Benefits and negative properties of archstone

Art-concrete is distinguished by a number of specific characteristics and properties, thanks to which it is possible to expand the scope of its use, reduce the cost of many works and processes, and implement various tasks.

The main advantages of archkamenya:

Fine-grained flat structure that lends itself well to sanding and allows you to obtain a perfectly flat and smooth surface.

Immunity to sunlight - concrete does not fade, does not change its physical properties and appearance.

High level of strength and resistance to various external factors - temperature, humidity, wind, shock, abrasion, vibration, etc.

Minimal hygroscopicity, due to which the material does not undergo carbonization, therefore, for a long time it retains its strength and integrity.

Plasticity and simplicity in work - providing an opportunity to realize the maximum of original ideas.

Low cost of the entire process - from purchasing materials and preparing a solution to creating a form, sculpture, decoration.

The ability to add a variety of additives, formulations to change the performance and achieve the desired characteristics.

The environmental friendliness of production and of the archstone itself, which is also important.

The ability to accurately imitate various more expensive textures.

Ease and ease of care.

A chance to achieve a perfectly flat surface that is non-slip and completely safe.

Good level of fire safety.

Easy maintenance without the need to use special products and the involvement of professionals.

When creating special structures, art stone can be made with a reinforced structure by adding reinforcing fiber to it. Fibers can be plastic, steel, glass. Fiberglass concrete is a lightweight and durable building material that is distinguished by excellent strength, a high level of resistance to atmospheric influences, the appearance of mother-in-law. Shrinkage, as a rule, is completely absent.

The disadvantages of the material are explained by the peculiarities of the concrete itself and working with them. So, among the disadvantages is often the need for additional strengthening of floors and walls in the case of using heavy decorative elements. Finishing weighs a lot, so it is simply not performed on wooden houses and lightweight structures, or a more reliable foundation is made in advance. Large decor on facades requires the use of technology, significant labor costs, and special tools.

It is difficult to create small elements and decorative details from art-concrete, the process of work itself is slow, because the mixture hardens for a day or two. If decor with complex geometry is performed, it is necessary to observe the dimensions very precisely, the details must be carefully adjusted. But it is difficult to attribute all these factors to the number of disadvantages - rather, they are simply work standards that it is desirable to adhere to in order to obtain a quality result.

Forms and methods of protection

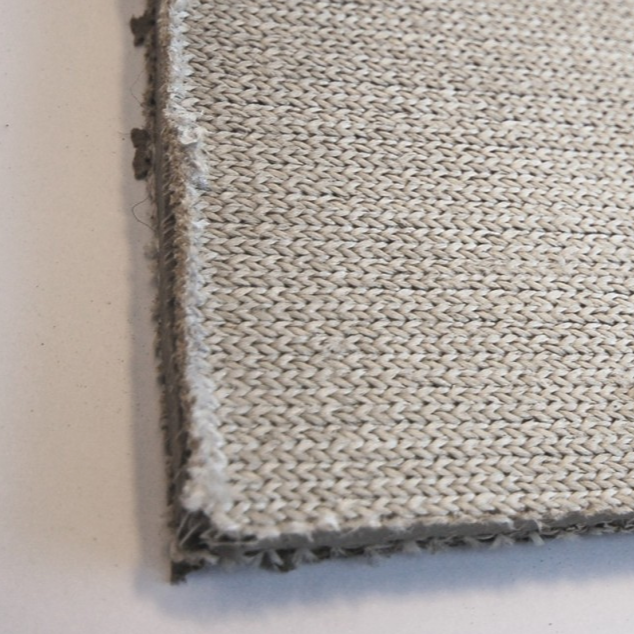

After setting, the concrete solution acquires a porous structure. Air inclusions in concrete can be reduced in various ways, but cannot be eliminated. Therefore, even concrete with the addition of various additives requires additional protection.

After curing, the structure of any concrete coating becomes porous.

After curing, the structure of any concrete coating becomes porous.

Destructive factors

Several factors influence the condition of the concrete surface.Before choosing the method and material of protection, it is necessary to determine the main destructive forces in each specific case.

Most often, street concrete requires protection from the following negative influences:

- temperature drops;

- high humidity;

- radiation;

- chemically active media.

The effect of the negative impact is enhanced if the concrete is exposed to several factors at once. Exposure to high humidity at low temperatures will lead to cracking and further destruction of the surface.

Under the influence of environmental factors, concrete structures weaken and collapse

Under the influence of environmental factors, concrete structures weaken and collapse

Operating principle

The outer protective layer creates a barrier that prevents the direct influence of the negative environment on the concrete surface. In addition, in reinforced structures, it is necessary to reduce the risk of moisture penetration deep into the structure, in order to avoid corrosion.

