Advantages

The positive characteristics of such products are associated with the material from which they are made. After appropriate heat treatment, the sand changes its structure, acquiring the properties of glass. As a result, the material acquires several valuable qualities.

The strength indicators of the white block are much higher than that of the regular red (about 2 times). Each product is marked with the letter "M" and a number indicating the value of the strength factor (for example, M400).

White brick is highly frost-resistant. It is able to withstand 200 cycles of temperature drop from freezing to subsequent defrosting.

Slow moisture absorption is an important quality. It enables white brick to retain its properties in any, even the most severe frost (minus 50 degrees)

White cladding brick does not burn. He tolerates heat calmly.

Due to the increased density coefficient, high-rise buildings can be erected from such bricks.

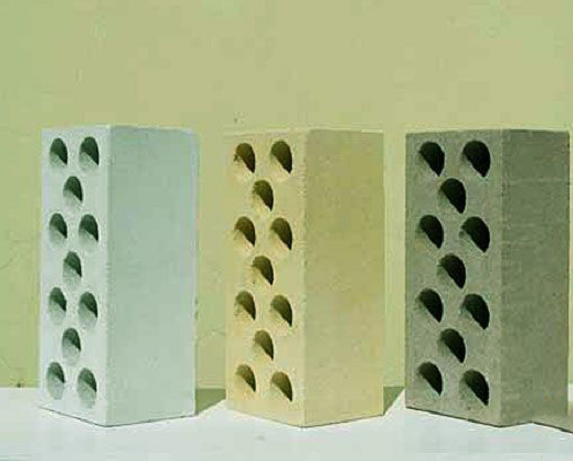

Manufacturers produce such bricks in different shades. Although the color of such products looks a little faded when compared to ceramic red brick, which stands out for its bright color.

Special purpose material

Usually, a special-purpose product is a material that has a non-standard shape, as well as dimensions that are required to perform a specific task. Several non-standard options belong to the group of such bricks.

- Eurobrick. Such a product differs from the standard one in its width. It reaches 85 mm. This option is considered facing. It is used as a design material when decorating facades.

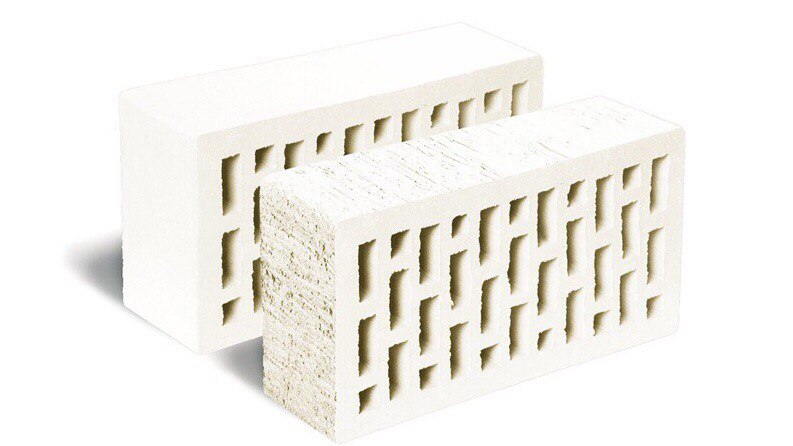

- White modular brick. It differs from standard products only in width and length (138x288 mm). The height remains unchanged at 65 mm. Modular bricks are very similar to ridged slabs. It also has special tabs for precise docking.

- White three-quarter brick. It differs from the classic product only in its length. It is somewhat shorter, reaching only 180 mm.

- White half brick. Already from the name it becomes clear that its length reaches only half of the standard size - 120 mm.

