What is a primer, what primers are

A primer is a liquid that prepares the surface for the next coat. It is clear that the "surface" is different, with different characteristics and problems. And "next layer" is also a very general name. The purpose of the primer is to improve the conditions for laying the next layer. To solve various problems, compositions of different properties are needed. Therefore, there are many soils and they act in different ways.

To choose the right type of primer, you need to imagine what you need it for, what problem it will solve

To choose the right type of primer, you need to imagine what you need it for, what problem it will solve

It is necessary to select a primer based on what tasks need to be solved. And this means that you need to have at least a general idea of their types, how they change the properties of the treated surface. According to the properties of the primer, they are divided into three groups: adhesive, filling and deep penetration. More about what happens to the surface after processing with each of the compositions is further described in more detail.

Adhesive

The adhesive primer serves to increase the "adhesion" of the two layers. After drying, it forms a sticky film on the surface, therefore it can also be called a film-forming one. It often contains sand of different fractions for better "adhesion" of layers. Scope - low-absorbent bases.

Weakly absorbent substrates are metal, glass, tiles, smoothed (fermented) concrete. One of the most famous examples of an adhesive primer is BetonoKontakt. I advise you to use it almost everywhere, but it is needed only on very dense substrates that almost do not absorb moisture. In other cases, it is irrational to use it.

The most popular composition of adhesive primers - Betonokontakt

The most popular composition of adhesive primers - Betonokontakt

There is only one example of using Betonokosntakt for the floor: if you put new floor tiles on the old one. In an amicable way, it should be removed. But sometimes you need to raise the overall floor level. And after removing the tiles and glue, you lose the desired height. Removing the tiles, then pouring the screed is expensive and time consuming. If the old tile on the floor lies "tightly", the floor is even, then you can go through the old coating once or twice with Concrete Contact, and then lay a new floor tile. It's all. There is no other use for this type of primer on concrete floors.

Filling

Filling impregnations, on the other hand, are applied to highly absorbent substrates. They clog some of the pores, reducing and leveling the absorbency of the surface. It makes sense to apply them on loose surfaces. In the case of concrete floors, fill-in treatments can be applied before:

- Painting or varnishing. To reduce the consumption of paints and varnishes.

-

Under the tile adhesive. In case it is necessary to extend the "lifespan" of the glue. Due to the fact that water will be absorbed less, it will remain mobile for longer. This will give more time to bring the tiles into the level.

- Before gluing the floor covering directly onto the screed. Some coatings (linoleum, parquet board, carpet) can be glued directly onto a flat concrete floor. To reduce the consumption of glue, you can walk through the filling primer.

If you are preparing a concrete floor for painting, so that less paint wasted and it lay smoother, it makes sense to cover it with a filler primer. A diluted paint and varnish composition is often used as this primer before painting. This gives the primary color, reduces absorbency.After all, any floor paint clogs the pores, and therefore fulfills the task of a filling primer.

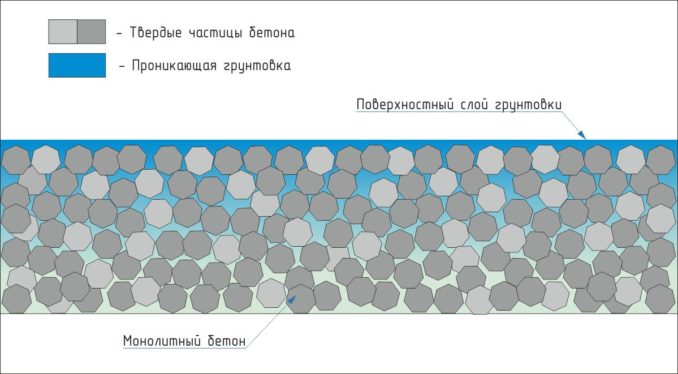

Deep penetration

Deep penetration primers are used on surfaces that are constantly dusting and crumbling. Soil components penetrate through the pores deep into the material, bind (glue) unstable particles together. Thus, the material becomes denser and less dusty. This composition has almost no effect on the amount of absorbed moisture. Deep penetration primers are also called penetrating or strengthening.

