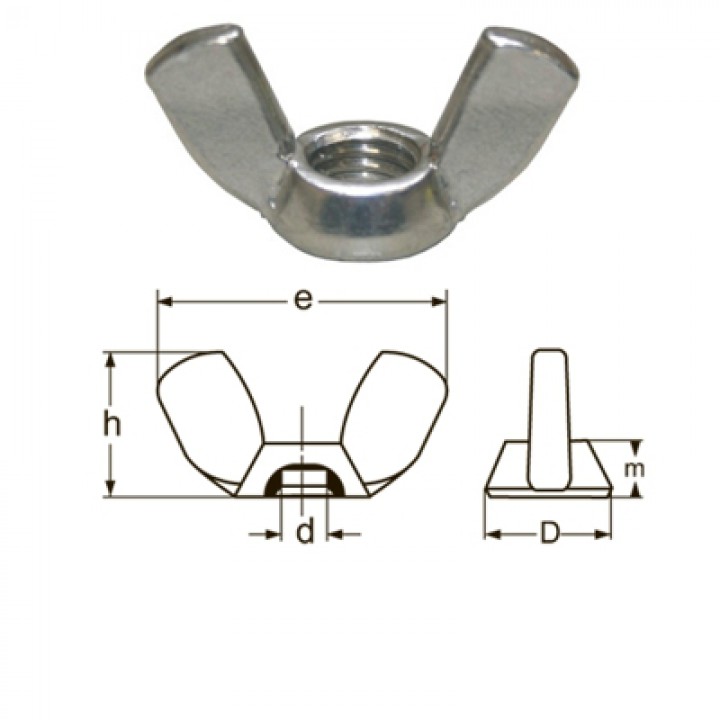

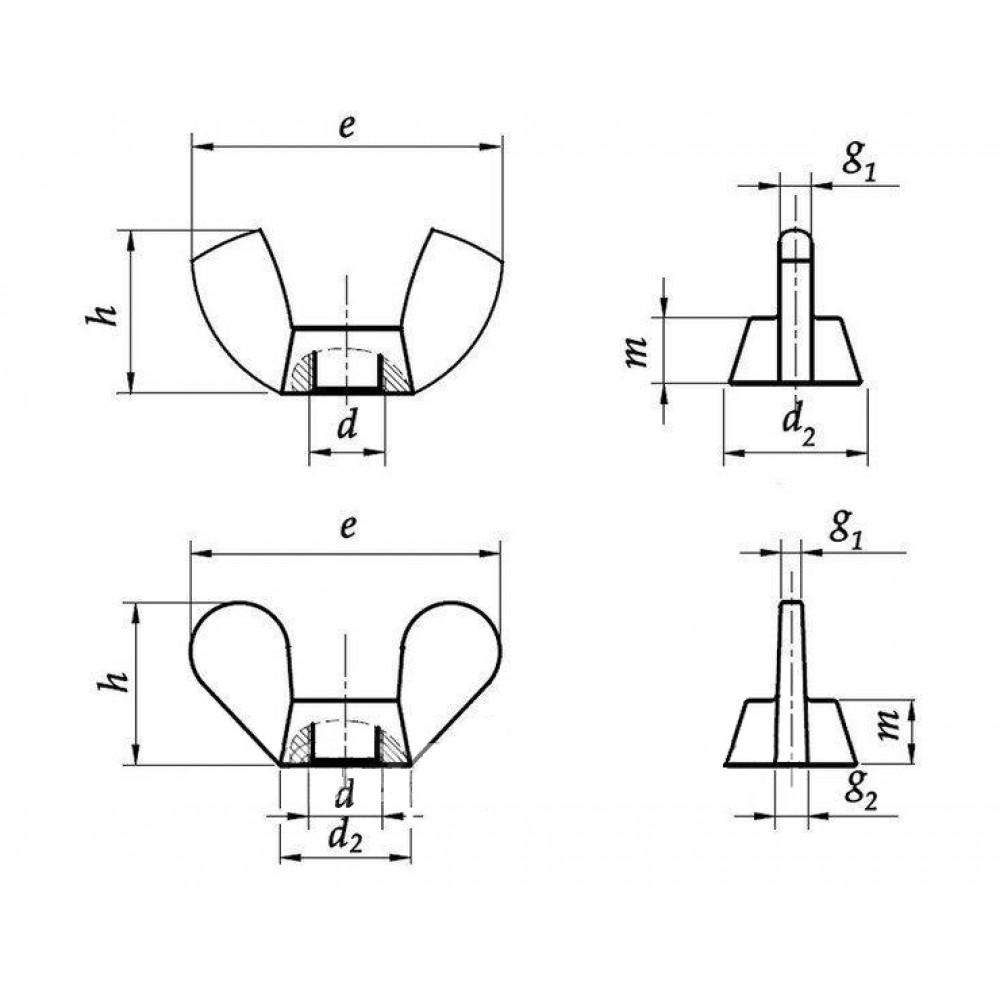

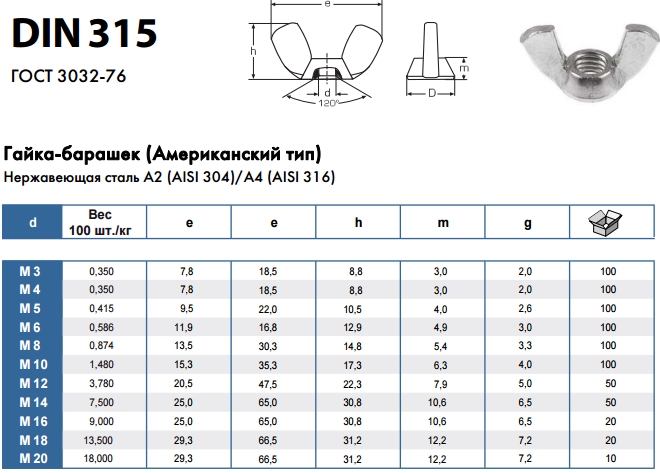

Dimensions (edit)

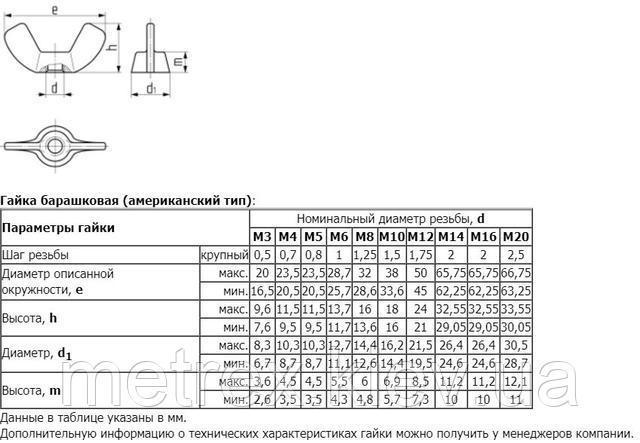

As indicated by GOST 3032-76, wing nuts differ in material of manufacture and size. The main parameter on which all the others depend is the diameter of the threaded hole. It conforms to industry standard bolt and nut sizes and markings.

The minimum standard size is M3. This means that the diameter of the bolt thread onto which such a nut can be screwed is 3 mm. A number of subsequent sizes of wing nuts looks like this: M4, M5, M6, M8, M10, M12, M14, M16, M18, M20, M24.

It is quite expected that the outer dimensions of the nuts will increase in the same order. Most German-style wing nuts have holes in the lugs. The purpose of the holes is not only to lighten the hardware: some craftsmen use them to fix the hardware in a certain position with a wire. But more often a cable or nylon thread is tied to them in order to avoid the loss of hardware.

According to the thread pitch, wing nuts are divided into products with coarse and fine threads, the pitch of which is determined by the size of the hardware. Only large threads have small lambs: M3, M4, M5, M6. Nuts M8 and beyond are available with both threads. This fact should be considered when buying fasteners. If there is no experience in determining the size of the thread, the stud or bolt on which the nut is supposed to be screwed can be taken with you as a sample.

Peculiarities

In the old days, nails or self-tapping screws were mainly used for the installation of wooden elements. However, as practice shows, these fasteners are not enough - the connection created by them weakens over time, and this can lead to injuries during the operation of furniture. That is why furniture nuts have come to the fore in recent years, they are optimal for the formation of high-strength joints.

The furniture nut is a fastening element with a threaded hole. It is made of galvanized steel, as well as of durable non-ferrous metal alloys.

