Enamel NTs 132. Introduction, history of creation

NTs 132 is the most demanded product from the line of nitrocellulose enamels, they are also called nitro enamels. The main quality indicators are regulated by GOST 6631-74. There are two types of NTs 132P for spray application and NTs 132K for brush or roller application.

NTS enamels are made on the basis of cotton cellulose treated with nitric acid. As a result of this treatment, cellulose nitrate-colloxylin is obtained. For the production of nitro paints, colloxylin is used with a nitrogen content of 10.7-12.2%,

Nitrocellulose with a nitrogen content of 12.05-12.4% is called pyroxylin and is used in the manufacture of propellants and explosives for the manufacture of ammunition. In this regard, gunpowder factories are often engaged in the production of colloxylin. Due to the high flammability and danger, only a few manufacturers are engaged in the production of nitro paints in Russia, one of which is PO Mercury LLC from Kazan.

New York. 1924, really familiar picture?

New York. 1924, really familiar picture?

The impetus for the production of quick-drying NC enamels was the rapid development of the automotive industry at the beginning of the 20th century. After Ford's invention of the conveyor belt, one of the most pressing issues in the production of cars was the acceleration of drying after painting the car bodies. Recall that before that, paints were used and were considered quick-drying with a drying time of one to two days. Of course, it is difficult to imagine the workshop of an automobile plant, clogged with drying car bodies. Capitalism couldn't afford it!

Therefore, in the 20s of the last century, on the instructions of automakers, DuPont specialists created a quick-drying enamel NC with a drying time of 15-30 minutes at 20 degrees Celsius.

For almost 50 years, from the 20s to the 70s of the 20th century, nitroenamels were actively used in the automotive industry around the world. Until they were replaced by more technologically advanced synthetic enamels. They are still used to a limited extent in the automotive industry, but not for painting bodies, but for painting body parts and suspension.

Enamel NTs-132P

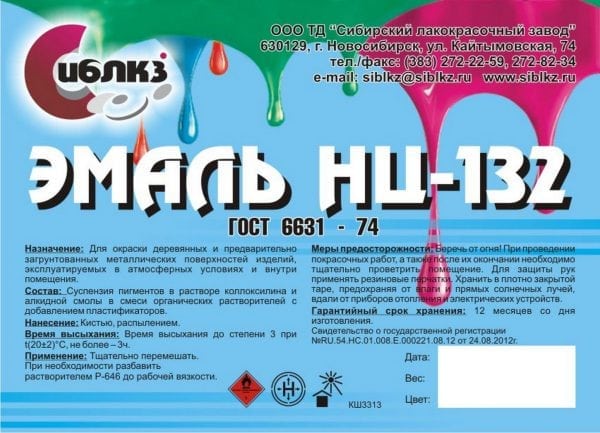

Appointment of enamel NTs-132P

For painting wooden and pre-primed metal surfaces of products used in atmospheric conditions and indoors.

Enamel composition NTs-132P

Enamel brand NTs-132P of various colors is a suspension of SVP (expanded pigment with nitrocellulose, plasticizer and dispersant) in a solution of colloxylin and alkyd resin in a mixture of organic solvents with the addition of plasticizers.

Properties of enamel NTs-132P

Enamel NTs-132P is universal, it can be used both as an independent coating and in a complex coating with various primers (including GF-021, AK-070, FL-03K, VL-02). The choice of primers depends on the surface to be painted and the climatic conditions of the coating. Enamel NTs-132P forms a weather-resistant coating, as well as it is resistant to water and industrial oils. The coating is resistant to temperature changes from minus 50 to plus 60 ° C. (temperate, moderately cold climate). Enamel NTs-132P is allowed to be applied on ferrous metals without preliminary priming. The enamel coating has high hardness and strength, it is elastic. Enamel NTs-132P is applied by spraying.

Views

Types and technical parameters of NTs-132 enamel are regulated by GOST 6631-74.

There are two types of paintwork materials:

- NTs-132 "K" is designed for application with a brush and has a certain density, but it can be diluted with a solvent to a more liquid consistency;

- NTs-132 "P" is a liquid form suitable for spraying with a spray gun.

Enamel specifications.

- The ambient air temperature for the use of paintwork materials should be in the range from -12 to +60 C.

