Facade cassettes: production features and technical characteristics of cassette facade cladding

Facade cassettes differ in composition

Facade cassettes differ in composition

The production of cassettes for facade cladding is carried out using aluminum, galvanized steel or composite materials. The method of their installation directly depends on the material from which the facade cassettes are made.

Cassettes made of galvanized steel are quite heavy. Therefore, when developing a project, one should take into account the significant load they put on the foundation of the building. In addition, it is necessary to take into account the fact that the frame on which the cladding will be attached must have a large margin of safety. As a rule, the frame for facade cassettes made of galvanized steel is made of a galvanized aluminum profile that can withstand a lot of weight.

Facade cassettes made of aluminum are stronger and lighter than steel ones

Facade cassettes made of aluminum are stronger and lighter than steel ones

Cassettes made of aluminum are characterized by a significantly lower weight, but at the same time they are significantly superior to their steel "brothers" in their strength characteristics. Due to its relative lightness, aluminum facade cassettes can be quite large, which, in turn, contributes to a significant acceleration of the installation process. It should be noted that the cost of aluminum cassettes is much higher than steel ones.

Composite cassettes are the lightest of their steel and aluminum counterparts. This material is distinguished by its cellular structure and relatively low cost. Most often, facade cassettes made of composite materials are used for cladding the facades of private cottages and residential buildings.

Composite facade panel device

Composite facade panel device

| When choosing composite cassettes for cladding the facade of your own house, keep in mind that some of them have a significant drawback: they can not only fade, but also deform under the influence of high temperature and direct sunlight. When buying, be sure to read the certificate of conformity for this product: it should say what temperature this finishing material can withstand. Today, several leading domestic companies are engaged in the manufacture of facade cassettes from composite materials, taking into account the requirements of GOST. |

The most common version of facade cassettes is galvanized steel cassettes. From above, the product is covered with a thin film of polymer paint. The color range inherent in steel facade cassettes is very diverse. Thanks to this circumstance, the broadest possibilities for design imagination open up.

In the domestic market, the most popular are facade cassettes of the MP 1005 and MP 2005 brands. The thickness of the steel sheet from which the facade cassettes of these brands are made can be different: the minimum indicator is 1 cm, the maximum is 1.5 mm. A distinctive feature of the cassettes of these brands is the presence of a protective coating made of PVDF or high-quality polyester.

The video demonstrates the production process of facade cassettes using the example of metal

The cost of MP 1005 and MP 2005 cassettes is quite high, which, however, is fully justified by their high performance properties. It should be noted that the price for similar foreign-made products is usually higher.However, this does not at all mean the technical superiority of the "foreigners" - domestic cassettes are practically in no way inferior to them, and sometimes even surpass them.

The choice of color solutions is practically unlimited

The choice of color solutions is practically unlimited

Consider the most important advantages of facade cassettes made of galvanized steel:

- High strength indicators and long service life without the slightest loss in the quality of the facade cladding;

- The design features inherent in this facing material allow its installation in a very short time;

- High indicators of facade protection from any adverse weather influences (rain, sudden and frequent temperature changes, ultraviolet radiation, etc.);

- Fire and environmental safety;

- In comparison with concrete slabs and finishing blocks made of facade ceramics, this finishing material has a significantly lower load on the foundation and facade of the building.

The materials for the production and manufacture of metal cassettes are:

- Galvanized sheet steel;

- Stainless steel sheets;

- Aluminum alloy sheets;

- Sheets of non-ferrous metals of copper and brass;

Advantages of a ventilated facade system made of metal cassettes:

- Modern and modern look and elegant facade design;

- High degree of fire safety;

- High level of safety - environmental friendliness and non-toxicity of the system;

- Resists sudden temperature changes, frost resistance;

- Facade cassettes - minimally susceptible to the influence of an aggressive environment does not rust, does not oxidize and does not absorb moisture;

- A wide range of colors for metal cassettes for facades;

- Ease of installation does not require costly preparation of the load-bearing wall of the building; it is easily attached and assembled into a common structure;

- Allows you to create a unique design of any complexity and configuration;

- High degree of strength and durability operation of the structure from 25 to 50 years without updating the appearance.