This is how deep penetration primer works on concrete floors

This is how deep penetration primer works on concrete floors

Actually, strengthening is a special subspecies of this type of soil. They contain more adhesive components. So when processing with a deep penetration strengthening primer, due to the adhesion of material particles to each other, it becomes less dusty or free-flowing. If you want the concrete floor to be almost free of dust, it can be treated with a deep penetration reinforcing primer. The effect is the same as when painting, only without changing the color.

Preparation of concrete walls for plastering

The process of preparing interior walls made of concrete for plastering consists of the following stages:

- The old coating is removed in the form of fragile plaster, whitewash, paint (in which cases it is possible to apply plaster on old paint, we recommend reading here);

- Defects of concrete walls are determined. If there are nodules, they are cut down with a hammer and chisel. Massive chips and deep cavities are sealed with a cement-sand mortar in a ratio of 1: 3, if necessary, steel meshes are used for reinforcement;

- On smooth walls, notches are made with a hammer and chisel, the maximum step of the notches is 10 cm;

- If a hidden wiring device is needed, wire strokes are made;

- The concrete surface is cleaned. A brush and water are used to remove dust and dirt. Wall treatment can be carried out using compressed air or a strong jet of water, which significantly speeds up the cleaning process;

- A primer is applied to the wall surface.

Notches on the concrete wall

Notches on the concrete wall

We'll talk more about the types of primers for concrete walls later.

Priming concrete walls before plastering

Priming of concrete walls is necessary in order to:

- Reducing the absorption of water from the solution into the concrete base;

- Protecting the concrete wall from the formation of mold and mildew;

- Increasing the strength of the protective (surface) concrete layer;

- Dedusting the concrete surface. The primer binds dust particles and makes the substrate clean;

- Improving the adhesion of the plaster to the concrete base.

Applying a primer to a concrete wall

Applying a primer to a concrete wall

Next, we will consider how to prime concrete walls in front of plaster:

- For smooth concrete surfaces, concrete contact primers are ideal. After application, the composition fills the pores in the concrete, and a rough layer with high adhesion forms on the surface, which contributes to good adhesion to the future plaster. We recommend formulations of the following manufacturers: Feidel Betokontakt, Knauf Betokontakt, Prospectors Beton-Kontakt.

- Old concrete surfaces can be reinforced with a deep penetration primer specially formulated for impregnating fragile substrates. Such a soil impregnates the top layer of concrete, thereby strengthening it and giving it the necessary strength. From manufacturers we recommend: Prospectors "Deep Penetration", AquaNova "Nova", Optimist acrylic "Deep Penetration".

Deep Penetration Prospector Primer

Deep Penetration Prospector Primer

For the preparation of porous concrete surfaces (aerated concrete, foam concrete), primers are required that reduce the absorbency of the base, thereby preventing uneven setting of the solution. The following primers are perfect: Knauf Mittelgrund, Knauf Rotband Grund (for gypsum plasters), Ceresit CT 17, Toiler TR10.

Remember to follow the manufacturer's instructions when applying the primer to the substrate. As a rule, the primer must be shaken before application, and the application process itself must be carried out in several layers.

Installation of beacons and reinforcing mesh

If the old wall has drops of more than 10 mm, then it is necessary to install beacons before applying the plaster. Lighthouses are needed for even application of plaster in the same layer in thickness. It is better to use metal profiles as beacons.

Lighthouses on a concrete wall

Lighthouses on a concrete wall

If the thickness of the planned plaster is more than 20 mm, then it is necessary to additionally arrange a reinforcing mesh. The mesh is fastened to the wall using dowel-nails.

Next, you need to prepare the solution in accordance with the manufacturer's instructions. To avoid the formation of lumps, add water to the dry mixture, and not vice versa.

Classification of primers according to the main component

Today, primer compositions are most often found on sale, based on: polyurethane, acrylic, natural components, polyvinyl acetate, epoxy and other components. Let's consider the most popular ones.

Polystyrene (polyurethane) primers

Polyurethane concrete primers are used very rarely for surface treatment of living quarters due to their high toxicity. Solvents included in such liquids are recommended to be used only for finishing facades or industrial premises.