- 120 minutes after application, the surface treated with NC-132 may acquire a slight stickiness. Full use is possible one day after staining.

- The film layer formed by the enamel after hardening is characterized by excellent smoothness, the absence of streaks, spots, bumps and depressions.

- The hardness index is not less than 0.15 cu. e. It is determined by a special pendulum device TML.

- The U-1 device allows you to measure the impact strength of the layer - not less than 50 cu. e.

- The gloss of the composition is in the range of 40-55%.

- The mass fraction of volatile substances can be easily determined by the color of the liquid. For black enamels, it is the lowest (22-28%), in other shades more than 29% of volatile compositions.

- The shelf life when kept in a sealed package without violating storage conditions is set at 1 year.

Enamels NTs-132 are produced in a variety of convenient formats in cans, ranging from 0.7 kg, 1 kg, 1.7 kg and up to large barrels for industrial facilities in 17, 25 kg and more.

Mode of application

After opening the package, NTs-132P enamel is thoroughly mixed until uniform density. The material can be diluted to working viscosity with solvent 646. Before painting, the metal surface must be cleaned of scale, rust, primed (on ferrous metals, enamel is applied in several layers without primer). Wooden bases are sanded and dust-free.

Application is carried out in two layers on a metal surface and in three layers on wood. For work, use a spray, but painting with a brush, roller, dipping method is also applicable. Application is carried out at temperatures from +5 to +34 ° C.

Color palette

Shades of funds are regulated by GOST. They differ in variety, which allows you to choose the desired option depending on the type of finish. The light palette is presented in white, cream, light gray and beige tones.

Dark shades include tobacco, dark gray, gray-green, black. Also in the color scheme there are gray-blue, protective and dark blue-green colors. For a vibrant result, you can use a golden yellow, orange-brown or red shade. Also in the palette there is a red-brown tint.

In addition, natural shades can be found in the assortment of dyes. These include green-yellow, gray-green, pistachio. Also available in gray-blue and light green tones. To get a different shade, you can order an individual production.

Application rules

After the surface is thoroughly dust-free, degreased and primed, you can proceed with the installation. Initially, mix the enamel well and remove the top film. Usually the paint has the desired consistency and does not need to be diluted. However, with an increased density of the material, it can be diluted with a solvent, when choosing which one should take into account the modification of the enamel.

Application is carried out with any available tool, taking into account the purpose of the paint, the amount of work and the relief of the painted surface. After the first layer is formed, it is required to leave the surface to dry for two and a half hours, and only then proceed to the application of the second layer.

Basic properties

Enamel NTs-132 has many useful characteristics. After hardening, it becomes strong enough, has a high resistance to mechanical stress, scratches, abrasion and friction. The protective film has excellent elasticity, therefore, parts with a large curvature can be painted with this enamel. These are the main properties of this paint:

- the protective layer reliably protects surfaces from the influence of household chemicals, moisture, water, detergents, oils, this enamel can be used in rooms with a very high indicator of air humidity;

- after the film has hardened, it can be polished and sanded, this will not deteriorate the quality of the coating, but on the contrary, it will become decorative, glossy;

- the consumption of enamel NTs-132 is small, this tool is very convenient and cost-effective;

- the protective layer has a long service life, dries very quickly, protects wooden and metal structures from damage, corrosion and other negative factors;

- the film does not fade for a long time, being in the sun, under the influence of ultraviolet rays.

This paint can be used in a wide temperature range, from -12 to +60 degrees. The manufacturer offers a wide range of colors of NTs-132 enamel; this paint is produced in yellow, red, black, white, brown, green, blue, and other colors, dark and light.

We understand the markings of enamels

For the correct use of enamels, it is important for the consumer to know what the marking indicated on the label or special insert attached to the product means. This label contains important information about the scope of application of this product, its properties and how to use it.

What is enamel

Enamel has been known since ancient times, initially it was a hard glassy coating obtained by high-temperature firing. Metal, glass or ceramics were covered with enamels. In the modern paint and varnish industry, complex multicomponent compositions are called enamels or enamel paints, which provide the product properties necessary for the consumer.

Enamel paints or simply enamels consist of the following components: a substance that forms a sufficiently strong film, a solvent, the main coloring pigment that determines the color, a structural filler and all kinds of additives that serve to impart certain properties.

