Advantages and disadvantages

Today, eurolining acts as a fairly popular finishing material. The high demand for euro lining was formed due to many advantages that many other types of finishing materials cannot demonstrate.

Several factors are worth highlighting among the main advantages.

The most affordable material for finishing is a wooden euro lining made of linden.

- Environmental friendliness is guaranteed.

- The material in question has a beautiful appearance. Any wood used is unique. Customers have the opportunity to choose from a wide range of shades and textures to create unique interior designs.

- The material acts as an excellent heat and sound insulation.

- The lining will be used for a long period, especially if it is properly cared for. It is able to serve its owners for up to 50 years, while maintaining its original unique look.

- Wooden Euro lining is characterized by ease of installation, which is possible due to the presence of a ridge and grooves. With the help of these panels, you can perform cladding as soon as possible, and you do not need to be a professional in this area to perform these works.

- With the help of euro lining, you can make additional finishing.

- Today you can purchase different sizes of eurolining made of wood, which are most suitable for a particular room, based on the surface area that needs to be sheathed.

Despite the impressive list of advantages of the material in question, the euro lining also has disadvantages, but there are very few of them.

Several indicators act as negative sides.

- When using euro lining made of wood, there is a risk that it will deform. This mainly depends on the type of wood you have chosen for the cladding.

- The material in question does not cope well with temperature fluctuations and is sensitive to high humidity, however, these parameters also depend on what kind of wood the boards are made of.

- It should be emphasized that the disadvantages mentioned earlier do not appear to be catastrophic, since they can be neutralized through the use of special processing of the boards and high-quality installation.

If you want to purchase euro lining, you need to know exactly in what conditions it will be used. For example, it will be installed in rooms with high humidity.

In such a case, it is important to pay attention to conifers. When it comes to cladding dry rooms, planks made from deciduous trees may be suitable.

You need to immediately determine the optimal size of the purchased panels

If the room has relatively small dimensions, it is better to pay attention to the panels that have a small width. When decorating large rooms, it is worth opting for a material with a large width of boards, as this will facilitate the sheathing process.

What is the material?

Lining is cladding boards of various thicknesses and lengths. They are made from several types of wood, which makes it possible to use them indoors for any purpose and outside buildings. To protect against moisture, each lamella is treated with special compounds at the production stage.

But for durable use in high humidity conditions, it is necessary to apply additional impregnation (including protection against mold and mildew).

The question of which wooden lining is better to choose should be asked taking into account the scope, appearance and class of material.

Peculiarities

The main dimensions of wood bases are regulated by standardization corresponding to GOST 8242-88 for profile parts made of wood for construction and 8486-86 for sawn softwood. There is also a European parameter for industry - DIN 68126/86. There are no strict regulations on the length of the lining.

The main features of the lining are its length and width. These indicators are taken as a guideline when calculating the number of products. Regardless of the dimensions, the laying of any boards is carried out according to the same principle. It is convenient for the consumer. Since, for example, if it is necessary to replace or repair it, it will not be difficult to find a similar part of the required size and with an identical fixing method.

To avoid any difficulties during installation, it is important to study the instructions supplied for a specific type of product. Usually it is in the package with the product.

Differences may be present if the lining is of European or domestic production. The differences are just in the typical sizes of the varieties. Domestic lining of the first, second or third grade does not correspond to the typical dimensions of European-made products of class A, B, C. Coincidence in dimensions can only be in products of the "elite" class. However, there is a difference here, since European-made products are usually more expensive in value.

By the way, the cost of the lining is very dependent on the size. In terms of length, shorter boards tend to be cheaper. Long planks are more expensive, as the blanks are usually needed for filing the overhangs and should not contain dead knots. If at the stage of processing there are dead knots in the long board, then they are cut off and products of the same harvested type, but shorter, are obtained. If dead knots remain, they will fall out of the finished products at any time, resulting in a marriage in decoration.

Experts also distinguish between live knots. They will not fall out when using the board, therefore, in some grade categories, they are allowed to be left. Lining with live knots is suitable for interior wall decoration. Inexpensive varieties are usually used for baths, hallways, and other similar premises, where a particularly sophisticated finish is not required. With proper processing, the lining of exquisite varieties can turn into a designer decor, so it is worth considering varietal types in more detail.

When decorating a bath with clapboard with your own hands, the material should be installed only in two directions - vertically or horizontally. In the case of vertical installation, you can use short, cheap boards, but in this case, the joints are simply hidden under decorative elements or shelves.

