Care and maintenance tips

HDF boards come in a variety of qualities. Models of well-known manufacturers with a powerful protective coating do not need special care. All dirt is best removed fresh, when dirt, soot or grease has not yet had time to dry. After each cooking, when cleaning the kitchen, the panels are simply wiped with a sponge or cloth dipped in soapy water.

If it happens that the dirt on the apron is old and dry, do not use aggressive detergents or abrasive substances to remove them. It is better to use special chemical compounds to remove such defects.

To make the panels last as long as possible, while maintaining their original appearance, follow some simple tips:

- Always try to keep the surface of the walls clean. After each cooking, take a couple of minutes to clean so that you don't have to spend half a day doing it later.

- Place heating appliances such as an electric kettle, coffee maker, oven or hob away from walls.

- Do not use steel wool or a knife to clean the plates. The maximum that is allowed with old dirt is to gently wipe them with the felt side of the dishwashing sponge using non-aggressive household chemicals.

- Treat your finishing with care. Do not test the strength of the panels with heavy objects and tools. Even the most practical material can be damaged if done on purpose.

What are PVC panels?

Many materials are used to decorate the kitchen. Increasingly, PVC panels can be seen in the interior. They are used for cladding not only an apron, but also walls and ceilings. A building material is made from solid polyvinyl chloride by extrusion. A chemical carbon compound is created with the participation of hydrogen, ethylene and chlorine (common salt). The result is a safe and environmentally friendly material suitable for the kitchen.

The panels are two lacquered and painted planes, connected by a kind of honeycomb - longitudinal stripes, which are clearly visible on the cut. Air cells give the material rigidity and resistance to temperature extremes.

The panels are two lacquered and painted planes, connected by a kind of honeycomb - longitudinal stripes, which are clearly visible on the cut. Air cells give the material rigidity and resistance to temperature extremes.

- PVC panels are wall sheets of a relatively small width (15–50 cm), 2.6 to 3 m long. There are panels 4 m long, and sometimes even 6 meters. When choosing the length of the panels, keep in mind that with a length of more than 3 meters, there are difficulties with transportation and lifting into the apartment. Material thickness - 0.5-1 cm.

- PVC lining - long plastic strips 10-12.5 cm wide. You can find plain lining and planks with imitation of the texture of natural materials, or with other patterns.

- PVC sheets - glossy or matte panels from 80 to 203 cm wide and 150-405 cm long. The surface looks decorative. The seams are not noticeable with proper installation. A variety of drawings and even photos are applied to it.