Thus, according to the principle of action, it is possible to divide the defense mechanisms into internal and external. For the most effective result, outdoor concrete should be treated in two ways at the same time.

Protection options

To determine the protection materials, it is necessary to specify the goals that need to be achieved.

Speaking of the outer protective layer, we divide the methods regarding the type of destruction that must be avoided:

| Type of possible destruction | Cause of occurrence | Choice of protection |

| Cracking |

|

|

| Corrosion |

|

|

As you can see from the table, water is the most common factor that destroys concrete. Freezing of moisture in internal pores is especially dangerous for concrete structures. Therefore, under any conditions, a waterproofing layer should be arranged, or concrete should be impregnated with a deep penetration primer.

Failure of a dense concrete base due to internal corrosion

Failure of a dense concrete base due to internal corrosion

DIY tricks

Since the innovative minimum of developments in the field of using natural concrete has not yet reached its maximum and research in this area continues, data on the exact proportions of the materials used in the composition have not been made public. However, many construction professionals experiment on their own to create their own material.

Ordinary PVA glue can be used as a polymer component.

It is possible to create geopolymer concrete with your own hands, provided a good base of chemical and physical knowledge, the ability to get the necessary substances and the ability to conduct experiments by trial and error. The recipe for self-preparation of 0.4 liters of the composition is as follows:

- 300 g of fly ash;

- 300 g slag;

- 80 g 45% KOH;

- 100 g of liquid glass (K2SiO3, 60.8% water);

- 52 g of water.

It is necessary to create a hardening temperature of the future concrete of 80 degrees. For a day at this temperature, the composition hardens by 110 MPa, in total it takes 7-10 days for the hardening process. For comparison, for ordinary concrete it takes up to 28 calendar days.

Independently natural concrete compositions are made in the same way as for the preparation of standard concrete. A small amount of the cement, which is intended for the manufacture of geo-concrete, and water are poured into the concrete mixer. Then fly ash and slag are added in equal proportions. The whole mass is thoroughly mixed. Next is the line of polymeric materials. The whole mass is mixed again until fully cooked. The well-known PVA of a special consistency or water-soluble resins can serve as a polymer component. Polyvinyl alcohol, which is part of PVA, will serve as an emulsifier for the composition, that is, as an astringent component.

When making geo-concrete with your own hands, you can follow the advice to add organic polymer additives to the prepared concrete composition in an amount of no more than 20% of the total mass of cement. When water-soluble resins, such as epoxy or polyamide, are introduced into the mixture, followed by the introduction of a polyethylene-polyamine hardener, geopolymer concrete will be of better quality.

Specifications

What is reinforced concrete? This is a successful combination of the properties of two different materials, which can be combined into one monolithic structure. First, a fill form is created. After that, the frame is made of steel. Next, the solution is mixed, which is poured into the mold. The product must stand for a certain time in order to acquire the required properties. In the process of hardening, significant adhesion forces arise between them, therefore, under a certain load, both materials are deformed together.

The properties of this material useful and in demand in modern construction include:

- high density;

- the ability to withstand very high weight and shock loads;

- resistance to moisture, high and low temperatures, their sharp fluctuations.

and its moisture resistance prevents corrosion of the enclosed metal. The hardened solution protects the iron from direct contact with fire in the event of a fire at the location of the structure.

Both materials have approximately the same coefficient of linear expansion. For this reason, even when exposed to elevated temperatures, internal ruptures and destruction are not observed, the original integrity is preserved.

A strong connection of the materials included in reinforced concrete is provided by:

- special lugs that provide 75% of the total grip;

- frictional forces;

- adhesion (gluing) of concrete and metal elements

Methods for the production of structures

The concrete solution is produced quite simply: the sifted dry components are mixed, after which water is poured into the homogeneous mixture (into the depression).

The video in this article will allow you to learn more about this issue.

Depending on the type of products, purpose, batch and requirements for their characteristics, several techniques can be used to make architectural concrete: production technology:

- Embossing.

This technology of architectural concrete is used when decorating vertical surfaces or when finishing paths and areas in country farms. To carry out the work, matrices are required to obtain the necessary texture of the concrete base.

Architectural forms for concrete

Architectural forms for concrete

For the same purposes, you can use relief rollers.

Roller for making a relief on a freshly laid concrete base

Roller for making a relief on a freshly laid concrete base

The process consists of the following steps:

- priming of a vertical base;

- reinforcing it with a mesh;

- applying a thick layer of solution;

- shaping the surface texture using the shape (about an hour after applying the solution) by manual punching;

Embossing on the wall

Embossing on the wall

in the case of garden paths, you should first prepare a base for the device of decorative plates, on which work is already being carried out to make a relief on a freshly laid solution;

Architectural concrete molds for embossing a concrete site

Architectural concrete molds for embossing a concrete site

coloring with this technology can be done after the formation of the relief.