Unlike conventional paints, all these fillers are in a dissolved state, which ensures high uniformity and, as a result, high protective properties with a thinner layer of application.

Letter and digital marking of enamels

According to the rules adopted in our country, enamels, like all other paints and varnishes, are marked with an alphanumeric designation consisting of five groups or positions, each of which contains certain information about the product.

Five position marking for paints and varnishes

The first position in the marking of any paint and varnish materials determines the very name of the type of product. It can be enamel, primer, varnish, paint or putty. The label indicates the manufacturer and the country from which this product originates.

The color and reflective properties of the surface after painting (matte, glossy, semi-gloss, etc.) are also indicated on the label.

), weight of the product with and without packaging, production date, shelf life, transportation and storage conditions, area of recommended use (for indoor or outdoor use), special characteristics that the manufacturer would like to highlight, for example, high strength, moisture resistant, etc.

An important marking characteristic is the fire safety class of the product.

The second position for all paints and varnishes is the two-letter marking. It contains information about the chemical composition of the coating base, which forms a protective film. All paints and varnishes are made on the basis of various resins - such as polymer, natural, polycondensation, and cellulose ethers.

Special qualities of the composition

A film is formed that is resistant to friction, scratching, and mechanical stress.

The answer to the question why the product remains in demand will be clear if the qualities of the NC-132 composition inherent in nitro enamel are considered:

High resistance on the film surface to water, household chemicals, frequent wet cleaning with detergents

The composition is used in rooms with high humidity.

An important advantage of the NTs-132 product is that the painted surface will not suffer from grinding and polishing. On the contrary, the decorative layer acquires an enhanced shine.

Enamel belongs to economical materials, consumption is low

It is easy to work with.

Protective and decorative coating with a long service life, with a high drying rate.

The coating has anti-corrosion properties.

For a long time, the brightness of the color of the enamel layer remains under the influence of direct sunlight.

Similar:

| Abstract and annotation. General requirements. Instead of GOST 9-77; Enter. 01….GOST 0-99 (ISO 5127-1-83). Information and library activities, bibliography. Terms and Definitions. Instead of GOST 0-84, GOST 26-80; ... | State educational institution of higher professional educationThe content and structure of the main part is determined by the student in agreement with the leader. Figures, tables, literature are drawn up ... | ||

| Interstate standard packingGost 0-92 “Interstate standardization system. Basic provisions "and GOST 2-97" Interstate standardization system…. | National standard of the russian federation gost r en 779-2007The goals and principles of standardization in the Russian Federation are established by the Federal Law of December 27, 2002 No. 184-fz "On technical ... | ||

| Index of Terms 46E. A. Torchinov. Signs of Buddhism Identification: Official Information for Religious Studies 132 | State standard of the union of the USSRGost 63-90 Report on the geological study of the subsoil. General requirements for content and design | ||

| New books received by the library in the IV quarter of 2011Autonomy of the Republic of Crimea: stat zb. Simferopol, 2011.132 p. (Code 336 Krim / i- 585 -980197) | GOST 119-73 * preliminary designBy the decree of the State Committee of Standards of the Council of Ministers of the USSR dated February 28, 1973 No. 501, the date of introduction is established | ||

| General requirements for the design of abstractsThe text of the abstract must be drawn up in accordance with the requirements of the gost, the main provisions of which are reproduced here | List of current sibid standards as of 01.01.2008GOST 1-2003. Bibliographic record. Bibliographic description. General requirements and rules for drawing up. Enter. 01.11.04 |

Top manufacturers

Different brands are engaged in the production of enamel. This helps you choose the best option for your needs.

Belkolor

This enamel is popular with consumers.

Advantages and disadvantages

uniform coverage;

bright shades;

affordable price;

short drying period;

the presence of chemical components in the composition;

the need to use personal protective equipment.

I like not like

"Tex"

This product is sold in many home improvement stores.

Advantages and disadvantages

quality certificates;

low price;

wide range of.

flammable properties;

toxicity.

I like not like

"Lacra"

The products of this company are manufactured in different countries - Poland, Canada, Switzerland.

Advantages and disadvantages

affordable prices;

high quality;

variety of shades.

the presence of chemicals;

the need for the use of protective agents when painting.

I like not like

"Continental"

It is a relatively young company with rapid development and capacity expansion.