- White quarter brick. The length is equal to one quarter of the standard size - 60 mm.

disadvantages

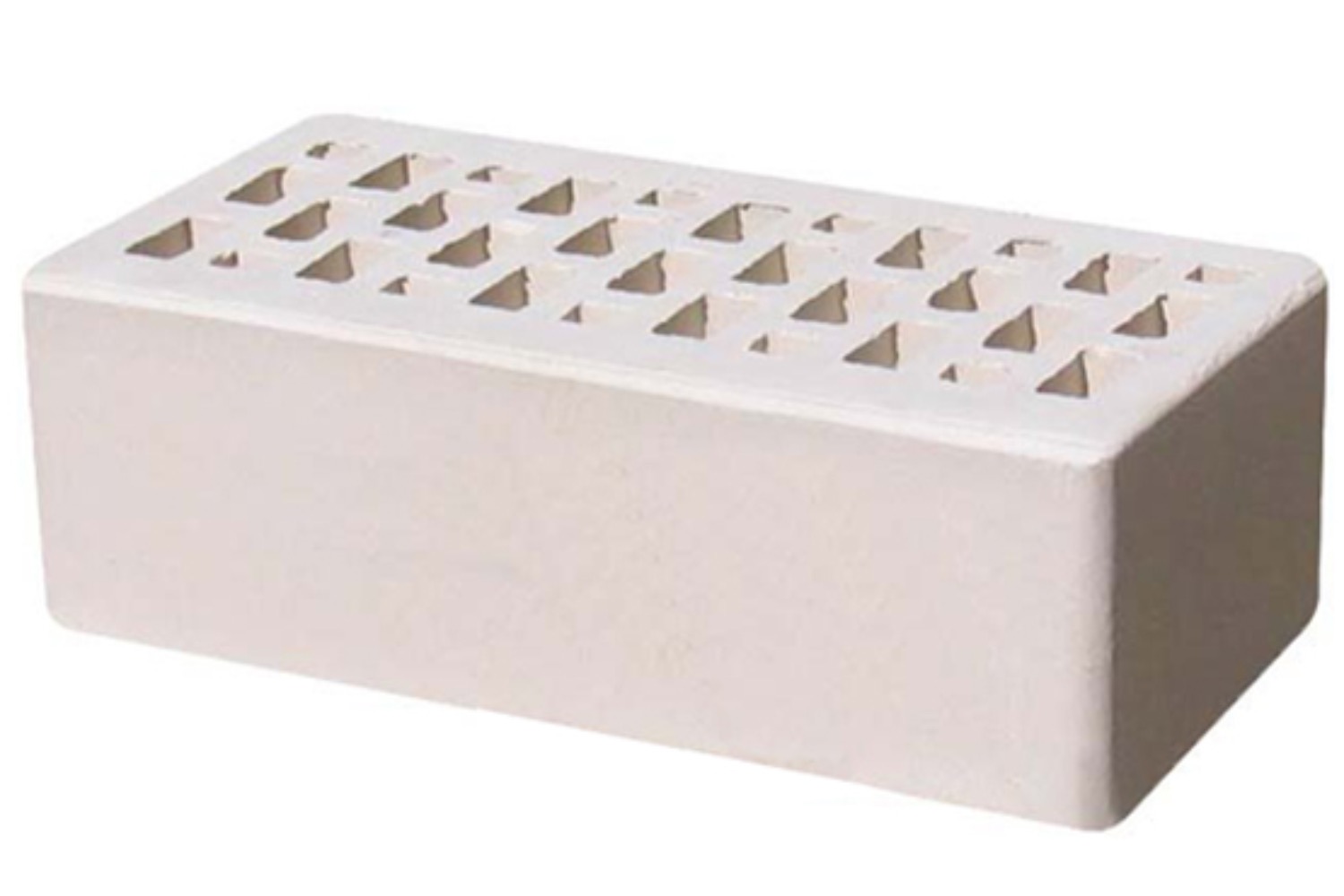

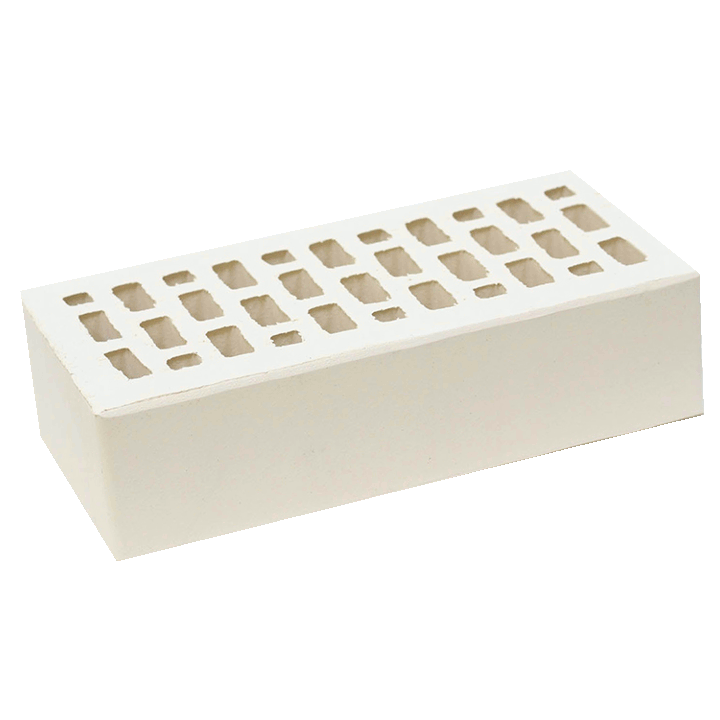

Despite such an extensive list of advantages, straw-colored hollow bricks have their disadvantages, among which the following are worth mentioning:

- Hollow bricks should not be used for the construction of load-bearing foundations of buildings. In this case, preference should be given to full-bodied products, since they have a large bearing capacity.

- Due to the presence of cavities in the structure, the product has a fairly high hydrophilicity. This is the second reason why this material is not allowed to be used in the arrangement of foundations.

- The price of such a brick is quite high, so not everyone can afford to clad a house with such material.

- Domestic bricks of this category are not of high quality, therefore it is recommended to use products from European manufacturers.

- To get a monochromatic facade of the desired shade, it is better to buy a brick from one batch. Otherwise, it will be difficult to avoid a slight difference in color and choose a suitable shade.

About the size of facing bricks

The most commonly used bricks are single size. Their longest part is 25 cm, while the other two sizes are 12 and 6.5 cm.One-and-a-half bricks are thicker - instead of 6.5 centimeters, this parameter is 8.8 cm. There are also double products with a thickness of up to 13.8 cm. These are all domestic measurements.

If we talk about European standards, then they mainly use bricks of slightly different dimensions: 24 cm long, 11.5 cm wide and 7.1 cm thick.

For Americans, too, everything is in its own way: 25 by 6 by 6.5 cm. Or 24 by 6 by 7.1 cm (the latter option refers to clinker, it is often made in Europe using NF - German standards).

Brick as a decorative material: features and difficulties of choice

