Varieties

The popularity and huge demand for double brick is due to its high performance. It can differ in texture, size, number of slots and shapes of voids. There are two types of blocks depending on the raw materials used for manufacturing.

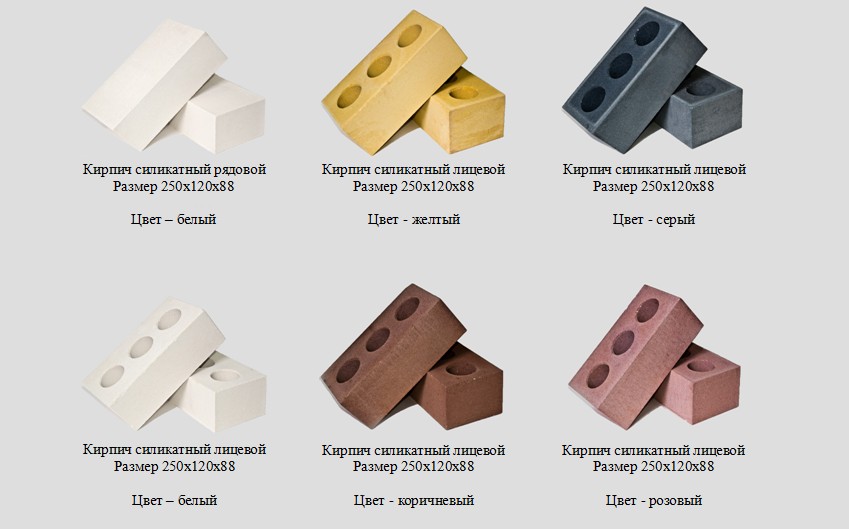

Silicate

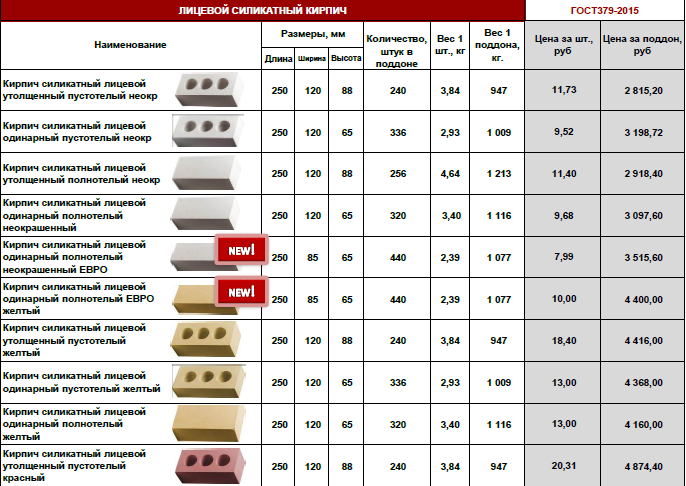

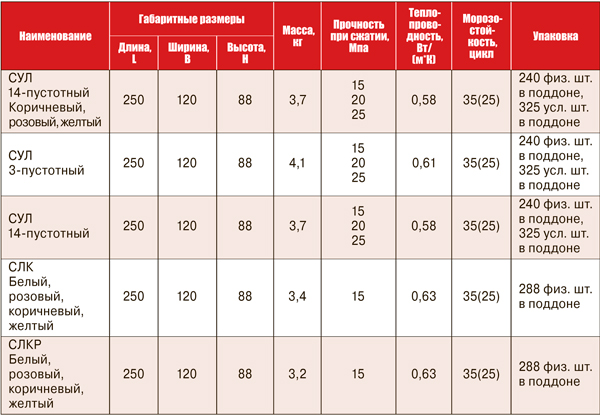

Their main feature is that the production is carried out from a mixture of 90% sand and 10% water. In addition, the product also contains additives that increase its quality. This is an absolutely environmentally friendly material that looks like natural stone. The process of making double silicate bricks is carried out by pressing a moistened mixture of lime and sand, after which various pigments are added to it, and sent for steam treatment. It can be either hollow, slotted or porous. By strength, silicate blocks are divided into grades from 75 to 300.

These blocks are most often used for laying out internal and external partitions. It is impossible to use silicate brick for the construction of basements and foundations of buildings, since the product is not resistant to moisture, and in the absence of a waterproofing layer, it can be subject to destruction. It is not recommended to make double silicate bricks and laying pipes, ovens. It will not withstand prolonged exposure to high temperatures.

As for the advantages, this product has excellent sound insulation and has the correct geometric shape. Despite the large weight of such bricks, their laying is quick and easy. In terms of their density, silicate products are 1.5 times higher than ceramic ones, therefore they provide durable and high-quality masonry. In addition, silicate double blocks are 30% cheaper than other types.

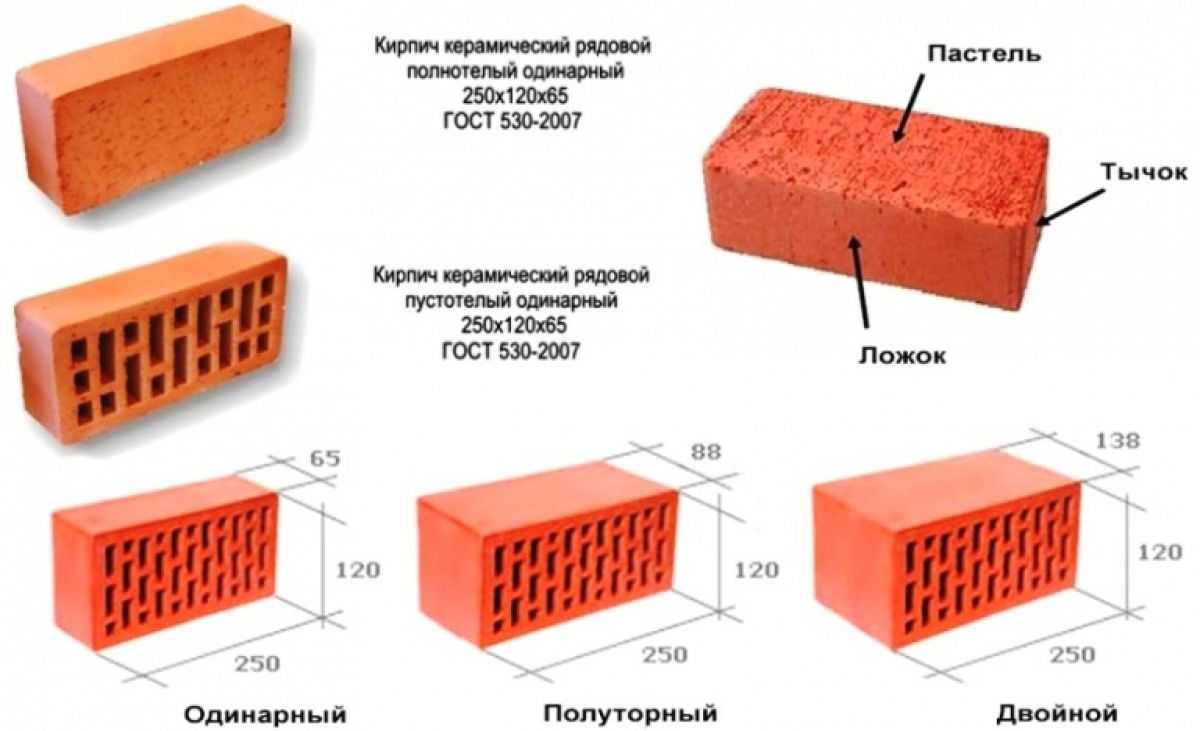

Ceramic

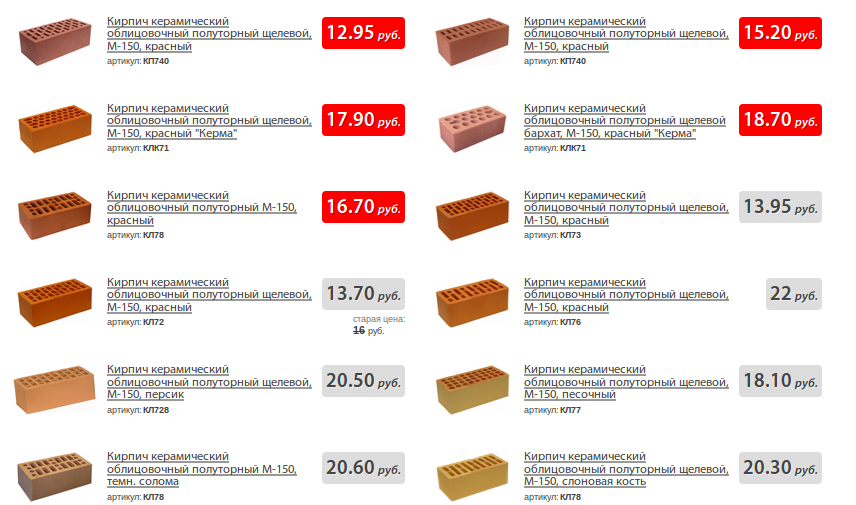

They are a modern building material that is used in almost all types of construction work. Its feature is considered to be large, which is usually 250 × 120 × 138 mm. Thanks to such non-standard dimensions, construction is accelerated, and the consumption of concrete pouring is significantly reduced. In addition, double ceramic bricks are in no way inferior in strength to conventional blocks, so it can be used when erecting load-bearing and self-supporting structures in buildings no more than 18 m high.The product is also characterized by high thermal insulation, the buildings laid out of it are always warm, and they are constantly maintained optimal microclimate.

The main advantage of double ceramic bricks is its affordable cost, while many manufacturers often make good discounts when purchasing blocks for the construction of a large object. These blocks, in addition to high quality, also have an aesthetic appearance. Usually brick is red in color, but depending on the additives, it can also acquire other shades. The product is environmentally friendly, and even with prolonged use and exposure to the external environment, it does not emit harmful substances.

These blocks are transported on pallets, where they usually fit up to 256 pieces. As for the marking, it can be different, more often everyone chooses M-150 and M-75 bricks for the construction of objects. In addition, double ceramic blocks are subdivided into solid and hollow; not only their price, but also their heat capacity depends on this parameter. Hollow bricks cannot be used for the construction of load-bearing walls, in this case only solid bricks are allowed. Despite the fact that the first is lightweight and significantly reduces the overall load on the foundation, the inherent cracks in it affect the thermal conductivity.

In addition, double bricks are subdivided into the following types.

- Private. These blocks are ideal for laying stoves, fireplaces and foundations.The only thing is that the front layout requires additional finishing.