In order to produce such a project, the entire structure is measured first. This allows you to accurately determine the amount of cladding material because it is the most expensive component of the system of curtain ventilated facades. Without a competent preliminary calculation, we do not start our main work. The impeccable manufacturing of the elements also affects the speed of installation, because the metal cassettes must be ideally matched to each other only in this way the external attractiveness of the facade is created.

All metal cutting is carried out on special equipment and in strict accordance with laser cutting technology, therefore, the price of metal cassettes is high. Metal sheets processed with a laser beam have a perfectly smooth cut and precise dimensions. This simplifies further fit and fastening. The cassettes are mounted without any gaps, the surface looks perfect.

The external qualities of a facade cassette made of metal sheets are acquired due to special coatings for spraying powder paints. Depending on the design idea, cassettes are painted in one or another color or shade. But, in addition to the fact that powder coating gives excellent aesthetic qualities to products, it also acts as a protective layer that can protect the metal from atmospheric factors, temperature effects, mechanical damage, corrosion and ultraviolet radiation. Another option for external finishing of metal sheets is zinc coating and painting.

The use of facade metal cassettes is especially advisable in the case when the walls of the building are fragile, porous. So, a wall made of foam concrete or expanded clay concrete is an ideal surface for hinged systems made of metal cassettes

In addition, their weight is relatively low, which is important for these types of load-bearing walls.The shape of the facade cassettes can vary from squares to rectangles, but in any case, they are one of the most durable and reliable materials for facade systems.

Table 1. Optimal dimensions of metal cassettes for a ventilated facade from a sheet of 1.0, 1.2 mm

| Sizes of front open-type metal cassettes, metal thickness 1.0, 1.2 mm | ||||||||

| Cassette width L, mm | ||||||||

| 375 | 500 | 600 | 900 | 1150 | 1400 | 1700 | ||

| Cassette height H, mm | 375 | |||||||

| 500 | ||||||||

| 600 | ||||||||

| 900 | ||||||||

| 1150 | ||||||||

| 1400 | ||||||||

| 1700 | ||||||||

| - Optimal dimensions | ||||||||

| - Possible sizes | ||||||||

| - As agreed with the production (before ordering) |

Table 4. Optimal dimensions of metal cassettes for a ventilated facade made of sheet 0.7

| Sizes of closed-type front metal cassettes, metal thickness 0.7, 0.8 mm | ||||||||

| Cassette width L, mm | ||||||||

| 375 | 500 | 600 | 900 | 1150 | 1400 | 1700 | ||

| Cassette height H, mm | 375 | |||||||

| 500 | ||||||||

| 600 | ||||||||

| 800 | ||||||||

| - Optimal dimensions | ||||||||

| - Possible sizes | ||||||||

| - As agreed with the production (before ordering) |

I would like to note that the final cost of building a ventilated facade made of metal cassettes depends on the quality of the geodetic survey of the facade, the development of design documentation, since it is impossible to remake already manufactured metal cassettes to a different size, then low-quality design documentation or work without it will lead to significant losses for "marriage" ... In this respect, a ventilated façade made of aluminum composite panels is more flexible.

We offer the development of high-quality projects of ventilated facades at a reasonable price, which will allow you to ensure that you meet the financial plans of the project in terms of the supply of materials.

If you want to order hinged systems from metal cassettes - contact us, phones in contacts.

Description of metal cassettes

The metal cassette is a kind of box with very narrow sides. The shape is geometrically correct: square, rectangular, triangular, trapezoidal. Such a structure already presupposes the presence of an air layer between the material and the insulation.

The material is produced by stamping. The thickness of the product ranges from 0.5 to 1.2 mm, which depends on the weight and strength of the alloy or metal used. The sizes of cassettes can be very different.

Materials for making

Several well-known alloys are used for the manufacture of facade cladding.

Anodized aluminum - the material is resistant to corrosion and does not need any additional protection. In addition, aluminum is lightweight, so this cladding can be used to decorate old, dilapidated buildings. Aluminum is beautiful in itself - a light gray shiny material, so it is usually used in its original form.