Facing bricks are designed to increase the level of exterior decoration, and therefore are often produced in the form of imitation of stone relief. And since the most attractive is the style of the old aristocratic mini-castle, where all shades of the main color appear - from lightbeige to dark brown, it is not surprising that there is an abundance of design proposals for the aforementioned color scheme. Beautiful brown houses bricks in the photo are an indispensable attribute of all catalogs of construction companies and agencies.

The magic of brown can be easily explained by the following reasons:

- The brown color is extremely rich in color and depth.

- This color allows you to implement various surface patterns, ranging from ordinary wavy lines to rather complex volumetric images.

- The presence of a predominantly brown shade indicates a high percentage of high quality clay, which gives the final product mechanical strength and durability.

- With a decrease in the percentage of iron oxides, which lighten brown brick to red tones, the material's resistance to external atmospheric influences increases.

Recommendations for the selection of shades and common design techniques

Not a single photograph is able to accurately convey the palette of shades of the finishing materials used. For example, the combination of straw and chocolate looks spectacular only if the shades of the two finishing materials are chosen correctly.

As a rule, a light straw shade with dark chocolate looks best. At the same time, there are several options for combining such colors:

- Most often, a lighter straw shade is used as the main color of the facade walls. Such a brick is laid over most of the plane of the walls. From chocolate-colored products, frames are made around windows and doors, emphasize the line of the cornice, make decorative belts and highlight the location of the floor slabs in the thickness of the walls. From dark elements, pilasters can be laid out in the corners of the house and in some places on the facade, for example, to emphasize the entrance to the house.

- A little less often, elements of a dark chocolate color are used as the main background of the facade, and elements of the facade are laid out from products of a light straw shade, emphasizing the corners and framing windows and doors.