Polyurethane concrete floor primer is considered to be the most resistant to chemical and weather conditions, and it also gives the surface high strength. This makes it the optimal concrete coating component for outdoor use.

Acrylic primers

Acrylic-based mixes are more suitable for interior work, as they are environmentally friendly and do not exude a pungent chemical odor. Such components are combined with any finishing materials and have good absorbency. In addition, acrylic compounds dry no more than 3-4 hours. If you need a primer for aerated concrete, then you should choose this particular composition. However, it is better not to use such primers for the outer walls of the house, as in the open air such a protective layer will dry out too quickly.

Water based primers

Such liquids are absolutely harmless to human health, so they can be safely used in poorly ventilated rooms and for children. The main advantage of water-based primers is the ability to apply to dry surfaces. In addition, when working with such a primer, there is no need to use protective equipment, since it does not smell. Solutions of this type are cheaper than others.

Organic primers

Compositions based on natural components penetrate well into the structure of the treated concrete surface. Such mixtures can be used at low and subzero temperatures. However, organic primers have the shortest lifespan. This fragility is due to the fact that they evaporate rather quickly.

You should not use this type of primer indoors, as it has a pungent odor.

PVA and epoxy primers

Polyvinyl acetate formulations dry the fastest (no more than 30 minutes), so it is recommended to use them if you are pressed for time. To improve the adhesive properties, after applying such a primer, it is better to cover the surface with an additional layer of PVA glue.

Epoxy primer for concrete is made on the basis of resins and is often used in surface preparation for self-leveling floors. Epoxy increases the durability of concrete.

Application technology

Primers are sold in the form of a ready-to-use solution or as a dry mix. In the latter case, read the instructions for preparation included in the package.The amount of water for dilution should be the same as indicated in the manual - most often 1: 1. With an increased volume of liquid, the solution may lose its properties, and with a reduced volume, the applied material will subsequently delaminate and it will be necessary to carry out the work again. Some types of primer will need to be constantly and thoroughly mixed during operation.

It is necessary to observe safety rules when working: put rubber gloves on your hands, protect your eyes with glasses. If drops of the solution get on your face or clothes, you should quickly rinse them off with warm water or wipe them with a damp cloth. If the composition has a pungent odor, then it is worth using a respirator to protect the respiratory tract.

Preparation of the base

This stage is especially important, you cannot skip it. If the base is properly prepared, then in the future you can get a resistant and durable coating, a uniform, quickly drying layer of soil, a smooth surface without defects.

The main stages of the work:

- During the renovation, the old finish is removed and the concrete surface is cleaned until a structurally sound concrete base remains.

- The surface is cleaned of oil stains, dust, debris, and, if necessary, dried.

- All large cracks are carefully repaired, irregularities are eliminated, the metal elements present are cleaned of rust.

How to apply correctly?

For processing large areas, it is better to use a roller, pass difficult places with a brush. Spraying the mixture with a spray gun will significantly speed up the process. At the same time, a little more liquid is added to the concrete primer, about 5% of the total volume of the mixture, so that it does not get stuck in the hoses and nozzle.

Basic rules for applying the solution:

- The soil is made homogeneous by thoroughly mixing with a construction mixer.

- The applied layer should be as uniform as possible.

- Works are performed only at positive temperatures - from +5 to +30 ⁰С.

- Very porous surfaces are primed in several layers.

- Large cracks and crevices are filled in 2-3 layers.

- The next layer is applied only after the previous one has completely dried.

- The humidity of the ambient air must be stable, no more than 65-80%, otherwise the solution will foam and become unusable. The exception is polyurethane compounds.

It is necessary to work carefully, try to avoid streaks on the walls, and puddles from the soil mixture do not form on the floor.

It is required to wait for the primer to dry completely, and then proceed to the decorative finish. If the base crumbles, the procedure is repeated.

