Popular brands of enamel PF-115

"Lacra"

Weatherproof alkyd enamel PF from the manufacturer "Lakra" is one of the most popular paints. You can choose a volume from 0.8 to 20 kg.

Good gloss, especially in greens, reds and blues. The yellow is a little dull. In general, saturation depends on the choice of hue and the number of layers applied.

The quality largely depends on the batch: if you painted part of the fence, and left the second part for the next season, it is not a fact that the new paint can will be of the same quality as the previous one (from the buyer's review).

The solution dries quickly, adheres well, and is very durable. Minus: pungent smell.

"Optimum" PF-115

Enamel dries faster than other solutions (maximum 7 hours). More suitable for covering decorative details inside the house. It paints well, one layer is enough (thick).

Reviews are different, someone thinks that the paint dries for a long time or is watery. This is possible if the operating conditions have been violated.

"Fazenda" PF-115

The paint will not fade, and the matte, pleasant shine will not disappear even after a year. The enamel is so strong that it is difficult to erase it even with a solvent.

The price for a jar is low, you can paint decorative surfaces both outside and inside the building (dries up in 8 hours). The paint spreads well through the pipes, no drips remain. The solution is not thick, so there is no need to dilute it.

The smell is pungent, but this is a minus of all paints and varnishes.

There is a waterproof paint PF-115 with the addition of antiseptic additives (BIO). This is a new class of coating, in which there is a protective antifungal, fungicidal, sporicidal, bactericidal agent. During storage, a film does not form on the surface.

You can paint walls, windows, doors, ceilings. The beige paint is popular in hospitals, schools, kindergartens and is suitable for painting concrete, metal and wood surfaces.

Service life - a year, drying speed - 24 hours.

Technical characteristics of PF-115 paint

-

Resistance to atmospheric and weather factors (precipitation, ultraviolet light, temperature extremes, wind loads).

-

Resistance to chemical influences: paint PF-115 is able to withstand the effects of fuels and lubricants for 24 hours, for at least 2 hours - for water, up to 15 minutes - for aggressive detergents.

-

Adhesion - about 1 point. There are also oil versions of enamel paint on sale that have less adhesion.

-

Covering rate - 80 ± 40 g / m2.

-

The percentage of non-volatile components in enamel paint is in the range of 49–70% (depending on the manufacturer of paintwork materials).

-

Specific hardness - 0.15-0.25 conventional units.

-

Viscosity - 90 ± 30 conventional units.

-

Drying time - up to 24 hours under normal conditions (humidity up to 65% and temperature about 20 ° C). For cherry and red paint, the drying time is up to 48 hours.

-

Flexural elasticity - about 1 mm.

-

Operating temperature range - from -50 to +60 ° С.

SAFETY REQUIREMENTS

6.1. PF-115 enamels of various colors are fire hazardous and toxic materials, which is due to the properties of the components that make up their composition.

Maximum permissible concentrations, hazard classes of components according to GOST 12.1.005-88 and fire hazard characteristics according to GOST 12.1.044-89 are given in table. ...

table 2

Maximum permissible concentration of vapors in the air of the working area of industrial premises, mg / m3

Hazard Class

Temperature, С

Flammable concentration limits,% (by volume)

outbreaks

self-ignition

lower

upper

Xylene

50

3

Not lower than 23

Above 450

1,0

6.0

Turpentine

300

4

34

300

0,8

6.9

White Spirit

300

4

Not lower than 33

270

1,4

6.0

Solvent

50

3

22-36

464-535

1,02*

—

Lead compounds

0,01/0,005

1

—

—

—

—

Chromium compounds

0,01

1

—

—

—

—

* Lower flammable limit at a temperature of 25 ° C and a pressure of 101325 Pa (760 mm Hg).

Solvent vapors are irritating to the mucous membranes of the eyes, upper respiratory tract and skin.

Lead compounds, being extremely dangerous, cause chronic intoxication, expressed in damage to the central nervous and cardiovascular systems, in changes in the blood, gastrointestinal tract and other organs.

Chromium compounds irritate and cauterize mucous membranes and skin, causing ulceration; when inhaling aerosols, the cartilaginous part of the nasal septum is perforated. They also have a general toxic effect, affecting the gastrointestinal tract.

6.3. The production of enamels must comply with the safety rules for paint and varnish industries, approved in the prescribed manner.

6.4. Production, testing and use of enamels must comply with the requirements of GOST 12.3.005-75 and GOST 12.1.004-91.

6.5. Persons associated with the manufacture and use of enamels must be provided with special clothing in accordance with GOST 12.4.103-83 and personal protective equipment in accordance with GOST 12.4.011-89, GOST 12.4.068-79.

Individual respiratory protection equipment - in accordance with GOST 12.4.028-76, GOST 12.4.004-74 and GOST 17269-71.

6.6. Work related to the manufacture and use of enamels is carried out in rooms equipped with local and general supply and exhaust ventilation in accordance with GOST 12.4.021-75, which ensures the state of the air environment in accordance with GOST 12.1.005-88.

Fire extinguishing agents - sand, felt, foam fire extinguishers ОХП-10, carbon dioxide ОУ-2 and ОУ-5, foam installations, water mist - according to GOST 12.4.009-83.

6.7. To protect the atmospheric air from pollution, air purification at gas cleaning plants and monitoring of compliance with maximum permissible emissions (MPE) in accordance with GOST 17.2.3.02-78 should be provided.

6.8. Waste generated during the cleaning of equipment is disposed of in accordance with the procedure for accumulation, transportation, disposal and disposal of toxic industrial waste.

(Modified edition. Amendment No. 5).

Advantages and disadvantages

There are many arguments for using the PF-115.

- Moisture and weather resistant. Although some experts are skeptical about the protective properties of pentaphthalic enamel, it nevertheless is able to take care of your structures, reliably limiting access to precipitation and UV rays.

- Lightfast and durable. The viability of the protective coating directly depends on the originality of the formulation and compliance with the dyeing technology. On average, the shelf life of the coating is 4-5 years.

- It has a low price - this is one of the main advantages of enamel, which often becomes a decisive factor in favor of its purchase, especially when the budget is limited.

- Provides excellent adhesion even when applied to smooth metal surfaces.

- Eliminates significant costs for preparing surfaces for painting - another opportunity to save on expensive and time-consuming technological procedures.

- Highly elastic and crack-resistant.

- Highly durable and wear-resistant, therefore suitable for painting floors.

- It is universal in application for external / internal types of work, for painting on metal, concrete, wood. Since PF-115 is able to combine well with the listed materials, it will be possible to protect various products with one product, saving on the purchase of specialized compositions for treating surfaces from a specific material.

- Possesses good decorative properties and allows to obtain a glossy, matte, semi-matt surface.

- Easy to use, can be applied with ordinary painting tools or special equipment, gives minimal shrinkage. Low-skilled personnel can work with PF-115.

- Differs in good fluidity, hiding power, thixotropy - the ability to reduce viscosity due to mechanical stress and to increase viscosity in a quiet state.

- Easy to clean with common detergents.

- A wide selection of color solutions, among which there are both classic strict shades and bright, saturated ones, which makes it easier to select the right color scheme for your own needs. In addition to the standard colors of enamels made in accordance with GOST, you can order a paint shade according to RAL.

Weaknesses are also present.

- Content in the composition of components that are harmful to health. The evaporation of these substances during the drying process is accompanied by a pungent odor.

- It has low vapor permeability, which must be taken into account when painting facades.

- Low indicators of chemical resistance to the effects of various aggressive media. Therefore, in some areas of the industrial sector with increased requirements for the quality of protective coatings, the use of pentaphthalic enamel is limited.

- Fire hazardous.

- Extended drying period.

When it comes to painting high-rise buildings - water towers, chimneys or just walls of multi-storey buildings - industrial climbers are usually involved in the work. The services of such teams are worth it.

In this case, it is most profitable to paint objects “in one go”, this way time and money are saved. It is unrealistic to do this with pentaphthalic enamel, since 24 hours must pass before applying each subsequent layer. Whereas there are quick-drying enamels, interlayer drying of which takes only half an hour, for example, the Anticor Sprint coating.

In addition, PF-115 is not recommended to paint metal structures used in aggressive industrial atmospheres, that is, those located directly at metalworking industries, thermal power plants or near them, and objects that are constantly in contact with the aquatic environment - piers, piles. More advanced materials are needed here than pentaphthalic paint, capable of providing a high degree of corrosion protection.

Physical state and chemical composition

The paint itself is viscous, with small solid particles.

PF-115 enamel differs in color, brightness, tone and density, which is created by pigments (colored powders), which are responsible for the formation of shades and give transparency to some materials.

Pentaphthalic varnish is composed of vegetable oils, resin, rosin and glycerin.

In addition to pentaphthalic material, various oils and a desiccant are added to the solvent - a substance that helps to dry faster on the surface.

An organic solvent (white spirit) is added precisely to oil solutions.

The transparent substance is extracted from oil, it has an oily consistency, it dilutes the paint if it is too thick and does not affect the composition itself.

The paint contains titanium white (titanium dioxide), a non-toxic substance that creates a white pigment in paint materials, holds the oil on the surface and scatters light.

Alkyd enamel differs not only in a variety of colors, but also in moisture resistance, well tolerates prolonged exposure to UV radiation, and does not crack after drying due to its strength and elasticity.

PF-115 is already selling a certain color, but you can change it if you add another paint to the solution. At the same time, the volume will increase.

The most common shades:

- Blue.

- White.

- Gray.

- Beige.

- Pink.

- Orange.

- Cherry.

- Citric.

- Terracotta.

- Khaki.

- Red.

- Salad.

- Ivory.

- Black.

- Blue.

- Turquoise.

After staining, plastic, bendable structural parts retain their original appearance - the enamel does not break off and does not wear off with frequent interaction.

Features and application of PF-133 enamel

Modern paints and varnishes are quite diverse. To obtain a high-quality result, you should strictly take into account the specifics of each option.

Enamel PF-133 is an excellent product, but it should also be used strictly according to the technology provided by the manufacturer.

Peculiarities

GOST 926 82 stipulates that this enamel, regardless of color, must be a suspension of dyes and fillers in an alkyd-based varnish. Organic solvents, driers, and sometimes other components are added to the mixture.

The product specifications are quite decent. Two coats of enamel (if they cover the previously primed surface) will provide reliable protection for 36 months in temperate climates.

Application of the composition is possible:

- pneumatic spraying;

- spraying in an electromagnetic field;

- by spraying in an airless space;

- bathing the product in the mixture;

- pouring jets;

- with a brush.

Preparation for work

When using enamel PF-133 in any area, it is necessary to stir it and bring it to the target viscosity using:

- solvent;

- xylene;

- nefras;

- special thinners (for subsequent painting in electromagnetic fields).

According to the standards for PF-133 enamel, its density is 1100 - 1200 g per 1 sq. m. The established requirements provide for a dilution of up to a maximum of 30%.

The difference is determined by the unequal chemical composition of the enamel of different colors.

It is important to remember that the product is toxic and poses a significant fire hazard.

Safety regulations

PF-133, as well as the thinners and solvents used with it, can provoke skin irritation and the appearance of eczema. It is worth fearing the destructive effect of the composition on the blood, mucous membranes and respiratory tract, as well as on the nervous system. Experienced painters prepare individual respiratory protection for work and wear rubber gloves. In case of contact of the enamel with the skin, it is immediately washed off with warm soapy water.

Pentaphthalic enamel, regardless of dilution and ambient temperature, is highly flammable.

At industrial facilities and construction sites, it is necessary to conduct continuous monitoring of air quality.

Practical properties and use

The composition adheres well to metal, the coating shines and turns out to be very hard. The product perfectly tolerates negative weather conditions, temperatures of -40 and +60 degrees. PF-133, in contrast to the more familiar PF-115, can “survive” chamber drying. No effort during air drying can give a film comparable in strength and stability.

The composition does not form streaks and wrinkles, it is immediately applied with a perfectly smooth layer. Drying time ranges from 24 to 48 hours, this is determined by the number of layers and the temperature. Contact with water within 10 hours (at room temperature and immobility of the liquid) does not lead to negative consequences.

Preliminary preparation involves priming with mixtures of PF, EF and GF. The use of their complete chemical analogs is also allowed. The tree must be thoroughly cleaned of any dust and dirt. The best option is sanding. It is not allowed to paint PF-133 over a damaged or poorly adhered previous coating.

It is allowed to dilute the enamel itself with a combination of xylene with white spirit up to 70%. In this case, the proportion of white spirit in the diluting composition cannot exceed 50%. Recommended operating air temperatures - from +5 to + 30 degrees, relative humidity - maximum 80%.

1 liter of PF-133 can cover 19.5 - 26 sq. m. surface. This indicator is influenced by the smoothness or roughness of the substrate, operating temperature, dilution, professionalism in application, the geometry of the product to be coated. If chalk or lime paint is located below, the composition must be removed completely, regardless of its safety and stability. With chamber drying, the air temperature can reach 82 degrees, which reduces the processing time to 120 minutes.

PF-133 should be stored in a dark, dry room, excluding exposure to wind and direct sunlight. The minimum allowable temperature is -20 degrees. Under standard conditions, the enamel can be stored for 12 months.When the warranty period expires, only special laboratory tests make it possible to recognize it as fit for use.

When buying paintwork materials, it is important to study the certificates of conformity for the practical characteristics and hygienic properties of the goods. Review on enamel PF-133, see the next video

For an overview of PF-133 enamel, see the next video.

Manufacturers

PF-115 is manufactured by many Russian enterprises. But the tough competition for the consumer led to the fact that the domestic market of paints and varnishes was filled with low-quality cheap enamels produced under the PF-115 brand, only not according to GOST, but in accordance with TU.

Some manufacturers of paint and varnish materials practice the implementation of special marketing solutions in order to distinguish their low quality products from other low-grade products. As a result of such a marketing policy, a brand of pentaphthalic paint appeared under the marking 116 with its other derivatives such as Ultra, Extra, Super.

Only products made in strict accordance with GOST 6465-76 deserve trust, but not with TU - technical specifications of enterprises, which most often establish individual quality indicators in order to reduce the market price of their products.

We offer you to pay attention to reputable manufacturers of paints and varnishes with a high rating of reliability among buyers

Lacre

This is a well-known Russian company specializing in the manufacture of decorative paints and varnishes. Universal alkyd enamels "Lakra" have excellent interlayer adhesion, high atmospheric resistance and hiding power. The range of colors includes over 40 color solutions. Most of them form a glossy finish. The guaranteed shelf life of paintwork materials is 24 months.

Prestige

The holding produces paints and varnishes of the highest quality combined with an affordable price. In 2005 the company presented two technological innovations - a budgetary pentaphthalic paint "Kazachka" and a premium high-quality alkyd enamel paint "Poller". Both products are manufactured in full compliance with the standards for this group of paintwork materials.

In the line of alkyd enamels, there are many other decent paint and varnish coatings. This is a super-white PF-115 with a high degree of gloss based on a cleaned, clarified varnish and a heat-resistant, anticorrosive, silver-colored decorative coating with natural aluminum powder as a filling fraction, which can be used to paint radiators, heat pipes, and chimneys.

A very interesting option is an eco-friendly semi-glossy acrylic quick-drying universal enamel, which, when applied, begins to smell like a green apple. As the polymer coating dries, the apple smell weakens and disappears.

Tex

One of the largest manufacturers of paintwork materials with a wide network of construction stores located throughout Russia.

There are several types of PF-115:

- universal alkyd white matt and glossy with the possibility of tinting according to the catalog;

- universal glossy color, which, in addition to wood and metal, can be painted on plaster bases, building structures made of gypsum plasterboard, fiberboard / chipboard;

- "Fazenda" - enamel forming a glossy finish, characterized by an economical consumption of 1 kg / 6-16 m2 in a single layer application and resistance to weathering;

- "Optimum" - enamel paints with a drying period of up to 7 hours. Interlayer drying interval - 24 hours;

- "Economy" for mass construction and painting of wood and metal structures.

Buyers still consider enamel paint made according to the original recipe to be a good "folk" remedy, noting the elasticity of the film and its resistance to external factors. Many summer residents are happy that, with a limited budget, you can quickly improve the outbuildings on the site after winter or update the old fence covering.

For these purposes, it is better to purchase imported UV-resistant enamel.There are no complaints about the protective properties of PF-115: such a coating is quite capable of protecting concrete, metal or wood from negative atmospheric influences.

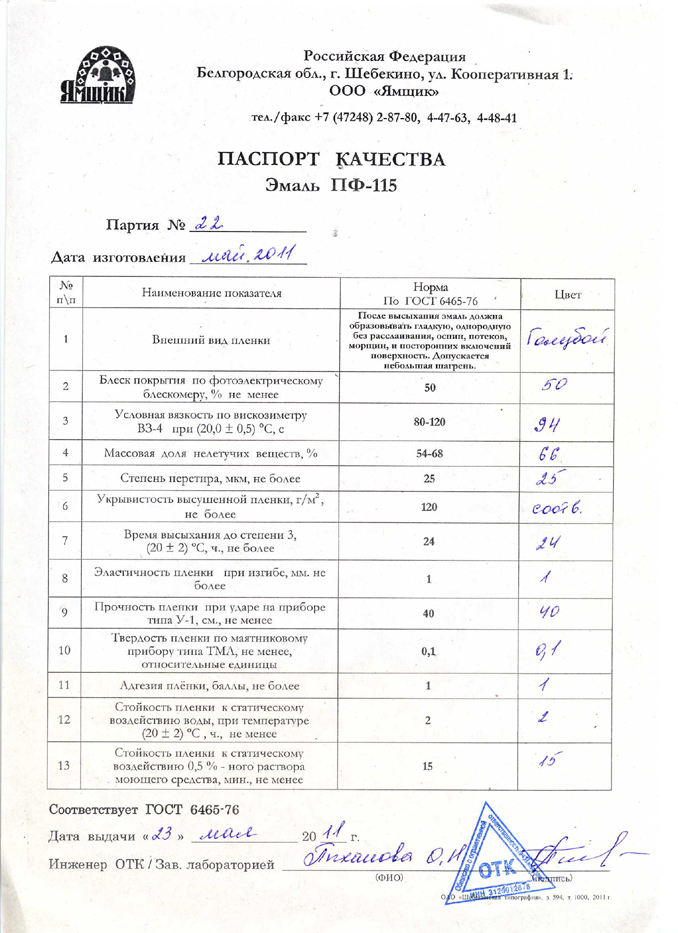

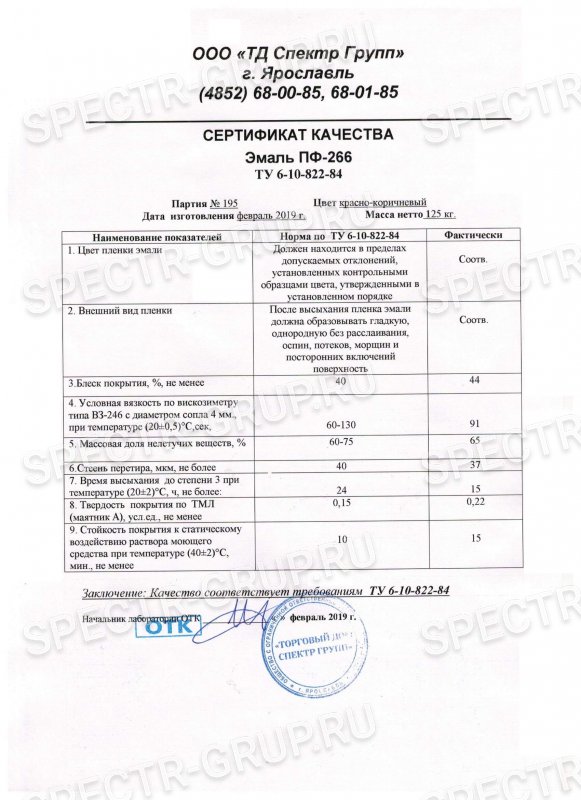

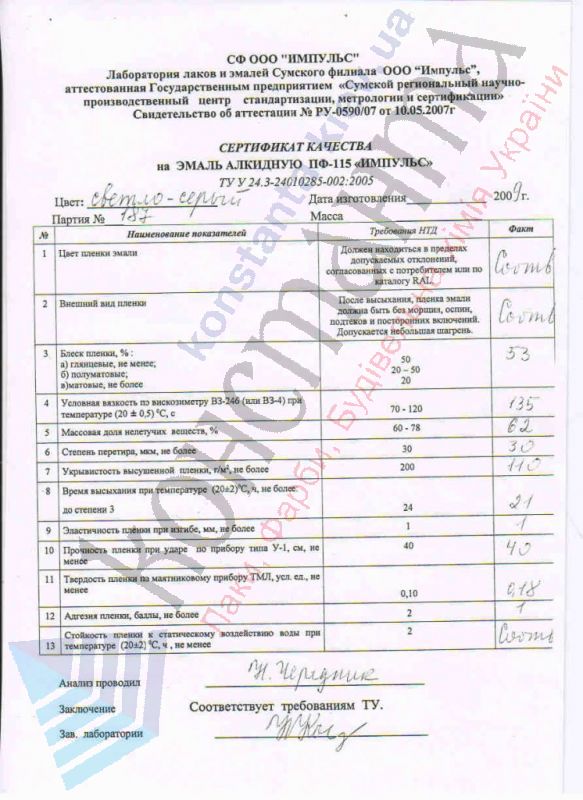

Enamel technical features

For enamel PF-115, the following technical characteristics are characteristic:

- the formation of a glossy coating (gloss level is 50%);

- adhesion level - up to 1 point (there are also oil options with lower adhesion);

- the proportion of non-volatile components ranges from 49% to 70%;

- bending elasticity index - no more than 1 millimeter;

- drying rate of the coating at room temperature - up to 24 hours;

- specific hardness - from 0.15 to 0.25 conventional units;

- conditional viscosity index - from 60 to 120 conventional units;

- ability to resist moisture - up to 2 hours, fuels and lubricants - up to 24 hours, aggressive detergents - up to 15 minutes.

The paint is characterized by high hiding power. On average, the surface service life at low temperatures is 4–5 years, but in hot climates it does not exceed 1 year.

The disadvantage of PF-115 is the fire hazard of coatings and a fairly high level of toxicity. When applying such enamel indoors, you should observe safety precautions (protective clothing and glasses, respirator).

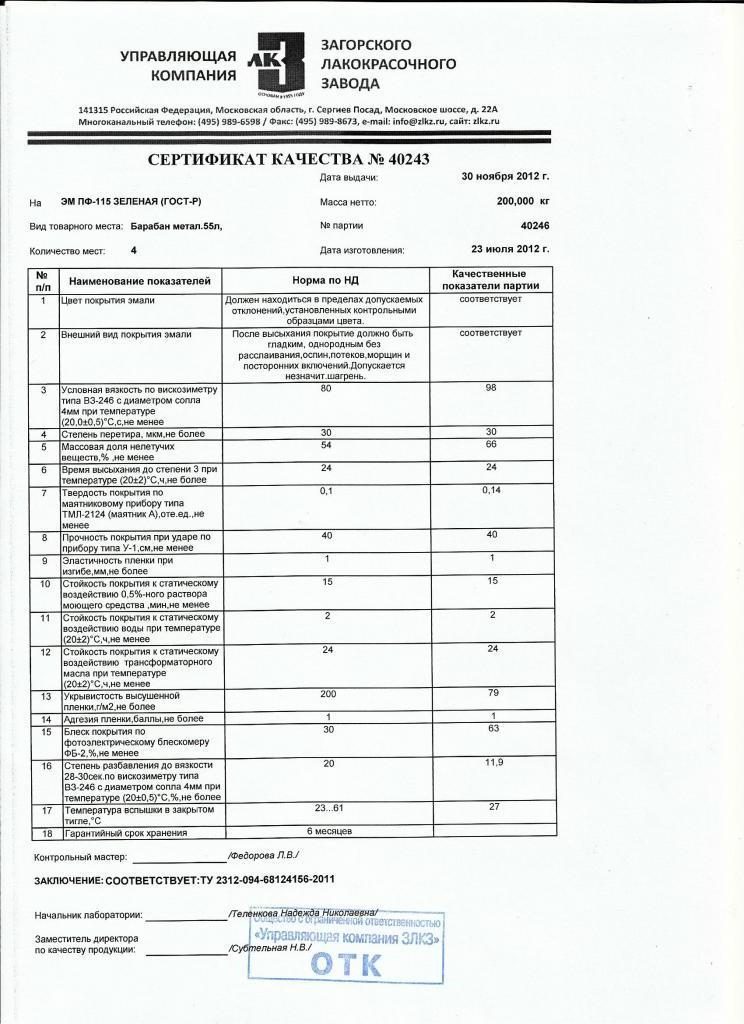

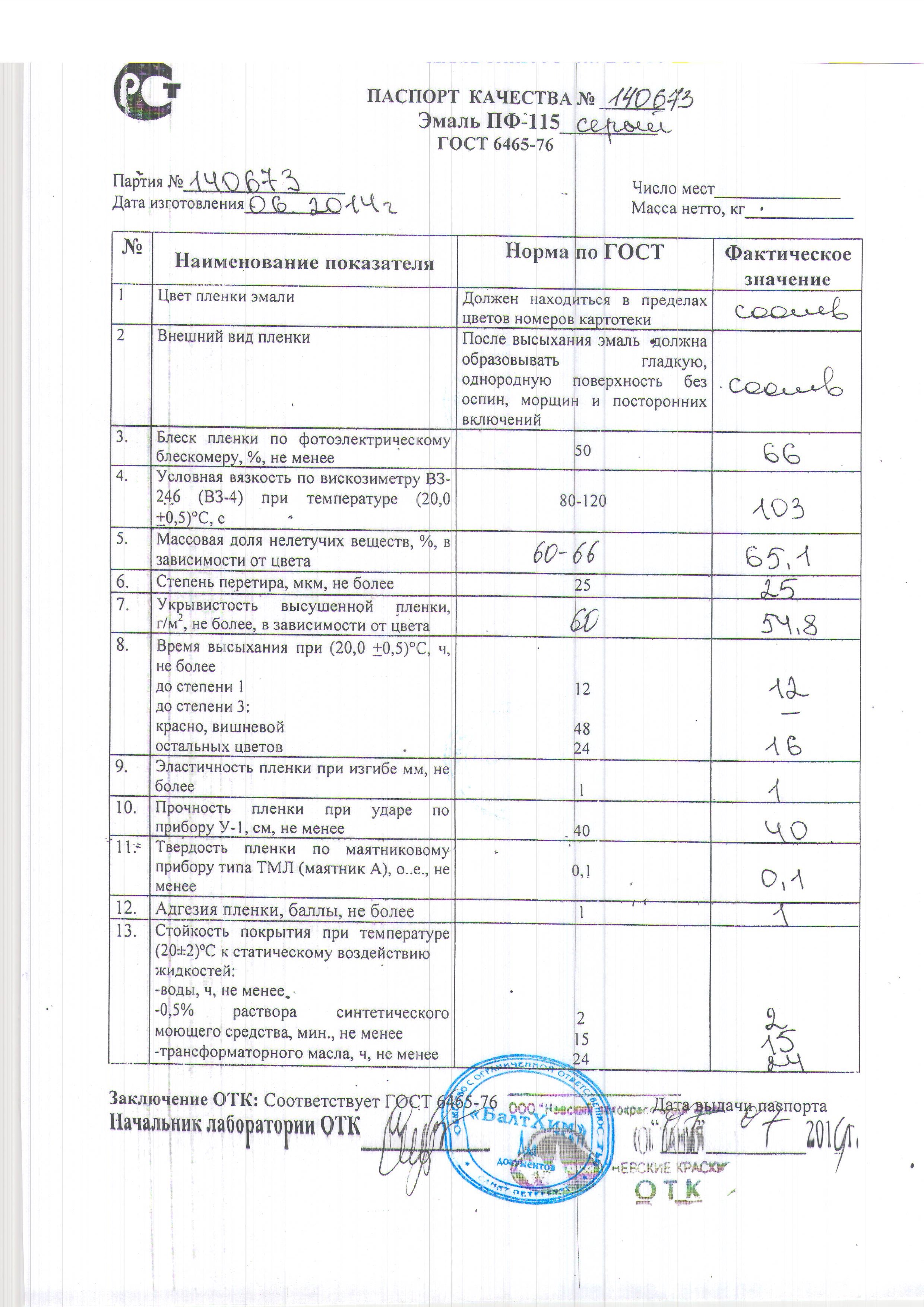

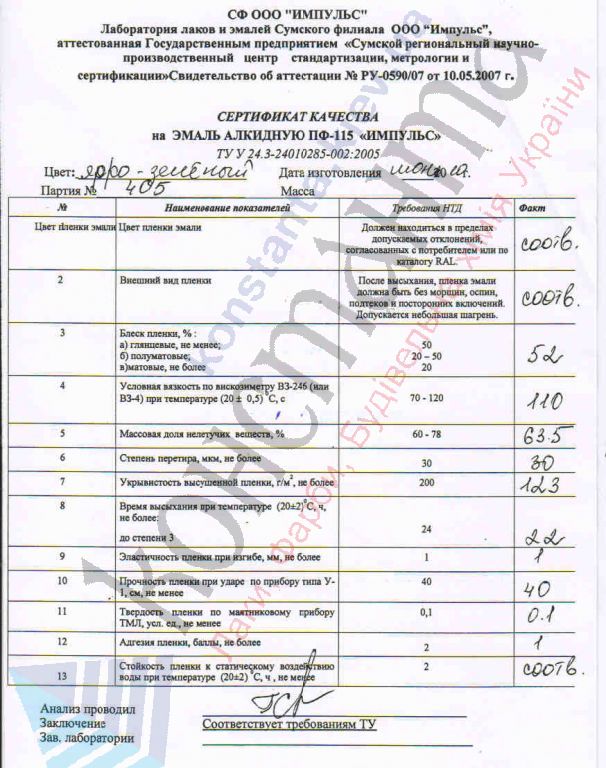

State standards

PF-115 production technology is regulated by GOST 6465-76. This standard was created by the USSR Ministry of Chemical Industry in 1976.

There are other government-established standards that regulate certain aspects of the production process.

List of GOSTs, which contain information about this enamel:

9980.1 - the rules of acceptance are stated;

9980.2 - the order of sampling has been determined;

9980.3 - rules for the use of packaging and labeling are outlined;

12.1.005 - lists the hazard classes of the components in the paint;

12.1.044 - fire hazard is characterized;

12.3.005b 12.1.004 - outlines the requirements for production and testing processes, as well as for the use of enamel.

GOSTs also regulate the use of protective clothing and devices to ensure the safety of workers.

What does marking PF-115 mean?

Well-known to professional builders and owners of private houses, PF-115 enamel appeared on the market in the distant 60s of the last century. Until now, it remains one of the most practical paints for various types of repair and construction work. Such durability of the paint is due not only to the low price, but also to a number of unique consumer qualities.

The paint is produced practically unchanged from the day it first entered the market. Its composition is regulated by GOST 6465-76. If you want to use the classic PF 115, then buy paint made in accordance with GOST. Many manufacturers make changes to the chemical composition and produce paint according to TU. It is very difficult to guess whether its properties are improved or worsened; it can only be verified experimentally. But there is not always time to do this, and not everyone can afford to buy paint, albeit inexpensive, for experiments.

The name of PF 115 encodes the chemical composition and the main areas of application. The index is understandable to a specialist, but does not mean anything to an ordinary buyer. Nevertheless, the information is very important.

The letter PF symbol means that pentaphthalic varnish (a type of alkyd resin) acts as a binder for the paint. The scope of application of pentaphthalic paints is exterior and interior work on a wide range of materials.

Numbers 115 show the scope of application:

- 1 - for outdoor work in various climatic conditions;

- 15 - the number of the chemical composition, determined by GOST and deciphered by the manufacturer.

