Instruments

It may sound strange, but the exact same tools are used to hammer nails into concrete as when working with other materials. Most often, a construction hammer is used, which has a head weight of at least a kilogram and a sufficiently long handle. Using a lighter tool is unlikely to succeed, because we need a lot of energy to work, and the long handle will serve as an excellent leverage. The easiest way to secure a nail to a concrete wall is to use a pneumatic, electric, or powder gun for the fastener. Having correctly configured the equipment, you can quickly perform a fairly large amount of work without much effort. Before using a powerful tool, be sure to read the user manual - not all nail drivers allow you to work with concrete. In the event that the manufacturer allows such an application of his product, it is worth clarifying the necessary settings and requirements for fasteners in the passport.

Installing fasteners

There is no universal scheme for installing a fastener for any base. Depending on the type of base surface where the dowel-nail is attached, the type of its installation is also different.

Installation in concrete and brick base

If the dowel is mounted in a brick base, then it is necessary to act according to the following technology:

Choosing the best location for the hole. This is usually the middle of the brick.

Drilling material with a hammer drill

This must be done very carefully so as not to damage the masonry. Increasing the speed on the tool is only possible after more than 10 mm of base has been drilled.

Cleansing the hole from brick chips and loose material.

Driving the dowel into the hole with a hammer.

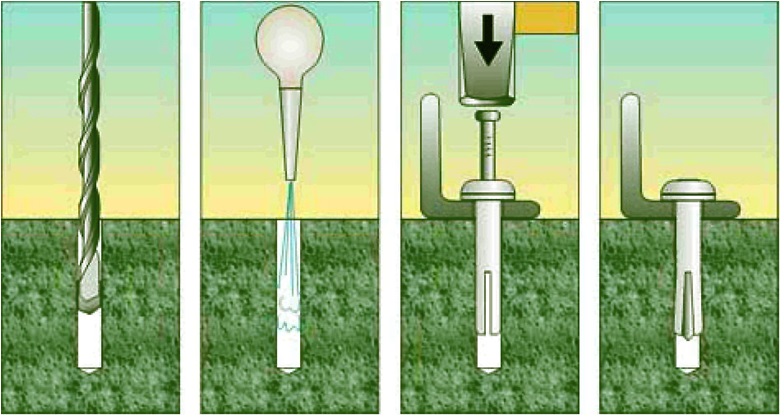

Stages of installation of a dowel-nail in a brick base When working with concrete, fasteners are mounted as follows:

Marking the hole with a hammer or center punch.

Making the required hole with a hammer drill and a concrete drill

It is important to understand that the marking of the dowel diameter must match the one indicated on the drill. The hole itself is made 5 - 6 mm longer than the dowel-nail.

Removing dust from the hole with a vacuum cleaner.

Deepening the cylindrical part of the dowel with a hammer.

Driving a nail into a dowel

In this case, 2 - 3 mm are left for the unhindered implementation of the suspension.

Installing fasteners in a concrete base

Installation in a plasterboard or tile base

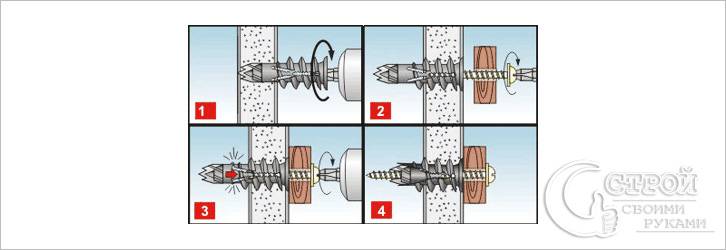

When working with drywall, it is necessary in advance to compare its bearing capacity with the weight of the attached load. If the attached object has considerable weight, then the dowel-nail is not used, as it can destroy the drywall. Usually, special drywall plugs are used. In the case when the weight is small, the installation technology does not cause difficulties:

- Making a hole suitable for the diameter.

- Inserting fasteners so that the stop is felt. In this case, you should not knock on it strongly with a hammer, light tapping is enough.

- Tightening the screw with a screwdriver or screwdriver.