- In multi-storey buildings, an interesting technique is often used: along the entire facade along the first floor, rust is performed using dark protruding and light sunken stripes. And the façade above the first floor is decorated in a light color with dark brick details and pilasters.

- Sometimes, in addition to the details on the facade, the walls under the windows are decorated with chocolate-colored bricks, as if combining the windows of the first and second floors into one whole.

- It is not necessary to use solid masonry from wall material of different colors. For example, pilasters and frames around windows and doors, made in the form of alternating dark and light elements, look very beautiful. In this case, you can alternate through one or two rows, create spectacular teeth along the edge of the pilaster.

- Often, decorative elements and patterns on the facade or fence are laid out from products of a contrasting color.

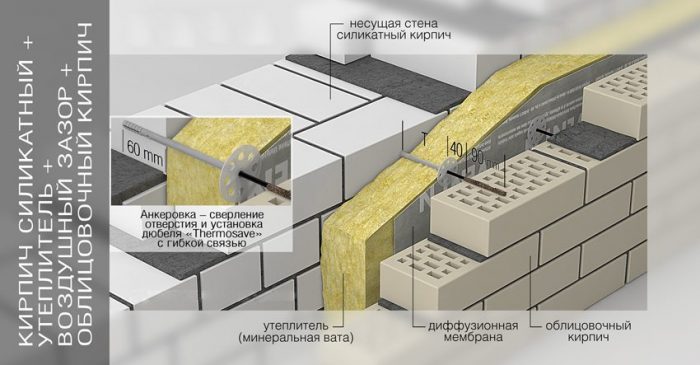

Insulation of the "white house"

There are no special requirements for insulating a house made of silicate blocks: almost any materials are suitable.

Choosing the best way

The most rational method is outside insulation, since in this case:

- the useful area of the house does not decrease;

- "Dew point" - the place of condensation formation - will be carried out outside the silicate walls;

- it is much easier to choose a suitable material for insulation, because these blocks have a rather low vapor permeability;

- this decision does not in any way affect the choice of finishing material: plastering, finishing with facing stone, siding, etc. is possible.

Before buying insulation, you need to determine the future finishing material. In addition to the type, it is necessary to calculate its optimal thickness, taking into account the weather conditions in the region. In the case of silicate walls, the owners of the future white brick house have an advantage. This is a low vapor permeability, only worsening when wet. However, when choosing a heater, this disadvantage turns into an advantage: it expands the list of heater applicants.

Potential thermal insulation

Several materials are suitable for protecting white block walls. Among them there are both old and proven "fighters" and relative new items.

Traditional materials

Mineral wool. This is a classic version with good characteristics. The material is not afraid of fire, it is produced in a very convenient form (mats, rolls), so the installation of mineral wool will not cause any difficulties. However, she has a minus: she is afraid of moisture. To get rid of the threat, it is necessary to arrange reliable waterproofing and high-quality ventilation. To ensure the latter condition, a ventilated facade is made. The minimum clearance is 40 mm.

Glass wool. This durable material has slightly better thermal insulation characteristics, moreover, it is not afraid of water or fire. Despite the advantage over its “colleague”, glass wool also needs a ventilation gap, but already smaller. As in the case of mineral wool, plastering is excluded

The main disadvantage of glass wool is irritation of the respiratory tract, therefore, precautions - goggles, dust mask, gloves - are required.

Universal polymers

- Styrofoam, expanded polystyrene (regular and extruded). These artificial "brothers" have good thermal insulation characteristics, especially the latter. Materials are indifferent to moisture, but they have a "personal dislike" for fire. In the production of both types, flame retardant additives are introduced into their composition, however, synthetics still melt under the influence of high temperature. They fix insulation directly to silicate walls without waterproofing. The gap between them and the facing material is 50 mm. Plastering is possible.

- Polyurethane foam. This is a champion: both in thermal insulation and in strength. There are two ways to fix it on the walls: spraying or mounting plates. This polymer requires a mandatory finish. It is better to use those that have fire resistance: for example, organosilicon enamels. The record holder has a drawback: this is the high price of the material.