In addition, under the shelves, where the aspen lining is almost invisible, you can use boards of a lower grade than on those parts of the wall that are visible. This method will allow you, when decorating a bath with clapboard, not only to reduce the risk of cracks due to high temperatures, but also provide additional savings.

Varieties and varieties of eurolining made of wood

Wooden Euro lining can be classified according to the production profile.

There are two profiles on the market today.

- The standard, which can be referred to as an ordinary lining, "collective farmer" or "classic". A special feature of this finishing material is the minimum number of grooves, which are practically absent.

- The lining has a similar appearance to the previous profile, however, more stringent requirements are imposed on this material. In addition to them, when joining the lamellas in this case, there is always a slight groove. In some situations, it reaches up to 15 mm.

We will present the most common types of Euro lining, which are characterized by a vertical fastening method.

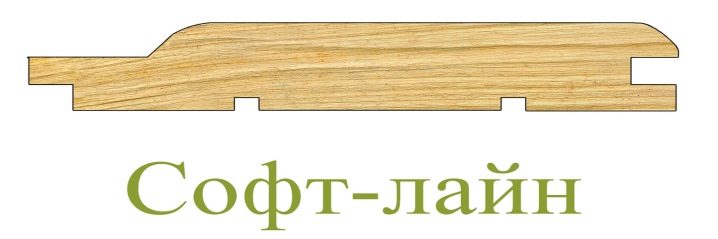

Softline - a view where the boards are slightly rounded.The width and length of the material allows you to quickly carry out facade finishing.

Other types of wooden lining can be distinguished, which differ in the horizontal method of fastening.

There are several varieties worth paying attention to here.

- American. With the help of the type of euro lining under consideration, you can simulate the laying of wood planks. Most often used for outdoor decoration. Euro lining is characterized by protection in the area of joints, where moisture cannot get. Since these panels can be purchased in various widths, the cladding of the house can be done as quickly as possible.

- Imitation of a bar. In this situation, the lining has a standard profile.

- Block house. If the building is finished with this material, it will look like a log house. They differ in different lengths and widths, so finishing is quite simple.

Tips & Tricks

When choosing the exact number of lining boards (in terms of usable area, width, net size without a thorn), remember that a short board is cheaper. So 1 m3 of a board with a length of 1.7 meters is almost 1.5 times cheaper than a standard board from 2.1 meters to 3 meters. When trimming, there are inconsistencies, which means you need to take care of which corner to choose and order for the final finishing.

The optimal number of lining boards is calculated according to the useful size (without a thorn). The shorter the length of the board, the lower its price. Therefore, for the choice of lining, dimensions and price remain the determining parameters. The overall financial cost will depend on the surface area that needs to be clapboarded.

The outer surfaces of the premises are sheathed with a special clapboard called "Blockhouse". One side of this original lining is rounded. The execution of such a surface requires special equipment in order to obtain the same size and shape of the surfaces. The details of the blockhouse, assembled in a specific finish, create the impression of a well-rounded log house. A feature of blockhouses is the ability to replace damaged elements, if necessary, without violating the integrity of the entire finish.

A special type of lining - "American". In fact, this is a planed board, in which a groove is cut from one end, and a tongue is formed on the other, this allows them to be firmly connected to each other. Chamfers on the side edges of the board create the appearance of a masonry made of wooden beams, it is not immediately possible to guess that this is an "American" finish.

Although it is also a lining for its intended purpose, but due to its impressive appearance, strength, width, weight, it is used only for external cladding. The house after finishing American takes the form of a solid log structure. Of course, if you wish, you can use the material for interior decoration, but in this case, part of the interior space of the room will be reduced.

For information on how to choose the right lining, see the next video.

How many units and squares of lining are in one cubic meter?

The mainArticlesHow many lining in a cube: how to calculate the cubic capacity of a lining

How many lining in a cube: how to calculate the cubic capacity of a lining

When performing construction work, many have difficulties when it is necessary to calculate a certain number of cubic meters of lining in order to sheathe the walls of the room.

It is not so difficult to calculate the area in square meters, but to determine how many cubes will go to the wall in the bath? How to calculate the molding in cubic meters?

With the help of our table, you can quickly carry out calculations and find out how many boards are in one cube of the lining.

| Name | The size | Volume of one board | Quantity in 1 m3 |

|---|---|---|---|

| Lining | 16x88x6000 | 0.0084 cube | 62.5 1 m2. |

| Lining | 16x88x3000 | 0.0042 cube | 62.5 1 m2 |

| Lining | 12.5x90x3000 | 0.0034 cube | 80 1 m2 |

Also, see tables of cubes for:

←

Table for calculating the cubic capacity of floorboards →

Calculator for calculating the number of lining:

The popularity of the use of lining is increasing every day.