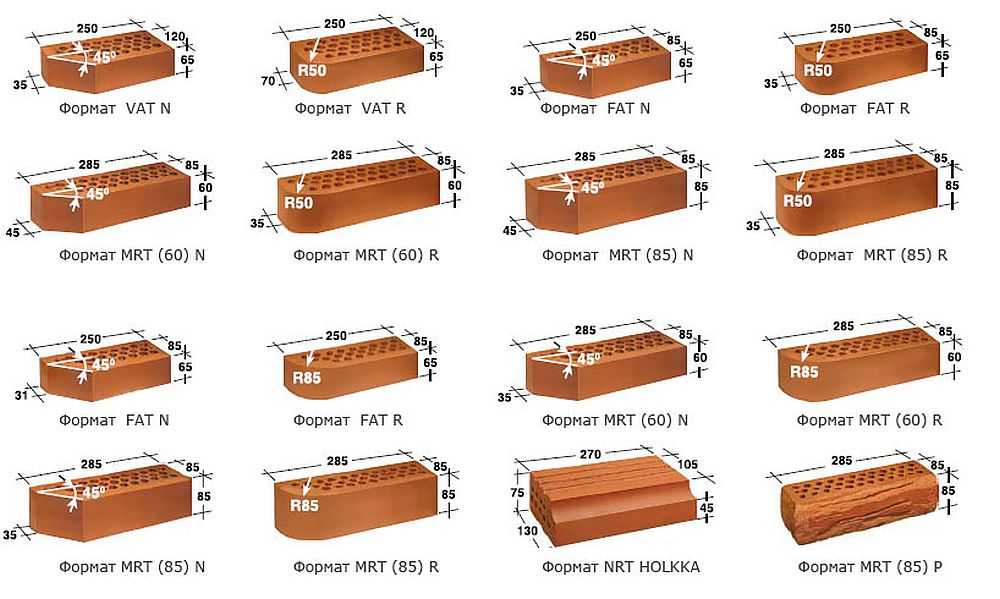

- Facial. It is produced in clinker and hyper-pressed versions. It can be either solid or hollow bricks. Unlike ordinary blocks, face blocks are produced in curly, trapezoidal, rounded and twisted shapes. As for the color, it is dark brown, gray, red, yellow and brown.

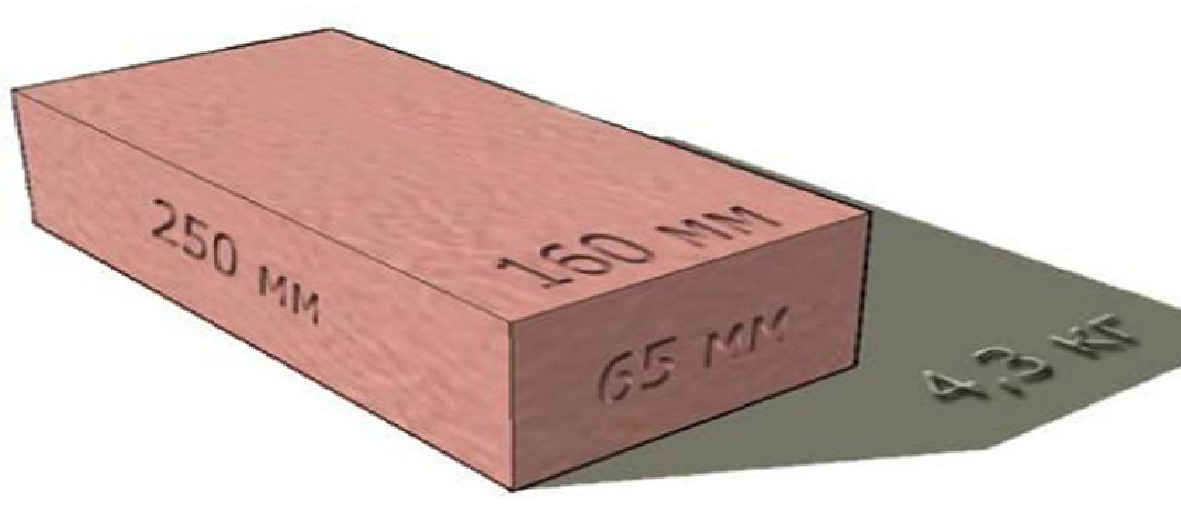

The weight of a solid brick in a classic design is 3.3-4.3 kg

It is used for buildings made of ceramic stone, in the construction of plinths of wooden houses, for bandaging foam concrete / silicate masonry, quite rarely - as the main building material. Before concrete slabs and foundations appeared, it was irreplaceable. This is due to its resistance to the action of groundwater, the possibility of using it in the layout of vaults and large-scale arches and selection for complex facade decor. However, the degree of thermal insulation of this material is quite low, which automatically increases the thickness of the walls, and, consequently, the load on the foundation.

The weight of a single solid red brick averages 3.45 kg (3.3-3.6 kg), a single hollow brick - 2.4 kg, a single facing brick - 1.45 kg.

- Construction slotted (hollow) brick weighs about 2.5 kg. however, it is also losing its popularity in the construction market. Taking into account the solution, 1 cubic meter of masonry weighs almost 1700 kg, which guarantees a significant weight of the structure and the corresponding load on the base of the house. In low-rise construction, it is much more profitable to use ceramic stone with high thermal efficiency.

- Silicate is the heaviest option. According to GOST 379-95, the weight of the silicate brick should not be more than 4.2 kg. but today many manufacturers in their work are guided by the TU, according to which even a brick weight of 5.0 kg is considered normal. The indisputable advantage of this material is its affordability. The disadvantages include fear of high temperatures and significant water absorption. The weight of a single solid white silicate brick is 3.7 kg on average. single hollow - 3.2 kg, single facing - 3.95 kg.

Porous blocks are the lightest building material. Their dimensions correspond to the thickness of the wall, however, due to their high thermal conductivity and low weight, they significantly reduce the load on the base of the house. The abundance of closed pores and through cracks in a ceramic stone explains its significant dimensions and minimal weight. 1 cubic meter of such material weighs no more than 800kg.

Facing ceramics. The indisputable advantages of this option include high frost resistance and durability. The weight of the facing brick is 1.6-4.3 kg. The heaviest are clinker solid stone, which is obtained from highly plastic clays by sintering into a monolith.

The clinker is characterized by high strength and durability, is not afraid of temperature extremes, and does not lose its texture and color for a long time. Considering the fact that in most cases the bed of facing stones is narrowed, the pressure on the foundation is insignificant.

How to choose a brick grade?

In the construction of household stoves and fireplaces, quartz and the so-called fireclay red bricks are used. The second option is more popular, since quartz at significant temperatures changes its structure and, as a result, thermal conductivity and volume. Gradually, this inevitably leads to deformation and destruction of the walls.

- Refractory red brick can withstand heating up to 1000 degrees Celsius. For such a material, frost resistance is essential, and especially for the construction of stoves in summer cottages, which are heated irregularly. The marking must indicate the designation F35 (means at least 35 freeze-thaw cycles).

- Fireclay brick.In addition to strength, this material is characterized by very fast heating and long-term heat retention. The most popular brands are SHA-5 and SHA-8. The letter A indicates the maximum possible temperature (1400 degrees Celsius). Grades ШБ-5, ШБ-8 can withstand up to 1350 degrees Celsius and their cost is significantly lower.