- Vibrocompression.

The production of products from architectural concrete by this method is carried out by means of matrices and a vibrating press, which exerts significant pressure with vibration on the formed product. This rather costly method is effective in the manufacture of large batches of unpretentious parts (paving stones, tiles). The strength of the finished product with this technology is the highest.

- Pressing.

With the help of a hydraulic press and molds, fairly thin-walled products can be produced. The productivity of the installations is not too high.

- Casting.

The most effective is the technology of architectural concrete by vibration casting. In this case, you can get products of any shape. The essence of the process is to pour concrete solution into molds on vibrating platforms.

Also, the use of deep vibrators is not excluded. The products are characterized by low cost, but the productivity of such industries leaves much to be desired.

Production of small architectural forms from concrete - finished goods warehouse

Production of small architectural forms from concrete - finished goods warehouse

In this way, you can make small architectural forms of concrete with your own hands.

Small architectural forms with their own hands from concrete

Small architectural forms with their own hands from concrete

It is not difficult to purchase matrices for making decor now.

Forms for small architectural forms of concrete

Forms for small architectural forms of concrete

- Handmade.

As noted above, the decor on the erected foundations and sculptural compositions are made by hand using special tools.

If there is no experience in carrying out this kind of work, there is no equipment or time, you can contact the reputable manufacturers of art-concrete products. The architectural concrete studio will be able to produce structures according to the available forms, or fulfill an individual order.

The main types of concrete floor coverings

According to their purpose, concrete floors in industrial buildings are divided into:

- Concrete industrial floor for terminals and industrial premises with high humidity levels.

- Floors for production halls with high stable mechanical stress.

- Floors in public areas with high throughput (hospitals, canteens, childcare facilities).

- Industrial refrigerator and freezer floors.

- The floors are antistatic, explosion-proof and fireproof.

- Self-leveling polyurethane industrial floors for indoor car parks, sports centers and industrial warehouses.

- Mosaic concrete floors are a little forgotten, but still relevant due to their simplicity and more attractive appearance compared to conventional concrete surfaces.

Concrete floors

Concrete floors

Necessary Requirements

Basic requirements and operating conditions for concrete pavements:

- resistance to constant mechanical stress: mechanical shear and abrasion (traffic);

- resistance of the floor covering to the fall of heavy objects;

- resistance to chemical attack (paints, solvents, acids, etc.);

- resistance to an increase or decrease in temperature in industrial premises;

- increased moisture resistance - no slipping for the safe movement of technical vehicles and employees of the enterprise.

Materials (edit)

There is a concrete base underneath the foundation of almost any industrial floor. Industrial concrete floors are laid on a pre-prepared cushion consisting of a compacted dry mixture of crushed stone and sand. The concrete floor is usually 300 mm thick. To create a concrete screed, concretes of grade B22.5 and higher are used.

| Concrete grade | Density of concrete, kg / m³ | Frost resistance, F | Moisture resistance, W |

| B22.5 | 2390 | 300 | 8 |

| B25 | 2405 | 300 | 8 |

| B30 | 2420 | 300 | 10 |

Concrete for industrial floors, due to the above requirements for the finished base, must be subjected to additional processing. Therefore, in order not to repair industrial concrete floors immediately after the foundation is installed, the finished surface of the industrial floor is reinforced with special compounds (hardeners).

Topping

Topping

There are two main types of hardeners:

- Dry mixes (topping) are scattered over the still damp concrete surface, and with the help of graters (see photo) rub it into the base of the floor ("ironing"). The mixtures consist of high-grade cement and special chemical additives, and the structure and strength of the future base is largely determined by the fine-grained filler.The most famous is quartz hardener. Its price and availability in purchase have gained particular popularity.

Topping tools

Topping tools

- Concrete floor impregnation is a hardening compound based on water and solvent. Penetrating into the small pores of the concrete base, it polymerizes and thus binds the surface of the concrete floor. The use of impregnation increases wear resistance and improves the adhesion of the final floor covering to the concrete base.

The construction of industrial floors can still be carried out on the basis of concrete, the main aggregate of which is marble chips. This type of material is obtained by crushing marble - a mineral with excellent decorative properties.

Materials (edit)

Materials (edit)

The concrete mixture is obtained by mixing washed marble chips, white decorative cement M400 in proportions 1: 2, and you can add sand of a coarse-grained fraction not more than 10% of the total volume.

The installation of polyurethane concrete floors is made on the basis of a mixture of synthetic materials, the basis of which is polyurethane. Floor covering based on this material has a wide range of properties and characteristics that allow its use in conditions of increased mechanical stress.