The usual one is used in those areas of fixation where it is required to create the strongest adhesion with the possibility of further dismantling. The part is used to make a threaded and eccentric tie, allows you to create a movable, detachable and one-piece fixation.

Furniture nuts are widely used in the manufacture of kitchen and cabinet furniture, as well as in the assembly of bed frames and sofas. The hardware ensures the strength and durability of the connection, and greatly reduces the likelihood of thread breakage during operation.

Application

As already mentioned, wing nuts can be found wherever a lot of effort is not required, but often lightweight structures have to be mounted and dismantled.

Thus, steel products are used to install fuel filters on some engines. This structural element has to be changed quite often.

In addition, they can be seen on the lids of sealed thermos tanks. The covers have to be opened and closed several times a day, and it is unacceptable to damage the sealing gasket, which ensures tightness, by overtightening the nuts.

The use of such products for fixing hatch covers, sealed doors or windows is also based on this.

In some cases, closed-type fasteners are used (when the ears of the nuts are connected in the form of a metal loop). Such hardware has a higher decorative component, therefore, it can be used to fix some household appliances.

Galvanized and stainless steel lambs can be seen in demountable timber structures.For example, sketchbooks or easels, which are attributes of artists, have a number of adjustable and folding parts. It is impossible to imagine them without shiny lamb nuts.

Wing nuts are widely used in photography tripods, stage lighting and sound amplifiers. Installing and adjusting such equipment is required very often, and it would be very inconvenient to carry keys and screwdrivers for this.

Closed-type plastic wing nuts with steel cores are used for mounting some electrical measuring instruments and radio equipment. Here they make it possible to reliably isolate the fastening elements, preventing the possibility of short circuits.

How soft plastic fasteners are used when installing plumbing and other plumbing equipment has already been mentioned. But it should be clarified that any tool cannot be used with such material, since the force created when tightening by hand is quite enough in this case.

The next video shows you how to make a wing nut with your own hands.

general description

It is useful to start the conversation about the thumbscrew with the fact that the production of hardware in this category has been completely transferred to DIN 316. Other standards do not apply to this fastener. There is no specialized GOST either, so the maximum can be guided by the general GOST for screws, tool and structural steels. The screw shaft has a metric thread. It got its name for the characteristic geometry of the head, reminiscent of really small horns.

The petals of the head part can be rounded (then they speak of the German version). In the American version, rectangular geometry is more characteristic. The nominal diameter can range from M4 to M24. The basic norms for fasteners are fixed in DIN ISO 8992.

Appointment

Wing screws are recommended for those cases where you have to systematically assemble and disassemble threaded connections. Fasteners of this kind are convenient to use and install. You can screw such a device with your own hands, without using additional tools. Moreover, the use of keys is contraindicated. This can severely damage the petals, and in this case, the fasteners will be inoperative.

Thumb screws are widely used:

-

for assembling various types of furniture;

-

to create various containers and boxes;

-

as part of the clamping of the clamps;

-

in the process of assembling temporary fences and temporary structures;

-

in other cases, when ease of installation comes to the fore.

Fixing rules

Installing any furniture nut is not difficult, in fact it is a one-way process. The most important thing in the work is to adhere to the established sequence of actions, this will prevent deformation of the thread, as well as breakage of the bolt.

During installation, a nut tool of a suitable size is usually used, if you perform tightening without it, then there is a high risk of uneven force tension. The main requirements for tightening the nut are as follows:

- the nut to the landing site must be screwed loosely, it is possible by hand, avoiding hesitation, the final installation is performed with a key;

- in the process of twisting the hardware, the end should be located exactly perpendicular to the direction of the axial rod, the presence of potholes and roughness is not allowed;

- in the case of lengthening the bolt, the tightening process should be kept under control; in this case, the turn of the key is performed according to the angle of rotation of the nut.

Before the very beginning of the connection of the structure, it is necessary to complete a complete set of all hardware elements, to make sure that they are compatible in terms of the type of protective coating, type of steel and mechanical characteristics. At the same stage, one should take into account the type of installation, the readiness of the seats, as well as the general aesthetics of the final connection.

After completing the surface preparation and the hardware itself, it is necessary to clean it of grease, check the functionality of the functional thread.If damaged areas are found, thoroughly clean them and perform a visual inspection in order to determine the accuracy of the adhesion of the surfaces to be joined.