Species characteristics

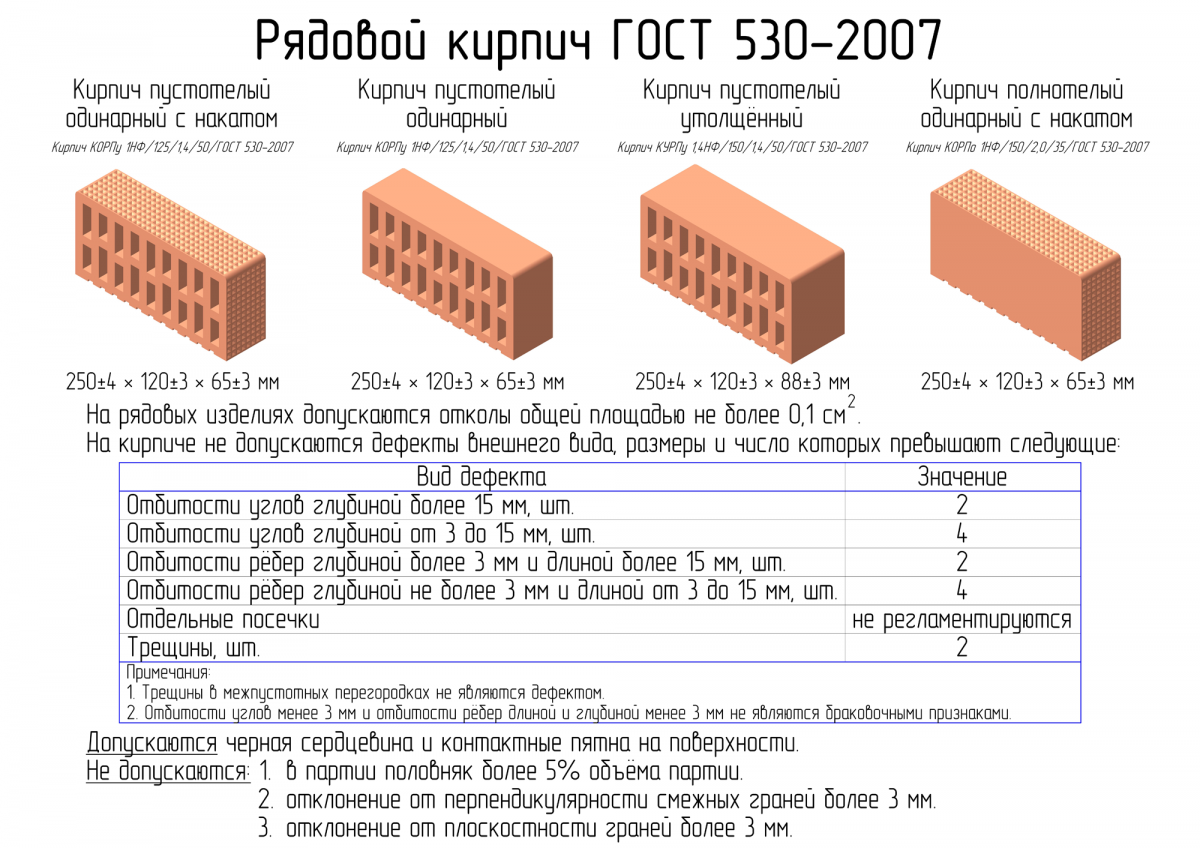

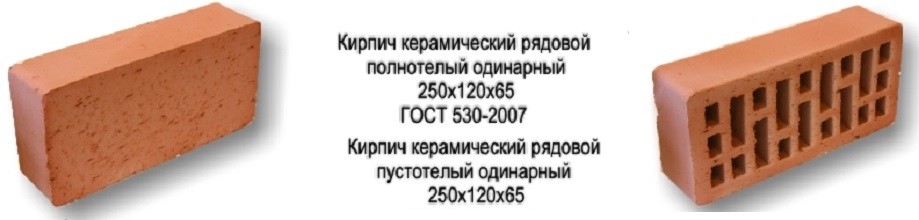

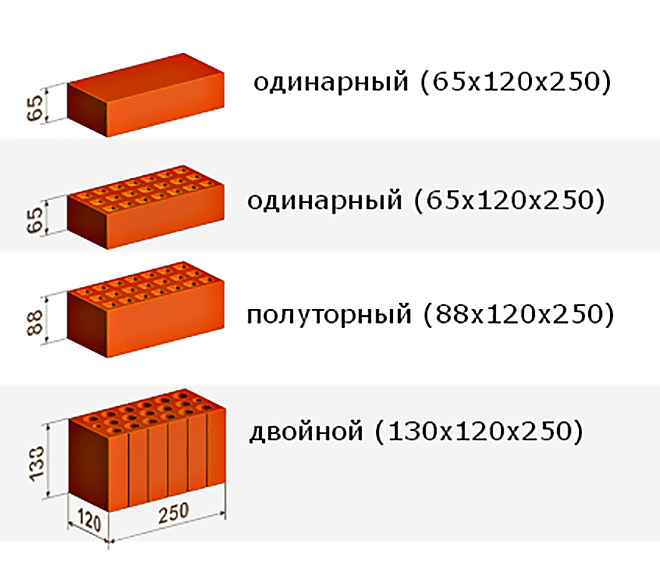

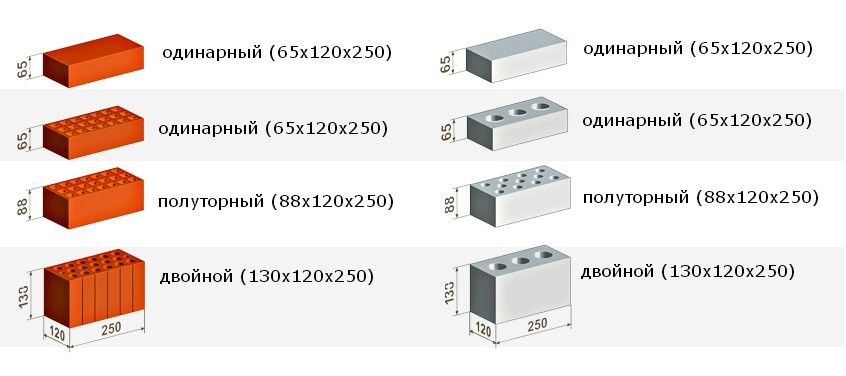

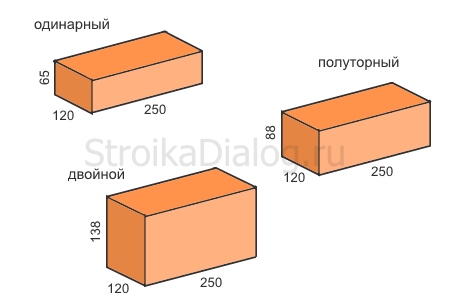

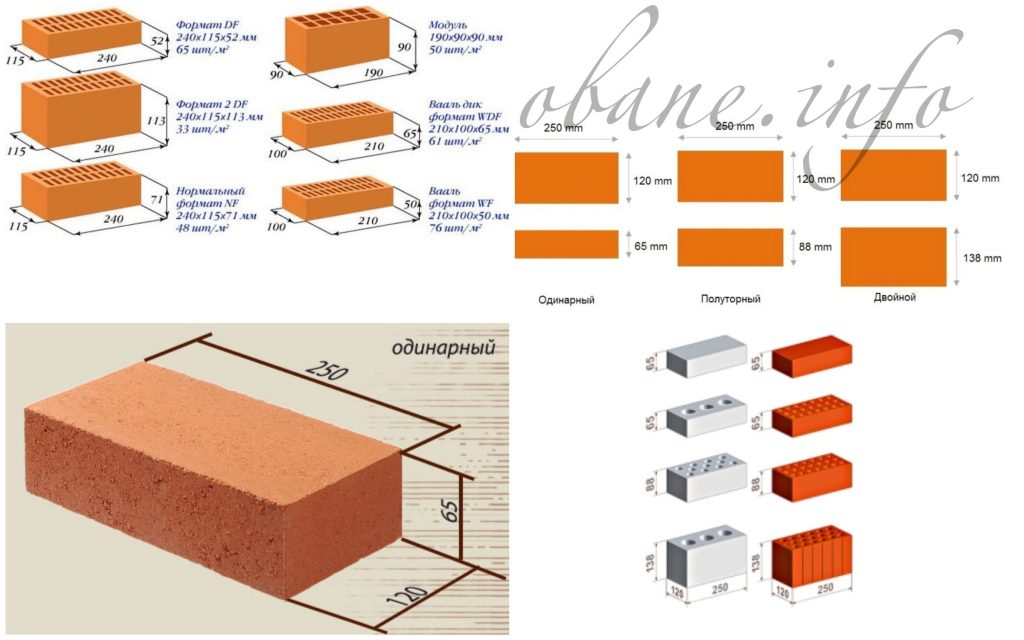

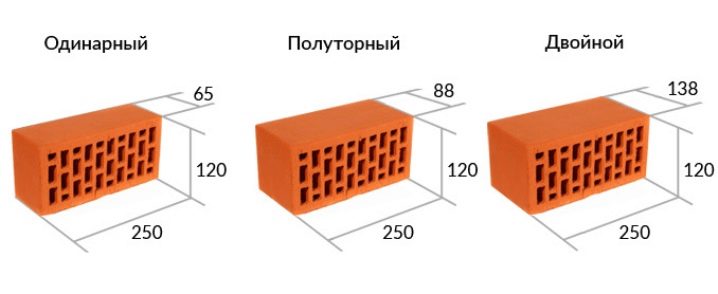

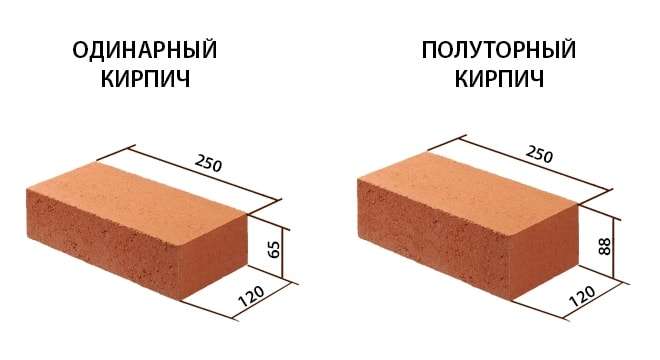

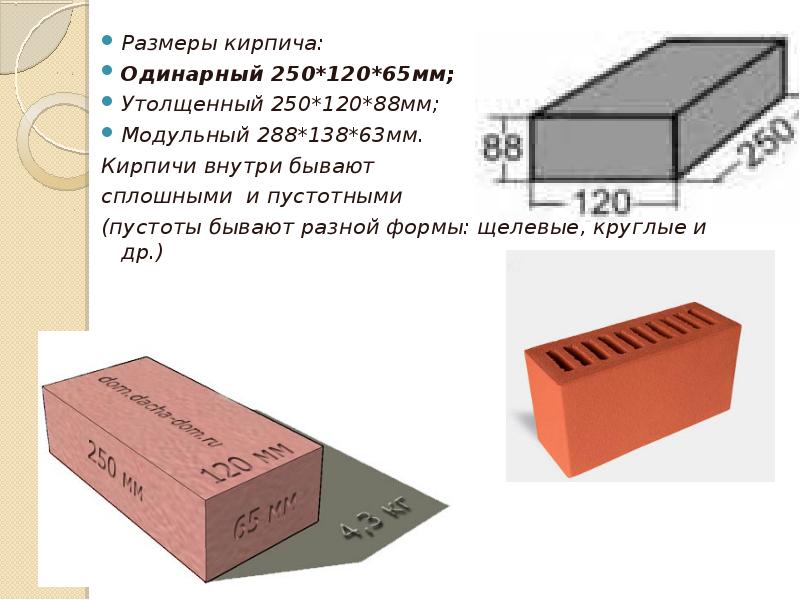

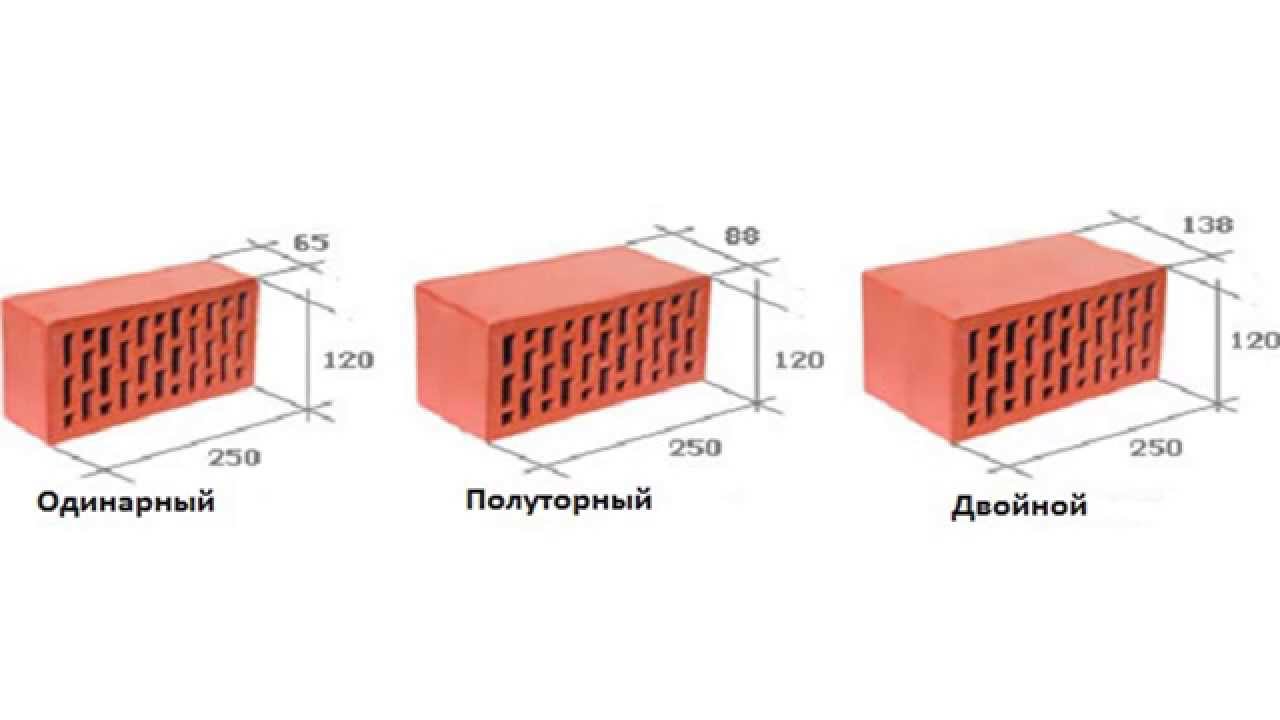

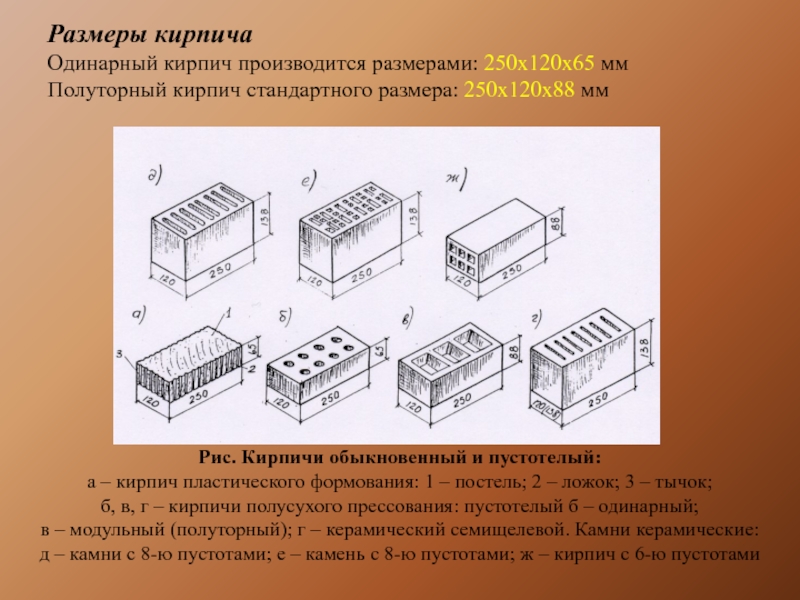

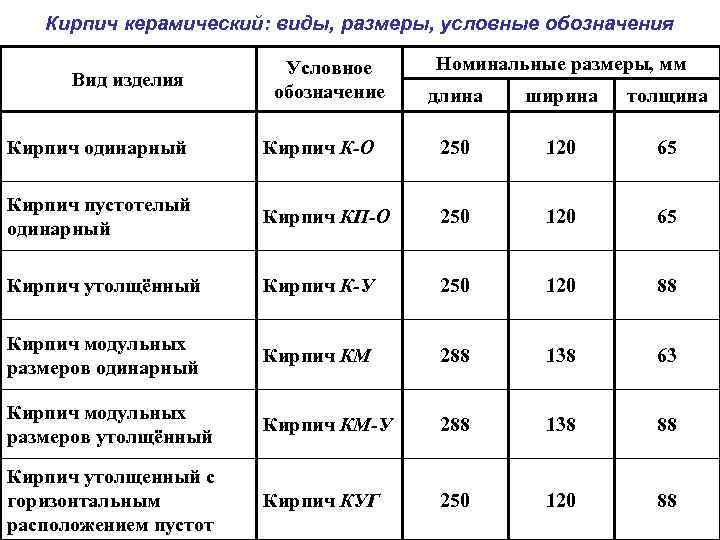

It is worth noting that dimensions are far from the only parameter that affects the types of bricks. Available in the same dimensions (250x120x65 mm, 250x120x88 mm, 250x120x138 mm) and hollow versions that can also be used in construction.

Their main difference is the presence of voids in the base of the material, which causes certain distinctive qualities.

Corpulent

Compared to hollow stone, solid stone has a number of advantages and features.

This parameter is necessary for the construction of highly loaded walls and structures. The integrity of the structure helps to prevent cracking of the base, except for the subsidence of the foundation.

At the same time, the laying process is somewhat easier and safer, with the help of a rubber mallet, you can easily adjust the row, and in the hollow version there is a risk of cracks or surface spalling. The full-bodied version is holistic and homogeneous, which is not very good in terms of heat conduction.

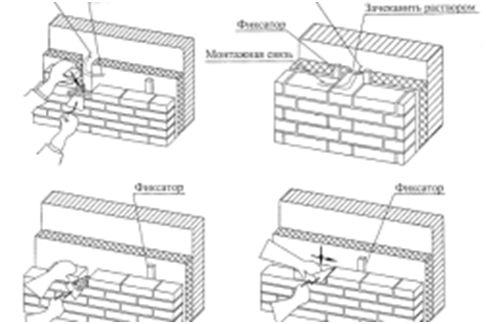

Masonry

Thus, there are no air pockets that could delay the influence of cold, and, accordingly, its transmission further down the structure. The disadvantage of high conductivity is easy enough to eliminate - during construction, a special material for insulation is provided.

In most cases, it is also used for the hollow version. If the stone is used as a facing, then even a fairly cheap insulation can be purchased, because the destructive effect of moisture and atmosphere on it will not be affected anyway.

Facing brick in most cases is a solid stone. Due to the small size of the material, it loses most of its quality characteristics if voids are present.

Facing

Facing red bricks are mostly solid, which helps to strengthen the walls of the structure and acts as additional protection against the influence of the external environment on the load-bearing walls and their cracking.

When making a foundation, this parameter must be laid in the base, otherwise it may not cope with the weight of the material and shrink.

In general, red bricks are somewhat lighter than white silicate bricks. The standard size weighs 3.7 kg. When cladding with this stone, it is necessary to determine whether the laid base can withstand the outer layer without deformation.