Application features

It is not difficult to apply the primer, but for the most effective result it is better to do it in several layers - optimally in 3 layers. To prepare the material for the first layer, it is necessary to take 4 times more water than the primer itself, for the second layer, take twice as much water as the primer, and for the third layer it is unnecessary to add water. Allow the previous one to dry before applying each subsequent ball. Works are best carried out at a temperature of + 5 ... + 25? С. Naturally, before applying the primer, you need to tidy up the surface itself: it must be clean, dust-free, free from cracks and seams.

How to use it correctly?

But for a high-quality performance of work, it is not enough just to purchase a high-quality primer for metal from a reliable manufacturer, you also need to use it correctly.

Algorithm of work for its application.

- It is necessary to prepare the work surface. All dirt, remnants of the previous paintwork should be removed from it, as well as strong rust spots should be removed.

- Grinding the metal will improve the absorbency of the primer and prepare the work surface more thoroughly. But do not confuse grinding with polishing.When polishing, the surface is completely flat, and sanding makes it slightly rough. It is the roughness that improves the adhesion of the primer mixture to the metal surface.

- Do not apply too thick primer immediately. If multi-layer application is necessary, each subsequent application is best applied three hours after the previous one.

- After working with the primer, it is imperative to wash the entire tool, the container with the product should be tightly closed and sent for storage to a place that fully complies with the requirements and recommendations of the manufacturer.

- Do not use a primer intended for outdoor use during interior work and vice versa. In this case, the mixture will not be able to fully fulfill its protective functions, and its service life will be significantly reduced.

Correct use of primer mixes is 50% of the successful completion of all work. Deviation from the specified recommendations or from the manufacturer's instructions may lead to the appearance of serious problems both directly during work and after their completion.

The priming of metal structures of any type is necessary not only to improve their appearance, but also to increase their service life. At the same time, some varieties of such compositions allow not only to improve the adhesion of the metal, protect it from the negative effects of moisture and rust, but also increase the strength of the structures themselves and make their color brighter and more saturated.

But it should be understood that a single use of a primer is not a panacea for all ills. It is certainly necessary and important, but the period of its positive effect on the metal has a limited time. On average, a conventional single-phase primer protects structures inside a building for up to 15 years, and outside it for 7-10 years. If we are talking about universal primers 3 in 1, then the duration of their protective functions does not exceed 5-7 years.

Primer application technology

In the assortment of modern building stores, you can find two types of soils: dry mixes and ready-to-use formulations. The technology of preparation and application of each of them is always indicated on the packaging.

Among the features of the preparation of dry representatives, the need for precise proportions should be highlighted. Excessive addition of water can violate the properties declared by the manufacturer.

The procedure for applying the composition should be carried out at positive temperature conditions and the humidity level specified in the manual. When the latter indicator changes, the applied liquid can form a foam, which will signal its unsuitability for use.

Mixtures are most often applied in two layers by spray or roller, in the absence of appropriate equipment or the impossibility of using it - with a brush.

Surface preparation for priming

In order to successfully complete the surface treatment, the following sequence of actions should be followed:

- Cleaning from debris and third-party dust.

- Sealing cracks and voids with putty.

- Cleaning grease and bitumen stains with solvents.

A clean and smooth prepared surface will significantly reduce not only time and labor costs, but also reduce the volume of fluid used.

Properties and characteristics of alkyd primer

Alkyd primer is a suspension consisting of several components:

- filling part;

- drier;

- solvent agents;

- additives of stabilizers.

The main structural component is alkyd varnish. And the general composition of varnish and other components is called glyphthalic (GF). The scope of application of the primer is the treatment of wood and metal surfaces.

Also, the composition is excellent for glass, concrete, plastic or steel substrates. Depending on the type of base, the following types of alkyd primer are distinguished:

For wood

Designed to strengthen the structure of wood, impart density to it, as well as improve adhesion properties. The soil is characterized by the presence in the composition of antiseptic additives that protect the wood base from mold and insects.

The applied alkyd primer for wood is subject not only to painting, but also to putty using acrylic-containing compounds.

For metal (anti-corrosion)

As a result of the formation of the thinnest film on the metal surface, the alkyd metal primer serves as a barrier to moisture penetration, thereby minimizing the likelihood of corrosion.