According to its physical state, paint PF-115 is a suspension, a suspension of solid and liquid particles of various kinds in a liquid medium. The particles are represented by solvents, dyes, pigments, desiccants, titanium dioxide and other fillers. The base is a fairly viscous pentaphthalic varnish, which is dissolved with white spirit or other organic liquids.

Chemical composition, marking, colors PF-115

PF enamel refers to alkyd paints. Read more about alkyd paints here

GOST No. 6465-76 has become a regulatory document that once determined the optimal combination of components that make up this alkyd paint. This standard is used to check the quality of the composition before releasing it for sale. It is also allowed to produce pentaphthalic enamel according to technical specifications developed by manufacturers independently. This affects the cost and can affect the quality of the coverage.

From a chemical point of view, alkyd paint-enamel PF-115 is a suspension, which includes:

- solvent;

- pentaphthalic varnish;

- titanium dioxide;

- color pigments.

The proportion of the components changes depending on the color.

- According to technical characteristics, enamel PF 115 white contains: pentafle varnish 28%, titanium dioxide 62%, white spirit 10%;

- Gray - pentafle varnish 20%, titanium dioxide 75%, white spirit 4.5%, carbon black 0.5%;

- Blue - pentafle varnish 26%, titanium dioxide 60%, white spirit 4%, azure 4%, zinc white 6%.

Marking

When painting, it is important to choose the correct enamel. For ease of orientation, manufacturers use the generally accepted markings indicated on the label of the paint container.

So, the standard designation of the universal alkyd enamel PF-115 has five components:

- the name of the type of paintwork - in our case it is paint;

- abbreviation (PF), implying the presence of a pentaphthalic-based varnish in the composition;

- digital key. In this case, it is the number 115, where the first digit means that the material is suitable for outdoor painting or restoration, and the last two reflect the chemical composition that corresponds to GOST.

Painting

The universal qualities of PF-115 allow you to paint the surface at an air temperature of 5 to 35 degrees Celsius. To apply paint, use brushes, brushes, rollers or spray guns. Immersion staining is also used.

Metal structures are painted with at least two layers of enamel after preliminary priming. For high-quality painting of wood, brick, concrete or plaster, you will need two or three layers, each 18-23 microns thick. The spread in thickness is due to differences in the structure of the painted material and the color of the paint.