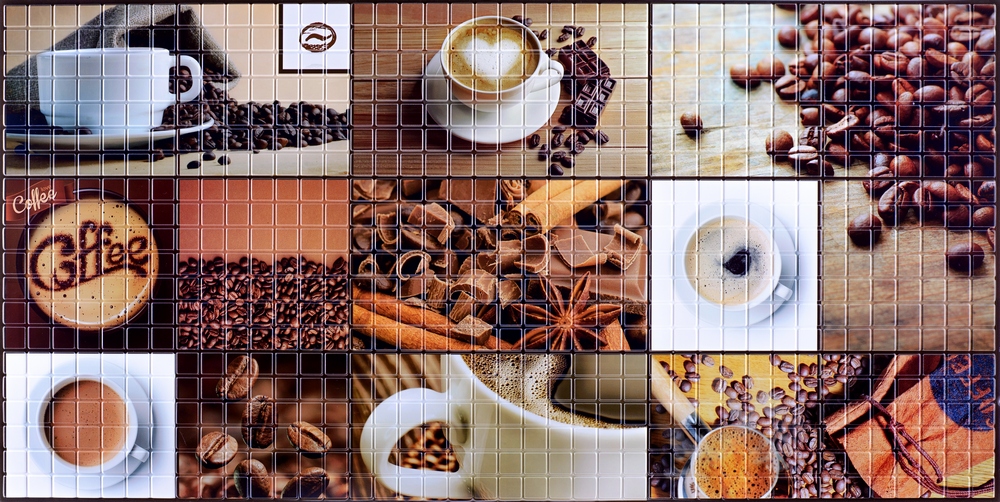

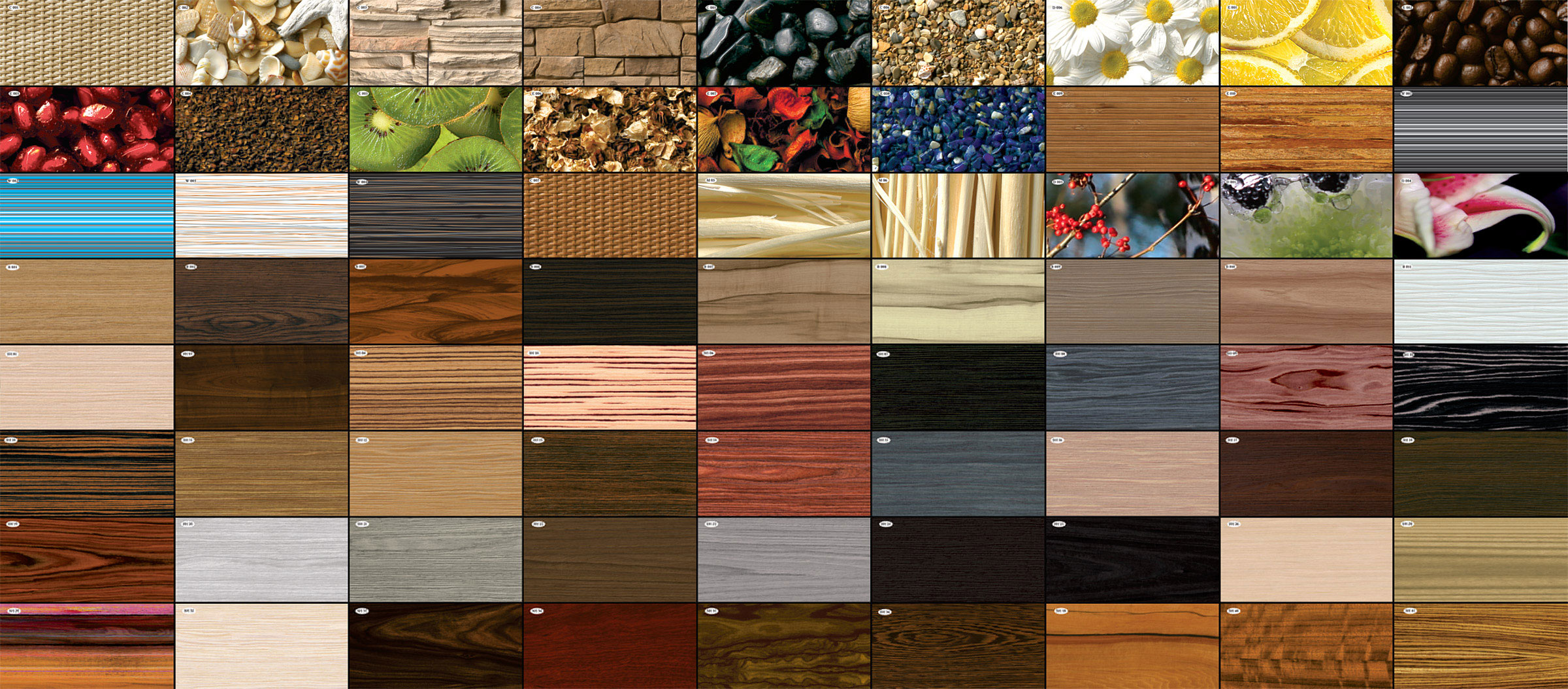

Decorative component

The main method of decorating kitchen stoves is photo printing, since the same veneer or PVC film will not be able to withstand intense kitchen loads.

Decorating panels using ultraviolet printing is carried out in different variations:

- Monochrome option - the slabs are covered with one specific color. The range of choice of tones is high, and it is quite possible to choose the ideal option for a particular interior.

- The two-tone color scheme allows you to create an individual style. As a rule, dark tones are chosen for the background, and bright light tones for the depicted elements.

- With full-color design, a rich and vivid pattern is obtained.But such panels are chosen either for non-standard design, or as the main decorative element of the kitchen.

- Photo printing - application of an image by means of ultraviolet printing on a panel, followed by varnish coating. Such a panel will perfectly complement any interior - both light and dark.

- The most sophisticated type of design is a full-fledged volumetric drawing with a 3D effect. An image is applied to the board, and a high-gloss protective layer is achieved by successive application of several layers of varnish.