Extruded polystyrene foam has a drawback - the lowest vapor permeability when compared with foam and ordinary polystyrene foam. To level the "inability to breathe" will help a vapor barrier device from the inside of the building. Another possible mineral insulation is stone (basalt) wool, the main disadvantage of which is not characteristics, but a higher price.

A white brick house is attractive and durable, reliably protects against noise, so the material is popular, even though it is not perfect. However, if during the construction process all the requirements for laying are observed, the walls are protected from the weather, then the shortcomings of white blocks can be forgotten for many years.

Construction features

The most rational option is to use two types of bricks at once: ceramic red and silicate. The first of them is intended for cladding white walls, the second - for the construction of load-bearing walls, as well as interior partitions.This combination makes it possible to fully exploit the best characteristics of both types of stones.

The inner, silicate, part of the wall will be able to guarantee strength, and will also be protected from moisture. The outer red brick wall will provide reliable protection from atmospheric precipitation. However, this cladding option is more suitable for large aerated blocks. For bricks, plastering, which can be easily combined with other types of finishes, will be a more suitable method of protection.

The masonry of silicate stones is almost no different from the usual "ceramic" work, so it does not cause any difficulties. “Almost” are some rules that are best to follow.

- Before starting the installation, the blocks are moistened with water. Such an operation will make the walls more reliable, because bricks that are not indifferent to moisture will no longer forcefully draw water from the solution.

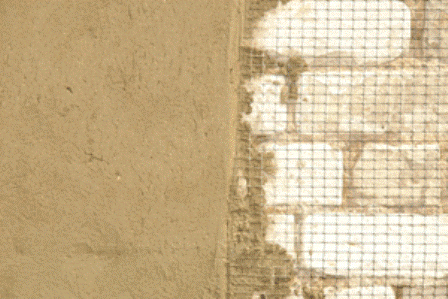

- Ligation of the longitudinal and vertical transverse seams of the masonry is required. To give the structure greater strength, a reinforcing mesh is laid on them every 2-3 rows.

- The best way for masonry of silicate blocks is "press-on". It is more labor intensive, but guarantees a better filling of the seams. First, the thick mixture is applied to a row (layer - 10 mm), leveled, and the excess is removed. Then the solution is applied to the block and pressed.

- If the composition is more liquid and mobile, then another method is used - "back to back". It is simpler, so the work goes much faster. In both cases, jointing is required, otherwise cracks will appear in the solution.

- For low-rise houses (1 or 2), a masonry of 1.5 bricks is more suitable, for higher buildings - at least two. The best stone for facing is a material with a rough surface.

Often, a large wall thickness may be required, but if such structures have to be additionally insulated, then it is unprofitable to erect too thick masonry.

Types of colors of facing bricks

When choosing a shade for finishing the facade of a house, they look at the range of windows, doors, roof and other elements. The choice of color also depends on the size and shape of the building.

So, if the cladding area is small, then the eye is able to see fewer color tones of the brick. Many of them will seem dimmer and paler than they really are. Therefore, when decorating small details, choose brighter colors, so that they play properly.

If you want to see in all its glory some not very bright or darkish tone, then use a sufficient area. Let's say you lay out an entire large wall with such a brick. Keep in mind that very dark colors are often perceived as solid blacks.

Also, remember about the combination of colors when they are around. Together they look different than alone.

If their brightness is approximately equal, then they can change tones (in a Bavarian-type masonry, this is important). This effect is especially noticeable when framing one color with another.

But on the border, the opposite is noticeable: the colors acquire a saturated edge (dark - dark, light - light), as if trying to isolate themselves from each other.

Colors of facing ceramic and clinker ceramic bricks

The range of colors for these products is extensive, but even one color can vary in shades by batch. After all, the resulting color depends on the firing, as well as on the presence of certain impurities (usually metallic). For example, iron gives redness. The more it is, the brighter the brick.

And if the cladding is carried out, in turn, using products from different batches, then on the walls not very aesthetic multi-colored groups of bricks may turn out. Experienced bricklayers, however, figured out how to cope with this: they take bricks from one batch, then from another, then from a third. As a result, the wall comes out with a uniform color - the color differences are small and not striking.