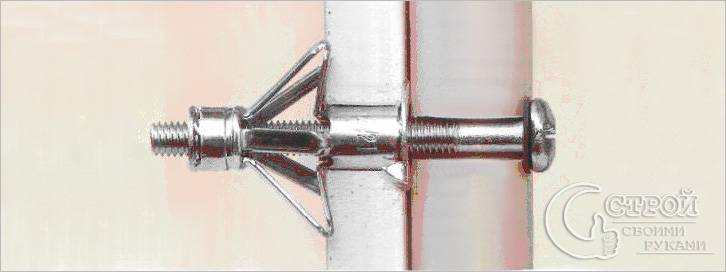

Special dowels in the shape of a butterfly with nails for working with plasterboard substrates

Since the tile belongs to fragile materials, in this case the work is carried out as carefully as possible according to the following algorithm:

- Marking the place where the fasteners fit into the tile. Here it is allowed to do it not only in the tile itself, but also in the seam.

- Creating a hole half a millimeter deep using a self-tapping screw for metal by tapping with a hammer on it.Only after this is it allowed to make a full hole with an impact drill.

- Installation of a fastener with a collar in a prepared base.

The work on making a hole for a dowel-nail is carried out extremely carefully

Installation with a construction gun

All of these technologies involved the installation of the expansion part of the dowel first, and then the installation of a nail into it. On the modern market, devices such as mounting-type pistols are now presented, which allow a kind of "targeting" of an attached object to the base with a dowel-nail.

In this case, a dowel of a certain type is used with a special washer on the nail, which allows the product to be tightly mounted to the surface. The principle of operation is that after installing the dowel-nail in the wall, the washer moves from its tip to the head and securely fixes the fasteners.

Construction gun with a set of dowel-nails

This type of dowel-nail has found its application in fastening metal structures to walls made of concrete, natural stone and brick. The most commonly used assembly gun with these fasteners is to install canopies over entrances and balconies. The length of such nails is from 30 to 80 mm, the cross section is 4.5 and 3.7 mm. They are made of zinc-coated steel.

Dowel-nails are a modern type of fasteners that allow fixing any structure to the finished base

It is simple to work with them, but it is important to correctly select and follow the installation instructions corresponding to the type of base surface. Only in this case a high-quality installation is possible.

There are a great many types of fasteners. In fact, for a material with varying degrees of porosity and hollowness, you must use your own type of fastener. The dowel-nail is a fastener designed for fixing in fairly dense, solid materials.

About what dowel-nails are, what sizes, what is their price per piece - you will learn all this from this article.

Application

When using electrical devices for screwing in dowels, you need to be very careful, as excessive force during installation can damage the drywall sheet. Drilling a hole in perforator mode for working with gypsum board is prohibited.

In tiled surfaces, a hole is made for the dowel in accordance with its size. In this case, it is better to stop at the molly dowel. To quickly perform the fastening, you can use the drive dowel. The advantage of this product is the fact that there is no need to make any additional holes in the material, which allows to preserve the integrity of the structure as much as possible.

There are some simple guidelines for screwing dowels into drywall:

- First of all, it is worth identifying what characteristics the drywall has, with which you have to work, and also determine the weight of the attached product.

- It is important to correctly select the screw, if it is not included in the standard package for the dowel, since the screw can damage the fasteners from the inside.

- The hole must be drilled slightly larger in diameter than the part itself. This feature of the work allows you to avoid cracking of the material during the installation of the part.

- Holes must be thoroughly cleaned of crumbs and dust. To do this, you can use an ordinary household vacuum cleaner.

- A screwdriver that can be screwed in without a screwdriver should not rotate at the end point of the installation. To do this, do not fix it in the base until it stops, leaving this work for a screwdriver with the appropriate setting.

- When the dowel-umbrella or fungus is already installed in its place, and the desired product is firmly located on the fastener, the hole formed in the drywall sheet must be carefully masked with acrylic, if it is small.In another situation, additional use of putty will be required. A positive feature of acrylic is its rubberized base, due to which the pressure level of the fastener on such a fragile material as drywall can be significantly reduced.

- The butterfly dowel has a certain installation technology - you need to press the folding blades of the product and push it inside. Even an ordinary screwdriver can screw this dowel to the required position.

