Imitation of a bar: distinctive features and scope

An imitation of timber can also be considered a type of block house, for the production of which wood is mainly used, although there is such a facing material made of PVC.

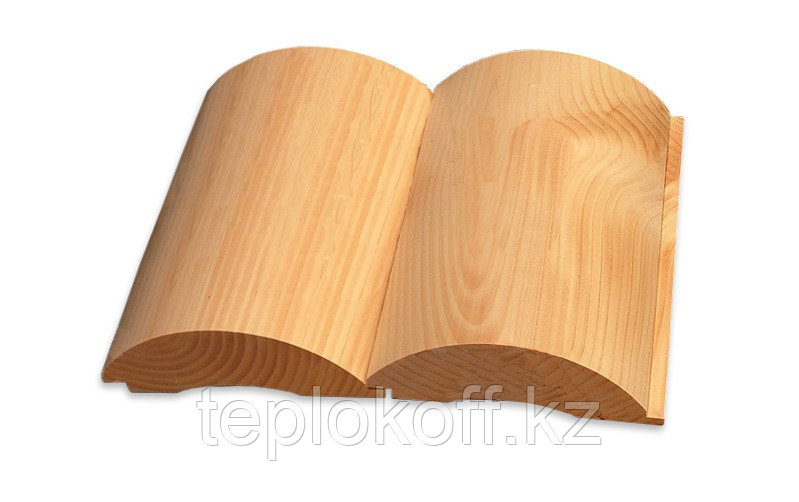

In the role of home decoration, siding imitation of a bar is very popular with developers, and it is an edged board, the outer surface of which, unlike a block house, is flat and profiled.

On the back side there is a special longitudinal groove, the purpose of which is to compensate for the expansion of the material due to exposure to moisture and ambient temperature.

Individual elements are joined to each other using grooves and spikes located on opposite end parts of the product. For the production of this material, wood of different species can be used, but most often imitation of a bar is made from pine, larch, birch, linden, alder.

If desired, the owner can ennoble his house with more expensive and rare materials, for example, using imitation of a bar made of Siberian cedar and other noble wood species.

This solution makes it possible, for example, to make the interior more luxurious, while at a very affordable price, since the cost of a set for finishing is disproportionately lower than if a profiled beam made of expensive wood was used for the construction of a log house.

Features of the choice of imitation of timber for facing houses

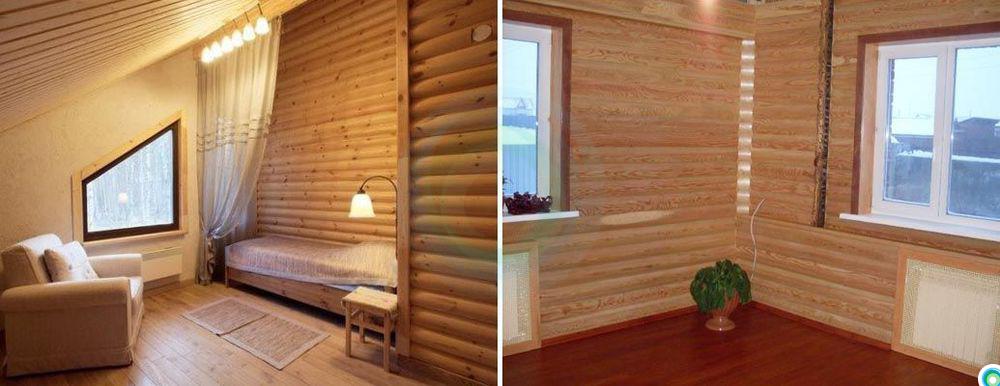

Imitation of a bar can be used both for the exterior (front) decoration of the house, and for interior decoration

But when choosing a material, you should pay attention not only to the type of wood, but also to the size of the board. On the market, this type of siding is presented in a fairly wide range, with:

- the standard length of the products is 3 or 6 m, but other sizes can be purchased upon request;

- the width of the imitation of the timber can vary from 110 to 190 mm;

- the thickness can be 18, 20, 34 mm, although the material with intermediate sizes 22 and 28 mm is also popular.