And there are good reasons for this:

- lining is a versatile material that is suitable for finishing both external and internal walls;

- the cost makes it affordable for the broad masses of the population;

- a rich assortment of materials used in the manufacture, allows you to use it in a variety of design projects.

But no matter what lining is chosen, errors in calculating the required amount of material can not only disrupt the current repair process, but also significantly change the expected result of finishing.

Algorithm for calculating the number of lining

In order to correctly calculate the cost of the lining, you must first calculate its required amount. To do this, you need to measure such indicators as the length, width and height of the entire room, which will be sheathed with clapboard. Next, you need to measure the length and width of the material itself, and in addition, the thickness of the board. For example, let the length of a wooden lining be 6000 mm, and its width is 95 mm, but let the thickness be two centimeters. From this, you can calculate the area of one part, which will be 0.57 square meters, and its volume - 0.0114 cubic meters.

Typical lining sizes: standard and variations

When determining the dimensions of Euro lining and other types of cladding panels, a profile that differs for different sawn timber is taken into account. In this case, in the marking, the dimension values are indicated in the following order:

- the width of the lining (working or full), that is, without taking into account the ridge (spike) or without it. The working width is understood as the width that the panel has after installation in the cladding - the groove of the next product hides the ridge, thereby leaving only the main part of the lamella in sight;

- thickness - the total thickness of the plank, excluding ventilation slots. It is the thickness of the lining for interior decoration that is of decisive importance in terms of the quality of heat and sound insulation: the thicker the plates, the worse they conduct sound and heat;

- lining length - the length of the entire lath, solid or spliced (with adhesive joints along the length of the lamella).

Below are in the form of a table the dimensions of pine lining, as the most popular facing material. For fine wood products, the dimensions may vary according to the manufacturer's standards.

| Profile type | Sectional profile picture | Width, mm | Thickness, mm | Length, mm |

| Classical | 95…140 | 12…15 | 1200…5700 | |

| Calm | 95 | 15 | ||

| Calm is thin | 95…140 | 12 | ||

| American (beveled) | 140 | 12-20…14-24 | ||

| Block house (convex) | 120 | 18…22 | ||

| Soft-line | 138 | 12,5 | ||

| Euro | 88…110 | 12,5 |

Despite the fact that the standards set the length of the Euro lining 1200 ... 5700 mm, lamellas with a length of less than a meter (300 ... 1000 mm) are allowed and panels with a length of more than 3 m are rarely marketed.

Depending on what dimensions of the lining were used for cladding, one cubic meter of material is enough for cladding up to 65 square meters of surface.

Typical sizes of plastic and MDF panels

The most diverse are the sizes of wooden Euro-lining, polymer and MDF lamellas have a smaller number of size variations.

For MDF panels intended for wall cladding, the following are provided:

- thickness 3 ... 30 mm (up to 60 mm for veneered versions);

- width 100 ... 900 mm;

- length 2.62, 2.44, 2.8 m (other lengths are permissible, according to the manufacturer's specifications).

For PVC cladding, typical sizes are:

- thickness 5 ... 10 mm;

- width - 100 ... 250 mm;

- length - 3 ... 6 m.

The most popular panels with a section of 10x250 mm, they have sufficient strength and good sound insulation.

Types of lining profiles

Since the lining is used for cladding many surfaces, manufacturers take into account the desires of buyers to give their premises a certain personality and make several types of profiles that can be selected not only in appearance, but also for certain types of work. Profiles differ from each other by the presence or absence of chamfers, types of locks, the shape and size of the front and back sides.

Traditional Euro lining

On the front side of such a profile, an additional chamfer was selected near the spike, as a result of which, after installation on the wall, pronounced seams are visible. The chamfer can be angular or rounded. The rounded one was named Softline.

Lining "Softline"

Since this shape of the surface has no corners, there is less chance of chips and burrs during operation, therefore Softline is considered more suitable for such premises as a sauna.

Lining "Calm"

The difference between this profile is the absence of a chamfer near the spike, so the seams after installation are not as pronounced as when using traditional lining. This is used when it is necessary to create an imitation of a wall assembled from a bar, therefore, most of the Shtil lining is produced thickened up to 25 mm and can be freely used for cladding the facades of buildings.