Fasteners for drywall today are presented in a wide variety

Therefore, the choice in favor of this or that product should be made based on the level of complexity of the structure that needs to be attached, its functional tasks and installation technique, taking into account the cost of the products.

You can find out how to install drywall with your own hands by watching the video below.

Molly dowel fixing

Dowel molly

Dowel molly

This type of dowel also has some installation features. A hole is drilled with an eight millimeter drill. Then a dowel is inserted into the drywall, which has a side with two teeth and is pressed tightly. Doing so will prevent the anchor from rolling when it is locked. After that, with the screw that comes with the kit, using a screwdriver or screwdriver, the dowel is screwed close to the drywall. In this case, the central part of the sleeve is twisted, thereby providing excellent retention to the object to be secured.

Molly dowel installation

Molly dowel installation

The molly dowel has a number of advantages, for example:

- Has the ability to withstand loads up to 35 kilograms.

- The screw and dowel are sold as a set.

- If necessary, you can dismantle the structure.

In turn, it has one significant drawback, namely the high price. However, a molly drywall plug is ideal!

Radical methods

To remove hard-to-remove dowels, you can use the following methods:

- drilling;

- dissolving with strong acids.

For drilling, you need a powerful drill, which has protection against biting the drill. This is necessary to protect the worker's hands, as residual fasteners can jam the tool and harm it. In order not to aggravate the damage, you need to take your time. If you do not plan to reuse the hole, then you can only remove the uppermost parts of the dowel, and the remaining damage can be plastered or painted over.

How to remove the dowel from the wall, when it is impossible not to remove it and the mandatory use of this particular hole is required? The most radical way can be applied. To do this, using a brush, apply a concentrated solution of sulfuric acid to the protruding parts of the dowel and leave it for a while. The acid destroys the bonds of building solutions, dissolves metal oxides, organic glue and paint

After such treatment, it is important to thoroughly wash off the acid residues, as it has a toxic effect. You need to work in personal protective equipment (respirator) and in a well-ventilated area

Peculiarities

A dowel hook (also called a hook or a nail) is referred to as a fastener. They are widely used in construction and installation work. Using these products, you can fix installation details on absolutely any surface - concrete, stone, plasterboard, brick or wood.

During installation, the spacer element tends to expand in the hole - it is this part of the rod that provides reliable fixation and fastening. But the non-spreading part does not change its shape.

Today this type of fastener is very popular, and this is due to a number of features that are inherent in the product:

- reliability;

- long service life;

- strength;

- wear resistance;

- ensuring a strong and durable connection between the fastening elements.

For the manufacture of such dowels, the manufacturer uses only high-quality and safe materials with high physical and technical parameters.

The following materials are involved in the production of such products.

Nylon (polyamide). It is one of the toughest and most durable materials. It is characterized by resistance to deformation and vibration, wear resistance. The disadvantage of this material is that fasteners made of polyamide are not recommended for use in frosty or rainy weather.

In addition to the above materials, from which the dowel hooks are made, it is worth noting another one that has the highest technical parameters - metal. For the manufacture of such dowels, stainless or galvanized steel is used. It is the metal dowel-hook that is preferred by the consumer. This is due to the fact that it has a great advantage over analogues due to its ability to withstand very high loads.

Drywall dowels

Particular care must be taken in the selection and, accordingly, installation of drywall dowels. To fix a shelf or cabinet on drywall, you need special dowels. Their choice will largely depend on the weight of the suspended structure. If you carry out incorrect calculations, then there is a great risk that the structure will simply fall.

One of the most common types of dowels is the plug dowel. It consists of two parts, namely a plug and a dowel, respectively. In most cases, it is used to fasten certain objects in a concrete wall. The spacer part consists of three nylon sections. There is a through hole in the tail section. It is this that greatly facilitates screwing, as well as a good course of the screw in the process of tightening it. Due to the expansion, which is carried out simultaneously from three sides, the dowel is securely held in the wall. In some cases, the plug can also be used for fixing in drywall. However, as experts recommend, it is better not to risk it. Although some people consider the plug-plug to be a universal fixture, it is best to use a special plug-nail. In general, all specialized drywall dowels have one main difference - the harpoon expansion principle. It is he who provides high-quality fastening of the structure. All drywall plugs can be divided into two groups:

- Decompressing.

