Advantages and disadvantages of PF-115 paint

The enamel has a high hiding power, therefore it is consumed sparingly (about 100 grams per square meter), which is important when painting a large area. Reasonable price for high quality products allows you to buy paints and varnishes for the purpose of performing large-scale painting work

The main advantage, which determines a wide area of use, is resistance to atmospheric influences (moisture, ultraviolet, temperature extremes, etc.). Subject to the application technology, paintwork materials adhere well to different surfaces.

The disadvantages of PF-115 enamel include a relatively long drying time, as well as a specific odor that can cause poisoning and an allergic reaction when the room is poorly ventilated. After working with paint, painting tools must be thoroughly washed. LKM belongs to the category of fire hazardous and toxic substances, when handling which it is required to observe safety measures.

Manufacturers

Complete drying in just 1 day and the absence of odor allows for quick local repair of the damaged surface without stopping the activity, i.e., isolating a large area around. High water resistance provides application for painting floors in baths and saunas. Unlike analogues of the Tikkurila Betolux Aqua type, Mitsar Rezolux Profi-52 enamel has passed state fire certification and can be used in residential buildings for painting stairs and public areas. In addition, Mitsar Rezolux Profi-52 does not require frost protection - a wide operating temperature range is from -15 to + 40 ° C. The price per kilogram of enamel at Mitsar Rezolux Profi-52 is about 270 rubles. That is almost 3.5 times lower in comparison with Tikkurila Betolux Aqua. So the Russian paints of the Mitsar plant are obtained both cheaper than imported ones and better in terms of their characteristics.

VGT paint has proven itself well, which is intended for both indoor and outdoor use.

In addition, this type of finishing material is characterized by high resistance to light, water and precipitation.

The enamel produced by "Lakra" also received positive reviews. Due to its versatile properties and strong adhesion to the surface, the paint is widely used in flooring.

To paint a cement, concrete or wood floor with quality, it must first be thoroughly cleaned, degreased and primed with an acrylic primer. The finish can only be applied to dry coatings.

Enamel produced by "Prestige" and "Tex" also deserves special attention. It is usually chosen for painting wooden floors. Enamel beautifully decorates wood, gives it an unusual texture and relief. In addition, this paint is produced in many shades and dries quickly.

Purpose and areas of application

Due to its high viscosity and excellent adhesion, the use of PF 115 paint is very wide.

The composition can be painted:

- wood;

- concrete;

- plaster;

- putty;

- brick;

- metal.

It is not suitable except for roofing work - with strong heating of sheets of slate or tin, cracks may appear and the color changes greatly.

Enamel is used mainly for external work for structures in the open air. It is used both as a monolayer coating and as part of multilayer ones, in combination with primers, anticorrosive and antiseptic impregnations, insulating layers. Enamel does not possess its own antiseptic and bactericidal properties, therefore, when processing wood and walls made of brick or concrete in humid conditions, such additives are necessary.

Enamel PF-115 possesses and very high decorative properties - according to GOST 6465-76 it is produced in 22 colors and shades. In recent decades, manufacturers have offered modernized paint, which is available in almost all RAL colors. In this case, the color number from the catalog is indicated on the paint cans or barrels. This is one of the few cases when it is preferable to buy a paint made not according to GOST rather than a standard one. But it must be taken into account that this type of enamel costs more than usual due to the use of expensive dyes.

The high elasticity of the film, which can be obtained by painting surfaces in two or more layers (a single-layer coating is used only when renewing a previously completed finish with the same paint, provided that there are no cracks and blisters on it) allows PF 115 to be used in completely different climatic conditions. The temperature range at which the finished coating retains its properties is incredible - 50 ... + 60 C. But the paint fully complies with the declared characteristics only if all technological rules for applying the coating layer are observed. We will tell you how to use enamel correctly further.

Safety requirements

Regardless of the color, PF-115 enamel and all additional solutions (thinning solvents) are very toxic.