The weight

If in doubt and there is a risk of shrinkage, then the foundation is additionally strengthened by adding a certain layer to it, but the procedure is quite laborious.

For more information about red solid brick, see the video:

Hollow

The hollow variant has several other characteristics and deserves the right to live as well. Basically, structures are made from it, which must not withstand heavy loads or with a high need for thermal insulation characteristics.

Thanks to this approach, it is possible to reduce the economic costs of construction, since the material is somewhat more expensive.

The need for a powerful foundation is also reduced, and, accordingly, its price is reduced, in addition, you can do without insulating material, but this depends on the region of residence. Inside the brick there are air layers, pockets, which form a heterogeneous structure.

Hollow

This is extremely useful as a heat containment, the insulating properties of such a stone are an order of magnitude higher than that of a corpulent one. Due to the presence of weak points inside the material, it has a higher risk of cracking and a lower resistance to mechanical damage.

Sometimes, even a small enough blow will lead to cracks or chipping off of pieces of stone. In the completed construction, this is of lesser importance, but during the installation process there are certain difficulties and it is worth taking into account a certain amount of marriage.

Varieties of basement bricks and their sizes

When building this section of the wall

products must be used that have a high resistance to private

exposure to moisture, as well as temperature extremes. Therefore, the application is required

building stone with a low porosity index. This is due

the fact that moisture settles in the pores of the bricks. And with temperature drops, it

passes from one state of aggregation to another, which leads to the destruction

structure of products. In total, for equipping the basement part of the wall, it is recommended

apply one of 4 types of bricks.

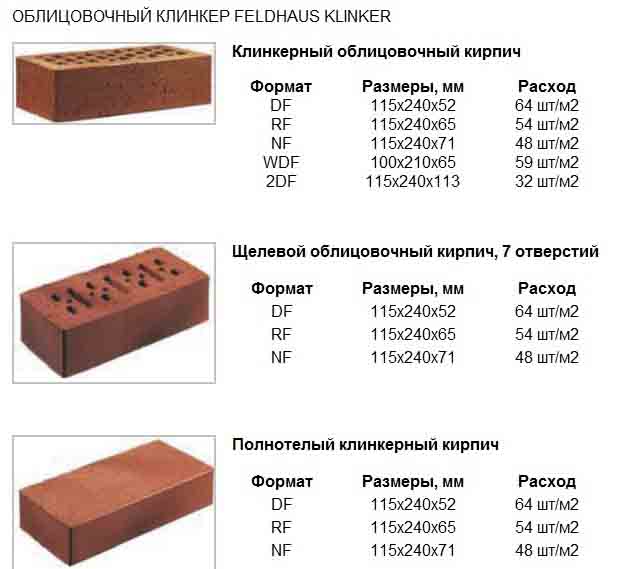

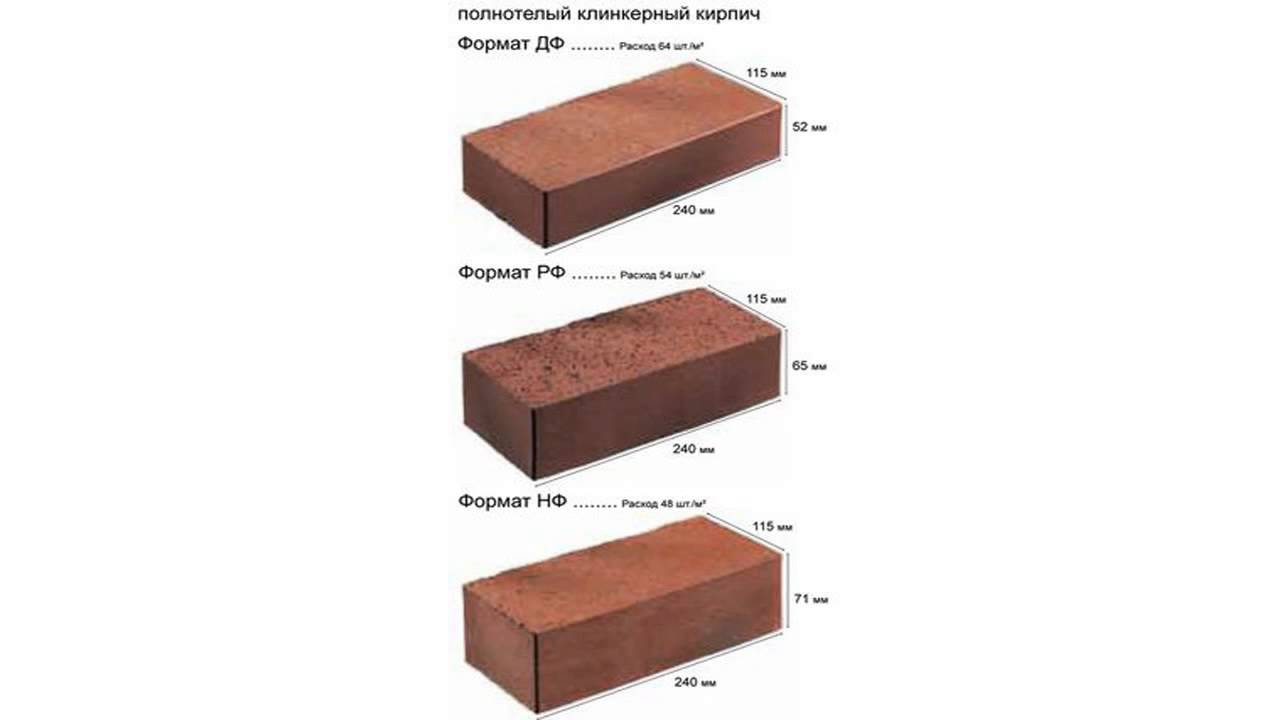

Clinker

This type of building material

has high performance of sound and heat insulation. In addition, it is heat resistant

and has high resistance to ultraviolet radiation, acids, alkalis and

even salt. And the level of porosity of clinker bricks does not exceed 6%. Such products are made from a certain

type of clay through high temperature processing. The finished material is not

requires additional hydrophobic impregnation. The color of a similar building stone

it can be either beige or dark red. Dimensions of products of Russian standards

the following:

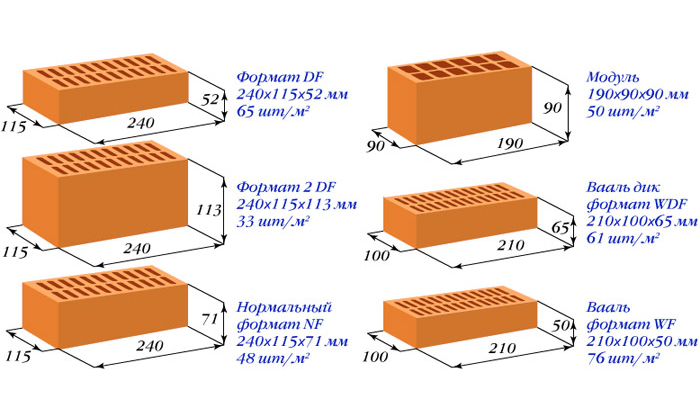

- Single brick:

250x120x65 mm; - One and a half:

250x120x88 mm; - Double:

250x120x138 mm;

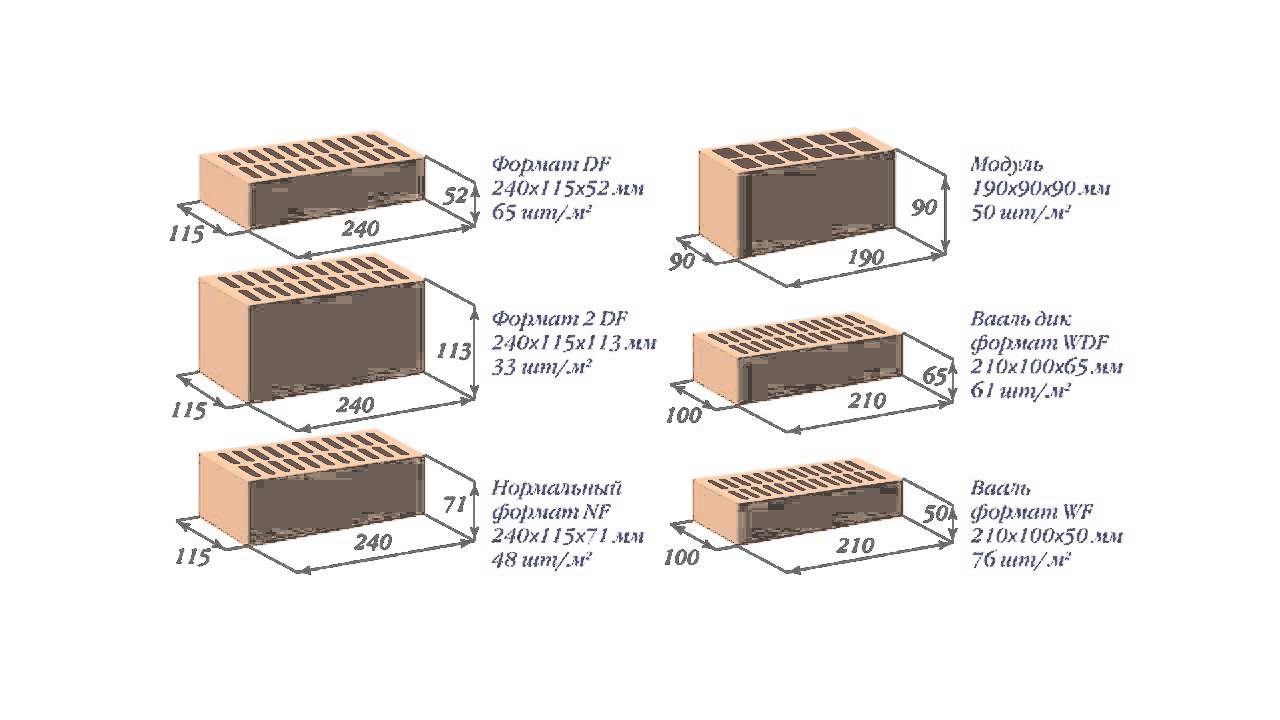

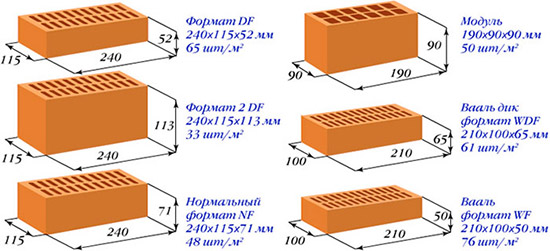

Products manufactured in other countries

differ in size from domestic options. So, in Germany, and

The Netherlands also produces clinker bricks with the following parameters:

- Single

240x115x52 mm - One and a half: 240x115x71

mm; - Double: 240x115x112

mm;

Therefore, before purchasing it is important

also take into account the country of origin

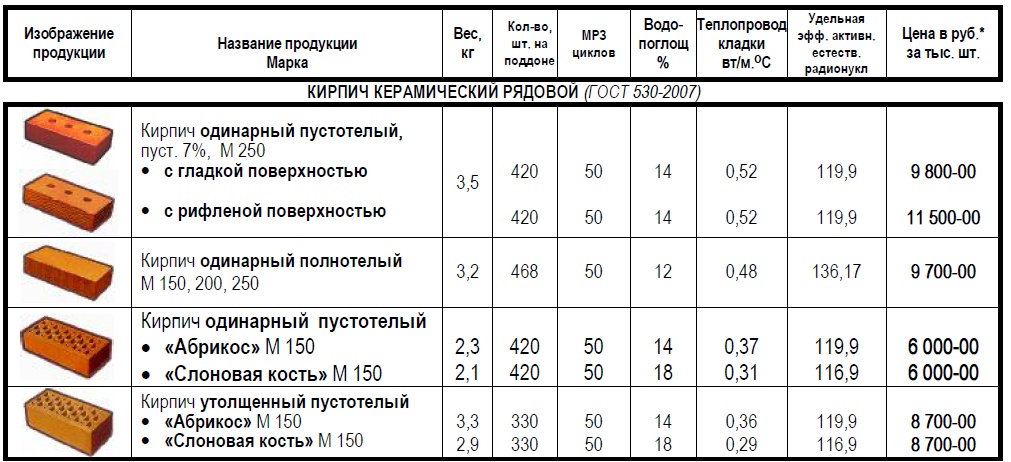

Ceramic red corpulent

Another versatile construction

material is considered red

ceramic brick. Such material can be used not only for construction

basement, but also in load-bearing walls. The characteristic features of such products

lower thermal conductivity parameters are considered even in comparison with

clinker options. However, it has a higher level of moisture absorption,

making up 14%. This is sufficient for the application of the material in places of accumulation.

moisture. The advantage of ceramic bricks is their low cost when

similar dimensions as in the previous species. Additionally issued

doubled products, the dimensions of which are: 528x120x65 mm.

Silicate brick

Often this type of construction

material is used for the construction of load-bearing structures. Products have

high rates of density and strength. And due to the accuracy of the geometry

their use for cladding is allowed. The downside is even more

a high level of moisture absorption, amounting to 16%, as well as an increased level

thermal conductivity. For this reason, for the construction of the basement, they are recommended

use only in regions with low rainfall.

Additionally around such structures

you will need to equip a two-level drainage, which will reduce the effect of moisture

for silicate products. At the same time, the dimensions of the brick for this type of base are also standard. What

touches the surface of the facing options, then they are made smooth, and also

decorative, on the front of which there is a certain relief. Exists

and a small spread in colors.

Acid resistant

The process of making such bricks

takes place according to a special technology where clay and dunite are used. Ready

products have a very high resistance to various chemicals,

however, during the laying process, an acid-alkali-resistant putty must be used. except

this, this type of building material has low rates

water absorption, amounting to only 8%. A distinctive feature of acid resistant

bricks are frost-resistant, allowing them without loss of properties

withstand 150 shock frosts.

Product dimensions are slightly different

from the all-Russian standard and are 230x113x65 mm. Additionally, in addition to the classic straight forms, are produced

still others, for example, radial longitudinal small, whose size is 113x70x65

mm, as well as wedge-shaped double-sided rib 113x65x65 mm.

Knowing the varieties as well as sizes

similar bricks, it is possible to calculate how much construction

material for the construction of the basement. The most common is the use of

clinker products with the best parameters for construction and more

attractive appearance. Ceramic red bricks are also used,

having slightly worse indicators, but having more affordable

price.

Dimensions and weight according to GOST

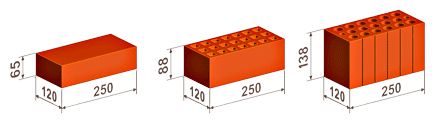

Standard sizes of single, one and a half and double products:

When designing buildings and structures, all characteristics are taken into account, including overall dimensions and weight of red brick.

Manufacturing products according to uniform dimensions allows the designer to easily select elements of a certain format for construction or cladding, and knowing their approximate weight - correctly calculate the loads of the structure being erected on the foundation.

It will be possible to purchase the material from any manufacturer and at any time after the preparation of the project.