- Checkpoints.

Spring checkpoint

Molly's pressure bore

Molly's pressure bore

Walk-through dowels are practical in cases where the fixing must be carried out in the ceiling, for example, when installing a chandelier. The spring-loaded dowel has a threaded metal rod, a spring mechanism, and folding locking wings. In the process of its installation inside the plasterboard structure, the spring mechanism opens when it is exposed to the locking hook-wing. This creates a secure attachment. In this case, the other end of the spring dowel can have a different shape: in the form of a ring, rod, screw, etc. The choice of shape is directly influenced by the object that will be suspended. This mechanism is also practical in cases where drywall is tiled with ceramic tiles.

Dowel self-tapping screw

Dowel and self-tapping screw

Dowel and self-tapping screw

This type of drywall plug is made of two different materials:

- Nylon brand TT22.

- Metallic DRIVA.

As a rule, they are used in cases where it is required to mount on a single-layer or multi-layer gypsum plasterboard. Moreover, it can have a decorative coating and insulation on the inside. The self-tapping dowel has the main difference between itself - this is the size. When making his choice, you should make sure that he will not stick out on the other side. As for the DRIVA self-tapping screw dowel, it is made from an alloy of aluminum and zinc.Remarkable is the fact that for their fastening there is no need to pre-drill a hole in the drywall. The end of this dowel is equipped with its own drill. They are very easy to screw into drywall, providing a secure fit. They can withstand a fairly large weight of an object. The dowel itself is twisted with a simple screwdriver or screwdriver.

Installation of a dowel, self-tapping screw

Installation of a dowel, self-tapping screw

Dowel umbrella

Its shape resembles an umbrella. The umbrella dowel provides a secure stop. It opens up in the space behind the stove. It is especially popular for fixing objects in the ceiling. For example, it can be used to attach a chandelier. To install it, you will need to pre-drill a hole in the drywall. Thanks to its full disclosure, the load is evenly distributed over the entire area. Here is the installation sequence for the umbrella plug:

The first step is to drill a hole in the plasterboard ceiling. The hole should be slightly larger than the diameter of the dowel itself

This is an important requirement, since at the time of fastening there is a risk of damaging the sheet.

After that, screw the dowel into the drywall

This must be done carefully so that the last turn does not scroll in the drywall.

At the next stage, the object itself is attached, and the resulting hole near the fasteners can be covered with a special putty

It is advisable if it is an acrylic putty, since it has a rubber base, which will prevent cracking.

"Fast installation"! Dowel nail

Dowel nail

Dowel nail

The dowel-nail has another common name "quick installation". Its popularity is mainly due to the fact that it is not necessary to use a screwdriver and tighten a self-tapping screw to secure it. In this case, everything is much simpler. A hole is pre-drilled in the brick / concrete, then a dowel-nail is inserted into it and hammered in with a hammer. Installation of certain objects on this type of self-tapping screw is very quick and easy. Where is it used most often?

Very often it is used for installing skirting boards. In most cases, skirting boards already have the required number of holes. The hole should only be made in the wall, at the pre-marked places

It is very important that the installation of skirting boards using a dowel-nail is very convenient, quick and simple. When all the holes are ready, a dowel-nail is inserted into the holes on the baseboard, which is hammered into the very side with a hammer

As for the size, it is best to use a 6 × 40 dowel-nails for skirting boards, and a 6 mm drill for drilling a hole. It is best to use a dowel with a fungus. A concealed cap will not provide the necessary stability, unlike a fungus. However, for plastic skirting boards, a countersunk cap will suffice.

With fungus

With fungus

It should be noted that the dowel-nail has different types and sizes. As mentioned above, the nail dowel has a countersunk head and a mushroom-shaped head. In the secret one - the side is small, the fungus, in turn, presses much more strongly. The dimensions of the dowel-nail are as follows:

- 6×40.

- 6×60.

- 6×80.

- 8×60.

- 8×80.

- 8×100.

- 8×120.