For example, white spirit can ignite at a temperature of 270 ° C, and belongs to the 4th hazard class. When adding thinner to paint, be careful not to be near fire.

Never mix solutions without a respirator mask, suit or gloves - toxic fumes can cause a strong allergic reaction, burn not only the mucous membrane of the mouth and nose, but also the skin of the hands and the eye cornea.

The room in which the painting is carried out must have serviceable ventilation hoods.

Within walking distance from the workplace there should be:

- Foam fire extinguisher.

- Carbon dioxide fire extinguisher.

- AUP-TRV (water mist) - sensors on the ceiling also for extinguishing cable wires.

- Sand box.

- Felt carpet (fire-fighting cloth).

For safety reasons, air purification should be carried out in rooms with paints and varnishes. Special gas cleaning machines are also processed - all waste is destroyed in accordance with all the rules.

Views

Today, on the windows of building stores, you can find a huge amount of enamels. Any enamel is a combination of varnish, coloring pigment and a special filler. Such mixtures can be made both water-based and solvent based from organic matter.

According to the composition of the varnish, enamels are divided into three types:

- alkyd;

- polyurethane;

- acrylic.

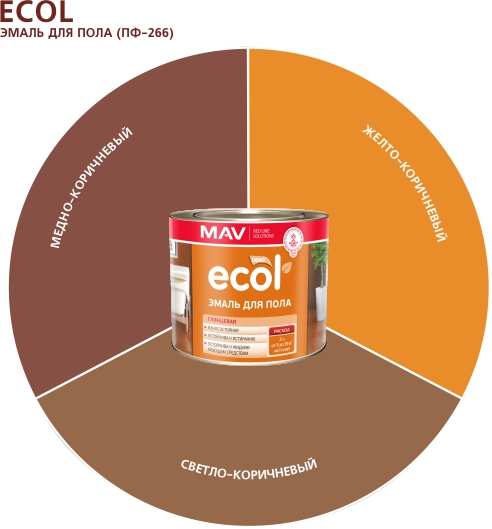

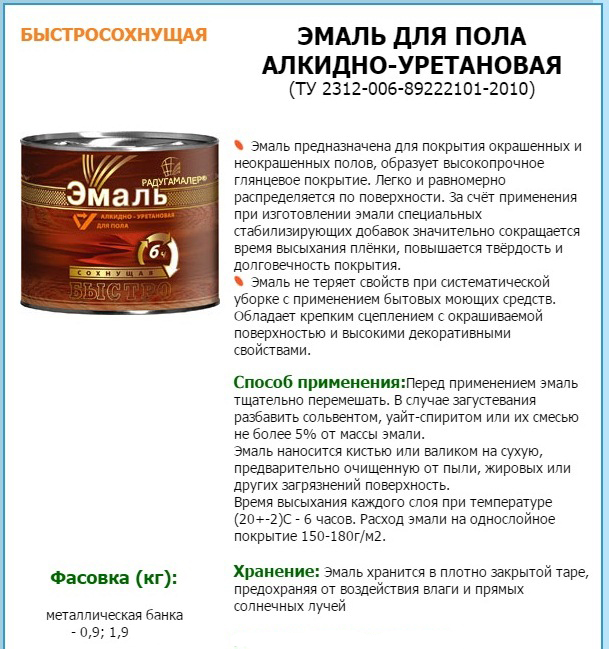

Alkyd enamel is considered water resistant and very durable. In addition, she is not afraid of frequent temperature changes. The product is suitable for covering floor coverings in a wide variety of environments. It is for the design of the floors that the masters advise to purchase PF 226 and PF 266 enamels. These compositions are quick-drying. For their cultivation, special white alcohol is most often used, which can be easily found in hardware stores.

Polyurethane enamels are suitable for painting almost any surface, since they have very strong adhesion properties to materials. Such enamels can even be applied to a damp surface. Most often they are used in public places, factories and industrial areas, where it is necessary to create the highest quality and durable flooring.