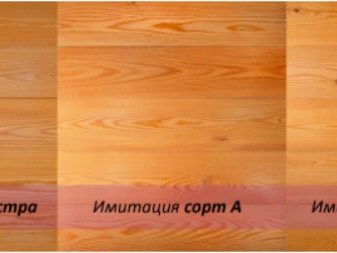

Imitation of a bar, as well as a block house, is classified by quality: for finishing it is possible to purchase material with grades "Extra", "A", "B" and "C".

When choosing a material, its class and dimensions, one should focus on its area of application. For example, for the decoration of premises it is recommended to choose products with a lower thickness in order to save space, and for the facade, a material with a larger width would be a more acceptable option, since in this case the number of docking joints, which are the most vulnerable places of such a finish, are reduced.

If the question of choice is between different types of wood, then, of course, it is worth taking into account the price factor, but do not forget that different types of materials have different density from each other, which determines their operational characteristics and affects the service life of such plating. This factor is especially important when finishing the facade, for which, for example, imitation of larch timber is the most preferable

This factor is especially important when finishing the facade, for which, for example, imitation of larch timber is most preferable.

Due to the high resin content and high density of wood, such material, with proper care, can last up to half a century or more. And, in addition, larch wood is distinguished by a beautiful pattern, pleasant texture and noble color.

How to take care of the timber after installation work

Transparent coatings

From rot, mildew, sun or moisture, the outer panels must be periodically coated with mortars, varnish or wax. Wax is considered the most popular remedy.

Stain or varnish refreshes tarnished surfaces, returns the gloss - the house seems to have just been rebuilt.

Several times a year, the facade is cleaned of dirt (without the use of aggressive cleaning agents).

How to apply wax to the timber correctly

Most often, oil-wax is used to renovate and protect the facade. The product is non-toxic, protects against fire, allows air to pass through, which means that the tree will breathe. If desired, paint can be added to the mixture - after the wax dries, the boards will change their shade.

The wax must not contain benzene or aggressive solvents.

You can prepare the composition yourself: mix 2 tbsp. natural beeswax with olive oil (6-7 tsp). To soften the wax, first melt it in a water bath and add the oil.

Store the home remedy in a glass jar in the refrigerator for no more than 12 months.

Note: the product is recommended to be applied to the boards before installation, and not after it. This is how all hard-to-reach areas are painted over.

Before applying a layer, you need to make sure that the timber imitation fasteners are "recessed" inward, and not stick out outward.

Sand the surface of the walls or ceiling with sandpaper or a sander. Check that there are no knots or gouges (coat the defects with a primer).

Use a coarse-grained sandpaper to prevent sandpaper particles from lodging in the gaps.

Only after thorough cleaning process the boards with a thin layer of wax. Remove excess with a clean, lint-free cloth.

Wax is applied to the ceiling using a roller (always with a long handle), the walls can be painted with a brush with long bristles. For the floor, it is better to choose wax with a matte finish, it is not so slippery.

Wait until the product is completely dry, then wipe the surface with a clean, dry cloth.

After treatment with the composition, the walls will not only shine, but will also be reliably protected from mechanical stress, are less exposed to rotting and mold formation.

It is necessary to cover the surface with a new compound every three years.

The timber simulator is ideal for facade cladding and not only "copies" a natural log, but also harmoniously combines with natural stone inserts or plastering.

If you want to renovate an old wooden house for little money, then imitation of a bar will be the best quality material for facade cladding.

Geometry and important working elements of the section

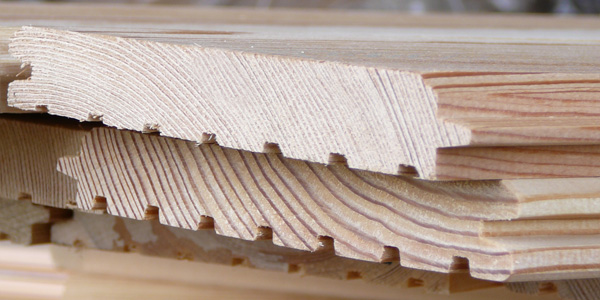

Both types of skins are made by profiling from chamber-dried blanks. The front side is smooth and does not need additional processing. And there, and there, grooves and spikes are carved on the edges, which together make up the lock.