Ventilated facade made of anodized aluminum cassettes

However, aluminum cassettes can be easily modified. The material is painted with polymer paint of any shade and can even imitate the texture of a natural material - wood, stone. In addition, the aluminum panel can have any configuration, up to complex curved lines.

Steel - stainless steel is used - a very expensive option, and galvanized. In this case, the finish has a characteristic steel color, the degree of gloss varies, and steel cassettes can be painted with polymer paint to give any other color.

Ventilated facade made of steel cassettes

Both the zinc layer, and polymer paint, and powder paint serve as protection for ordinary steel, since it is not resistant to corrosion. In addition, the steel cassettes are quite heavy, so here the load on the walls will be hefty.

-

Brass is a very expensive material and is rarely used. The color and shine remain natural.

-

Copper - or rather, copper alloys. As a rule, they are used in combination with cassettes of a different shade, since they have a very rich color and bright shine: a building completely clad with copper literally "burns" in the daylight. But how front sandwich panels are used for exterior decoration of a house, you can understand by reading the content of this article.

- Zinc-titanium - an alloy of two metals creates a material of exceptional strength and reliability. A zinc-titanium facade can last up to 150 years. The natural patina, which gives the material a mesmerizing matte finish, also serves as a protection against corrosion. In addition, the cladding is very light: the weight of 1 sq. m is 6-10 kg.

But how the facade is finished with foam and plaster can be seen in this video.

Mounting method

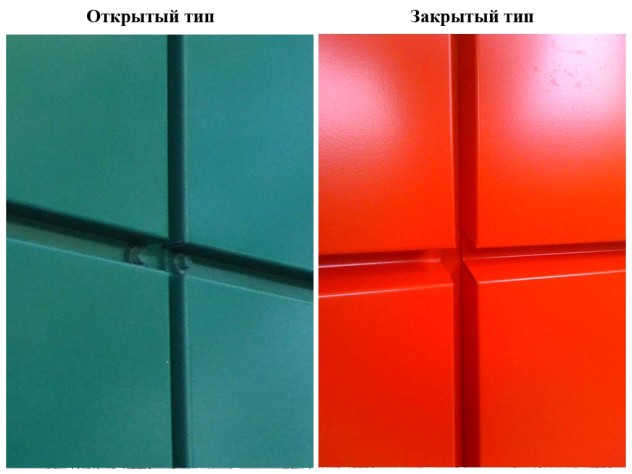

There are two types of ventilated facade assembly, respectively, 2 types of cassettes are produced.

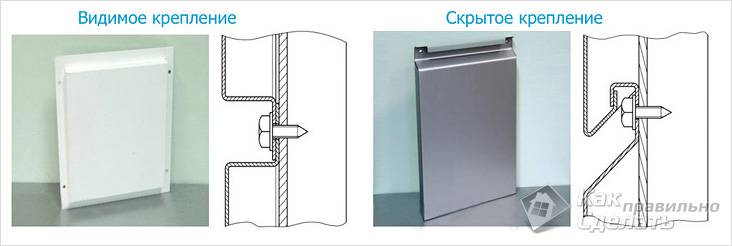

- Products for open fasteners - the cassette has folded edges with perforation for fasteners. Each panel is fixed separately to the frame posts. The next fragment is overlapped, the fasteners are selected to match the color of the finish. This method greatly facilitates future repairs, since the facade surface does not form a single whole.

- Option for concealed installation - during installation, each panel is inserted into the groove of the bottom and fixed to the self-tapping screws only in the upper part. There is only one bent edge, and it acts as a fixation point for the next cassette. The assembly is carried out from the bottom up, the first panels are inserted into a special starting rail.

In this case, the fasteners are hidden, the cladding gives the impression of being monolithic. In addition, this method increases the resistance to wind loads. It is much more difficult to repair it, since the cassettes are connected to each other.

You may also be interested in learning more about how to insulate the facade of a wooden house from the outside.

Video: calculation and insulation, finishing with metal cassettes

On the video, the facade cladding with metal cassettes:

You can also install cassettes using the hinged method. In this case, the products are fixed on U-shaped posts. The advantage of this assembly is that it can be repaired very quickly.

We also recommend that you familiarize yourself with the options for exterior decoration of the house.