The most common and frequently used drawings are city landscapes, wildlife or fruits.

PVC apron: what to say about this material

PVC panels are a very popular material for interior decoration, which is also used in the kitchen.

Chemically speaking, PVC is a mixture of ethylene, chlorine, as well as hydrogen and carbon. To improve the quality of the material, stabilizers and dyes are added to it during production, as well as special additives that affect its immunity to ultraviolet radiation.

PVC aprons are resistant to sunlight and moisture

PVC aprons are resistant to sunlight and moisture

There are several types of PVC panels:

- Rack narrow (lining);

- Sheet panels;

- Square tiles;

- Sandwich panels;

- Monochrome;

- Thermal printing;

- Offset printing;

- Metallized;

- Laminated;

- Lacquered;

- With a frieze;

- 3d panels.

This material - PVC or plastic - has its pluses and minuses.

Plastic wall panels for an apron: advantages and disadvantages

First, it is worth considering the clear advantages of plastic panels.

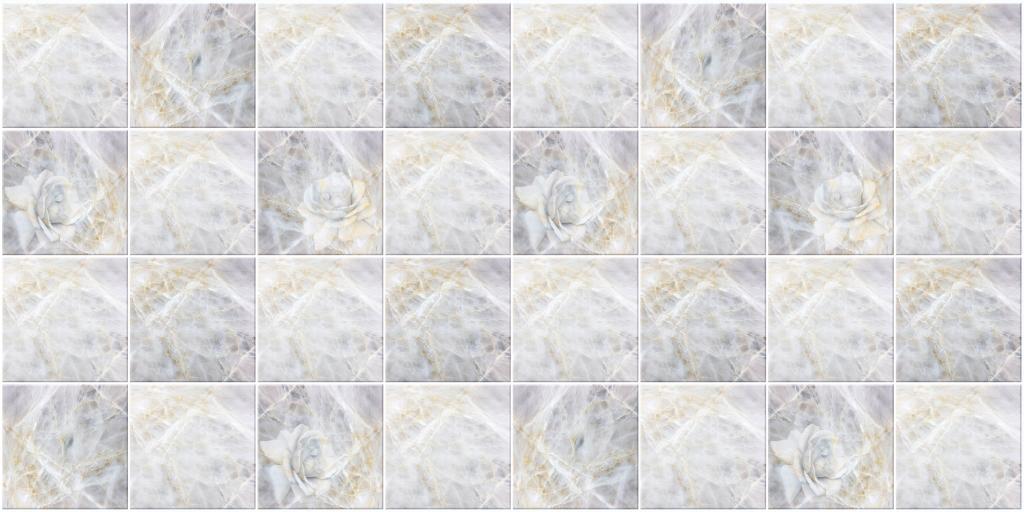

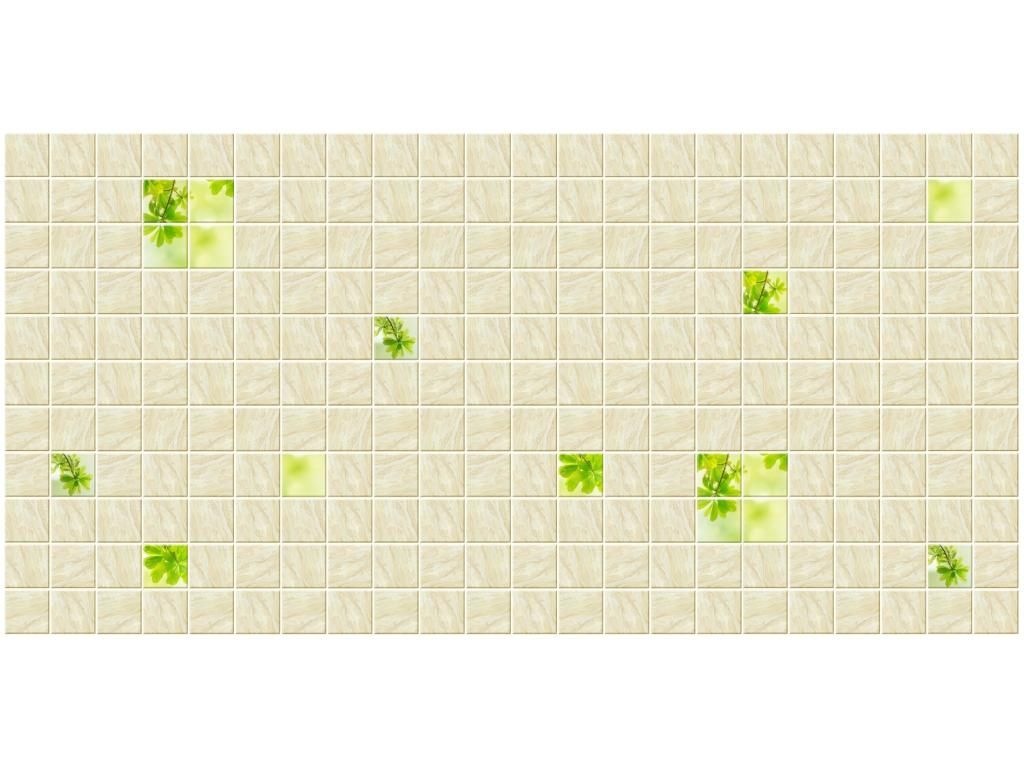

At the moment, aprons made of soft plastic made under a mosaic are quite popular.

At the moment, aprons made of soft plastic made under a mosaic are quite popular.

Advantages of PVC panels:

- Durable, if you believe the manufacturer, who assures that their service life is at least 10 years;

- High temperature resistance;

- High moisture resistance;

- High soundproofing characteristics;

- Low weight of the panels;

- The ability to choose a variety of drawings, patterns, imitation;

- Low price.

Obviously, these advantages are already enough to draw attention to this material. Cons of PVC panels:

Cons of PVC panels:

- When heated and burned, they release substances that are unsafe for the human body;

- With a sharp temperature drop, they are prone to deformation;

- They are "afraid" of mechanical shocks;

- Pests can grow in the gap between the wall and the panels;

- Not always convincing in appearance, they can look fake, cheap.

Of course, it is worth mentioning how to fix such panels. There are three popular fixing options: with the use of lathing, with the use of fastening clips and mounting plates, with the help of liquid nails.

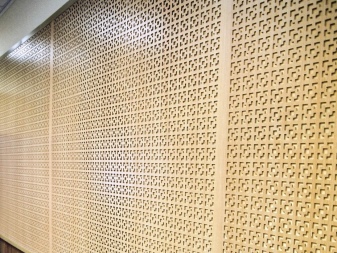

Decorative MDF panels