The role of the main component of the composition is played by zinc phosphate. Since the metal is a hard and smooth base, the anticorrosive alkyd primer performs another function - it increases the adhesion of the paint to the base by creating a rough layer.

Universal

This group includes the alkyd primer GF-021. It is distinguished by a set of universal characteristics, thanks to which the composition interacts well with any surface. The universal acrylic primer gains its versatility due to the use of zinc chromate.

Alkyd urethane primer

The composition is used for the treatment of metal and wood substrates for industrial use. Unlike pure alkyd primer, it is a combination of additives dissolved in uralkyd resin.

Alkyd-urethane primer forms a film that is resistant to not only positive, but also negative temperatures (up to -45 ° C).

Alkyd primer, the price of which varies from 220 to 350 rubles. per bucket 10 kg, compatible with paints based on alkyd varnish or acrylic, alkyd-containing impregnations, polyvinyl acetate glue, nitro paint, and acrylic putty mixtures.

The use of an alkyd primer is not recommended for gypsum, previously plastered walls or other crumbling surfaces.

Specifications

Peculiarities

To understand how important a primer is for concrete surfaces, you need to know all its features. First of all, it serves to protect against mechanical and chemical influences.

Surface treatment is necessary due to the following factors:

- The structure of concrete is porous, which is why it absorbs moisture, which destroys the material. The primer thoroughly clogs the pores, significantly reducing the absorbency of the substrate. This extends the life of the structure.

- The concrete surface does not adhere well to some materials. The primer improves adhesion and increases the strength of the coating.

- The top layer of cheap concrete is brittle and the primer will strengthen it. Therefore, material processing is mandatory in rooms with high climatic or mechanical stress.

- Almost all formulations have antiseptic properties. This prevents mold and mildew from growing on the surface.

The primer guarantees good sealing of walls and floors, retains strength and improves performance. That is why it can be used not only before finishing the floor, but also as a topcoat.

Outdoor aerated concrete primer

Finding a suitable composition for external processing of aerated concrete blocks is not difficult. The presented assortment of soils allows you to choose the best option in terms of price and quality.

The most popular types.

- Aquastop Facade by Eskaro. Has a vapor-permeable and water-repellent ability. The composition contains silostan. The drying time of the layer is 2-6 hours. Water is used as a diluent.

- PGS-116 from Polyplast. Vapor-permeable, adhesive primer. After drying, the surface becomes rough, which enhances the adhesion between the aerated concrete and the finishing layer. The emulsion does not require dilution and is sold ready-made, which simplifies application. Drying time of the protective layer 3-6 hours.

- E-110 from Siltek.The primer has a strengthening and water-repellent effect with an acceptable level of vapor barrier. To achieve maximum results, the product is applied in 2-3 steps. Drying time - 4-6 hours.

- It is used for materials with increased absorbency. The soil penetrates deep into the aerated concrete, significantly increasing its strength and adhesion. The protective layer provides protection against fungus for a long time due to the addition of fungicides to the emulsion.

Classification of primers according to the main component

Today, primer compositions are most often found on sale, based on: polyurethane, acrylic, natural components, polyvinyl acetate, epoxy and other components. Let's consider the most popular ones.

Polystyrene (polyurethane) primers

Polyurethane primers for concrete are used very rarely to treat the surfaces of living quarters, due to their high toxicity. Solvents included in such liquids are recommended to be used only for finishing facades or industrial premises.

Polyurethane concrete floor primer is considered to be the most resistant to chemical and weather conditions, and it also gives the surface high strength. This makes it the optimal concrete coating component for outdoor use.

Acrylic primers

Acrylic-based mixes are more suitable for interior work, as they are environmentally friendly and do not exude a pungent chemical odor. Such components are combined with any finishing materials and have good absorbency. In addition, acrylic compounds dry no more than 3-4 hours. If you need a primer for aerated concrete, then you should choose this particular composition. However, it is better not to use such primers for the exterior walls of the house, as in the open air such a protective layer will dry out too quickly.

Water based primers

Such liquids are absolutely harmless to human health, so they can be safely used in poorly ventilated rooms and for children. The main advantage of water-based primers is the ability to apply to dry surfaces. In addition, when working with such a primer, there is no need to use protective equipment, since it does not smell. Solutions of this type are cheaper than others.