Operational and technical characteristics of the curtain wall

The operational characteristics of the system of hinged ventilation facades include:

- small financial costs for maintaining systems;

- the IAF system is today the only correct thermal protection and protection of walls from destruction from an environmental and economic point of view;

- this façade technology is optimally suited both for cladding new buildings and for the reconstruction of already used buildings;

- the use of such a system provides an excellent opportunity to select and change the appearance of a building by varying the nature, texture, formats and colors of facing materials;

- the IAF system increases the service life of the building;

- the presentable appearance of the building remains for a long time and does not require special maintenance or regular repair;

- it is possible to replace individual parts without destroying the entire structure.

The profile system of hinged ventilation facades allows the use of various materials and panels for wall cladding.

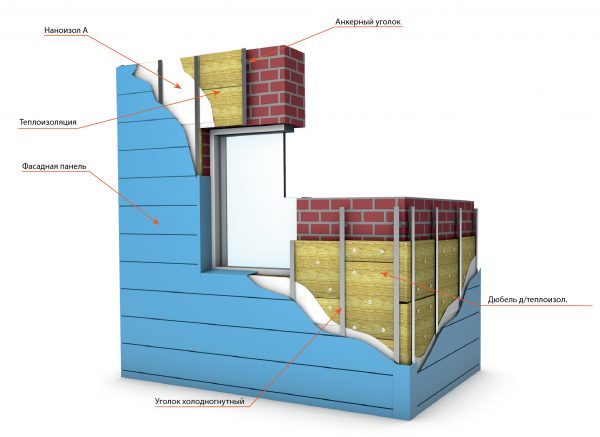

Moisture is removed through a special vapor-permeable membrane

The main technical characteristics of ventilated facades are:

- Protection from precipitation. The design of this system is designed so that moisture in contact with the dew point is removed into the drainage, avoiding contact with the insulation layer and the main wall of the building.

- Thermal insulation. The presence of insulation will help to reduce heating energy costs to a large extent. Also, thermal insulation allows you to reduce the thickness of the main load-bearing walls of the building, which reduces the load on the foundation. The insulation is protected from moisture, environmental influences, ultraviolet radiation and condensation thanks to the profile system of ventilation facades.

- Soundproofing. Insulation and external cladding panels themselves have excellent sound-absorbing properties in a wide frequency range.And the use of these materials in combination gives significant sound insulation (on average, the sound insulation of walls when using IAF systems doubles).

- Thermal insulation. Natural ventilation of the facade, which prevents the accumulation of excessive heat inside the building, is ensured by the use of insulation and a special profile system for ventilation facades. Thanks to this, an optimal temperature regime and a comfortable microclimate are formed inside the premises, which does not require the use of expensive air conditioning systems.

- Diffusion of water vapor. In the process of life in a person's house, unnecessary vapors are formed (using a shower, iron, cooking, etc.). Some of it is discharged through the ventilation, and some - through the "breathing" walls. Since the IAF system provides for natural ventilation of the walls, the formed moisture in the form of steam is removed without difficulty.

- Absorption of thermal deformations. Thermal deformations, as a rule, occur during daily and seasonal changes in air temperature. The scheme of mounting a hinged ventilation facade and fixing the frame to the wall is designed so that the IAF system has the ability to absorb thermal deformations. This helps to avoid internal stresses in the materials of the substructure and cladding.

- Fire safety. The materials from which the components of the system of hinged ventilation facades are made, as a rule, belong to the category of non-combustible or hardly combustible, which prevents the spread of fire.

A large number of advantages that ventilation facades have against the background of other options for finishing external walls makes them the most popular in Russia and foreign countries. The main advantages are the ability to install in any weather conditions and in any climatic zone, and excellent noise absorption, and excellent thermal insulation, and a wide range of materials, textures, colors and shades for finishing, and fire resistance, and much more. The external cladding screen serves the building as a reliable barrier against the effects of the external natural environment that can harm the load-bearing walls, as well as the substructure of the illegal armed group

But in order to create a durable exterior of a building, it is very important that all components of the installed system are of high quality. We recommend that you familiarize yourself with the material on aluminum facades

Assembly stages

To create a ventilated facade, the installation of a frame is required, which is attached to the building with anchors and brackets. They begin to install it after checking the walls for the expected load. It is made by experiment: two dowels are hammered, onto which a fragment of the sheathing is fixed with a load.