The back side of the block house or imitation timber planks are not flat. Here you can find ventilation longitudinal grooves. The materials are similar in width and length of the slats. The width starts from 140 mm and goes up to 240 mm, and the length of the planks is usually 6 meters. But the thickness is slightly higher for the blockhouse - it is offered with a thickness of 28 to 45 mm, while the imitation of timber has a range of 16 to 35 mm. Given the different consumption of materials, the cost of materials can differ significantly, so sometimes it is better to buy a thin imitation of a bar instead of a blockhouse.

In terms of the complexity of installation, both materials are approximately the same. However, if the owner, without the relevant experience, decided to do all the work on his own, the house block can cause a little more inconvenience. The fact is that the correct arrangement of joints and corners formed by panels rounded in cross-section requires more attention.

In general, a block house or imitation of a bar is sewn using the same technology. For them, you need to assemble a frame from a bar, and fasten it with nails / screws through the lock, or using clamps.

The amount of wood in the block house panel is greater, and its "non-flat" geometry makes the panel more resistant to various kinds of mechanical stress.

Installation of lathing

Installation of a simulation of a bar or block house

From the point of view of perception and aesthetics, the house block is not quite suitable for finishing the ceiling, the flat surface of which looks much more harmonious. A false beam is preferable for these purposes, although a lining is even better.

Made of wood, a block house, like an imitation of a bar, must be treated with special compounds: antiseptic, fire protection, protective and decorative. Due to the rounded shape, the surface area of the block house panel, other things being equal, is larger. Accordingly, 15-25% more varnish / impregnation may be required for processing than for a wall from a false beam.

So block house or imitation timber which is better? The answer is now clear: while both types of panels are quite similar in technical terms, each material has both strengths and weaknesses. The correct choice depends on the preferences of the owner of the house.

The block house wall is more embossed

Timber imitation is somewhat cheaper

It is interesting: Adhesive for PVC panels in the bathroom - features of choice

How to choose the right one

If it's easy to figure out the dimensions of the panels, then in terms of selecting their other parameters, it is important not to rush. The material for the manufacture of panels is selected based on the purpose of its use and the specifics of the microclimate in the room:

- made of larch - suitable for any indoor environment. Indicated for people suffering from asthma and problems with the respiratory system;

- from oak, they demonstrate high resistance to moisture and mechanical stress, it is optimal to use in a room for a child, a gym, a kitchen;

- made of coniferous wood are characterized by a high resin content, therefore they should not be used in rooms with high temperature conditions (kitchen, sauna, bathroom).

As for the manufacturers, the buyers' attention is the products of Wood Stock House, Tarus Les LLC, Realvood LLC and others.

Oak

Oak Larch

Larch Coniferous wood

Coniferous wood

House block installation methods.

Wood

During the installation process, the only difficulty may arise when designing corners and window / door openings. It is also worth remembering that certain types of fastening are associated with a high risk of causing serious damage to the board.

Advice: if necessary, you can additionally insulate the walls with blocks of foam or glass wool, as well as a building film to protect against drafts.

For exterior decoration, it is better to use a thicker version of a wooden house block (more than 3 cm). All panels need additional processing at intervals, which should be repeated every 4-6 years.

Metal. Like any other block, house requires preliminary lathing of the building. Advice: unlike the wooden block of the house, the lathing can be made not with bars, but with a metal profile. It's easier and cheaper. The lathing is made with a more frequent frame pitch (35-40 cm).

In the case of using the U / L-shaped profile, the panel is fastened with self-tapping screws screwed into special mounting holes on the house block panel, if wood was used for the lathing, then the use of galvanized nails is allowed.

To give an aesthetic look and final design, it is necessary to use additional additional elements (at the joints and corners of the sheathing). The advantage of the metal block house is also the possibility of its installation under any temperature conditions and the absence of the need for additional processing of the assembled finish.

Vinyl. The method of fastening is identical with the metal block house. The main difference is the need to leave a small gap between the panels (1-2mm no more!).This is done in order to create a "temperature reserve"; in the hot season, vinyl panels tend to expand slightly in size, so a rigid fit of the panels is contraindicated and can lead to cracks. For the same reason, you do not need to drive a nail or a self-tapping screw tightly into the perforated hole (leave a couple of millimeters between the nail head and the panel).