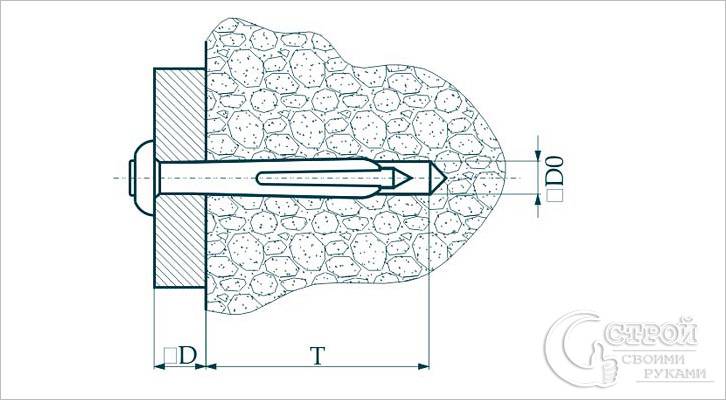

Dowel-nail dimensions

Dowel-nail dimensions

As for the choice of a drill for drilling a hole, it should be selected directly for the diameter and length of your chosen dowel-nail.

Masonry dowel installation rules

Considering the fact that it is somewhat more difficult to install the dowel fasteners designed for bricks than fixing the dowel used for concrete work in the wall, you should understand this procedure in more detail. In this situation, it is very useful to take advantage of the experience of specialists who are often faced with the need to reliably fix objects that have even a very significant weight on brick building structures.

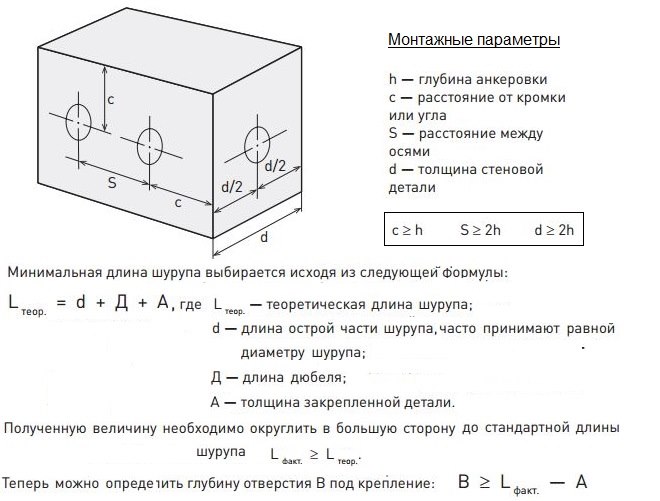

During installation, the distances from the edges and between the dowels must be observed, depending on the size of the dowels and the depth of anchoring.

If in order to fix a dowel for work on concrete in a building structure, which is hammered in like a simple nail, it is enough to use a minimum set of tools, then for a neat and reliable fixation of fasteners in a brick wall you will need:

- a hammer drill or drill needed to drill the bore hole;

- drill of the appropriate diameter;

- glue designed for laying ceramic tiles;

- a set of rubber spatulas of different sizes.

Dowel installation procedure

The very procedure for installing a dowel into a brick wall consists of the following steps.

The first thing to do is to carefully drill a bore hole for mounting the fastener. This can be done using an electric drill or a hammer drill, on which the drilling-only mode (no impact) is enabled.

It is important that the diameter of the drill used to perform this procedure exactly matches the diameter of the dowel itself.

After drilling, the hole must be thoroughly cleaned of construction dust and pieces of material that has crumbled into its internal cavity. You can check how thoroughly you cleaned the hole using the dowel itself: it should enter without difficulty and obstacles.

When the hole is thoroughly cleaned, you can start working with dry tile adhesive, which must be diluted with water in the proportion indicated by the manufacturer.

After the glue mass is ready for use, it is necessary to fill the hole drilled for the dowel with it. You can use a rubber spatula for this, and you can push the glue mass into the depth of the hole using the dowel itself or a regular pencil. When the hole is completely filled with glue, you can insert a dowel into it, which should go into it until it stops. After that, it is necessary to allow the adhesive composition to completely solidify, which is quite enough 24 hours.