Lining "Landhouse"

Lamellas, which include such types of wooden lining, are one of the most expensive, since during their production the front side is subjected to milling or other processing methods, which form complex patterns on the surface of the wood. There are even profiles with a woodcarving effect, which are obtained using hot stamping under press.

Lining "Blockhouse"

If the "Calm" lining imitates the walls made of timber, then the "Blockhouse" profile has a completely rounded front part. Thanks to this solution, after assembly, the wall looks as if the house is assembled from rounded logs. It is mainly used for cladding the facades of buildings.

Lining "American"

This profile is not just chamfered near the spike, but a smooth transition from it to the middle of the front part is made. Thanks to this solution, an exact imitation of siding panels is achieved, but at the same time the house is faced with natural wood.

Double-sided lining

Such a profile does not have a back side - both of its parts are made front. Such a lining is useful if you need to make a thin wooden partition. Also, when facing the wall, it is possible to choose a more successful pattern or place small defects on the back side.

This lining is strongly not recommended for use in rooms with high and variable humidity, since it is the only one of all types of Euro lining that does not have compensation (ventilation) channels.

Varieties of finishes

The finishing material includes different types, classified according to various characteristics. With regard to the type of wood, three types of plates are distinguished.

Types of material

- Hardwood. It is most often made from oak, alder or linden. It has minimal thermal conductivity, therefore it retains heat well in the room. The resin content is low, which makes the planks vulnerable to moisture. Not recommended for use in damp rooms and for outdoor use.

- Coniferous. Pine, cedar, larch, spruce are taken as raw materials. Conifers are characterized by high resin content. The resin protects the planks from moisture. Therefore, they are durable, serve for several decades.

- From exotic breeds. They are made from varieties that grow in the tropics. These are merbau, teak, bukit, kumara and others. They are very hard and durable. Difficult to process, resistant to moisture and insects. Their price is higher than that of analogues.

The dimensions of the planks differ depending on the wood from which they are made. So, the dimensions of pine lining may not coincide with aspen lamellas, etc.

You need to know that not only wood can be a raw material for making lamellas. They produce PVC plastic models. They are cheaper and easier to keep clean. Significantly differ in their dimensions and performance from wooden products.

Instagram @ lesobirzha.pokraska

Instagram @svitderevakopychyntsi

The appearance of the finished finish determines the profile of the planks. They differ in the size and shape of the front and back sides, types of locks, the absence or presence of chamfers.

Profile types

- Traditional euro lining.A chamfer is removed near the spike, due to which a pronounced seam is formed on the wall.

- Softline. It is made similarly to the previous version, but the chamfer is not angular, but rounded. The absence of corners makes the canvas suitable for facing rooms, baths, etc.

- Calm. It is characterized by the absence of a chamfer at the castle. The seams between the lamellas are almost invisible, which makes it possible to imitate a wall assembled from a bar. Therefore, the dimensions of the calm lining may differ from their counterparts. A version thickened to 25 mm is in demand, which is used for facing facades.

- Landhouse. The front side of the board undergoes special processing: milling, hot stamping, etc. A complex pattern imitating carving is formed on the surface.

- Block house. The front part is rounded on both sides. When assembled, it simulates a wall made of rounded logs. Good for decorating the facade of the house.

- Bilateral. Both sides are front. This makes it possible to choose an interesting pattern and hide minor defects by turning the lamella over. Partitions can be assembled from double-sided plates. Not recommended for rooms with high humidity, as there are no compensation channels.

- American. A chamfer is removed near the spike, while a smooth transition is made from it to the center of the plank. The result is an imitation of siding.

Wood quality

Hardwood is classified into 4 grades. Coniferous edged lumber - by 5 (plus - selected). In this case, the best variety is recognized as selective and is designated "O" or a horizontal stripe. The rest of the quality assortment is indicated by numbers or the corresponding number of strips. It is characteristic that a particular lumber is evaluated by the worst of the cut sides or edges. And the varieties are determined due to the absence or presence of cracks, chips, deformations, knots, possible rot and moisture. The type of sawn wood is also dependent on the delicacy of processing.

Typically, first grade lumber can be used for a variety of building structures - permanent and temporary. And also - for the final finishing of walls and floors of standard thickness. Second-rate lumber is suitable for the construction of decking, formwork, battens. Third-class - for supporting structures of the third category. But the fourth grade is used for the manufacture of small blanks or for containers. It is characteristic that the moisture parameter for the latter of the varieties is not standardized. But for the previous ones, the humidity parameter should not be higher than 22 percent. When it exceeds - the material is called "raw". At the same time, it significantly loses its strength.