Polyurethane floors

Polyurethane floors

Decorative concrete coatings

Basically, art-concrete is the name of the direction in the visual and applied arts. It provides for the use of a cement-sand mixture, sealed with polymer resin and enriched with modifying additives, which can be used to decorate both the interior and the facade.

The material does not need special care, is durable and is surface painted with water-based paints to give the finished look. With its help, you can get a great variety of effects, but the greatest interest is attracted by the imitation of concrete itself.

This type of wall and ceiling decor gained popularity thanks to the loft style concepts, which provide for the presence of bare structural surfaces in the interior: concrete slabs, brickwork, blocks. For example, we offer several photos in which decorative art-concrete was used as a finishing material:

Not only walls, but also floors are finished with decorative concrete.

Decorating a country house with white and gray decorative concrete

Concrete texture applied to plasterboard sheathing

Pronounced concrete texture on the ceiling

Finishing of walls and floors using printed concrete technology for block masonry and with application of texture

Loft-style studio space, all surfaces are finished with concrete look

Popular manufacturers

Everything that you saw in the photo is imitated by means of decorative plasters, which are made by many well-known manufacturers:

The Italian company San-Marco offers compositions of the Concret Art series, with the help of which it is possible to obtain three types of concrete coatings with different effects: cellular, aged formwork, patinated concrete.

Coating art concrete from San Marco

Another Italian manufacturer also has a series of art-concrete - D. Compositions with the effect of concrete are offered in as many as 15 color options, and another type, with the Empire effect, which is shown in the photo below.

Decorazza art concrete with Empire effect

Decoraz option art-concrete

Monochrome coating

Combination of concrete and masonry textures

- The application of art-concrete involves the complex use of several compounds. In addition to the plaster itself, this is a deep penetration primer and base paint-primer. Masking tape is used to obtain the Empire effect, involving the application of contrasting pearlescent lines. On the usual Art beton compositions, the reliefs are made with a Venetian trowel.

- The Russian manufacturer VGT (VGT) also offers its own version of the decorative plaster "Art-concrete", which contains, in addition to the acrylic copolymer, dolomite and marble chips.Thanks to dolomite, when smoothing, dark inclusions are obtained, making it possible to imitate not only the texture of concrete, but also travertine stone. Sold in white and tinted before use. Color and primer can be purchased complete with the base.

Interior with VGT art concrete

The Russian manufacturer Asti (Asti) produces an excellent version of decorative plaster with an enlarged filler, thanks to which it is possible to more reliably perform imitation on the concrete surface with traces of formwork, shells and microcracks. The base can be supplied without filler, or with the addition of mica, which allows you to get completely different effects. The color is traditionally gray. In addition to the Hi-Tech Concrete plaster itself, it is completed with Asti Fon background primer, Velor toner and Creative matte or glossy varnish.

Design option with Asti art concrete

In addition to the manufacturers presented above, in Russian stores you can also see art concrete from such companies as: Top-Ciment (Spain), Real Home (Russia), RustOnu (Italy) - their Ironic Novacolor plaster imitates concrete with a touch of rust.

Features of the use of concrete in the interior

The use of architectural concrete is widely met with great acclaim. However, not everyone is ready for such an ascetic accent. The introduction of concrete elements can be too extravagant, especially for the older generation.

The use of concrete can be extremely problematic. A slight exaggeration can turn a room into an unpleasant bunker. The contradictory nature of the material can be considered its main drawback. Calculating the benefits is much easier.

The composite is extremely durable, scratch, temperature and water resistant. It is also worth noting that it is correctly positioned and acoustically insulates the interior. Concrete is not demanding to maintain, but it is worth focusing on proper impregnation.

This is especially important in the kitchen, where the material is exposed to grease stains. Remember also the significant weight of the composite

Installing a large element will require pre-reinforcement of the substrate and strong fixings.

Design options for white elements

Sometimes, taking care of the strength of the products, such concrete elements are not stained during the preparation of the solution, but are left white. In this case, other methods are used to give color.

- Spraying. This is the only option ideal for transforming vertical surfaces. In this case, the acid dye is sprayed onto the walls. The operation is performed sequentially, layer by layer.

- Painting with stencils. This is the most popular way. Templates can be purchased at the store, or cut by hand from any sheet material. More often they make patterns or an ornament imitating brick paint.

- Stamping. Matrices for work are made of rubber or silicone. First, they are protected from moisture with moisture-resistant additives, then pigment is applied. The stamps are pressed into the concrete, and after the entire surface has been treated, it is covered with protective impregnations.

In order for the painted walls to be durable, all proportions must be observed. However, the addition of dyes at the stage of preparation of the solution is the best option, which will ensure the ideal quality of the coating - its uniformity.