Components

Components

- The first thing that is done at the start of installation is the marking of the walls for the brackets for the lathing. For the accuracy of the data, it is worth using a laser or water level. The markup starts from the bottom of the building, it must provide a strictly vertical plane of the frame. The step of installing the rails depends on the size of the metal cassettes: if the panels used are longer than 70 cm, additional brackets are installed. Anchor holes are drilled with a hammer drill. It is worth avoiding driving fasteners into the connecting seams of the wall, since brickwork is especially sensitive to destruction. A paronite gasket is placed between the bracket and the facade surface. The length of the anchor for a concrete wall is 8 cm, if the building is made of bricks, you will need fasteners 10 cm long.

- The lathing rails are fixed on the installed brackets, fixing is done with screws.

- Next, a layer of insulation is laid. To maintain fire safety and reduce heat loss, non-combustible materials are used, these include mineral wool, extruded polystyrene foam. They are attached to the surface using special dowels with a round massive head, they will need 5 pieces per 1 m2.

- The insulation layer is protected from moisture penetration and weathering by a special wind membrane, its parts are installed with an overlap and fixed with self-tapping screws. If necessary, a waterproofing sheet is laid.

- The main vertical lathing is mounted from the hat profile; its height provides space for ventilation of the facade. To install the first row, a starting profile and a basement ebb are fixed at the bottom.

- Installation of metal cassettes starts from the bottom, from the left corner of the building. Before installation, the protective film is removed from the side parts. The lower part of the facade panels is snapped into place on the starting plate, the upper part is fastened with self-tapping screws. The installation of the next rows follows the same principle: the bottom clings to the adjacent panel, and the top is fixed with fasteners. The cassette is held by two screws fixed at the ends of the upper edge, if necessary, fastening takes place at intermediate points.

Installation features

Installation features

Installation of facade cassettes includes the installation of additional accessories that provide a presentable appearance of the cladding and protection from moisture. These elements include:

- cover plates;

- slopes;

- platbands;

- external and internal corners;

- crutches.

Installation diagram of metal cassettes

Installation diagram of metal cassettes

Without the installation of these parts, the structure will have an unfinished appearance, and the advantages of the cassette facade cladding will be lost.

When choosing the thickness of the panels for finishing the building, be guided not only by the manufacturer's recommendations, it is important to take into account the wind speed and weather conditions of the region, mechanical loads on the facade. For unfavorable conditions, use a thicker material and create a strong batten

Installation of a ventilated facade made of metal cassettes requires taking into account all technological features and installing the lathing without the slightest distortions. Such cladding will protect the walls of the building from negative effects for many years, improve the appearance and insulation.

Panel manufacturing and device

The cassettes are produced exclusively in an industrial environment. Only a few Russian companies are engaged in the manufacture of such products in accordance with GOST. In the workshop, the production process is carried out using high technologies on the principle of a closed cycle.

In essence, the very work on the creation of products consists in stamping a sheet of metal having a thickness of 0.5 to 1.5 mm. For production, cutting and bending equipment is used. As a result, box-shaped finished products are formed. Quality control of products is carried out at every stage of the technological process.

First of all, when starting to manufacture, the shapes and dimensions of the elements are determined. Dimensional accuracy is a very important nuance in production, since all components as a result form an integral structure with a large area, where each detail must ideally fit the one installed next to it. Therefore, the production facilities are fully computerized.

The cut material is sent to the next stage of production - to the angle-cutting machine, which performs the tasks of shaping the corners and contours of the cassettes. After completing these works, bending the workpieces is given the final shape. Products that came off the conveyor are already completely ready for installation, no additional processing is required for the elements.

Insi metal cassettes are Russian products of this line of building materials. In addition, composite and aluminum products of the Alucobond and Puzzleton brands can be distinguished. The latter are available in a variety of shapes including angular, triangular and trapezoidal.