Advantages and disadvantages

compliance with sanitary and epidemiological standards;

high quality;

a wide range of colors;

reasonable prices.

the need to use protective equipment during work;

flammable properties.

I like not like

Rating summary table

Enamel NTs-132 is considered a popular product that can be used for painting various types of surfaces.

At the same time, it is important to strictly observe application instructions and safety rules

Peculiarities

Enamel NTs-132 has been produced since the 70s of the last century, and it is hard to believe that currently no paint and varnish compositions have been invented that would surpass it in their characteristics.Unlike paints, enamels, after complete hardening, form a smooth, uniform layer that protects the surface from various influences.

Initially, the main difference between enamel and paint was the type of thinning liquid. For enamel paints and varnishes, volatile compositions on an organic basis were used. In the case of paint, it could be drying oils or ordinary water. Over time, more and more water-dispersible enamels and paintwork materials based on acrylic began to appear.

The letters NTs indicate that this enamel belongs to the group of nitrocellulose, that is, paintwork materials made on the basis of nitrocellulose. It is a white fibrous structure, loose in appearance, reminiscent of ordinary cellulose and obtained from it using nitrogen treatment.

The composition of NTs-132 includes volatile and non-volatile parts. The first group includes alkyd resins (No. 188 according to the classification of resins), colloxylin-nitrocellulose with a nitrogen content of 10.7-12.2%, plasticizing additives and pigmenting particles. The non-volatile group is different for different types of enamels. It includes either 40% toluene, butyl or ethyl alcohol, about 15% active high-boiling solvents and slightly less low-boiling ones. In the second case, xylene is added instead of toluene, and the solvents reach 30%. An anti-flotation and fire retardant additive can be added to enhance decorative properties, smooth surface distribution.

Manufacturers pay attention to the exceptional resistance of NTs-132 enamel to various influences. In addition, such positive qualities are noted:

In addition, such positive qualities are noted:

- high strength and wear resistance;

- elastic structure is suitable for use of any shape and shape of surfaces;

- water resistance allows the use of enamel in structures with high humidity and outdoors;

- ease of care for surfaces covered with paintwork materials - can be washed with any household products;

- a layer of enamel can be sanded and polished to give a glossy shine, which will further affect the decorative appearance of products;

- the coating does not fade in the sun and does not lend itself to ultraviolet radiation;

- withstands strong temperature fluctuations;

- the material is economical and has a low price;

- long service life. When processing the surface with enamel in two layers in moderate climatic conditions, the coating can retain its decorative and quality features for up to two years.

Interesting: Silicone transparent sealant - features of choice

Scope of application

Enamel NTs-132, although it belongs to toxic and fire hazardous materials, but due to its protective and elastic properties, it has found widespread use. Wooden products, structures located in a harsh climate, high humidity will perfectly preserve their original appearance. Metal surfaces and concrete bases will be reliably protected from corrosion. This is applicable both in the domestic environment and in the processing of materials in industrial production.

In households, due to its excellent decorative properties, paintwork materials can be used to paint furniture, walls and decor items. Facades of buildings and metal fences due to low consumption are also beneficial to process NC-132. But the harmful substances emitted when working with nitro enamel forced some countries of the world to restrict the use of this product and even ban it completely.

Technical characteristics of Enamel NTs-132 GOST 6631-74:

| Film gloss,%, not less |

40-55 |

| Mass fraction of non-volatile substances,% - - (depending on color) |

22 — 40 |

| Nominal viscosity according to the VZ-246 viscometer with a nozzle diameter of 4 mm at a temperature of 20 ° C, s |

60 — 150 |

| Hiding power of the dried film, g / m2, no more --- (depending on the color) |

30 — 100 |

| Drying time to degree 3 at a temperature of 20оС, h, no more |

2 — 3 |

| Flexural elasticity, mm, no more |

1 |

| Film strength on impact, cm, not less |

50 |

| Film hardness, conv. units |

0,22 — 0,3 |

| Film adhesion, points, no more |

1 |

| Film resistance to static action of liquids at a temperature of 20 ° C, h, not less: - water - industrial oil |

6 |

Before use, enamel grade NTs-132K is diluted with solvent grade 649,

enamel grade NTs-132P with solvent grade 646 in accordance with GOST 18188.