After the tile adhesive has completely hardened, you can screw a threaded element (stud or screw) into the dowel

In this case, be sure to pay attention to the fact that screwing in occurs with some effort. This means that your dowel is firmly anchored in the brickwork.

Fasteners obtained using such a simple technology are highly reliable and can withstand even significant weight loads.

You can also use this method if you need to install fasteners in a porous material (the use of concrete dowels for such structures is also prohibited). Such materials, in particular, can be gas or foam concrete, porous bricks, etc. Taking into account their high popularity in the modern construction market, the choice of fasteners that could ensure reliable fastening of objects fixed to such structures is a rather serious problem.

In conclusion, we suggest you watch a couple of videos that highlight some of the nuances of installing dowels into bases made of various materials.

Product classifications

When choosing a mount, 5 main factors are taken into account:

- the amount of load - on the dowel, on the surface, on the structure;

- the nature of the load - stationary, dynamic;

- type of fixation;

- the nature of the material - stone, concrete, brick, drywall;

- surface construction - wall, ceiling.

Actually, there are several types of fasteners for different methods and materials.

The video below tells about the rules for choosing dowels:

By type of installation

The dowel, or rather, the nail, can have a slightly different structure, due to which you need to work with it with different tools.

Manual assembly - that is, using mechanical tools. Nails for such work are divided into 2 types:

- without thread - the nail is hammered in with a hammer, there is no way to unscrew it;

- threaded nail - driven in or screwed in. Its main advantage is the possibility of dismantling.

Installation using a construction and assembly gun - the nail has a restrictive collar, but does without a spacer body. This option provides a much faster installation and, moreover, is designed for a higher load.

By surface material

More interesting from the user's point of view, as it allows you to determine which fasteners are suitable for which wall or ceiling.

- The most common are threaded or non-threaded nylon plugs with diameters ranging from 2 to 16 mm. They are used for fastening to a standard building stone - brick, concrete, and can withstand from 200 to 450 kg of stationary load.

- Dowel for aerated concrete - the material is considered to be relatively low-porous, so such an attachment is quite acceptable. The dowel is held by spiral ribs and wedging when driving a nail.

- Frame - have a great length, from 60 to 360 mm. They are produced in 2 types: for solid solid material and for hollow slotted material. The expansion part of the dowel is lengthened and is designed so that when passing through the slotted base, the dowel will hook several jumpers, which will provide fasteners.

- Distance dowels allow you to fix elements - lathing, for example, at some distance from the wall. The distance can vary from 1 to 30 mm. The distance plug is divided into 2 parts - one for the rail, the second for the material, and connected with a screw of a special design. In this way, numerous irregularities in the wall can be compensated for and a perfectly flat surface can be obtained.

- Universal - able to "independently" determine the presence or absence of voids. When fixed in a solid material, the spacer body expands and is tightly fixed, and when it enters the voids, it bulges and adheres to the support.

- Metal dowels behave in the same way, that is, with a metal case. They are designed for attachment to thin-walled surfaces, but at the same time they hold a sufficient load. When the screw is screwed in, the metal dowel bulges and presses against the thin support.

- The nail dowel provides quick installation of battens, skirting boards, battens and other things, when it is necessary to strengthen a large number of elements. The nail here is knurled in the form of reverse cones. It is inserted together with the dowel into the drilled hole through the rail and hammered in with a hammer. Cannot be dismantled.

- Products with spring-loaded folding strips - butterfly dowels, are used to fix objects to a hollow surface - to false ceilings, for example, when installing a chandelier. Having passed the hard layer, the dowel opens under the action of the spring, rests against the skin from the inside. Typically, the model is sold with hooks or threaded rods.

- For fastening structures with a large weight to concrete and solid bricks - garage doors, sun-protection awnings and so on, metal dowels with threaded rods or bolts are used. The fasteners are designed for a very heavy load - up to several tons.

- Dowels for drywall and aerated concrete - both metal and plastic, have a tip in the form of a pinned drill and a large thread on the spacer body. For such dowels, the hole is not drilled, but the entire structure is screwed in with a regular screwdriver.

- Insulation holder - a special dowel for fixing a heat insulator or solid foam material. Holes for it are drilled in brick and concrete, but the dowel itself is hammered in without a nail.