Organic primers

Compositions based on natural components penetrate well into the structure of the treated concrete surface. Such mixtures can be used at low and subzero temperatures. However, organic primers have the shortest lifespan. This fragility is due to the fact that they evaporate rather quickly.

You should not use this type of primer indoors, as it has a pungent odor.

PVA and epoxy primers

Polyvinyl acetate formulations dry the fastest (no more than 30 minutes), so it is recommended to use them if you are pressed for time. To improve the adhesive properties, after applying such a primer, it is better to cover the surface with an additional layer of PVA glue.

Types of primers

Today, the following types of material can be found on sale.

Acrylic primer

The polymer composition provides high adhesion, strengthens well, protects the base from water and chlorine-containing compounds. It is applied to ordinary concrete covered with plaster or paint. The finished layer is able to successfully withstand external negative influences, has a stable shade, and has antiseptic properties.

It dries quickly - up to 5 hours, so it can be used with a tight deadline for work. Easy to apply, improves adhesion. As a result, the pores are reliably sealed, there is no concrete dust, steam and air freely circulate through the finished layer. Safe for health. It is undesirable to use it for processing the facade parts of buildings.

Firming primer

Refers to the type of soil intended for surfaces with low absorbency. The composition contains quartz sand. As a result, the surface is slightly rough, which ensures the best application of a decorative coating or arrangement of a self-leveling floor.

Forms a waterproof layer with waterproofing properties. Quickly penetrates into walls, ceilings, floors, closing small pores, strengthening, dust-free concrete surface, increasing the quality of adhesion to decorative materials.

For outdoor work

Deep penetration frost-resistant compounds do not form cracks and do not contribute to the delamination of finishing materials at low temperatures. Usually they are made on the basis of silicate or acrylic and are intended for mineral surfaces.

Primers penetrate the interior of the substrate, reliably seal the pores, preventing the penetration and absorption of moisture. So even with a sharp onset of cold weather, ice does not form in the thickness of the walls, which means that destruction does not occur.

Depending on the type of surface to be treated, the following concrete primer for outdoor use is offered:

Trading networks offer compounds for creating smooth surfaces well protected from moisture for finishing work: laying ceramic tiles, painting, plastering. There are soils with silicate filler for processing foam concrete, cinder blocks with a cellular structure. The mixture penetrates deeply into the smallest pores and closes them.

Verified brands: Reesa Tiefgrund, Weber, Tikkurila, Caparol.

For interior work

Such soil is usually odorless. For work, a latex, alkyd or universal acrylic variety is suitable. If you plan to decorate rooms with high humidity, then it is worth purchasing special formulations with antiseptic characteristics. A primer for absorbent surfaces increases the adhesion of the surface to mortar, glue, paint.

For concrete floor

A deep penetration primer is the best option for such a floor. It is absorbed into the concrete base, making it durable, while leaving the structure of the building material porous. A one-component polyurethane primer mix for concrete helps to reduce the looseness of the surface.

Today, two types of floor primers are produced, differing in the method of application: universal and specialized, which in turn are divided into mixtures for external or internal use. The former are in high demand, but are inferior in their properties and quality to the latter.

Some special solutions provide an increased degree of protection against stress, mechanical stress and aggressive external environment.

Types of solutions for purpose and requirements for future coverage:

- strengthening;

- acrylic;

- polyurethane;

- epoxy.

If there is looseness or damage on the surface of the concrete base, the mixture should be applied until it stops absorbing. The resulting film will indicate that the problem concrete area is well saturated.

Types of primers for mineral materials

For the processing of these materials, acrylic primers are used. They dry for 2-3 hours and do not have a pungent odor. Polyvinyl acetate solutions dry for half an hour and can be used for interior work. Then a PVA composition is applied to the surface.

For finishing plastered external surfaces, polystyrene compounds containing toxic solvents can be used.

The primer penetrates deeply into the concrete structure and strengthens porous materials, but is not suitable for loose surfaces. Adhesion is enhanced by the small latex segments included.