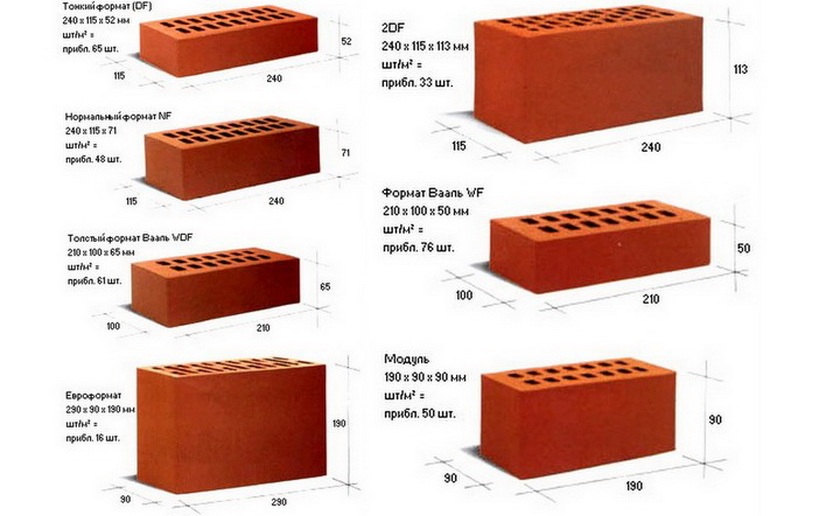

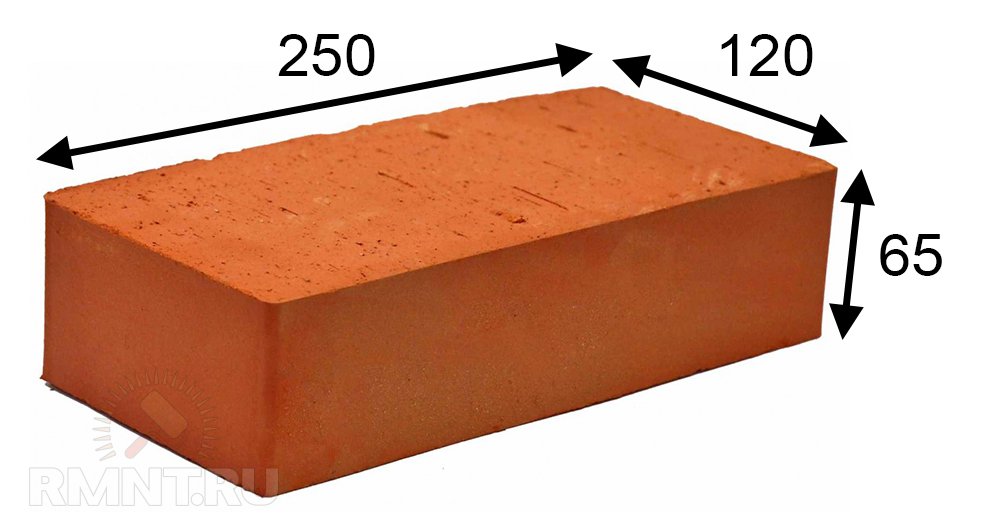

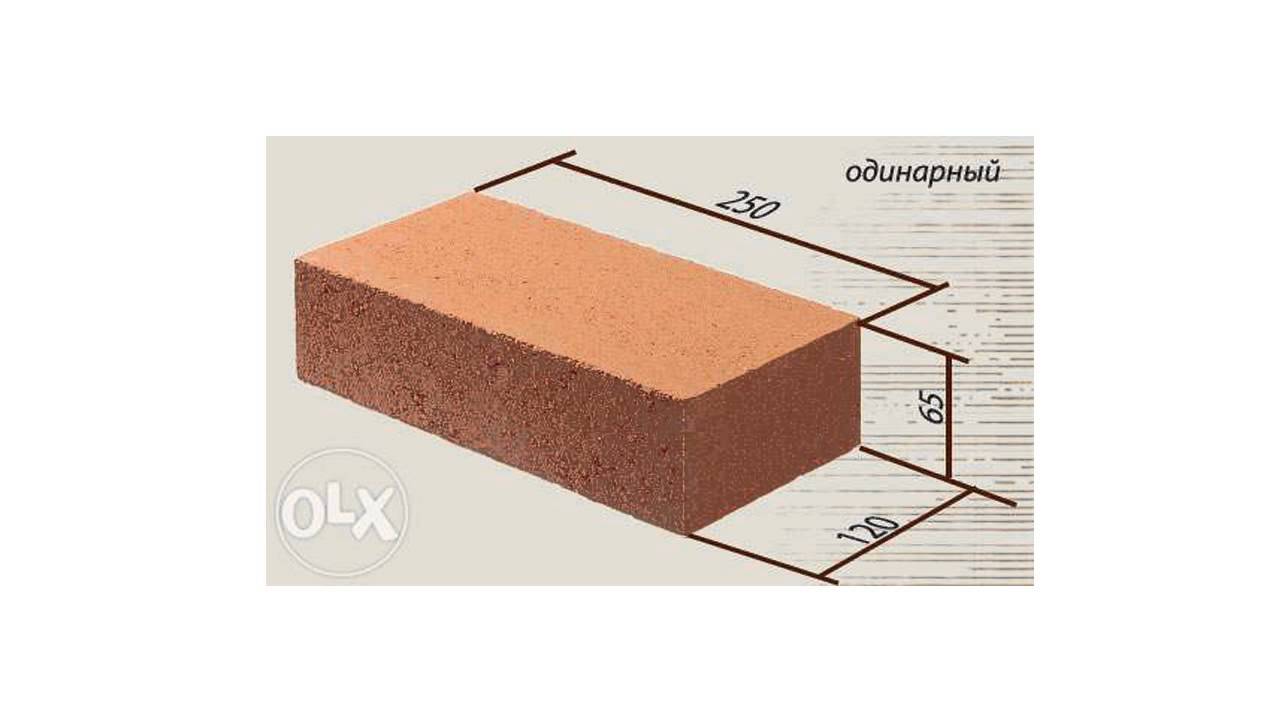

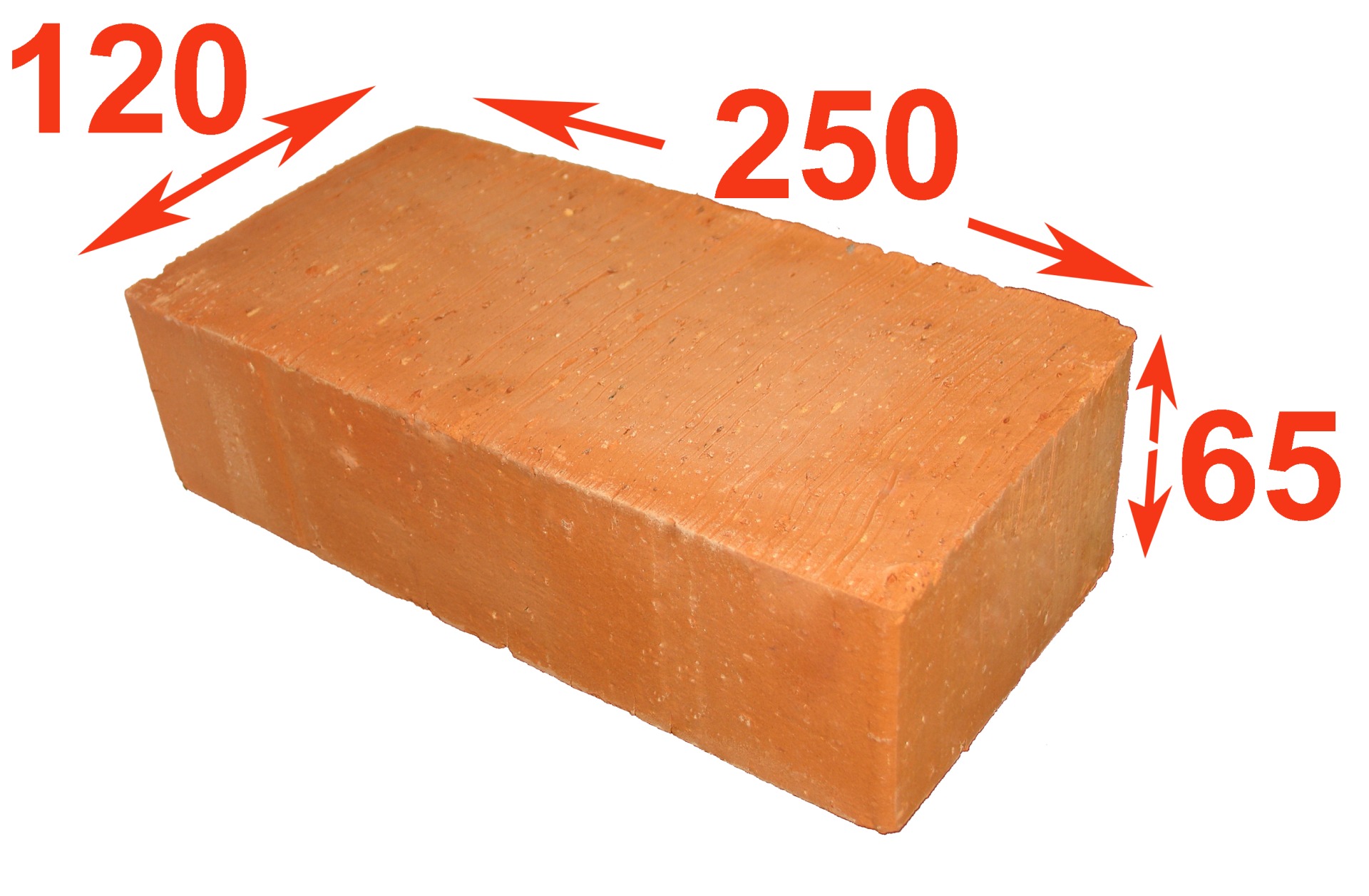

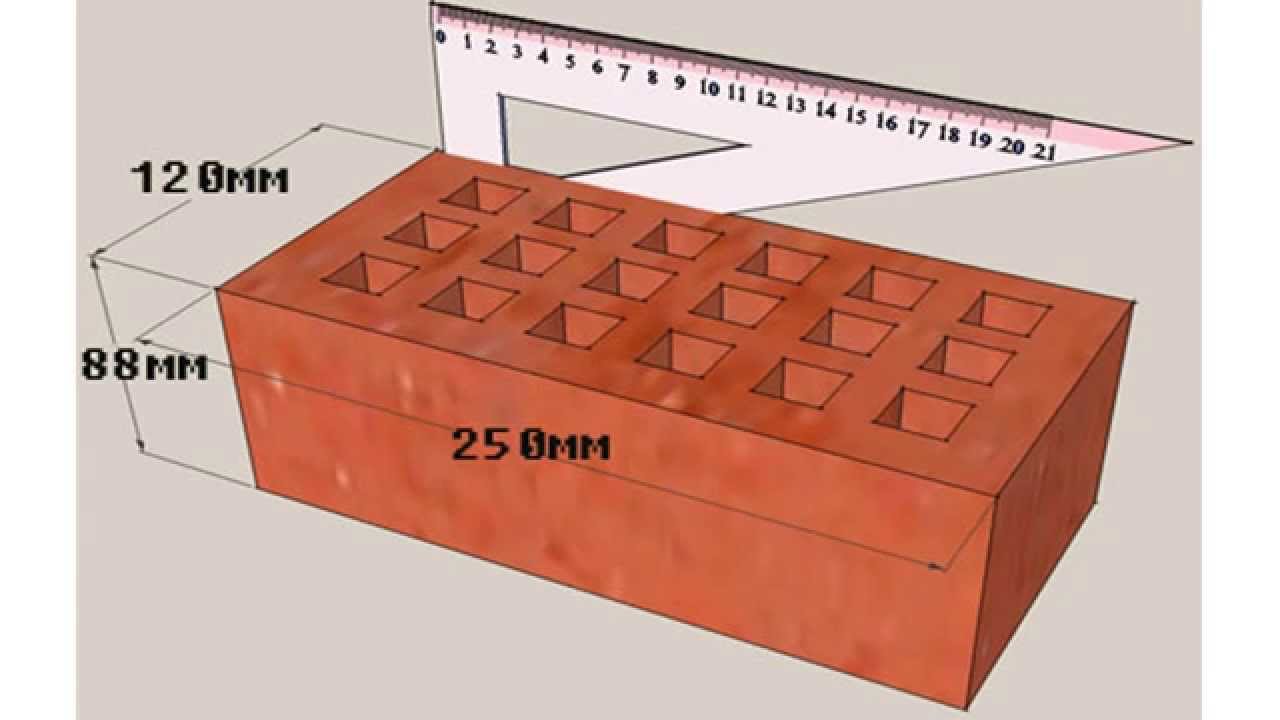

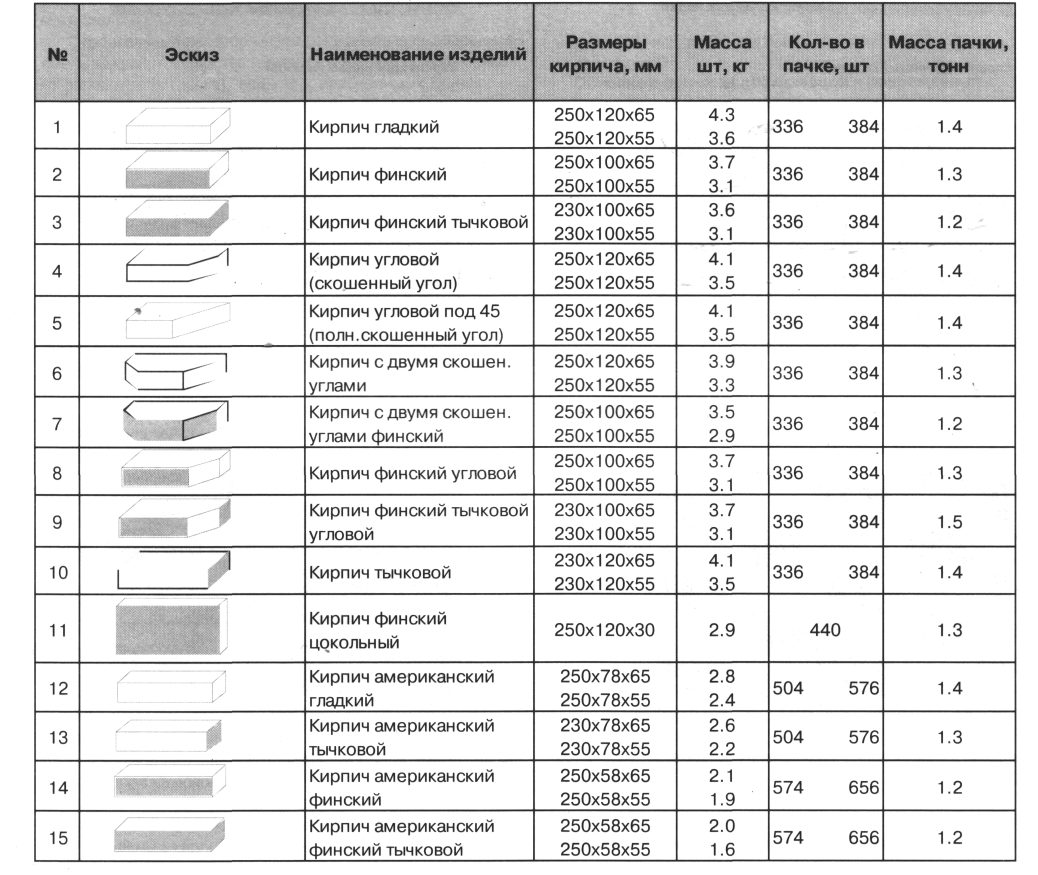

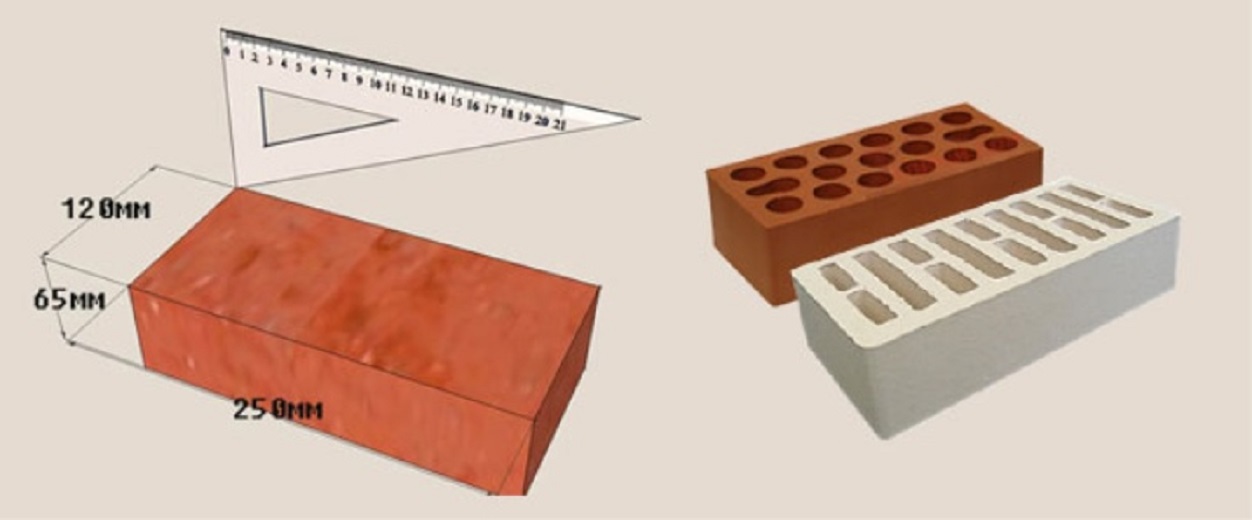

Standard sizes of red brick in normal (regular) 1NF format:

- length - 250 mm;

- width - 120 mm;

- height - 65 mm.

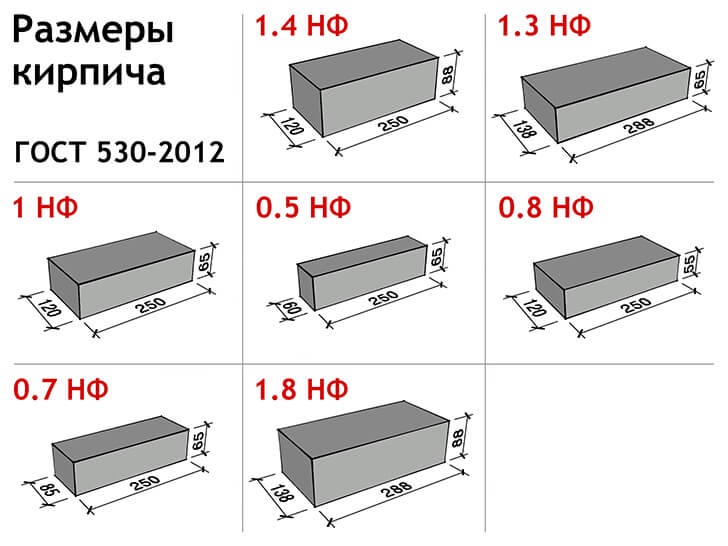

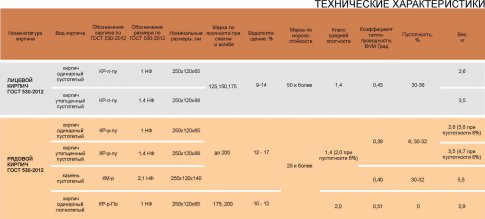

It is the dimensions of single elements provided for by GOST that are a kind of starting point - i.e. a material with other parameters will have a different marking instead of 1NF, where the number denotes its proportions of the ratio with a single one.

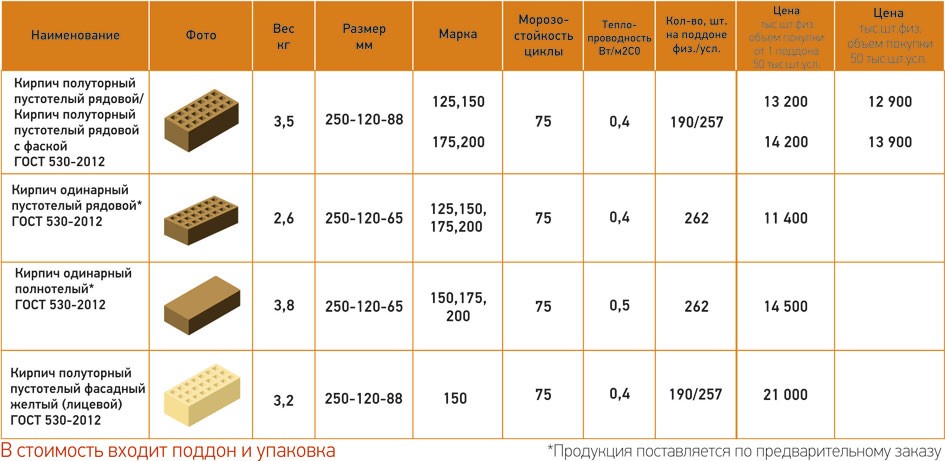

So, the size of a one-and-a-half red brick will already be 250 × 120 × 88 mm, and will be designated as 1.4 NF. Products of these formats are produced as ordinary and facing.

The list of sizes of facing red bricks can be supplemented with euro format products (0.7NF, 250 × 85 × 65 mm), and ordinary ones - with double elements (2.1 NF, 250 × 120 × 138 mm).

Dimensions of red brick euro format

Thin face material (euros) will help reduce the financial costs of facing, and a large stone (double) will significantly speed up the process of building a house.

Many are often interested in the question of how thick the red brick is. For materials of basic formats (single, one and a half and double), it is standard - 120 mm.

The exception is euro size elements, the width of which is reduced to 85 mm.

Deviations from standard dimensions

According to GOST, the maximum permissible deviations from standard sizes on one element (regardless of the format) are:

- in length ± 4 mm;

- in width ± 3;

- in thickness ± 2 mm for front and ± 3 for ordinary material.

Standard red brick weight

The GOST does not reflect information on how much a single or red brick of other dimensions weighs - the standard indicates only material classes in terms of average specific gravity.