Wall panels made of MDF for an apron are used quite often, and it should be said that this is a reasonable choice.

The MDF panel has a wood texture that will undoubtedly fit into many styles: for example, country or loft

The MDF panel has a wood texture that will undoubtedly fit into many styles: for example, country or loft

Judge for yourself, MDF panels:

Very dense, hard, durable;

It is a safe, environmentally friendly material, which cannot be said about the same plastic panels;

These wall panels do not require special, special care;

They are highly resistant to moisture;

This is a fireproof material, which is very important in the kitchen;

It is processed, thanks to which it can be decorated with a variety of drawings and images;

Inexpensive;

Not afraid of fungi and mold;

Easy to install.

It is not necessary to install MDF wall panels on a perfectly flat surface.

Wall panels were stripped off in the kitchen

Skinali - this is how modern glass wall panels are called, which are distinguished by photo printing made with special equipment.

In addition to various patterns, images of nature can also induce an appetite in any person.

In addition to various patterns, images of nature can also induce an appetite in any person.

Blurred abstraction is in vogue today, but if you are a conservative, then still lifes, floral images will be a good choice.

You can install such panels in any kitchen - they, thanks to the color and pattern, can create a variety of effects. For example, expand the space, make accents, play along with the dominant colors in the interior.

Panel fastening safety

The purchased panels must be fixed. You need to know how to fix a wall panel. To be strong and safe. It is best to attach it to the lathing. This is how it is done. Take wooden slats or metal. Concrete is drilled in the right places. The slats are attached to the wall.

With the help of screws - reinforced in concrete. Since wood can rot, smart people came up with the idea of covering the wooden crate with insulating materials used to isolate the foundations of summer cottages during construction.

Then the crate sits firmly on the wall, and the panels can be easily attached to the frame. Without fear for the wooden base. If there is a decision to make a metal grill, then steel is better. A high-quality frame is provided. But there is also an easier way of fastening.