- A very specific type is the injection dowel. A mesh anchor is inserted into the hole for the fasteners, then a dowel is driven in and a quick-hardening compound is injected through a protective sleeve with a syringe. Under its pressure, the anchor mesh inside the material expands, forming an anchor in the form of a ball. When fixing in a slotted brick, it is allowed to use a dowel without a grid.

The length, thickness, weight of the dowel-nails are discussed below.

Dismantling features

When choosing which dowel is good and which one is not suitable for the task at hand, it is necessary to take into account the possibility of dismantling. If there is a possibility that the mount will need to be removed in the future, it is advisable to think about it before installing it.

To quickly and correctly perform dismantling, you will need a variety of tools that are usually in the arsenal of any master. Some types of dowels (chemical, for example) cannot be dismantled).

How to dismantle the dowel:

- To remove an ordinary plastic dowel, it is enough to find a self-tapping screw of the appropriate size. The self-tapping screw is screwed 2/3 into the dowel itself, the screw head is carefully clamped with pliers, then pulled out of the monolith together with the dowel. In some cases, a corkscrew will suffice.

- The head of the self-tapping screw, which is inserted into the dowel, can be pry off with a nail puller. Here you need to ensure that the working part of the self-tapping screw fits snugly in the hole itself.

- Homemade wood dowels are taken out in parts - first, a piece of wood (easiest along the grain) is crushed into separate pieces using a chisel (preferably with a thin blade) and a hammer. After the dowel is destroyed, it is pryed off with an awl, sharp knife or nail and pulled out of the nest.

- In some cases, the dowel firmly sitting in the monolith is easier not to dismantle at all - it is better to cut off the part that comes out to the surface, carefully cover the depression with plaster of paris and carefully align.

- If part of the screw is stuck in the dowel, you will need a heated soldering iron. First, the plastic base of the dowel melts gently, then the fragment of the fastener is pry off with round-nose pliers or nippers and removed.

- A metal dowel, which was driven into concrete with a construction gun, is first treated with strong, frequent blows of a hammer, acting on the protruding part of the product from different sides. Usually, the anchor plug will loosen during the process and can be easily removed. If it is difficult to loosen, you can make a groove nearby with a drill with a hard alloy tip or a metal punch. Thanks to the circular funnel, the area of adhesion of the fastener to the wall will decrease, and it will be easier to remove it.

Dowels for concrete today on the construction market of Moscow and the region, other regions are presented in a wide variety, therefore, it will not be difficult to find fasteners that exactly meet the requirements and operating conditions. The main thing is to choose reliable suppliers and focus on product quality.

Concept, purpose and application of anchor fasteners

Anchor is a type of fastener that is driven in, screwed in or inserted into the base and is able not only to be fixed in it, but also to hold an additional structure.

Translated from German, anchor means "anchor". By the method of action on the base, fasteners of this type really resemble an anchor - the working part of the anchor expands when fastened and holds the connection on the base.

Fasteners of this type are used when working with solid base materials - concrete, brick, natural stone. The anchor allows you to hold sufficiently massive or dynamically loaded structures, for example, sanitary ware, air conditioners, wall-mounted TVs, sports equipment, suspended ceilings, etc.

Expert opinion

Torsunov Pavel Maksimovich

The versatility and reliability of the anchor connection allows them to be used when working with other materials. For example, there are anchors for fixing in porous and lightweight materials, for connecting furniture elements. This type of fastening connection has found its application even in dentistry - the anchor pin is fixed in the root canal of the tooth and serves as a support for a filling or microprosthesis.

Corner mounting

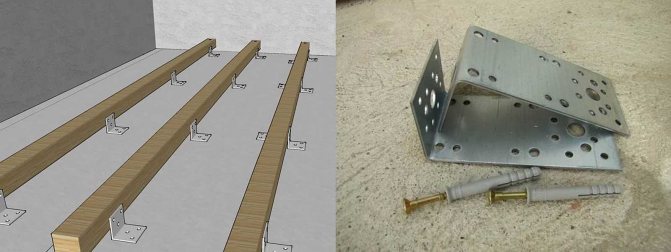

This method of installing lag is difficult to call correct, but it is quite reliable and working. Allows you not to "take away" the desired height from the premises.The timber is fastened to the concrete using mounting angles. The corners need solid, good steel with drilled holes. They are located on both sides of the timber, it can be staggered, or one opposite the other.