Tightening the nut directly begins with its landing on the wooden module and initial tightening by about 75%. Next, you need to make sure that there are no gaps around the entire circumference and if the mestizo is located correctly, perform the final tightening of the nut.

During installation, it is important to adhere to safety standards

The following video talks about the types of nuts.

Peculiarities

Both of these variants of wing nuts are now equally widespread. But the evolution of such manual fasteners did not stop there: new modifications appear, but now from other materials.

The main technical feature of the wing nut is its self-sufficiency. Of course, using it without a bolt or stud is impossible, but even these hardware are selected so as not to use a key or screwdriver to hold them. For example, a hairpin can be welded or have a loop instead of a head, with which it is movably attached to an object or part. The bolt should also not have a wrench head or screwdriver. For example, bolts used when installing wood products may have a rounded head and special stops that, when cutting into the wood, prevent rotation when tightening the fasteners.

The wing nut combines both fastening hardware and a tool for its installation. The need for such a fastener arises in cases where it is necessary to quickly tighten or loosen the thread of the fastener of a removable part, which is not a member of the supporting structures. Finding a wrench or screwdriver would take an unreasonable amount of time. At the same time, for functional fastening, the effort of one hand is sufficient without additional devices.

Views

Fasteners with a through hole are widely used in the furniture industry, while furniture nuts can vary in shape, as well as in the parameters of the internal thread. The most common hardware is a hex nut, its technological design allows for rotational movement progressively, evenly, without requiring special physical effort when tensioning.

Nuts can be made in a multi-sided shape, have a trapezoidal or metric thread. Different diameters make furniture nuts unique - this allows them to be used in any work, even when the weight of the structure is strictly limited.

There are several popular types of nuts on sale that are used in the manufacture of furniture.

Spherical - the model is a typical hex nut with a cap outer surface and a plug on one end of the threaded hole. It is used in detachable mountings. The cap helps to close bolts and other protruding elements, thereby reducing the risk of injury during product use, as well as giving the design an aesthetic appearance.

Hammered

Such nuts are mainly used in automated furniture production; they have not found widespread use in everyday life. In the factory, a hole of a suitable diameter is formed in the structure, after which the nut is hammered in with a hammer.

This ensures accurate assembly and high speed of work.

Mortise

These furniture fittings are manufactured from corrosion-resistant, zinc-plated stainless steel. Outwardly, this design resembles a sleeve, while the internal thread remains flat. A metal disc with a hole at the end is provided. This design allows you to firmly hold the hardware in the material and prevent the risk of twisting during the tightening process. Widely demanded for unilateral fixation.

Hidden

Hidden furniture nuts play a special role among the presented assortment of hardware. Their structure provides the most durable fastening when assembling furniture blocks of any type. A countersunk nut looks like a small bar with a metric type female thread.The hat is semicircular, decorative. All elements are manufactured from corrosion-resistant galvanized steel. Models are indispensable for assembling tables, as well as beds and cabinet furniture, it is distinguished by a decorative look - hardware is almost invisible on the outside of furniture, therefore it is often used in the manufacture of cabinet furniture.

Materials (edit)

Wing nuts are made from various materials. Metal fasteners are traditional.

Due to the small static and dynamic forces acting on the joints with such nuts during operation, carbon steels can be used for their manufacture. These alloys are relatively strong, their cost is low, but there is a minus - they corrode. In addition, such products do not always satisfy aesthetic requirements. Often, oil-impregnated coatings are applied to them in an attempt to slow down corrosion damage. For this reason, galvanized steel products are more common, not only successfully resisting corrosive processes, but also having a rather presentable appearance. In addition to zinc, other non-ferrous metals can be used to cover steel wing nuts: copper, nickel, tin, silver and their alloys.

The most durable are stainless steel hardware, however, combining strength and aesthetics, they have a high cost. But since such removable fasteners are never used en masse, the use of stainless steel is quite justified.

The unique properties of organic polymers have led to their use for the manufacture of fasteners with special requirements, for example, with increased resistance to moisture. Modern fasteners for furnishing bathrooms do not require increased strength, but water resistance is required. Therefore, here you can not do without plastic nuts, which do not require much effort during installation, tightening with one hand.