This is to attach the panels directly to the wall. Prepare the mount. And screw the panels directly onto the wall. You can still stick it on. For this, the concrete is prepared, primed several times. Then you can apply modern sealants. Stick the panel. Press until dry. But still, it will be better to fix it with a crate.

How to mount

If you do not want to spend money on installing panels by professionals, then you can try to do it yourself. In order for the panels you have pinned to last as long as possible, they need to be properly secured.

There are also certain features of the installation of panels. Firstly, it is undesirable to install panels in the cold season. The fact is that almost all types of panels are sensitive to temperature changes. Therefore, in the cold season, when the heating is on, they become susceptible to temperature changes.

One of the most sensitive materials is plastic. When the air heats up to more than 40 degrees, the plastic expands. This is worth remembering for those who install plastic panels in their kitchen. Leave at least a few millimeters between the panels so that the picture does not lose its attractiveness over time.

If the panels you are installing create a full-fledged picture as a result, then they must be installed in the correct sequence. The installation of panels begins with the design and calculation of the consumption of materials. This will prevent you from wasting extra money on unnecessary panels. Measure the space that you are going to cover with decorative panels and calculate how many materials you need for this.

So, for example, wood panels must be screwed to the wall with self-tapping screws, since they are quite heavy. But PVC panels are very easy to stick to the wall. True, for this it must first be aligned. Glass panels are fastened with a special groove system.

Features of mounting HDF panels

Installation methods for HDF boards are the same as for other apron boards. They are planted on an adhesive composition, fastened with self-tapping screws or on a crate. The latter method is used only in the case of a large curvature of the walls or if it is necessary to create a false box to hide communications.

To install the plates, be sure to use aluminum or plastic strips. They have different functions:

- the edging strip is installed on top of the panels, if the edge is not hidden by the attached objects of the headset;

- connecting elements are needed for the organic joining of fragments - they provide a strong connection, into the joint of which dirt or moisture will not clog;

- the corner piece can be external or internal, it is used to connect parts of the apron in the corners.

Planks are used for any type of panel mounting.From the tool you will need a jigsaw or a grinder, a drill with a cutter, a screwdriver, a level, a plumb line, a chopping thread, a construction pencil, a tape measure, a spatula and a mallet.

The main methods of fixing panels will be discussed in more detail below.

Algorithm for installing HDF on adhesives

- Free up space for work: remove the lower parts of the kitchen set, clean the wall of dust, debris and old coatings, treat with an antifungal primer.

- Measure, mark the places for the outlets.

- Cut off the necessary panel fragment, having previously tried it on the wall. Cut the slab as carefully as possible, since the material tends to crumble.

- Cut out the holes for electrical outlets with an appropriately sized cutter.

- Install the edging profile on the self-tapping screws.

- Apply liquid nails, hot glue or other compound to the back of the board and to the wall for better adhesion. Disperse the mass evenly so that no cavities form.

- Fit the panel to the edging and press it firmly against the wall, wait until it engages.

- Use a mallet to achieve the perfect vertical level of the panel by knocking it in the places where it starts to protrude. Additionally, this will provide maximum grip.

- In the process of fixing the plates, install, if necessary, a connecting or corner profile, duplicating the connections with a sealant.

Fastening the apron with self-tapping screws directly to the wall

Installation of HDF kitchen wall panels using self-tapping screws is carried out according to a similar algorithm with the above. The method of installation differs only in the direct fastening of the slab to the wall. Instead of applying adhesive to the panel, drill holes in the wall and hammer in the dowels. Install the plate and screw it with self-tapping screws directly to the wall using a screwdriver.

Instead of self-tapping screws, you can use “quick installation” dowels. To do this, drill holes in the panel and hammer the fasteners into the prepared areas on the panel and wall. The unsightly caps of the self-tapping screws are hidden either by cabinets or by special plastic plugs, which are best placed on a sealant.

Installation of panels on a crate

This method is used if it is necessary to hide it under the communication panel or in the case of a large curvature of the walls.

For the lathing, wooden slats 20x40 mm or an aluminum profile are used. Consider the features of panel installation using the example of a wooden frame:

- Surface preparation is different in that wallpaper or old finishes can be left in place.

- Measurements and cutting of panels are made in the same way as for other installation methods.