Another option is acrylic semi-gloss enamel. It is considered quite resistant to various negative influences from the outside. In addition, it can be used to cover both wood and concrete floors. This mixture can be called universal, in addition, it does not have an unpleasant odor and dries quickly. The product is great for renovating residential floors.

Popular brands of enamel PF-115

"Lacra"

Weatherproof alkyd enamel PF from the manufacturer "Lakra" is one of the most popular paints. You can choose a volume from 0.8 to 20 kg.

Good gloss, especially in greens, reds and blues. The yellow is a little dull. In general, saturation depends on the choice of hue and the number of layers applied.

The quality largely depends on the batch: if you painted part of the fence, and left the second part for the next season, it is not a fact that the new paint can will be of the same quality as the previous one (from the buyer's review).

The solution dries quickly, adheres well, and is very durable. Minus: pungent smell.

"Optimum" PF-115

Enamel dries faster than other solutions (maximum 7 hours). More suitable for covering decorative details inside the house. It paints well, one layer is enough (thick).

Reviews are different, someone thinks that the paint dries for a long time or is watery. This is possible if the operating conditions have been violated.

"Fazenda" PF-115

The paint will not fade, and the matte, pleasant shine will not disappear even after a year. The enamel is so strong that it is difficult to erase it even with a solvent.

The price for a jar is low, you can paint decorative surfaces both outside and inside the building (dries up in 8 hours). The paint spreads well through the pipes, no drips remain. The solution is not thick, so there is no need to dilute it.

The smell is pungent, but this is a minus of all paints and varnishes.

There is a waterproof paint PF-115 with the addition of antiseptic additives (BIO). This is a new class of coating, in which there is a protective antifungal, fungicidal, sporicidal, bactericidal agent. During storage, a film does not form on the surface.

You can paint walls, windows, doors, ceilings. The beige paint is popular in hospitals, schools, kindergartens and is suitable for painting concrete, metal and wood surfaces.

Service life - a year, drying speed - 24 hours.

Technical characteristics of PF-115 paint

The technical characteristics of the PF-115 may change not only from color changes. Due to the slightest difference between oil or other components, the proportions in the paint may change, and therefore the properties of the entire composition (everything is compared according to GOST 6465 76).

Due to these differences, the period during which the paint can be used can be reduced or increased, that is, the service life depends on changes in the slightest proportions.

In the first place in terms of stability - enamel PF-115 white (varnish is contained in a large ratio, not less than 27-28%). Enamel PF-115 gray contains the least substances - about 20%, in blue up to 25-26%.

But this does not mean that all colors except white are unstable - the composition of the solutions contains many other impurities that improve the quality.

Enamel PF-115 specifications GOST 6465 76

table

| Shine | From 50% |

| Weight loss after complete drying | Up to 71% |

| Dilution with water (viscosity) at 20 ° C | Up to 123% |

| Drying at 19-22 ° С | Through the ducks |

| Shockproof | Up to 40 |

| The ability of the pigment to overlap the surface color | Up to 115 g / m2 |

| The cost of enamel for 1 layer depends on the selected color | Up to 180 g / m2 (maximum 0.18) |

| Maximum use temperature | Up to -50 ... + 60 ° С |

| Toxic substances | Moderate discharge, not above average |

| Flammability | Flammable |

| Smell | Harsh, poisonous |

| Hardness | Up to 0.25 |

| Cohesion of surfaces of dissimilar liquids or solids | 1 point |

| Permeability (dielectric) | Up to 11 |

Always wear protective clothing, gloves and a respirator mask.

After completing the work, ventilate the room - the smell of paint should completely disappear.

Painting scheme with enamel PF-115

Metal primer: use "GF-0119", "VL-05", "GF-021", "VL-023" (always with the number 0 at the beginning).

It can be painted without primer, but then the enamel must be diluted with a solvent (sometimes up to 50%).