Depending on the class of average density, the products are divided into several groups according to thermal characteristics:

- 2.0 and 2.4 - ineffective (normal);

- 1.4 - conditionally effective;

- 1.2 - effective; 1.0 - increased efficiency;

- 0.7 and 0.8 - high efficiency.

Before proceeding directly to the question of how much 1 standard red brick weighs, you need to consider its types depending on the structure.

The material is available in several options:

Hollow (slotted)

With the amount of voids up to 45%. It is much lighter than corpulent, but less durable.

Corpulent - the number of voids is no more than 13% of the total volume of red brick.It differs in a larger mass, but the strength characteristics of the elements are an order of magnitude higher.

Table 1. Weight (weight) of red bricks of single (250 × 120 × 65 mm), one and a half (250 × 120 × 88 mm), double (250 × 120 × 138 mm) and euro (250 × 85 × 65 mm) formats:

The weight of a red facing brick does not differ from the weight of an ordinary hollow brick. The only thing worth noting is that cladding products are produced only 0.7NF, 1NF and 1.4NF, and there are no double formats for finishing work.

How much does an oven red brick weigh?

Kiln brick

Interested in the weight of red oven bricks, many consumers do not know its main purpose - this is a brick with increased characteristics, but not refractory.

Note! A material made of ordinary clay is intended for laying the body of the stove and chimney. If you need elements for laying out the internal heated surfaces of the furnace, then for this, special refractory products made from special types of clay are used.

If you need elements for laying out the internal heated surfaces of the furnace, then for this, special refractory products are used, made of special types of clay.

Standard kiln material also has a fairly high heat resistance and increased density compared to traditional building or cladding products.

In this regard, to the question of how much a red brick weighs for a stove, one can unequivocally answer that it is heavier than the usual corpulent one and its mass is in the range of 3.7-4.2 kg.