Metal facade cassettes what is it

Recently, facade cassettes or, as they are also called, metal cassettes, are gaining popularity as a type of ventilated cladding for building facades.

Front cassettes are rectangular or square metal structures made of sheet steel with edges bent at the sides in the form of a thin box.

Attached to the facade with rivets or self-tapping screws. Manufactured from galvanized sheet steel, cassette facades are widely used in the installation of hinged structures designed for various types of structures.

Cassette facade - material characteristics

The demand for facade cassettes is explained by the high parameters of the material:

- great quality

- optimal size range

- variety of fasteners

- constancy of parameters of each cassette

- can be used for external surfaces and interior decoration

Despite the high prices, the relatively new cladding is still in great demand among builders.

After the restoration of objects using this coating, their realizable value increases. The appearance of the renovated building benefits noticeably.

The dimensions of the facade cassette, which have accurate technical calculations, allow efficient and efficient installation work, avoid fitting when facing old walls that have irregularities and defects.

Facade steel cassettes have a multi-colored coating made of modern polymer mixtures, which allows you to embody bold design projects.

The advantages of facade cladding include high corrosion resistance, insensitivity to negative environmental factors.

Manufacturing of facade cassettes takes place in production conditions using high technologies (on the principle of a closed cycle) and imported modern equipment. In a nutshell, production is a stamping of a steel sheet having a thickness of 0.5-1.5 mm. The result is profiled box forms. Quality control takes place after each operation.

Installation of facade cassettes - fastening technology

In practice, it has been proven that a facade made of metal cassettes is distinguished by the integrity of the component parts and presupposes an excellent facing of the surface of the entire building. The details of fasteners are also varied - from crutches, corners and slopes to platbands, strips and profiles. Thanks to this arsenal of fastening material, a wonderful end result is obtained.

Installation of facade cassettes is carried out in two ways. The first is a visible fastener, which implies fastening elements with bent side surfaces in which there are holes. They are attached to the panel using a self-tapping hat profile. This is an easier way. And the second is vandal-proof - this is a hidden fastener, for which cassettes of a modernized design are used (as a rule, they are used for external cladding of the facade of a house).

Facade cassettes - seamless hidden fasteners

The principle of seamless hidden fastening is that the outer surface is bent at the top of the metal cassette and has a special edge designed for coupling with the lower facade cassette.

The first row starts from the lower left corner by engaging the bottom of each cassette with the original rail. Fastening takes place through the edge of the upper holes. Subsequent rows are attached at the bottom to the top of the row in front of it, etc. Thus, with the help of this set of elements, hidden installation of various surfaces is performed.

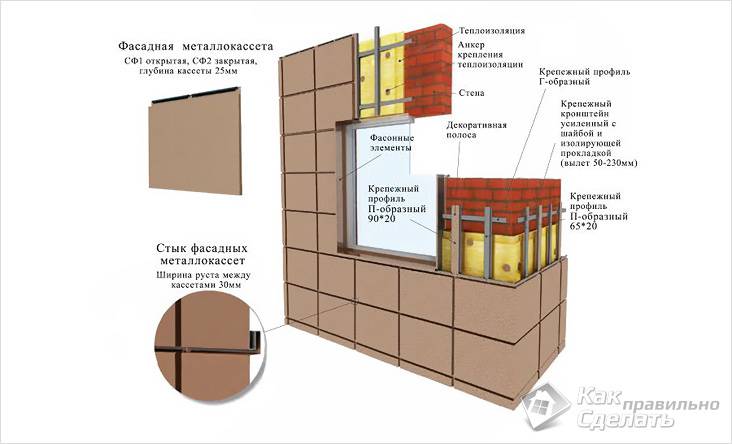

Facade metal cassettes are ventilated hinged structures with layers of fastening profiles arranged horizontally, which are mounted with brackets on the main wall.

Insulation containing mineral wool serves as an interlayer between them. Mineral wool is covered with a layer of membrane that protects it from moisture and wind penetration. This "sandwich" fixes the disc dowel.

A hat profile is attached to the L-shaped profile, the height of which forms a distance that provides ventilation inside the cassette.

Installation of facade cassettes

Installation of facade cassettes

Installation methods

The installation of a ventilated facade from cassettes can be performed using two types of product fastening: hidden and visible.