- First you need to prepare the slats. Cover the material with an antifungal compound or linseed oil, then dry well. This is done to increase the resistance of wood to the conditions of the kitchen.

- The slats are attached to the wall using quick mounting at a distance of 400-450 mm. They can be installed both parallel and perpendicular to the floor.

- Do not forget about the use of connecting strips, corner strips and edging.

- Attach the panels to the rails directly with self-tapping screws.

- Seal the joints with sealant for maximum joint strength.

Next, install the lower modules and secure the protective plinth, not forgetting about silicone or sealant.

Types of panels for the kitchen

There are various types of wall panels for the kitchen, each of which is recommended for use in certain cases or depending on the interior of the room. They can be conditionally divided into wall and universal. The first type is a finishing material only for walls, and the second one can be used for the ceiling as well.

Main types:

- Glass panels for the kitchen. The best option for creating an apron. Also, with the ideal choice of pattern and color, the glass looks good on the ceiling. However, it is impractical to use glass for decoration of all walls.It is better to combine glass panels for the kitchen with other decorative and finishing materials. With the help of such a material, it is possible to obtain an ideal gloss, as well as an easy-to-clean surface.

- MDF panels for the kitchen. Not the best for kitchen use. It accumulates moisture and grease and is also easily damaged. However, if such sheets are laminated, you can get rid of almost all the negative characteristics of the material. Such panels can be colored, brick-like, patterned or photo-printed. Separately, it should be noted acrylic panels for the kitchen, which have good characteristics and at the same time affordable cost.

- Plastic panels for walls. One of the most affordable wall decoration options. Differs in medium density, original design and ease of maintenance. PVC panels for the kitchen can be of various thicknesses and densities. Thin white panels can be used for the ceiling, and colored sheets of maximum thickness for the walls. For finishing, matte or glossy panels are used, monochromatic, with photo printing or a brick look.

- Chipboard panels. High-quality fiberboard with proper care can last a long time. Most often they are laminated to protect the material from moisture and grease. They create a perfect gloss that is easy to maintain.

- Panels made of postforming and artificial stone are made of chipboard, on which a polymer coating is applied. This allows you to make a panel for brick, stone or other natural materials. For manufacturing, you can also use an artificial stone, which, although difficult to install, has a stylish design, durability, moisture resistance, as well as a beautiful appearance under a brick or natural stone.

- Tempered glass. One of the most popular design options for an apron, which in its characteristics is not inferior to ceramic tiles. However, you can create a variety of ornaments and real paintings on glass. For example, you can print a pattern for a brick or stone, color drawings for the design of kitchen furniture. They also imitate kitchen mosaics or ceramic tiles. Making mosaic designs with tempered glass is much easier than using real mosaics. In addition, dirt and mold do not collect between the joints.

It is worth noting the features of the installation of wall panels. The frame installation method takes more time, and is most often used if a large area cladding or ceiling decoration is required. In this case, it is not necessary to pre-prepare the base. At first glance, adhesive technology looks simpler. However, thorough alignment of the base is required before using it. In addition, this method is not required for finishing with ceiling panels.

Peculiarities

HDF is gaining more and more popularity. Literal decoding HDF - high density fiberboard. HDF and MDF are almost identical. The main difference between the first, as you might guess, is the increased density, and therefore strength. At the same time, HDF has a thickness of 3-4 mm, while the thickness of MDF is twice as thick and starts from 6 mm.

HDF is almost two times cheaper than natural wood, while the board is an excellent alternative to wood. Its physical, chemical and environmental performance is higher than that of fiberboard, although the panel itself is a relatively young canvas in furniture art.

Thus, it is quite obvious that HDF in many respects surpasses the known materials for the manufacture of furniture, as well as natural wood in price.

Due to its density, HDF is highly prized in industries:

- Sub-floor production. HDF is suitable as a base for laminate or natural veneer.

- Furniture manufacturing.HDF is gradually replacing plywood and finds itself in furniture cases, especially in the back walls, cabinet doors, and the bases of chest of drawers.

- Aligning walls and ceilings. HDF replaces fiberboard well when leveling floors and significantly reduces the time when leveling walls when replacing plaster and sanding.

- Basis for suspended and stretch ceilings. HDF is attached when they want to hide the wiring, for example, and other unaesthetic moments of repair.