Metal: Primer GF-0119, GF-021, VL-05, VL-023 or similar - 1 layer + NTs-132 enamel - 2 layers;

Wood (profiled): NTs-132 enamel - 2-3 layers;

Advantages and disadvantages

High consumer demand for enamel NTs-132 is due to a number of undeniable advantages of the material, namely:

- the elasticity of the composition allows you to paint products of any geometric shapes and relief with enamel;

- increased moisture resistance of the paint provides ample opportunities for its use in damp rooms and outdoors;

- good wear resistance indicators guarantee the preservation of the original appearance of the painted surface for two years;

- ease of care due to the resistance of the enamel layer to the effects of cleaning and detergent chemicals, including abrasive products;

- resistance to ultraviolet rays. The enamel coating does not fade in the sun and does not crack;

- high resistance to extreme temperatures and their sharp change allows you to use enamel in any aggressive environment;

- the optimal combination of price and quality makes it possible to significantly save money and get a good result;

- a wide range of colors of produced enamels greatly facilitates the choice and helps to implement bold design decisions. Painted surfaces acquire a decorative glossy effect.

The disadvantages of the material include the high toxicity of the liquid composition, which is why in some countries the enamel NTs-132 is sold with restrictions

Therefore, when working with enamel, it is necessary to strictly observe precautions and use personal protective equipment in the form of a respirator, glasses and gloves. The disadvantage is the high flammability of the enamel, which means that painting should not be done near sources of fire and heaters equipped with electric heating elements.

Consumption

The enamel is sold ready-made and does not require additional dilution. Application can be done with a spray gun, roller and brush. In comparison with a brush, it is much faster and easier to work with a roller, but it should be borne in mind that its use significantly increases the consumption of enamel. It is recommended to paint surfaces with paints and varnishes in two or three layers.

At the same time, paint consumption directly depends on the hiding power of the material. The higher this value, the less paint will be needed for coloring.

The preparation of the working surface has a great influence on the consumption of enamel. If a metal base is painted, then it must be thoroughly cleaned of rust, scale and dirt. Then the surface needs to be degreased and treated with a primer. Wooden bases also require preliminary preparation, which consists in drying and subsequent grinding of the surface. Then you should prime the wood and wait until the auxiliary layer is completely dry.

Primer compounds AK-070, VL-02 and GF-021 have proven themselves well.

Instead of a ready-made primer, you can use a solution of NTs-132 light enamel and a solvent, taken in a ratio of 5: 1. It must be remembered that wooden objects, due to their high porosity, have good absorbency and need double or triple staining. This property of wood should be taken into account when calculating the required number of cans and purchase material with a small margin.

How enamel differs from paints

By definition, enamel is a thin glassy layer obtained by fusing (fusing) a powdery mass (quartz sand, borax, potash, soda, boric acid) onto the surface of an object. As you can see, neither in the method of application, nor in composition, enamels have anything in common with traditional paintwork materials.

Therefore, the concept of "enamel", as one of the varieties of paints and varnishes, should be understood as a solution of one or another varnish, most often pigmented, forming, after natural drying, a smooth, even surface with increased protective properties.

In the process of using various paintwork materials, a certain stereotype of differences between paints and enamels has developed, which lies in the nature of the origin of the used diluent. For enamels, exclusively organic volatile thinners, and for the actual paints: drying oil, water. However, there are not so many general use enamels based on organic solvents. Already now, most of the enamels, i.e. paintwork materials with protective functions, are made on water-dispersion acrylic base... However, see for yourself.

Scope of application

Enamels NTs-132 are intended for painting concrete, metal and wooden surfaces. Excellent adhesion and plasticity indicators allow the material to be used on products with complex relief, as well as on substrates subject to vibration, deformation and serious mechanical stress.

Due to its good hiding power, the material is used for finishing facades, painting large rooms and metal fences. And excellent protective properties, comparable to the capabilities of specialized enamel XC-5132, allow using enamel as an anti-corrosion agent for processing metal surfaces. The paint has proven itself in harsh climatic conditions with sharp temperature changes and high humidity.

Enamel NTs-132 is a reliable and proven paint and varnish material widely used in industry and everyday life. The paint has high performance characteristics, attractive appearance and durability. Using this inexpensive and effective tool will help you quickly and efficiently freshen the room, renew the facade and keep the production premises clean.