The vinyl block house has a greater number of different options and styles of performance, but at the same time, it is less resistant to temperature and mechanical damage than its metal counterpart.

What's next?

After finishing the finishing works, the wooden block of the house is subjected to secondary finishing (varnished, painted, etc.). House block made of other materials is brought into its proper appearance with the help of various additional elements.

Video cladded house block house

Note: finishing a house with a block house looks very attractive with other materials (natural stone, decorative putty, etc.) for interior and exterior decoration of the house

Conclusion: The use of synthetic materials in the long term is more profitable than wood and will require less effort and cost to maintain a decent appearance of the building. The tree is preferable to use in order to give the house a richer and more colorful look. Do not forget that over time, the paint will begin to fade and fade, and only the wooden version will be able to renew it.

Pros of decorating a house with a block house:

- Low costs for finishing and materials

- Simplicity and high speed of installation

- A minimum of tools are required for assembly.

- Versatility of panels (can be used for both internal and external cladding)

- Gives a solid and representative look to your home

- The ability to additionally protect the house from cold, moisture and wind

- Wide possibilities for combining with other materials

- This finish will hide all kinds of communications.

- Long service life

The negative aspects include the individual characteristics of each material, but with the correct layout, their influence can be negated.

Material advantages

- The advantages of such a lining are similar to the advantages of the usual one, but this list is supplemented by the beauty and durability of the result obtained. Therefore, such panels make it possible to refine the appearance of the house, make it more presentable, more natural, "more expensive".

- In this case, you can hide the defects that have arisen during the construction.

- Ecological cleanliness. The material will not harm your health.

- Strength and lightness. Thanks to this, the structure is even stronger, without much weight. Therefore, the supporting structures, together with the foundation, do not experience excessive loads.

- Does not crack, is protected from temperatures.

- Ease of installation, which simplifies and reduces the cost of the procedure.

Types of waterproofing materials

Waterproofing materials can be liquid, in the form of a film (membrane made of polymer or mineral filler) or roll.

Each material differs in its properties.

For external wall cladding, sealants are chosen, but only if the area is not large.

The anti-corrosion mixture contains a resinous product (bitumen) and is applied to walls only if metal structures are to be installed.

For walls in the bathroom or kitchen, use a waterproofing coating.

Compositions of coating waterproofing for walls:

- Cement mortar.

- Acrylic solution.

- Silicon solution.

- Crystalline liquid.

As for the film membrane, it protects the walls from dampness. Made from synthetic rubber, PVC, polypropylene. The membrane film is corrugated.

Types of imitation of timber for interior decoration

Nowadays, manufacturers use coniferous woods, less often larch, to make imitation of timber. In terms of external aesthetics, the material is very similar to ordinary wooden blocks, but it has a greater width (up to 180 mm) and a small thickness.You can verify this by looking at the photo below. Such characteristics allow you to use the material economically and not eat up precious cm of the area of the rooms. The interior decoration of a house from a bar is of two types.

Monolithic - such a do-it-yourself log house finish got its name due to the density and uniformity of the base cladding created with it. It is used for walls, floors, ceilings of private houses, as in the interior in the photo below. The main advantage of a monolithic finish is its high protective properties for the base, which is completely hidden under the cladding. But its installation is somewhat difficult and without certain skills to perform do it yourself can become problematic;

Combined - if you started building a log house with your own hands, you should think about the combined interior decoration of rooms with imitation of timber. This design has an unrivaled look, as evidenced by the photo below. But it is used for incomplete decoration of the room, and for creating original combinations with wallpaper, ceramic tiles or textiles.

In cases where both types of timber imitation are used, it is mandatory to select accessories for decorative elements that give the interior of the room a logical completeness, integrity, and individual character. This refers to all kinds of moldings, mensols, cornices, balusters, decorative overlays, balustrades, wooden corners.

How to install imitation timber: preparation of the base

Decorating a wooden house with imitation timber begins with the preparation of wall surfaces.

Clean the walls from dust, dirt. You may need to apply a primer solution (we wrote about it above).