Open mounting

It is a method of fastening cassettes by screwing self-tapping screws through a hole on it into a profile. This is the easiest and most convenient installation method. Cassettes for such mounts have curved edges in which holes are made for self-tapping screws. The advantage of this method is the possibility of dismantling in case of need to replace the cassettes. Moreover, removing the elements does not require a special tool.

Concealed installation

The principle of operation is to screw the upper part of the cassette to the profile, and the lower part by snapping into the lower cassette. Thus, these products have only one side with a curved edge and holes for self-tapping screws. The appearance of the finished facade differs from the visible one, because with the hidden method, the connections are invisible. The disadvantage is the dismantling of the cassettes, because the possibility of partial replacement of elements is excluded.

Beautiful examples

Since the color scale of the material is quite diverse, it is possible to distinguish such a building from the total mass of structures without much difficulty. By using contrasting alternation of colors during installation, for example, light and dark shades that outline the correct geometry of the building, the structure is easy to see from afar. And the bright red details, highlighted in the overall design, in combination with the cold gray color, will add originality and attractiveness to the design, guaranteed to interest passers-by with such a bold finish.

For information on how to mount facade cassettes, see the next video.

Cladding material assembly process

Installation, as well as disassembly of panels, is a simple process. Metal cassettes can be installed at any temperature. First of all, you need to make a frame for the cladding. The design is represented by horizontal and vertical profiles. The production of this system is the most difficult and crucial stage that requires close attention. The metal panels themselves are attached to the erected frame using self-tapping screws.

Assembling open cassettes

Installation is carried out from bottom to top. The edge of each next panel is laid on top of the previous one and fixed with self-tapping screws.

useful in work

Not every cassette material is suitable for a particular fastener. For example, steel fasteners cannot be used to assemble copper panels.

Assembly of closed cassettes

Installation of closed panels is also carried out from bottom to top, but also from left to right. Here, the edges of the panels are joined together and attached to the subsystem. The process is more complicated, but at the same time it allows you to get a more durable structure.

It is worth remembering that only certified materials and high-quality installation of panels will allow the external appearance of buildings to hold out for a long time in its original form.

The structure of the hinged facade structure

The metal cassettes are fixed on a subsystem, which is produced by the panel manufacturers.

System structure

System structure

The subsystem provides ventilation, facade insulation. The hinged ventilated facade consists of a load-bearing wall, a layer of thermal insulation, brackets for fixing the cladding. The role of the finishing material is decor, protection.

How illegal armed groups work

Due to the temperature difference outside and inside the house, air rushes outside from a warm room. On the way, the air flow must pass through the wall, illegal armed group. Materials are heated to varying degrees - the closer the surface is to the interior, the warmer.

Due to the ventilation gap in the system, the outer layer of the facade has a temperature several degrees higher than the environment.When heated, an air stream moves from the facade system continuously. Fresh air enters through the gaps in the system, allowing moisture to evaporate.

The brackets should not have a high thermal conductivity (aluminum), otherwise the heat losses will be up to 15%. You will need a thicker insulation. It is better that the brackets are made of steel, alloys.

Number of panels

To calculate the number, size of cassettes, it is necessary to develop a project. You can order at the store where the systems are sold, and perform the calculation yourself. Would need:

- Measure the main dimensions of the walls to be faced (height, length), dimensions of windows, doors. You need to measure the distance from corner to corner, piers. Write down the values.

- The values are multiplied to calculate the area of the walls, openings.

- The area of the openings is taken away from the area of the walls.

- The remaining 4 values are added together to obtain the total area to be covered.

- According to the size of the walls, the dimensions of the cassettes are selected so that the cladding is without trimming. The angular profile is taken into account.

Frame diagram

Considering the previous calculations, the subsystem is calculated. The diagram should contain information about the location of the fixing points of the brackets to the wall surface. Each cassette is equipped with mounting holes for attaching to the frame. When drawing up a diagram, take into account the distance from one hole to another.

The type of panels according to the method of fastening is important. When open, the shelves of each element overlap. When choosing a distance between horizontally located guides, the height of the panels is taken into account.