A rusty surface can be treated not only with PF-115 (in two layers), but also with Unicor K - a water-dispersion ground paint, with the addition of auxiliary substances and a synthetic polymer (one layer is enough).

PF-115 paint is suitable for processing pro-lined wood - apply no more than three coats. Wood treated with linseed oil will be covered with a protective film and will save enamel consumption.

Plaster, brickwork, concrete coating, old, worn out or surfaces requiring restoration are processed in three layers.

After applying the solution, you need to wait at least a day; in some cases, removable parts can be dried at a temperature of no more than 110 ° C (within one hour).

Requirements for materials protecting concrete

The protective compound must make the surface resistant to abrasion. For painting concrete floors, not all oil-based paint will work. The protective composition should give the surface resistance to abrasion, ensure its ability to withstand chemically active substances, which is especially important in garages and industrial premises. When choosing a material for painting floors, you need to take into account other operating factors: moisture resistant characteristics, frequency of temperature changes. When purchasing paint for a garage, it is necessary to assess its biological safety and toxicity.

Requirements for paints are set out in several GOSTs. The main characteristics are:

- hiding power - the ability of the paint to completely cover the original color, g / m2;

- specific gravity of non-volatile substances,%;

- conditional viscosity;

- the degree of grinding - the minimum size of the coloring matter, microns;

- drying time at a temperature of 19.5-20.5 ° C, h;

- impact strength of the coating, cm;

- bending strength of the coating, mm;

- conditional lightfastness, hour;

- resistance to water, hour;

- resistance to engine oil, h.

Tools required for staining

The solution can be applied with a wide brush, roller or pneumatic spray gun.

The choice depends on personal preference, but the sprayer will need more solution (and this is an extra expense).

If you choose a brush, it will take more time to work. Paint with a roller is faster and more economical.

When using a spray gun, you need to make a more liquid consistency (if you need to paint large sheets). For smaller details, a roller or brush is suitable (mainly for thin gates).

You need to work quickly with the spray gun - fill the container with the solution as soon as it ends, and treat the surface without stopping so that the mixture does not have time to dry out.

The second layer should be applied after the first has dried (in a day).

You can paint with aerosols, but they are much more expensive, although they are convenient to use.

Working with a brush on metal is the most unprofitable - drops of paint flow down, stains remain, more material is wasted. Plus the brush - it will crawl into all the cracks and smear all hard-to-reach places.

The best choice is a roller. The layer is applied evenly, and not much paint is wasted.

After cleaning the structure from dirt, apply a thin layer of primer to the part (the surface must be dry). It is better to treat with 2-3 layers of soil mixture.

Purpose of enamel PF-266

The product is used for painting wooden and metal surfaces. It can be used for processing both domestic and industrial premises. Universal paint is suitable for all surfaces.

Important! The composition (GOST 6465-76) processes only internal surfaces, this enamel is not suitable for external work. The emulsion is intended mainly for the treatment of non-residential premises of sufficiently large dimensions.

For this reason, manufacturers offer their products in large metal containers (30 - 50 l)

The emulsion is intended mainly for the treatment of large enough non-residential premises. For this reason, manufacturers offer their products in large metal containers (30 - 50 liters).

Safety measures when working with paints and varnishes

Enamel PF-115 is characterized by a long term of use, subject to the storage conditions. Due to the flammability, it is forbidden to store paint cans near an open fire.Protection against ultraviolet radiation and high humidity must be provided. The manufacturer guarantees the safety of technical characteristics in the temperature range of -40 ºС… + 40 ºС. The packaging must be airtight to prevent the paint from drying out.

When working with alkyd enamel, it is recommended to use personal protective equipment in order to prevent the suspension from getting on the skin. Requires the use of glasses, gloves, and respirators to protect the respiratory system.

Individual protection means

If paint gets on the skin, wash it with soapy water. When performing interior work, it is necessary to provide effective natural or forced ventilation. It is forbidden to paint hot surfaces and structures located near open flames.