- Automotive industry. HDF is used for interior decoration of vehicles.

- In the industry, containers and packaging are not made from HDF for food products.

The use of HDF as a material for the manufacture of kitchen aprons is no less common.

In addition to the above qualities, they have soundproofing properties, are safe for health, have a perfectly flat surface, are resistant to abrasion, are economical and easy to clean.

The characteristics of the panels are now more or less clear. It remains to figure out the properties that a kitchen apron requires:

- moisture resistance;

- heat resistance;

- hygiene;

- durability.

For all three parameters, HDF has high performance.

Flaws and dignity

HDF boards are made from high density fiberboard produced by dry process. On the front side of the boards, an image is applied using ultraviolet printing and then varnished. The standard dimensions of the elements are 2070x695x3 mm.

Advantages of slabs:

With a thickness of only 3 mm, such boards are very durable and resistant to all kinds of influences. Water, steam, open flame, dirt, boiling water, soot or fat get on them - all this is easily removed, and the decor retains its original appearance.

Durability of HDF panels. In comparison with other coatings, such an apron is able to serve for more than 10 years, undergoing constant stress and at the same time retaining all the saturation of the colors.

The material is environmentally friendly. Since the panels are made of natural wood, they are non-toxic and do not emit harmful substances even when heated.

The decorative qualities of the slabs are so diverse that they can be easily matched to any interior. The technology of photo printing allows you to apply absolutely any pattern or ornament to the plates.

This apron is easy to operate. No matter how dirty the material is during cooking, it can be easily cleaned with any non-aggressive and non-abrasive chemical agent.

The panels are easy to assemble. It is convenient to cut the slabs (if necessary, adjustment), there are several installation methods using different fasteners.

Plates can be installed even on the most curved surfaces

The high density of the material with its minimum thickness allows you to ignore the bends and unevenness of the base.

The anti-corrosion properties of the boards protect the walls from mold, which cannot be said about other apron panels.

In addition, the cost of such an apron is pleasantly surprising. Although the price depends on various factors, it is lower than the cost of the same ceramic tile. Increases the price of HDF panels for photo printing to order.

The high price for an exclusive picture is not the only drawback of HDF boards. The remaining flaws are as follows:

After several years of use, the outer layer of the varnish may turn yellow.

The standard dimensions of the slabs are limited and if it is necessary to cover a large area of the walls, additional costs for additional elements will be required.

When cutting, the material tends to crumble and requires a neat fit.

If a poor-quality apron is installed incorrectly, deformation of the plates is possible.

Low-quality cheap panels tend to deform from constant exposure to moisture

When buying boards, pay attention to the manufacturer .. The decorative qualities of HDF boards make the material unique.

Such an apron in the kitchen will become a real highlight of the interior.

The decorative qualities of HDF boards make the material unique.Such an apron in the kitchen will become a real highlight of the interior.

Laminated wall products: how to choose and install ↑

Laminated wall panels made of chipboard, MDF or HDF boards will cost a little more. Products made of wood fibers differ not only in cost, but also in characteristics. Chipboard products for wall surface mounting are produced in the form of boards in standard sizes.

Glossy laminated sheets design

Why laminated chipboard panels are better for walls in the kitchen? A conventional chipboard is a compressed shavings glued with acrylic-based glue. The upper part is a thin paper decorative film. Paper, under the influence of water or steam, begins to pass moisture into the board, wood chips swell.

Rack chipboard slabs in horizontal laying

In laminated panels, the top film, which imitates wood or stone, is covered with a transparent polymer layer - laminated. The polymer layer protects the paper and the inner structure of the material from getting wet, scratches.

Advantages of products from chipboard laminated with film:

- Moisture resistance.

- Durability.

- Wide range of finish design options.

Panels are sold in the form of slabs of different thicknesses. The size is selected depending on the degree of load on the surface.

Matte wood chips in a classic kitchen

Finished sheets are cut out. It will not be possible to cut out products of the desired shape on your own - the edges must be closed with special tapes, which are glued under the influence of high temperature. If you leave the cuts open, moisture will enter through the cracks and the top coat will peel off.

MDF boards are made by hot pressing. The production does not use adhesives that emit toxic substances. The bonding of particles inside the material occurs due to resins released during the heating process.