Then, you need to put a waterproofing layer for wood - most often it is a film membrane, sometimes it is replaced with glassine - a bare, roll material, impregnated with petroleum bitumen.

Fasteners for imitation of a bar may differ - the film sheet is attached from below, connected with construction tape, glue or self-adhesive strips, while the membrane overlap should be no more than 15 cm.

For fixing profiles on a concrete wall plastic dowels are not suitable - only self-tapping screws, clamps to simulate a bar (curved plate with a hook and two holes) or galvanized nails.

If the wall is without flaws - irregularities, potholes or chips, the crate is installed tightly. If there are defects, then synthetic linings are inserted into the gaps.

To prevent the crate from turning out to be a curve, apply a level to it. The distance of one bar from another should be no more than 80 cm.

Then pipes and wires are carried out, a layer of insulation is laid, another frame of the sheathing is placed and a film membrane is stretched over it. The second crate is necessary for air circulation.

Preparing the timber before installation

The next step is to unpack the panels. It is not recommended to lay the canvas immediately; wait a few days for the tree to absorb all the moisture (the wood may increase in size). This will prevent possible distortion after installation.

Installation of imitation of a bar for outdoor decoration houses start only after applying a protective compound to the surface of the tree.

Install panels from bottom to top only.

Where to begin? Cladding and fastening of the false timber

Imitation of timber for exterior decoration of the house should be carried out only in sunny, dry weather. It is better to fix a light beam on the sunny side - when it burns out in the sun, there will not be as noticeable changes in color as on dark panels.

Attach the first plank to the batten using a self-tapping screw, clasp or nails. Drive nails into the longitudinal groove of the panel (comb).

The first (starting) board should be set up with a comb - level it with a building level, fix it. If the first panel is placed unevenly, then all subsequent boards will lay down crookedly. The result will be a strong bevel.

The next step is to install the second board.

When attaching the second panel, insert the spike into the groove of the first board. Do not drive it close to the first bar, leave a small gap (no more than 4-5 mm). The gap is left so that the canvas does not deform due to possible temperature changes in the room or outdoors.

Using this technique, install the boards to the top of the ceiling. To make the parts fit together beautifully, saw down the corners (45 ° angle is suitable for outdoor wall mounting) or install a decorative strip.

Imitation of a bar vertically, "raise" the ceilings, make a room with a low ceiling higher.

Installation of imitation timber inside rooms

The interior decoration of a wooden house with imitation of a bar differs little from external installation work on the street.

The only thing, with vertical installation in the rooms of the house, for fixing the boards, they do not take self-tapping screws, but nails intended for furniture.

Otherwise, all actions are repeated.

New panels can be attached to old wood surfaces using a construction stapler.

The last step is to treat the surface with a protective solution.

How to mount an imitation timber on the ceiling: installation sequence

Ceiling cladding is considered the most difficult job due to the strong pressure on the hands during installation.

To reduce the load, choose boards that are not too wide (a wide panel visually makes the ceiling smaller).

The length also needs to be selected - the fewer joints, the better.

Ceiling installation begins with the installation of a wooden frame and film (if the beams are curved). Start fixing the boards from the side of the window (no more than 3 cm wide).

The technique is the same as for wall cladding - if necessary, put a layer of insulation between the beams.

If there are already beams on the ceiling, then it is enough to stretch the vapor barrier layer, without the lathing.

Varieties

The block house, like the entire sheathing profile, is divided into 4 classes: extra, A, B, C. The differences are due to the quality characteristics of the material. For example, the best type of finishing boards for timber are Extra class lamellas. They have no knots, no resin pockets and are characterized by an even, smooth surface.

In this case, even the slightest errors in the tree structure are not allowed. Blue, wormhole, and even more the falling out knots are unacceptable.

Class A allows minor imperfections on the back. For example, it may be a slight roughness. However, there can be no blue or cracks on such a profile.

Classes B and C are inferior in quality to the above two analogs. However, if there are still basic restrictions in the material of category B, class C also allows the presence of knots, and even through cracks. It is difficult to call such material suitable for purchase, since the buyer often does not have the opportunity to view the product due to its closed packaging.

Despite the fact that the entire profile is sorted for quality, often on the shelves you can find a lot of bad raw materials for finishing buildings.