold welding is stronger than others. When making glass cutters, the diamond can be attached to the handle with this glue.

Cold welding is not applicable if the load on the parts is significant, the weld seam does not work well for tearing. You should not use glue intended for gluing metals in gluing wood, if the glue has a filler - metal powder, then it will not glue the wood. When choosing welding, look at the temperature limit of the application - high-temperature cold welding is stronger than others. When making glass cutters, the diamond can be attached to the handle with this glue.

Advantages and Disadvantages of Cold Welding

This connection method has a lot of positive aspects:

- High bond strength.

- Ability to withstand severe mechanical stress.

- Versatility.

- The gluing procedure is very fast.

- Cold welding glue is inexpensive and can be purchased at any hardware store.

- During work, no waste and substances harmful to humans are emitted.

There are also a number of serious disadvantages:

- The strength of the seam will be much weaker than with conventional welding.

- Cold welding makes it very difficult and ineffective to repair serious defects.

- After work, it is imperative to clean and grind the seam, otherwise the quality of the bond will deteriorate greatly.

- Two-component compounds must be mixed before work.

Adhesive for metal

Varieties of cold welding

In fact, cold welding is a glue with a high degree of ductility, made on the basis of a well-known epoxy resin. By its structure, this glue can be two-component, then it can be stored for a long time, or one-component, which must be applied as quickly as possible so as not to encounter a loss of its adhesive properties.

As a rule, such a product is produced by manufacturers in the form of a two-layer cylinder, the outer shell of which consists of a hardener, and the inner core is an epoxy resin mixed with metal dust. Such an additive in the form of metal dust is necessary in order to give the resulting joint high strength and reliability. It contains cold welding and other additives, which give it, as well as the joints obtained with its help, unique characteristics. Most of these supplements are kept secret by manufacturers, but the most famous of them is sulfur.

Cold welding is classified mainly by the area of its use, that is, by those materials that can be joined using its various types. So, today the following types of this tool are successfully used.

Cold welding for metal

Such a tool is actively and successfully used not only by home craftsmen, but also by motorists, as it allows you to quickly and effectively solve many problems associated with the operation of the car. The connections obtained with its help make it possible not only to forget about the problem that has arisen for a short time, but also to operate the restored parts for a rather long time.

However, it should be borne in mind that cold welding shows itself optimally when joining parts that do not experience significant loads during operation.Such a tool has found widespread use in the repair of plumbing devices, in which it is necessary to quickly eliminate the leaks that have arisen. But no matter how reliable it is, you should always remember that it only serves to eliminate the problem that has arisen only for a while. At the first opportunity, you should use overhaul methods.

Adhesive "Cold welding" for various types of plastics

This tool, which is less common, is used, as its name suggests, to perform quick repairs on plastic parts. Such glue is used both in manufacturing enterprises and for performing repairs in a domestic environment. Most often, the need to use such a tool arises in cases where it is necessary to repair plastic pipes and cases of various devices.

Cold welding types for various materials

Such glue can also be used in cases where it is necessary to make joints of products made of hard rubber. Naturally, such welding found wide application in the performance of construction and repair work. It should be noted that the linoleum compounds obtained with its help are significantly superior in their characteristics to those for which glue or double-sided tape was used.

We have listed only the main types of cold welding, but there are others that are less common. All these tools are distinguished by high efficiency of obtaining and reliability of connections, provided that all the necessary requirements were strictly adhered to when performing the work.

Manufacturers and specifications

Both domestic and foreign products are found on store shelves. Each manufacturer uses its own additives that affect the technical characteristics of the adhesive.

| Name | Primary setting time, min | Complete drying, hour | Work and holding temperature, ° С | Critical operating temperature, ° С |

| Penosil | 5 | 1 | 17 | 120 |

| Poxipol | 30 | 3 | 18 | 250 |

| Zollex | 60 | 18 | 20 | 250 |

| Nowax | 20 | 3 | 20 | 180 |

| Alteco | 20 | 2.5 | 18 | 250 |

| Diamond | 20 | 3 | 18 | 1300 |

In addition to the above manufacturers, brands such as are widely known:

- Moment;

- Mastix;

- Abro;

- Hi-Gear;

- Loctite;

- Weicon;

- Devcon.

How to use cold welding

Any novice craftsman can use cold welding for metals (instructions for the glue are attached). There are no complicated operations and cunning tools here. All you need is:

- the glue itself;

- acetone for cleaning the surfaces of the metals to be joined;

- clamps, clamps (not always needed);

- sandpaper if rough sanding is necessary.

Cold welding technology

- The preparatory process, which includes cleaning the surfaces of the two parts to be joined. Degreasing them with acetone. You need to get the surface rough, so use coarse sandpaper.

- If liquid glue is used for the connection, then it must be mixed with a hardener. This usually produces a temperature. If "plasticine" is used, then before applying it it is necessary to knead it well with your hands.

- In working order, the glue lasts no more than three minutes, so it must be quickly applied to the welding area.

- After that, two metal products are connected to each other. Clamps can be used to create pressure, although this is optional.

How long does cold welding dry? It all depends on its composition and manufacturer, but the range is wide enough: from 1 hour to 8.

Here's a simple technology that answers the question of how cold welding works. If you strictly follow the instructions, then the weld should turn out to be strong. You should not engage in amateur performances, which will necessarily lead to a violation of the characteristics of the cold connection, for which the instructions are attached.

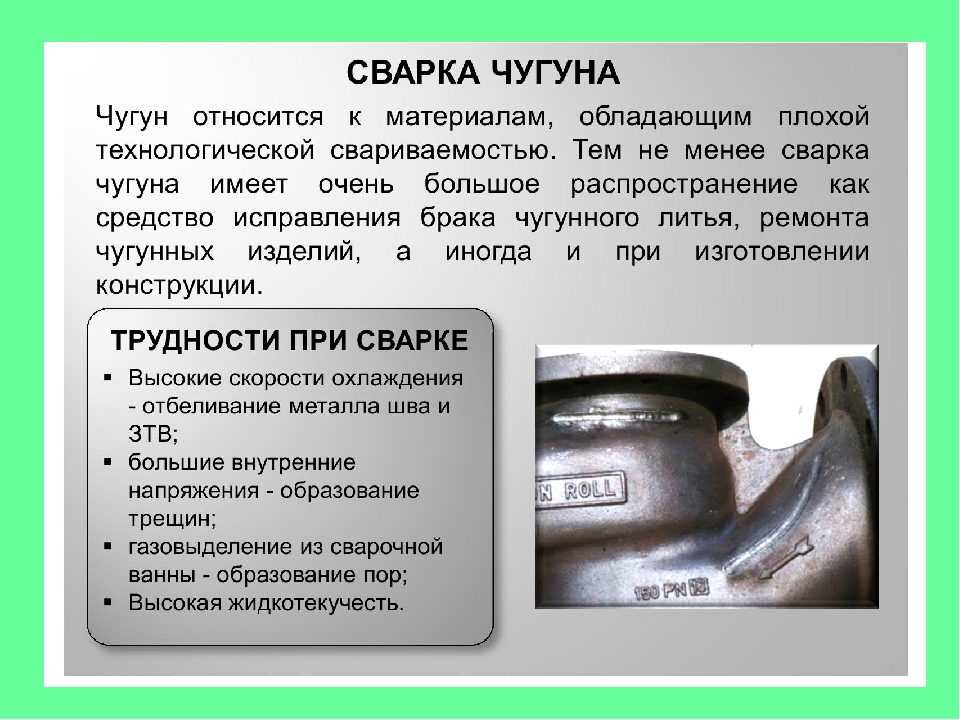

When it comes to cold welding for cast iron, in most cases the adhesive is not used.Here, completely different welding technologies are used, in which electrodes are used, but the metal is not heated. The technology of cold welding of cast iron is actually very complex, and an inexperienced welder cannot carry out it on his own. The adhesive can be used for minor repairs or temporary fixes.

Application area

In recent years, plastic has been increasingly used in various types of technology and other areas. Accordingly, cold welding for plastics is becoming more in demand every year. It is worth highlighting the main areas of application of this material:

- Repair of plastic instrument cases;

- Putty on bumpers on cars;

- Repair of fishing rods;

- Sealing leaks in plastic pipes;

- Bonding of plastic elements.

It is worth noting that cold welding glue for plastic is capable of attaching other materials to it, which expands its scope.

Suitable brands

There are many brands that can fit this case. After all, not so high requirements are put forward here as, for example, for cold welding for stainless steel. EP380 is one of the most common and easy-to-use brands. It has the following parameters:

|

Parameter |

Meaning |

| Connection strength |

3,500 PSI |

| Maximum working temperature |

93 degrees Celsius |

| Curing time |

15 minutes |

| Setting time |

4 minutes |

| Volume |

14 ml |

In addition, there is an even more reliable option, which is cold welding for Poxipol plastic. It refers to two-component, in which each material is in a separate container. This mixture has the following parameters:

|

Parameter |

Meaning |

| Shear test |

237 N |

| Peel tension |

5.4 MPa |

| Primary hardening time |

1 hour |

| Time of retention of the plastic state |

10 minutes |

| Full solidification time |

24 hours |

| Maximum shear force of the joint |

993 N |

| Average shear stress |

2.2 MPa |

Choice of cold welding for plastics

Selecting the right brand is quite difficult, since there are many different options on the market that are difficult to list. To make the right choice, you need to be guided by the technical parameters of the product. If operation at high temperatures is planned, then it is advisable to find out what temperature cold welding can withstand, since it often turns out to be lower than that of the plastic itself, which can interfere with normal operation.

Features of cold welding of plastic

One of the main parameters is the strength of the connection, so you need to know the data for tensile and shear, depending on what loads the product will be subjected to. The strength of the connection also contributes to the resistance to vibration loads. If you need a tool for quick repair, then you need to select a material that dries quickly. The spread in this parameter is from 3 to 15 minutes.

Instructions for use

Instructions for the use of cold welding for plastic require a clear sequence of actions. The first step is to prepare the surface to be joined. Processing is carried out using solvents and sandpaper to remove grease and increase the area of the joint. Without degreasing, the quality of the joint begins to drop sharply.

Surface preparation for cold welding of plastic

After that, you need to measure the amount of cold welding used, since after stirring it can no longer be reused. When preparing, you need to measure out an equal amount of each component. Then you need to start mixing, you should get a homogeneous mixture of soft consistency. It can be used to sculpt figures to seal cracks and chips, and also be used as glue. A few minutes after kneading, the mixture will begin to harden, so do not delay the repair process.

After applying to the surface, you need to press down the mixture with something.If pipes are connected, then it is advisable to use a tourniquet. Otherwise, you can make any press yourself.

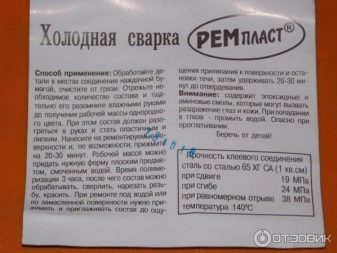

Security measures

Like many other materials, plastic cold welding requires certain safety precautions. After all, this is not the safest remedy for health. The following situations should be avoided:

- Contact with the composition of the mass in the eyes of a person or on open areas of the skin;

- Storage of the product in direct sunlight;

- Work with the mixture without protective equipment such as gloves and goggles;

- Storage in a place accessible to children;

- Contact of cold welding with food and other foreign objects with which a person will then come into contact.

If the mixture gets on the mucous membrane, rinse it with water as soon as possible. After that, it is advisable to see a doctor. If there was contact with the skin, then this is not so scary and you can do with thorough washing with soap.

Overview of foreign manufacturers

There is a large selection of completely different glue welds on the market, and not all of them are of good quality. In this regard, we have compiled a list of products from both foreign and domestic manufacturers. Selected the most practical options that customers love. Let's start with foreign ones.

Poxipol

Price ~ 400 rubles.

Excellent two-component product, time-tested. Available in two colors: transparent and regular. The price of this product varies by volume, small packages cost from 380 rubles, and large ones from 800.

Poxipol is intended for bonding metal, concrete, faience, wood, marble, plastic, glass, reinforced concrete, fiber cement, ceramics, granite and porcelain. After complete cooling, welding can be drilled, sanded and even threaded. By the way, it cools down very quickly, initial drying occurs after 10 minutes from the beginning of work. The seams are durable.

This glue is two-component, you need to mix it yourself. Manufacturers have taken care of the convenience of their customers by including self-cleaning mixing trays in the packaging. If there is any product left on the tray, it can be easily peeled off.

DONE DEAL

Price ~ 400 rubles.

DONE DEAL is a two-component adhesive designed for car repairs. Its heat resistance has an amplitude from -55 ° C to + 150 ° C, which allows it to weld heated parts. This adhesive also allows welding on cast iron, aluminum alloys and non-ferrous metals. The seams are very strong and durable. You need to work with this weld quickly because it dries up within the first five minutes.

Abro

Price ~ from 200 rubles.

Abro is a representative of dry cold welding. Bonds a range of materials such as metal, wood, glass, plastic, ceramics. Due to its ability to maintain its properties at a temperature of 260 ℃, it is suitable for repairing: gas tanks, radiators, mufflers, battery housings, oil pan, cylinder heads, body and body parts.

Abro has a peculiarity, when it hardens, it increases its volume, the effect of a cork is obtained. Due to this ability, this glue is suitable for the repair of barrels and plumbing. It can also work underwater.

Linocol linoleum adhesive

Price ~ 300 rubles.

Linocol welding is suitable for filling gaps in PVC floor and wall coverings. Allows you to bond materials at a distance of less than 1 mm to 4 mm. Usually sold in a volume of 50 ml, this is enough for 15-20 meters. Within one minute, it sets, and after 6 hours the seam will be completely ready. This welding is immediately ready for use, it is presented in the form of a homogeneous mass.

The kit does not include a metal nozzle in the form of a needle, therefore, to work with a narrow joint line, you must purchase it yourself.

Weicon

Price ~ 650 rubles.

An incredibly strong and durable adhesive. Produced in the form of a stick of welding paste. Its technical characteristics are good news.Works at temperatures from -50 ℃ to 300 ℃. The finished joint is resistant to esters, salt water, various oils, most acids and alkalis. It hardens and adheres to the material very quickly, initial drying takes place within 5 minutes.

It is not universal; a special stick is made for each material. The range includes cold welding for steel, copper, stainless steel, aluminum, plastic, concrete and for sealing leaks.

Werner muller

Price ~ 725 rubles.

The German company Werner Muller produces adhesives for the repair of PVC floor coverings. There are three types of welding to choose from (type A, type C, type T), depending on the width of the space between the pieces of material and coating, how to choose a welding mixture is described above.

The tube of this product holds 44 grams of adhesive. Cold welding from Werner Muller evens out the edge heights, ensures optimal seam insertion and prevents strong absorption of the product, but do not forget to apply tape before welding.