MDF panel: installation option

Such stoves for the kitchen can be installed on the wall in the working and dining area without fear of health: the material is absolutely harmless.

Instead of tiles, sheet panels

Advantages:

- Environmental friendliness.

- Affordable price.

- The possibility of fine processing.

MDF panels for wall mounting

Resistant to wetting.

New on the market - HDF panels. Plates with such markings are distinguished only by their increased strength. The decorative coating of the slabs, due to the flexibility of the material and the ability to cut out any shape, can be made in the form of stone, ceramic tiles, wood planks.

Laminated wall panels with a plastic decorative layer are especially popular. Instead of a paper textured film, a polymer PVC coating is glued to the surface. Among the options for the topcoat:

-

Glossy monochromatic surfaces.

- Skin texture.

- Imitation of the structure and shades of natural stone, wood.

Imitation of mosaic masonry

Plating with metal imitation: chrome, textured aluminum, nickel.

Sheets can be made with a uniform, even surface, or with the division of the top layer into fragments. Such panels are installed in the kitchen instead of tiles.

Laminated boards on the backsplash and countertop

A wide range of sizes of wall particle boards for the kitchen allows installation, both vertically and horizontally, in a limited area. When installing, as an apron for the working area, choose plates that are identical in color or in a contrasting shade. Often they carry out the installation of countertops and panels from the same slabs.

Vertical installation of MDF slats in wood texture

Kitchens with paneling of entire walls look extraordinary. Installation is carried out on special fasteners in the form of hooks. Sheets, depending on their size, can be quite heavy. Therefore, a metal frame is installed under the mount.

Laminated matte board in the form of a school board

If necessary, the sheets can be easily removed.It is not recommended to fasten the plates with screws directly to the wall or wooden lathing - if the integrity of the top layer is lost, the sheet will begin to get wet from the inside.

Varieties of wall panels for the kitchen

Panels are classified on several grounds:

- Depending on the size of the area. There are narrow panels in the form of a small strip above the worktop. This option is suitable for massive kitchen sets that take up most of the workspace. Full-wall panels, on the other hand, are chosen for the design of compact work walls; they look stylish and serve as a bright accent. It is recommended in each case to measure in advance the dimensions of the headset and walls in order to choose the best kitchen apron in size.

- Depending on the style of the interior, there are classic, modern, retro and eco-panels. Some emphasize the dignity of kitchens in a minimalist style, others look win-win in a vintage interior.

- Depending on the installation method, there are slatted, tiled, mosaic and sheet panels. Sheet panels are the simplest and most affordable option. The apron is installed on the wall using mounting glue. Tiled, slatted and mosaic require more effort, since they are installed in a certain order so as not to violate the integrity of the pattern.

- Depending on the material of manufacture, plastic, wood, glass, ceramic, metal, from MDF, fiberboard, chipboard are distinguished. The features of each material will be discussed in detail below.

Features of Plastic Kitchen Aprons

Plastic is the most popular option for wall cladding. The advantages include an affordable and low price, ease of installation and moisture resistance. Plastic is easy to clean with water and mild cleaning agents, and has heat and sound insulating properties.

A large selection of plastic aprons is also noted - it is easy to choose a panel for a kitchen in any style. The vertical arrangement of the panels visually raises the ceiling, the horizontal arrangement expands the space.

Cons - splashing water leaves streaks on the wall that spoil the look of the kitchen. Plastic is unstable and to mechanical damage, scratches and impacts, therefore, clean it only with soft sponges. The material is not resistant to heat, therefore it is not suitable for installation near a stove and other heat sources, it may melt due to high temperatures.

Wall panels made of MDF, fiberboard and chipboard

Models from MDF are distinguished by their strength and durability, attractive appearance and a variety of designs. MDF boards do not deform from moisture and steam, retain aesthetics and hygiene. This is an environmentally friendly material, it is more expensive than chipboard and fiberboard, however, it will last longer. MDF is easy to maintain and install, fits into any interior.

Ceramic kitchen apron

Tiled or mosaic options are made from ceramics. They look sophisticated and stylish, fit into vintage, classic, Provencal interiors. Patterns with Scandinavian or Mediterranean motives are popular, where each tile has an original pattern. The ceramic apron serves for more than a dozen years, does not deteriorate due to water, temperatures, steam, sunlight. For care use soapy water or chemical cleaning agents.