After applying a layer of enamel, the surface must dry. Drying at 20 ° C takes up to 24 hours. When faster drying is needed, high temperatures (100-110 degrees) are allowed.

After the enamel dries, the surface becomes glossy, uniform, smooth. It is resistant to abrasion, weather and chemical influences. PF-115 is compatible with almost any type of paintwork.

Surface preparation

Before applying the enamel, it is necessary to carry out preparatory measures so that the paint and varnish layer lays down qualitatively.

The work is done in this order:

- Remove traces of grease, dirt, old paint coat from the surface. To do this, you can use washing powder, soap or soda solution. Sand the wood materials. Remove traces of rust from metal structures.

- Dry the surface thoroughly (especially when it comes to plaster or concrete).

- If metal is to be painted, treat it with a degreasing agent and apply an anti-corrosion primer.

- If wood will be covered with enamel, apply drying oil, Biotex primer or universal varnish.

- For porous surfaces, an alkyd primer is preferable.

Primer application rules:

- Dilute the composition with a solvent (if necessary according to the conditions of the instructions).

- Stir the composition with a wooden stick.

- Apply the primer in a thin layer using a brush or roller.

- Let the surface dry.

Note! Pentaphthalic primers can be applied over old paint. However, then you need to sand its layer

Security measures

Painting should only be carried out using personal protective equipment (goggles, gloves, respirator).If paint and varnish material gets on the skin, wash the affected area with warm soapy water. When carrying out work, it is necessary to provide good natural or artificial ventilation. There should be no sources of ignition near the area to be painted.

Enamel consumption

One of the advantages of the PF-115 is economical consumption. Specific indicators depend on many circumstances:

- Application method. When working with a spray gun, paint and varnish material is consumed less economically compared to using a brush.

- Manufacturing technology. PF-115 is produced not only according to GOST, but also according to TU. In the latter case, the flow rate is approximately 50% higher.

- Substrate preparation degree. A well-primed surface reduces the consumption of paints and varnishes.

- Consumption per 1m2 even depends on the color of the enamel. The most economical option is black paint, and the most wasteful option is white. Other colors are intermediate.

- The type of material to be painted. Consumption per 1 m2 for metal will be less than when painting wood, which absorbs part of the paintwork.

Enamel consumption - from 100 to 180grams per square meter of one layer.

Scope, technical characteristics of PF-115

Pentaphthalic-based alkyd paint can be painted on almost any exterior surface - it is used for work on concrete, metal and wood.

Oil paint PF-115 is suitable for processing the facade, walls, basement or roof. Any house, be it a wooden hacienda or a concrete panel-type structure, can be effectively painted in a short time. For each of them, the proportions of the use of components have been determined, which ensure the optimal technical characteristics of the PF-115. By the way, the general technical characteristics of this enamel include:

- the gloss of the film formed during coloring is 50%;

- paint adhesion 1 point or less

- mass fraction of non-volatile substances in the total volume - 50-70%;

- elasticity (when bending) - up to 1 mm;

- impact strength - from 40 cm;

- hardness - from 0.15 to 0.25 conventional units;

- drying time at a temperature of about 20 ° C - no more than 24 minutes;

- viscosity (conditional) - 60-120 s;

- resistance to: water - 2 hours, technical oil - 24 hours, detergent (0.5%) - at least 15 minutes.

These technical characteristics determine both the advantages and some disadvantages of pentaphthalic enamel. Let's analyze in more detail.

Advantages of PF-115

The main advantages of using this enamel are:

- high resistance to external atmospheric factors such as moisture, extreme temperatures (from -50 to +50 degrees) and ultraviolet rays;

- possibility of long-term operation - the shelf life of the coating in normal climatic conditions is about four years. But it is worth considering that with constant exposure to high temperatures and moisture, it can be reduced to one year;

- wide range of colors;

- increased resistance to chemical compounds - the coating can be safely washed using special detergents;

- high adhesion density with the base due to the high adhesion rate in the compositions (according to GOST up to one point);

- versatility of application: concrete, metal, wood. Including application on plaster or wood base covered with varnish is allowed;

- low consumption rates ensuring economy. The consumption of PF-115 enamel paint per 1 m2 according to the instructions is about 150 grams, and depends, among other things, on the technology used, as well as on the type of surface;

- low cost. PF 115, in comparison with other paints and varnishes, has a low price - 1 kg of material will cost about 60-70 rubles.

Disadvantages of PF-115

Among the disadvantages inherent in working with enamel, experts point out:

long drying time - complete polymerization of the coating is about a day

This is quite a lot, considering how much the enamel of other types dries;

low fire safety class - despite the fact that a number of brands declare the presence of a KM-1 certificate, for the most part, PF-115 enamels are characterized by increased flammability;

toxicity and specific smell of the composition - working with paint requires compliance with all precautions, since it contains solvents and chemical components that are harmful to the human body and evaporate during drying;

the complexity of cleaning painting tools - as a rule, after the end of the work, it is easier to throw out the brushes than to dissolve PF-115, which has dried up during use.