For a video review of NTs-132 enamel, see below.

Manufacturers

Plants producing enamel NTs-132 and other paintwork materials are located in many cities of Russia.

For a long time and widely known NPO "Ladoga", which has two production - in Omsk and in the Crimea. The Novosibirsk plant "Kolorit" has developed a system of discounts for regular customers and a dealer program to facilitate the sale of its high-quality and budgetary products.

LLC "Belkolor" is popular with ordinary consumers. Buyers note the excellent covering ability, bright colors and fast drying of the NTs-132 enamel from this manufacturer. The Belgorod enterprise has a twenty-year history, it has grown from a small workshop into an international brand with premium lines, which are not inferior in quality to foreign counterparts.

The paintwork materials of the "Tex" company receive good reviews. The availability of products in a variety of hardware stores, combined with low price tags, makes it a worthy competitor in the paints and varnishes market. The manufacturer is ready to confirm the quality of its products with many certificates.

The Lakra group of companies manufactures its products in Canada, Switzerland, Poland and other European countries. Tempting prices are due to the availability of production facilities in our country. The enamels maintain the western level of quality characteristics.

LLC "Continental" is a rapidly developing young company in the construction market in Russia. But high quality standards, dynamic development and increasing production capacity in combination with a huge range of products allowed them to occupy their niche in the paint and varnish sales market. Enamels of the Krafor brand, produced by this manufacturer, are positioned as corresponding to GOST and sanitary and epidemiological standards. The factories of the company are located in many cities of the central part of Russia, in Udmurtia, as well as in the Czech Republic, Slovakia and Serbia.

For an overview of NTs-132 enamel, see the next video.

Manufacturers

Among the enterprises producing NTs-132, the most famous are the Omsk association "Ladoga" and "Kolorit" from Novosibirsk.The companies provide a bonus system of discounts to large wholesalers and offer a high quality and inexpensive product. Popular among consumers and products of Belgorod "Belkolor", whose enamels are distinguished by good hiding power and richness of shades. The line of enamels of the "Tex" company, which produces a wide range of paints and varnishes at quite affordable prices, is widely represented.

The largest enterprise for the production of NTs-132 enamel is the Lakra group of companies, whose production facilities are located in Canada, Poland, Russia and Switzerland. And the youngest and fastest growing company is Continental LLC, which focuses on high European quality standards and produces a huge range of paints and varnishes.

The Krofor plant is also well known both in the domestic and in the Eastern European market. The company's products are manufactured strictly in accordance with GOST, are of good quality and have many positive reviews.

Properties

The material has a lot of useful properties. Very durable, resistant to abrasion, scratching, and other mechanical stress. The film created on the surface has excellent elasticity, so the paint can be applied even to parts and products with a large curvature.

Other material properties:

- the protective film provides resistance to the influence of water and household chemicals, detergents, oils, enamel can be applied in damp rooms;

- there is the possibility of grinding and polishing the coating without compromising quality - on the contrary, you get a decorative gloss;

- the consumption of the product is low - the enamel is very economical and easy to use;

- the material is durable, provides quick drying and protection of metal surfaces from corrosion;

- does not fade for a long time under the influence of ultraviolet radiation.

The enamel can be used in different temperature conditions: it can withstand temperature changes from -12 to +60 degrees. The variety of paint colors is amazing - the production of white, black, red, brown, yellow enamel, pistachio, green, blue and many others with various shades of lighter and darker has been established.

Consumption

Enamels NTs-132 go on sale in a ready-to-use liquid form. After opening the can, you can start finishing work immediately with a spray gun, brushes or rollers. If, nevertheless, there is a need to dilute the product, this is done using solvents.

For enamel of NTs-132K type it is necessary to use composition 649, and for NTs-132P - 646 version in accordance with GOST 18188. In any case, the composition in a newly opened jar must be immediately stirred to give it a uniform consistency. The time to achieve hardness and dryness is about 2 hours at a temperature of 20 C. If the thermometer readings in the room or outside are different, then the final result can be achieved at different times.

It is customary to apply two or more layers of paintwork materials on the surface to achieve the best coverage. Enamel consumption is determined by the characteristics of the covering power of the product. This indicator indicates how many grams of the composition should be applied per 1 m2. The color of the composition affects the consumption most of all. Dark shades: black and dark blue-green require 30 g / m2 of enamel, and light shades - white and cream - 100 g / m2.