Product design features

A solid single brick after laying requires additional finishing or plastering of the base with other materials, since it does not have an ideal surface. The grade and strength are usually indicated on the stone, and stones of the M100 or M150 brand are used for the construction of buildings of 1–2 floors. If the building is more than 3 floors, then ordinary brick laying is not performed.

It is produced in the form of rectangular products and happens:

- hollow;

- corpulent.

These types of products differ in thickness, size, resistance to low temperatures, strength, texture and weight.

The strength of such a product is indicated by the letter M with numerical values, and frost resistance by the letter F with a numerical value.

- Strength. For example, a stone of the M50 brand is usually used for laying partitions, or it is used for low structures that are not heavily loaded. Brick of the M100 brand can be used for the construction of the main walls. Products of the M175 brand are used for the construction of foundations.

- Water absorption. Water absorption is also considered important, which indicates the ability of the product to absorb moisture. This value is determined as a percentage and indicates the amount of moisture that a brick can absorb in percentage. The tests are usually carried out in a laboratory setting where the brick is placed in water for 48 hours. Standard brick has a water absorption of 15%.

- Frost resistance. It determines the ability of the product to withstand freeze / defrost cycles and this indicator is also affected by the level of water absorption. The less moisture the brick absorbs, the greater its resistance to low temperatures. Under standard construction conditions, it is recommended to use brick grade F25, and for load-bearing foundations - F35.

- Thermal conductivity. This is also an important indicator that can fluctuate depending on the type of brick. For a standard product, the thermal conductivity is 0.45-0.8 W / M. To ensure good thermal insulation of the building when using this type of stone, it is recommended to lay out walls up to one meter thick. But this is rarely resorted to, and therefore an additional layer of thermal insulation is usually used for the base.

A bit of history

Brick is one of the oldest building materials. He can only compete with wood and stone, which exist in nature in a finished form.Now, during excavations of settlements that are about 10-15 thousand years old, they find the remains of walls built precisely of brick. True, we are talking about red clay brick, but white silicate brick appeared later.

In those days, the brick very slightly resembled its modern counterpart, but gradually they began to bake the clay in the oven and in the sun, but the accuracy and correctness of the dimensions left much to be desired. This building material was especially popular in Greece, where whole buildings were erected from it or combined with marble. Then bricks with a size of 600 * 300 * 30 and 600 * 300 * 90 mm were common. The richest people could afford to order bricks, even with a certain pattern, covered with glaze, and build a three-story house out of this material.

But with the onset of the Middle Ages, many of the achievements of antiquity were forgotten, incl. and brick production technology. The masters remained only in Byzantium, but then, after its collapse, they began to develop technology already on the territory of European states. Gradually, there brick replaces wood and natural stone, whole cities, churches, and the first industrial buildings are erected from it. Ceramic brick at that time already had clear dimensions. So, products with parameters 150 * 70 * 35 mm were used, there was a special monastic type with a size of 280 * 130 * 70 mm, which was used for the construction of religious buildings. Larger bricks were 280 * 130 * 80 mm in size and were named after Martin Luther.

Brick factories at that time began to appear on the territory of many European countries, as well as in Russia. Each plant had its own approach, its own rules, each produced a brick of a certain size, with its own brand. Attempts to somehow standardize the size of bricks and bring them to a single sample were one of the first to be undertaken by Peter I, under whom it was believed that the most optimal would be products with dimensions of 280 * 140 * 70 mm. This was a real breakthrough in terms of quality: now all the bricks were the same, the number of dishonest manufacturers decreased, and factories could not cheat and sell smaller pieces one by one to save material.

Despite the wide popularity of ceramic bricks, the wide pace of construction required an easier and faster production method.

This is how the silicate brick appeared, when people began to pay attention to the pyramids built of limestone. They were durable, reliable, kept their original appearance, and then they decided to start using lime in the construction of buildings.

At first, they tried to make whole houses at once, then separate walls, but only at the end of the 19th century, for the first time, it was possible to make silicate bricks. The method of production has hardly changed in our days: then the brick was first pressed, then sent to autoclave processing. It was in Russia that the first factories for its production appeared, and already in 1927 a standard for the size of a brick was introduced and then it regulated the dimensions at this level of 250 * 120 * 65 mm. By the way, these parameters are included in the basis of the modern GOST, which sets the dimensions of bricks.

Since then, sand-lime brick has become one of the most popular building materials. It owes such a wide distribution to its main advantages: low price, ease of production and economy, since walls made of silicate bricks can be thinner than walls made of ceramic, but at the same time they are not inferior to them in frost resistance, sound insulation and other indicators. In addition, silicate brick has a pleasant appearance, it can be dyed in bulk and given any shade that will hold firmly.

Parameters of bricks of various types

Products of a standard size (designation 1NF according to GOST) are considered the most rational, taking into account the thickness of the dressing, for laying self-supporting walls. A bar of normal shape and standard appearance has the following side values:

- the bar has a length (spoon surface) of 250 mm;

- width (butt surface) 120 mm;

- height (thickness) 65 mm.

1 cubic meter of masonry contains 512 silicate blocks of a standard type. In this case, the weight of a solid bar is 3.6 kg, and a hollow bar is 2.1 kg.

Values are greater than standard

Schemes of transportation of silicate bricks: a, b - cross; c - "in the tree".

Stones of one and a half size (1.4NF) are used to speed up the process of masonry. A piece product is a bar 250 long, 120 wide, and its height is 88 (mm). 1m³ of finished masonry holds 378 one-and-a-half pieces. A one-and-a-half corpulent bar weighs 4.9 kg, and a hollow one - 4.3 kg.

Double brick (2.1NF) allows laying at maximum speed. It is a silicate bar with a length of 250, a width of 120, and a height of 138 (mm). In terms of volume, it is equal to 2 blocks of normal shape, respectively, 1 cubic meter of masonry made from it contains 256 double stones. The weight of a solid bar is 7.7 kg, a hollow bar is 6.7 kg.

Specialized types of products

Less common are bricks of the following categories:

- euro (0.7NF), the length of which is 250, width - 85, height - 65 (mm);

- modular single (1,3NF) with dimensions l = 288, d = 138, h = 65 (mm);

- ¾ the size of a normal shape, where l = 180 mm;

- ½ NF with a length of 120 mm;

- ¼ NF - length 60 mm.

Wedge-shaped products are used for laying vaults and arches. They have the following varieties:

- end wedge III-22 with dimensions 230х114х65 / 55 and wedge III-23 with dimensions l = 230, d = 114, h = 65/45 (mm);

- rib wedge III-44 and III-45 of the same size.

Stone building structures are always sized, which is a multiple of the width (120 mm) of a brick bar, folded with the width of the masonry joints. About the thickness of the walls, it must be said that it is a brick, half a brick, etc. that is, it is proportional to the length (250 mm) of the product. In the dimensions of the bars, slight deviations in length, width and height (± 5, ± 4, ± 3 mm) are permissible, associated with the process of shrinkage of the silicate mixture during the production of the material. The use of bricks of standard sizes in the construction of buildings determines the quality and durability of the building.

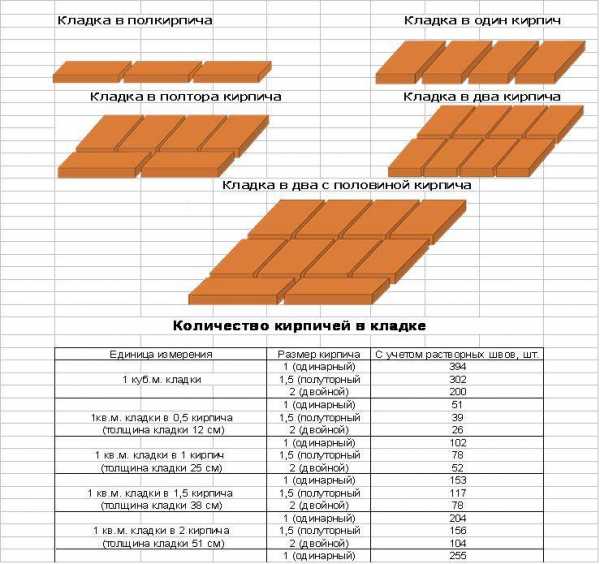

Applications

Walls or partitions are most often laid out of silicate bricks. It is used for load-bearing walls or columns that are subject to increased stress. Silicate has increased strength and copes well with this function. Before purchasing a building brick, it is worth deciding what type of masonry it will be used for, for cladding or for the main part. The thickness of the wall will affect the choice between ordinary and cladding material. For a masonry of 25 cm, a single one is used, and if the wall is thicker, then it will weigh more, for this you need to think about making it easier. For this, a hollow single or one-and-a-half brick is used.

For the construction of load-bearing walls and chimney masonry, a single brick is used (height - 250 mm, length - 120 mm, width - 65 mm).

In monolithic or frame high-rises, white silicate one-and-a-half or double brick is used to fill the void (walls and partitions). Up to the 4th floor, you can use hollow material, but for the outer walls of frame houses, it is better to immediately take a solid one, since a ventilated facade can be mounted on top of it.

Single silicate is usually used for the construction of load-bearing walls and internal partitions, laying out the outer part of chimneys.

Often during construction, several types are combined in one masonry. So, for the outer part, a facing one-and-a-half or double with voids is used, and the main masonry is made of full-bodied. In this way, several problems are solved: the cost of materials is reduced, the thermal insulation characteristics are increased, and the total weight of the structure is reduced.

For the restoration of old walls, you can use facing colored silicate. Facing silicates have good decorative properties, but they are not recommended for laying in damp places. Also, silicate bricks cannot be used in places experiencing increased thermal loads (in ovens, fireplaces, etc.)

Facing or private?

Like ceramic bricks, silicates are produced in ordinary batches and face-to-face. Both types of production are controlled by stringent quality and process standards.Each company is responsible for the quality of its products.

With the help of ordinary materials, all load-bearing walls, partitions and other structures are erected, the surface of which is subsequently finished with plaster. This is a working material that does not have any special requirements in terms of appearance. With the help of a silicate private, good sound insulation can be achieved.

For cladding, face silicate is used. It should have a perfectly flat surface without chips and cracks, have smooth, sharp edges, uniform color, without age spots. Many companies manufacture bricks of different shapes to order. For example, rounded corners or multiple faces (poke and spoons).

There should be no roughness or cracks on the front side. Basically, the facing is of a single size. This is due to the classic use of bricks of this size. Color variations are made from one and a half bricks.

On request, batches with drawings or decorative coatings are produced. Especially for window openings or arches. Sometimes, an artificial stone is made in the form of an imitation of a wild natural stone.

Silicate brick is popular all over the world, it is an excellent solution both in low-rise (cottage) and high-rise construction. Its good physical and mechanical properties make it suitable for almost any construction site. Even taking into account the disadvantages of silicate, its use is justified at least by its price, which is often lower than for red. You should be aware that the season affects the price. In winter, the price of a hollow body can be higher than a full body.

Video illustrating the production of sand-lime bricks: