How to make a plank wall with your own hands

What tools will be needed:

- Panels.

- Wood filler.

- Varnishing or painting.

- Universal adhesive.

- Electric drill.

- Saw.

- Forked hammer.

- Quadrant.

- Level.

Stages of work:

The choice of cladding.

It comes in various lengths and thicknesses, but the tongue-and-groove method is most commonly used. There are many known cladding systems to choose from. Some need pins, others are glue.

Wall panels are an integral part of the classic style, chalet, English and American style of decoration, as well as art deco.

Wall panels are an integral part of the classic style, chalet, English and American style of decoration, as well as art deco.

Unfold the cladding and lay it on its side. Leave the wood in the room to be sheathed two weeks before renovation. This helps the material to acclimate and shrink before installation. If necessary, carefully remove the skirting board and trim from the wall. If you need to redirect any plumbing, do so before installing the cladding.

Attaching the planks.

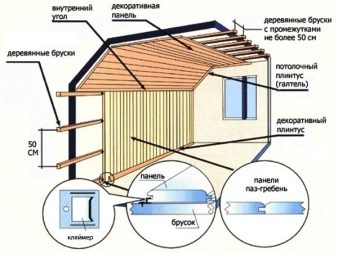

A timber batten is a piece of processed lumber used to support the cladding. Wood slats must be nailed to the wall or ceiling before attaching the cladding. But if the work area is flat, a simple application of glue is sufficient. Attach the wider planks to the wall.

We fix the frame for the wooden panels to the wall.

We fix the frame for the wooden panels to the wall.

If you are finishing with plaster, the planks should be 22 mm high and 50 mm wide. For facing masonry or planks, the height should be 38 mm and the width should be 50 mm. Attach the battens to the wall or ceiling at a 90 degree angle, at 400 mm intervals. If the battens run horizontally, position the lowest one just above the level of the baseboard. When installing the planks on the ceiling, make sure they are securely attached to the beams. Marking the position of each beam on the ceiling will make the job easier.

Preparation: sanding and coating the veneer.

Before attaching the cladding to the battens, ensure that the cladding surface is smooth and ready for the finish of your choice. Sand the outer surface of the cladding and remove dust. Then wipe the surface with a clean, lint-free cloth dampened with spirit. Apply two coats of your trim to the front and back of the board to prevent distortion of the wood.

Wall panels can be fixed in two ways: on the lathing or directly on the wall using glue.

Wall panels can be fixed in two ways: on the lathing or directly on the wall using glue.

Do not cover the inside of the groove. Only apply the final layers as you trim and fix the boards. Mark the boards at your chosen height with a knife or pencil. Mark 45 degree angles with a custom quadrant

It is important to place the corners correctly. Use this same technique to mark and cut boards to length.

Remove any irregularities with sandpaper. Apply two coats of your trim to the front and back of the board to prevent distortion of the wood.

Correction of the cladding.

Choose your starting point. Working from left to right, place the first plank against the wall. Use a level to check the position of the board. Insert the pins through the board into the rail. Then hammer in the studs, one per bar. Place the next plank in place. Use a 50mm wide board trim - cut off the side of the groove to protect the tongue of the new board while making it easier to put in place with light hammer blows. Secure with a safety pin. Check the corners.

Unusual styling options will add warmth and coziness to your interior, while adding a touch of luxury at the same time.

Unusual styling options will add warmth and coziness to your interior, while adding a touch of luxury at the same time.

Completion.

Install the skirting board and any other moldings.They must be pretreated in the same way as the veneer. Secure everything in place with panel glue. Carefully fill all pin holes with wood filler that matches the color of the wood. Don't spread the filler around too much. When the filler is dry, wipe it off lightly. Finally, apply one or two coats of treatment.

Waxing the wood helps to maintain the natural shine and integrity of the material.

Waxing the wood helps to maintain the natural shine and integrity of the material.

Lining material and its advantage

In this chapter, we will look at what material the lining plates are made of.

Plastic

For lining the ceiling, plastic lining is suitable

But it has a huge disadvantage - if you move it carelessly, it can be broken or scratched. The main advantage of plastic over wood is its resistance to moisture

Also, the panel is easy to clean without the use of special products. The cladding of a private house inside with wooden clapboard will save time on cleaning the premises.

MDF panel

MDF panels are similar to wood. The lining of this material copies any surface. Installation does not take much time and effort. Manufacturers offer a large selection of varieties and colors. The material is not moisture resistant and cannot be used in steam rooms and in rooms with a humidity of more than seventy percent. On the site you can see additional information on the material: clapboard decoration inside the house, photo examples.

Wood

Wooden lining is created from deciduous and coniferous trees. Deciduous include the following.

Linden

It is more common in areas with a temperate climate and humidity. The lining wood is soft, amenable to processing. Keeps you warm. Possesses medicinal properties.

Alder

The Birch family. It grows in Kazakhstan and Russia. Facing with this clapboard will fill the atmosphere of the room with coziness and soft light, with shades of pink.

Oak

It grows from the Far East to the Northern Hemisphere. Over time, the color of the wood darkens, giving the product an antique look. Very strong and durable. Withstands temperature extremes and moisture resistance.

Conifers include ...

Abash

A plant from the Malvov family. It has a high thermal resistance and deformation threshold. Has a beautiful chocolate shade.

Aspen

This type of tree is from the Aspen family. It grows in many European countries and on other continents. When heated, it releases special substances that neutralize microorganisms. This lining has an average service life.

Cedar

The Pine family. It sprouts on the shores of the Crimea. Has a pleasant aroma. Long lasting. It will give the interior a beautiful and finished look. The price for wood is quite high.

Larch

Pine family. Wooden panels are not inferior in strength to oak. Among the disadvantages of this type is the accelerated drying of wood. Lining made of such wood will perfectly fit into the interior of the room. Has a beautiful pattern.

Hemlock

It grows in America, directly in Canada. Long lasting, beautiful. Resistant to external influences of the environment.

Successful examples and options

The statement that clapboard trim looks good only in the country and in a country house in a "rustic" style is considered erroneous. The material combines well with other textures and, when used correctly, looks great even in high-tech interiors.

- Noble wood is ideally combined with plaster, wallpaper, tiles. Combinations like these make it easy to create a cozy classic or calm modern interior.

- Of course, the clapboard trim looks as organic as possible in country style. In an apartment, you can create such a corner in the dining room or living room. Preference should be given to the profile of light natural shades.

- And if you paint the panels in warm pastel shades, they will perfectly fit into the Provence style. Don't forget to complement the interior with plastered walls and rough wood floors.

- Wood panels are indispensable when creating a Scandinavian style. For it, choose light, bleached materials. The lining is used here for wall and floor decoration. Don't forget the wooden beams on the ceiling. And so that the room does not look boring, "dilute" the wooden surfaces with stone textures.

- Artificially aged lining in the finish is one of the hallmarks of shabby chic. It will look organically in small living rooms, attic, bedroom. In the bathroom, a light vertical or horizontal lining looks good.

- In modern interiors such as hi-tech, wood profiles are a backdrop that does not attract attention. For this, the panels are painted in white or beige, sometimes silver.

How to sheathe a balcony with clapboard, see the video below.

Drying process and parameters

The effect of a constant vacuum changes the nature of the heat exchange processes occurring, steam is released, the drying agent moves at a speed of about 0.03 m / s. The process takes place under the control of wood moisture sensors, without installing a dry or wet thermometer. No fans are needed for vacuum chambers, no wood dampening systems are used.

Drying in vacuum achieves practical moisture values:

- Residual level in the range from 6 to 0.5%;

- Stack difference no more than 1%;

- The difference in length and thickness is not more than 0.9%.

Manufacturers of vacuum-type drying chambers have certificates of conformity of devices to European standards, offer versions for various volumes of loading of raw materials. The use of dryers is assumed, regardless of the type and type of wood. The cost of the installations is high, the power consumption is significant, the payback is long, - the indicators depend on:

- Capacities of the camera in terms of capacity;

- Materials used in the manufacture;

- Installation of additional devices and accessories.

Varieties of wood wall decoration

Wood wall cladding can be done in different materials, such as the options below.

Lining

Clapboard is a great way to add personality to a room. It is often used in salons or cafes to create a cozy feeling. There are different clapboard finishes, from vintage styles to modern interpretations. A simple interior cladding with aged clapboard with decorative slats can create a unique charm to the room.

This simple solution can make the atmosphere of the room cozy and brighter and more welcoming.

This simple solution can make the atmosphere of the room cozy and brighter and more welcoming.

Board

If you want to drastically change the look of your exterior walls, planking is a great way to achieve this. But this isn't just a cosmetic upgrade. Exterior planking can benefit from additional insulation for a building project.

The board is suitable for Scandinavian, rustic and eco-style, as well as minimalism and chalets.

The board is suitable for Scandinavian, rustic and eco-style, as well as minimalism and chalets.

The boards are available in different colors. Deliberately aged boards are also popular. This small block cladding is a color-fast alternative to traditional exterior cladding. Plank cladding made with recycled wood requires minimal maintenance and ensures long-term reliability.

The sleek, calibrated elements fit perfectly into a minimalist design, as long as you don't overdo it with quantity.

The sleek, calibrated elements fit perfectly into a minimalist design, as long as you don't overdo it with quantity.

Laminate

Similar to the planks that were popular in the middle of the last century, laminate panels can be installed horizontally on one or all walls. Vertical laminate panels visually increase the height in rooms with low ceilings. They can also be used for both residential and office furnish of an apartment with wood. Laminate is easier to install than real wood planks because it is lighter and thinner.

This material is characterized by good resistance and attractive appearance, it is often used for wall cladding in urban apartments.

This material is characterized by good resistance and attractive appearance, it is often used for wall cladding in urban apartments.

OSB

Oriented strand board is a versatile structural wood panel with many strength and performance characteristics of plywood. The combination of wood OSB and adhesives creates a strong, stable panel that resists warping, delamination and imperfections. In terms of their strength, OSB panels are lightweight, easy to handle and install.

This material is characterized with a pronounced and extraordinary texture. It is well suited for all lovers of modernity and avant-garde.

This material is characterized with a pronounced and extraordinary texture. It is well suited for all lovers of modernity and avant-garde.

Parquet board

Any kind of wood can be installed on the walls, including parquet. The advantage of hardwood parquet on walls is the same as for floors, as the wood is durable and can be painted and coated with protective agents. With parquet, you can create a variety of designs in different colors, patterns and finishes.

A wide variety of parquet colors allows you to create a unique interior with a creative idea at a reasonable price.

A wide variety of parquet colors allows you to create a unique interior with a creative idea at a reasonable price.

Ends and cuts

Even a section of the wall from the ends is capable of riveting the eye. Wood-paneled walls evolved from the fact that recycled waste of some other products became one of the most popular wall coverings, specifically butts and cuts. A close examination of each such wall block reveals growth rings and variants of the tree bark with an individual painting.

Wall cladding with scraps of boards and round timber creates an extraordinary and very stylish look.

Wall cladding with scraps of boards and round timber creates an extraordinary and very stylish look.

Wall panels for room decor

Quite often, minimalist designs require warm accents, which is why wood paneling is relevant here. Walls and floors are sensitive to color and tactile surface structures. The use of wood as a material in those areas where it has already proven itself over the centuries has a significant reason. With wall panels, it is easy to create a trendy industrial look with the feeling of an enlarged space where the floor seems to flow smoothly into the wall.

This is a classic finishing material, which is often made to order according to specified dimensions.

This is a classic finishing material, which is often made to order according to specified dimensions.

Standard sizes

Interestingly, the tree species also affects the size of the wooden lining. In practice, most often others for the manufacture of this material are used such species as pine, larch, cedar, linden, alder, oak, aspen. The types of rocks also affect the difference in the cost of the material from them. If you make all the calculations correctly, then there will be no overpayment for the purchased volumes of lining.

Below will be given the basic data of the lining board: width, length, thickness. Knowing these dimensions makes it possible to choose the optimal number of lining boards.

There are some differences in varieties:

Aspen

Aspen lining most often it is used in the decoration of baths, saunas, hananes. Manufactured and supplied to the market by Russian and European enterprises. For imported products, increased requirements for quality, humidity conditions, and dimensions are characteristic. All requirements are laid down in the EU standard DIN 6.

Our GOSTs are less demanding in quality, so the material is a little cheaper, but both standards are the same in size:

- thickness: 12 - 40 mm;

- width: 76 - 200 mm;

- length: 0.2 m (minimum) - 6 m (maximum).

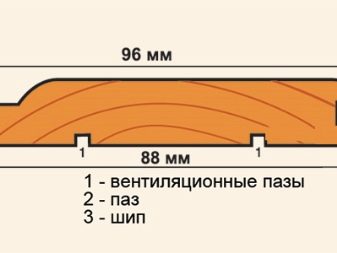

- thickness: from 12.5 mm to 15.0 mm. (Euro lining - 12.5 mm);

- effective width: 88 mm;

- overall width (dimension);

- length: from 1000 mm to 3000 m.

Oak

Oak lining is durable, durable, beautiful and noble texture. Residential and office buildings decorated with oak clapboard are distinguished by their natural attractiveness.

The standard dimensions of such a lining:

- thickness: from 12.5 mm to 15.0 mm. (sometimes it happens - 14 mm or 12 × 5);

- width: from 50 to 108 mm (determined by the manufacturer);

- length: from 1000 mm to 3000 mm. (most often 3000 mm, 2700 mm, 2500 mm, 1800 mm.

Pine

The bulk of the lining is produced from pine blanks. Its ease of handling and storage at a low cost makes the material available to most buyers.

Pine lining dimensions:

- thickness: from 12.5 mm to 15.0 mm. (popular - 13 mm, or 12.5);

- width: from 50 mm to 108. (determined in production);

- length: from 500 mm to 3000 mm. (preferred - 3000 mm, 2000 mm, sometimes up to 6 meters).

Larch

Along with the standard dimensions of a conventional lining, factories can also produce lining with data that differ from the standards. However, standard indicators are more often used in construction practice.

Wood paneling standards:

- thickness: 12 - 40 mm;

- width: 76 - 200 mm;

- length: 0.2 m (minimum) - 6 m (maximum);

- spike size: 4-5 mm.

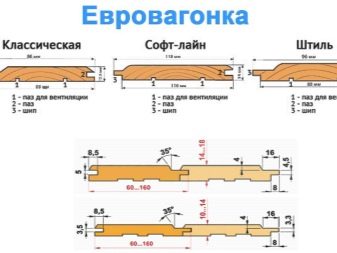

Wood Euro lining standards:

- thickness: 13, 16, 19;

- width: 80, 100, 110, 120 mm;

- length: 0.5 m - 6,000 mm;

- spike size: 8-9 mm.

Permissible deviations:

- thickness: 0.7 mm;

- width: 1 mm;

- length: +/- 5 mm;

- spike size: +/- 0.5mm.

A simple board of the lining type has a fairly wide range of parameters, its thickness is in the range from 1.2 to 2.5 cm, width - from 8 to 15 cm, length - from 60 cm to 6 m.

The EU standard is limited in thickness and width - 12.5x96 mm and uses 4 lengths:

- 2.1 m;

- 2.4 m;

- 2.7 m;

- 3m.

At Russian enterprises, other sizes for mass use can also vary: thickness - 1.3; 1.6 and 1.9 cm with a width of 8, 10, 11 and 12 cm, while the length is limited to 6 meters.

Sometimes, according to individual orders, manufacturers also make lining with specific dimensions (thickness - 20 mm, width - 120 mm, 125 mm, 140 mm). Euro-lining boards undergo chamber drying, so the standard moisture content of the material is maintained, which should be at the level of 10-15%. Ordinary lining boards are not brought to such humidity, and it remains at a level 2 times higher than the European level. This affects the quality, but reduces the cost of production. Drying in special chambers is very costly in terms of technology and finance.

The main parameter by which you can immediately distinguish the lining from the usual lining board is the size of the spike. In euro lining, it occupies 9% of the board width (or 8 mm), in a conventional lining board, the protrusion is shorter - from 4 to 6 mm. In the boards, made as lining according to EU standards, grooves are made on the back sides for air passage. This prevents condensation from forming and relieves internal stress that can occur during temperature changes.

The difference between euro lining and lining:

- A clear fulfillment of quality requirements is carried out.

- Eurolining boards dried in chambers have a moisture content not exceeding 12%. In an ordinary lining, this indicator is in the range of 15-28%.

- The outer surface of the boards is sanded and does not require further processing after facing.

- Each package with boards is packed in plastic wrap.

- There are more grooves for ventilation and condensate drainage.

- The size of the eurolining spike is 9 mm, the usual one is 5 mm.

Dimensions (edit)

In addition to a certain shape, planks can be made in various sizes. The permissible deviations of European products are regulated by DIN quality standards, domestic manufacturers - by GOST.

The following values apply to the standards.

- "Standard lining". The thickness of such products ranges from 12 to 40 mm, the width is from 76 to 200 mm, and the length is from 20 cm to 6 meters. Thorn - from 4 to 5 mm. Quite significant weight is characteristic.

- "Eurolining". It is characterized by more accurate dimensions, in thickness it is 13, 16 and 19 mm, in width - 80, 100, 110, 120 mm, length is from 50 cm to 6 meters, spike is from 8 to 9 mm.

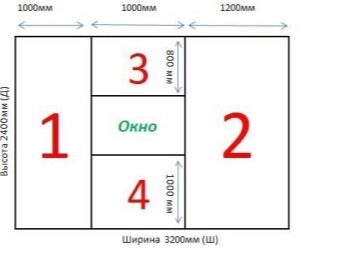

Tips & Tricks

The calculation of the number of lining should be started, knowing the length, width, height of the room in which the finishing will be carried out. The product of the width and height will give the square meters of the area to be trimmed. This rule is valid if the trimmed area of the usable area is of the correct shape. If this is not the case, you will have to calculate the parameters of individual sections, and then summarize the indicators. To calculate the number of lining, you need to multiply the parameters of indicators that relate to the room with the parameters of the thickness of the lining. If you need to find out how many pieces of panels are in one cube, you will have to multiply the length, width and thickness of the selected products. It is desirable to increase the obtained values by 10–15%, since the use of trim parts is impossible without residues. The increased result is useful for unforeseen situations.

For example, it is known that the length, width and thickness of one pine panel is equal to the following values: 125x50x2000 = 12,500,000.This value is in millimeters, but cubic meters are needed, so you need to translate: 0.125x0.050x2 = 0.0125 m³. To calculate the number of boards in a cube, you need to divide 1 by the resulting value: 1 / 0.0125 = 80. It turns out 80 whole lining panels. If a fractional number came out in the calculations, it must be increased to the nearest integer value.

To calculate the number of square meters in a cube, the area of one workpiece should be taken into account. To do this, you need to multiply the known section parameters: 0.125x2 = 0.25 m². It is known that there are 80 boards in a cube, which means 0.25x80 = 20 m² in one cube. To find out how much material is required for covering a room, for example, 5x5 meters, its total area must be divided by the area of one panel. It turns out that for the described example you need 5x5 = 25 / 0.25 = 100. For a room equal to 25 m², you need 100 pieces of pine lining of a standard size. If we take into account the price for a package of 10 pieces from 270 to 710 rubles, then the costs for the entire volume of material will be from 2,700 to 7,100 rubles.

No. 4. Which wood is best?

In fact, any wood can be used for the manufacture of lining, but the properties of the lining will differ in many ways, as well as its price. The cheaper lining is not always worse, since the material should be chosen based on the conditions of its operation. As for the color of the wood, his choice is a purely subjective opinion.

All the lining that is present on the modern market can be divided into two main types:

- lining made of coniferous wood;

- lining made of hardwood.

Coniferous wood is distinguished by a high content of resins and essential oils, due to which it resists the formation of fungus and withstands high humidity. This material has found a wide range of applications, excellent for external cladding, but completely unsuitable for saunas and baths. Under the influence of high temperatures, resin begins to stand out, and this process can continue for a long time. Not only does the material become sticky, it can also ignite spontaneously. Nevertheless, spruce and pine wood in the Nordic countries is used for the arrangement of saunas, but the material is de-resinated.

Most often, the following conifers are used for the manufacture of lining:

- Pine. It has a nice pattern, high strength, is inexpensive, but from time to time it must be varnished so that the material does not start to darken;

- spruce. The wood has excellent thermal insulation properties and a pleasant shade;

- larch. Very resistant to external influences, does not warp even with significant temperature fluctuations, is resistant to pests;

- cedar. Expensive wood with excellent performance properties, color from yellowish to coffee.

Hardwoods are less durable, but do not emit tar and heat poorly, which allows them to be used in baths and saunas. They require regular processing, otherwise, under the influence of external factors, they will change their color and deteriorate. Most popular hardwoods:

- oak. The most durable and durable, resistant to decay, dense, with a beautiful wood pattern, but such material also costs a lot;

- Linden. The wood has excellent soundproofing qualities and a delicate pleasant aroma; it is often used for decorating baths;

- ash. Due to its high hardness, such wood does not crack at all. Color - dark yellow;

- black alder has a pleasant light coffee color, resistant to moisture.

Separately, it should be noted that only wood with a low density is suitable for a bath, otherwise the material will be very hot, which can result in burns.

Material specifications

Material specifications

Material specifications

Raw materials for the manufacture of lumber, the size of the boards, the quality of processing are provided in the standards. According to the quality of material processing, there are 5 types of boards and 4 types of beams.

Selected grades of sawn timber are produced:

- dry with an allowable moisture content within 22%;

- from raw wood - moisture content above 22%;

- from material treated with antiseptics.

For grade 4 sawn timber, moisture content is not regulated by standards. Requirements for surface roughness are established by GOST 7016.

Depending on the purpose of the lumber, additional parameters are established that characterize the quality of raw materials. For example, for the structure of ships, the number, size and nature of the placement of intergrown knots on a 1 meter section of the length of lumber are taken into account.

For the manufacture of flooring, cracks and cores are possible in the material. The assessment of the suitability of the material is carried out on the best side.

Defect Regulatory Limitations

The table of norms of restrictions on the defects of wood material in accordance with GOST 2140-81 provides for the presence of knots. Their size is calculated as a fraction of the width of the boards and the amount per 1 running meter. For bars, standards are not established.

To characterize the quality of the boards, they are distinguished:

- rib knots;

- rotten and edging;

- thickness of 40 mm or more.

The permissible defect rates are calculated based on the parameters specified in the standards. The measurement of the diameter of the knots is carried out along a contour drawn parallel to the longitudinal axis of the material.

The permissible presence of cracks in a semi-finished product depends on the integrity and conditions of material preservation. Distinguish through cracks, deep and shallow, reaching the end.

In the manufacture of boards and beams, raw material defects are taken into account, including the inclination of the fibers, pockets, the shape and size of the core, traces of wood diseases.

The damage to the harvesting by mushrooms is analyzed separately. As a result of their impact, poisonous stains and rot are formed on the tree, which affect the quality of the material. As a result of wood processing, mechanical damage can occur.

Foreign inclusions in the form of wire, fragments are not allowed in semi-finished products. Biological damage by a wormhole is calculated in pieces per 1 m of the workpiece and should not exceed 2-6 shallow defects.

Standard parameters

Lumber sizes GOST 24454-80 for conifers are specified in certain standards. The optimal parameters for the height and width of trimmed semi-finished products should correspond to the data in the table.

For example, for semi-finished products with a thickness of 50 mm, lengths from 75 to 275 mm are allowed in increments of 25 mm. Taking into account the demand of consumers, it is allowed to manufacture sawn timber with dimensions that differ from the standard.

The actual dimensions of semi-finished products made from wood with a moisture content above 22% should be slightly larger. The indicator should take into account the change in size as a result of shrinkage.

The optimal parameters are set for the domestic market and export from 1 to 6.5 m. The parameters of the material intended for the manufacture of container boards are from 0.5 m with a graduation of 0.1 m.

For the formation of bridge beams, the length of the semi-finished products is 3.25 m. The dimensions of the semi-finished product intended for export are from 0.9 to 6.3 m with a gradation of 0.3 m.

Deviations from the indicated dimensions are calculated separately for each type of product.

The dimensions of the cross-section of the edged material and the length of the boards are determined by GOST 8486-86. For example, for a board with a length of 6.5 m, a gradation of 0.25 m is set. Most often, the size of 6 m is in demand among consumers, which has already become the standard.

In this case, the width of the material is from 75 to 275 mm, and the thickness is 16.19, 22, 25, 32, 40, 44, 50, 60 or 75 mm. The parameters of the height, width and length of the board determine the number of pieces in 1 m³.

The weight of finished semi-finished products is calculated by multiplying the volume by the density of the material, which depends on the degree of moisture, the type of tree, and the conditions of its growth. The technical parameters of wood are taken into account when transporting it.

Types of lining profiles

Variety is important in finishing, so manufacturers make different variations and modifications of the lining. Traditional eurolining after installation forms distinct seams

If this type of lining has a rounded chamfer, then it is "Softline". Its outer part is devoid of corners, which allows to protect the wood from burrs and chips for a long time. Softline is well suited for saunas. The "Calm" lining does not have a chamfer near the spike, and, as a result, there will be no pronounced seams after assembly. The thickness reaches 2.5 cm, so it can be used for facade decoration. "Landhouse" - a lining with a complex rounded shape at the edges. Finishing with this coating will make the interior more "expensive". Another interesting option is the "Blockhouse", a feature of which is the rounded front side. This material can be used to finish surfaces inside log houses and facades.

Several more types of lining:

- "American". Has a sloping surface. Elements are overlapped.

- Bilateral. Both sides are obverse. It is used not only for wall decoration, but also for the construction of partitions.