Wood surfaces should be thoroughly dried and sanded for better adhesion. To reduce the absorbency of natural material, it is better to use a primer or a thin layer of highly diluted enamel of the same type. Primers are suitable for AK-070, GF-021, FL-03K, VL-02.

Surface preparation before painting

Before applying the enamel, be sure to prepare the surface. For this, all dust, dirt, debris is thoroughly removed, the base is degreased. If the paint is applied to a wooden surface, it is necessary to remove traces of rot, mold from it, and if a metal part is painted, then rust and traces of corrosion are removed. After cleaning, metal surfaces must be primed using one of the following mixtures: GF-020-021, FL-03K, GF-032.

It is also desirable to prime the wooden base, for this you can dilute the enamel with solvent 646, the proportion should be 5 to 1. It is not necessary to prime the wood. A layer of enamel is applied only on a completely clean and dry surface. If there is a thickened film on the paint, it must be removed and the mixture is thoroughly mixed, and if the paint and varnish material is too thick, solvent 646 is used.

Enamel NTs-132

enamel NTs-132 description

Nitroenamel NTs-132 is a suspension of SVP in a solution of colloxylin and alkyd resin in a mixture of volatile organic solvents with the addition of plasticizers.

Purpose of nitro paint: enamels NTs-132

Nitrocellulose enamel nts 132 is used to paint wooden and metal surfaces of products. Metal paint nts 132 will protect surfaces used both in atmospheric conditions and indoors. NTs-132 black painted in two layers on the ground will protect the metal for 2 years. NTs-132 white is used for painting indoors.

enamels NTs-132 application:

NTs-132 paint is applied by pneumatic spraying methods. When touching up small areas, the enamel can be applied with a brush. Depending on the type of application, the paint is produced in two types NTs-132 P - for application by pneumatic spraying and NTs-132 K - for application with a brush. Differences in nts 132 technical characteristics affect the price. Nitroenamel NTs-132 for a brush has a higher viscosity and a more expensive price than NTs-132 P. Consumption rates of enamel nts 132: an average consumption of 80 g / sq. and depends on the color of the enamel. The consumption of paint nts 132 also depends on the type of surface - the consumption will be less for metal, more for wood.

The manufacturer recommends to dilute NTs 132 to working viscosity with solvents 646 or 649. Moreover, how to dilute nts 132 depends on the method of application - with a brush (645 solvent) or a pulver (646 solvent).

enamel NTs-132 characteristics

| Parameter | Meaning |

|---|---|

| NTs-132 film colors | must be within the permissible deviations established by the samples (standards) of the card index of colors. NTs-132 yellow is golden yellow samples 285 and 286. |

| Film appearance | smooth, uniform surface, without wrinkles and foreign inclusions |

| Conditional viscosity according to a viscometer of the VZ-246 (VZ-4) type with a nozzle diameter of 4 mm at a temperature of (20 ± 0.5) ° С, s | 60-100. |

| Mass fraction of non-volatile substances,% | 22-40. |

| Enamel film gloss,%, not less | 55 |

| Drying time at a temperature of (20 ± 2) ° С up to degree 3, h, no more | 2 |

| Hiding power of the dried film, g / m2 | 40-100. The lowest value for enamel NTs-132 black - 30 g / m²; the highest is 100 g / m² for NTs-132 enamel white. |

| Flexural elasticity, mm, no more | 1 |

| Film strength upon impact on the U-2 device, cm, not less | 50 |

| Film hardness, conventional units, not less | |

| by pendulum device type M-Z | 0,3 |

| by pendulum device type TML (pendulum A) | 0,15 |

The nts 132 paint has a water resistance characteristic of 1 hour, and an oil resistance of 6 hours. The color of the paint nitroenamel nts 132 after exposure to water may lighten and cloudy a little, and after oil it can become cloudy.

If you need to buy NTs-132, please contact our specialists by phones:

(4852) 59-99-09, 59-99-08, 59-99-04.

If you know how much nitroenamel NTs-132 you need to buy, send the quick order form at the bottom of this page

Depending on the type and color, NTs-132 enamel has a price from 81 to 115 rubles.