You can fix the logs to the concrete floor with corners

But setting the level will be quite problematic. We'll have to tinker. First, the corners are fixed to the floor along the line. Then the timber is fastened along the edges, leveling. Then align the middle. And this is the hardest part. Most likely you will have to either raise the bar or press it down. When fastened in the middle, it won't be so difficult to set the intermediate ones. But this is provided that the timber is even and not twisted. Otherwise, there will be difficulties at each fastener.

When put on one side, you can already put the corners on the other. There are already no problems

It is only important to give stability. The level has already been set

Control won't hurt, though.

Product selection

There are several types of self-tapping screws, which differ from each other in the type of fastening, material and structure. The choice of this or that name depends on the situation and external influences that have a direct impact on the fastener. Consider the most common types of screws and their scope.

Self-tapping screws with dowels

Self-tapping screw dowel for foam concrete with plastic cover

This is the most common type of fasteners in the construction market - they are produced in the form of self-tapping screws with two types of thread and plastic dowels. The presence of a dowel is explained by the fact that a hole drilled with a drill in concrete is not able to provide a tight fixation, without which the fixing will not be reliable. The plastic casing serves as a seal, which smoothes this circumstance as much as possible.

If you are choosing self-tapping screws for aerated concrete, then fastening with a dowel is the most optimal option. Given the low density of the foamed material, self-tapping screws for aerated concrete without a sealant will not be able to provide the proper reliability factor.

The plastic casing increases the contact area of the self-tapping screw with the wall, which is especially important in the case of low-density concrete.

There are two types of self-tapping screws with a dowel, which differ from each other in the structure of the thread.

Herringbone carving

- "Herringbone". The herringbone profile is a non-communicating thread that is fixed in the hole according to the principle of driving nails into concrete. After fixing, such a self-tapping screw cannot be removed by unscrewing, which significantly complicates dismantling. However, they also do not need to be tightened - a few strong blows are enough, which in some cases can significantly simplify the installation process;

- Universal profile. This product looks like an ordinary self-tapping screw and is mounted accordingly. The screw is simply screwed into the dowel, and when dismantled, it is removed by unscrewing. This type of fastening is somewhat inferior in reliability to the previous name.

Dowel fixing scheme

The dimensions of self-tapping screws for concrete are from 3 to 6 mm in diameter and from 12 to 220 mm along the length of the product. Herringbone screws can be more massive in diameter, but are somewhat limited in length.

Installation of self-tapping screws with dowels is carried out in pre-drilled holes, which must correspond to the diameter of the plastic casing. The dowel should fit snugly into the hole and not dangle. After that, the fastener itself is driven into it.

Self-tapping screws without dowels

Screws without dowels

Before screwing the self-tapping screw into concrete without a dowel, it is necessary to drill a hole with a special drill with a diameter of 6 mm (the diameter of the pins is 7.5 mm). Only after that the screw is screwed into the hole by means of a screwdriver - the variable notch will expand the cavity, and the upper thread will fix the self-tapping screw.

Variable thread screw

This type of fastening refers to stationary solutions - before screwing the self-tapping screw into concrete, it is necessary to accurately determine its location, since after fixing, it will no longer be possible to unscrew the fasteners.

Cover type

For the most part, self-tapping screws for concrete are made of carbon steel, which is covered with a protective layer to protect against corrosion. The exception is stainless steel screws, but their price is an order of magnitude higher than conventional counterparts.

There are several options for a protective coating, among which the following should be highlighted:

Galvanized. The zinc layer has a characteristic metallic silver luster - it is the most reliable anti-corrosion coating today. These products can be used both indoors and outdoors;

Zinc and oxide coatings

- Copper-plated. The yellow screws are copper or brass plated - their use is limited to interior work;

- Oxidized. Black self-tapping screws are exposed to blackening, as a result of which an oxide film forms on their surface, which prevents the formation of rust. They can only be used in conditions with normal humidity.