And a number of manufacturers also decided to help consumers by releasing packs of bricks, the color of which is different.Moreover, sometimes even the surface of individual parts has smooth transitions of shades. All of the above features are the norm for this type of brick.

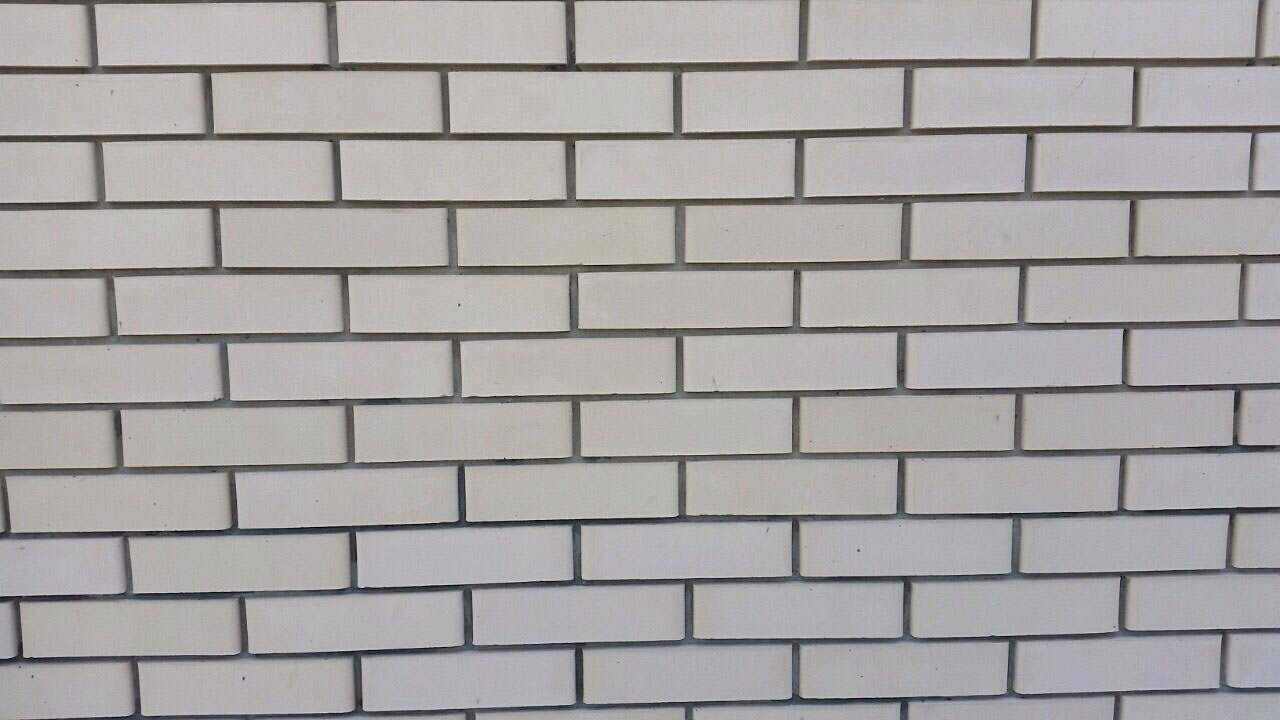

So that you can appreciate all the color features of ceramic facing bricks, below we give a photo of not individual bricks, but masonry made of certain colors of ceramic bricks:

Hyper-pressed brick colors

There is no firing here, so the color pigment added to the molding mass sets the tone for the products. Thanks to this fact, all the bricks are painted exactly over the entire volume, and the batches do not differ in scale from each other. However, the added cement, with its dirty gray color, reduces the brightness of the products. They can always be distinguished from clinker and ceramic bricks by their slightly grayish tint - the so-called "concrete".

Photo of facing hyper-pressed brick and its color:

White.

Black.

Pistachio.

Brown.

Red.

Peach.

Gray.

Chocolate.

Blue.

Ivory.

Straw.

Terracotta.

Green.

Colors of silicate facing bricks

The easiest way is to paint such a brick throughout the mass, for which the dye is added to the mixer container, where the mixture is prepared. To measure out the required amount of paint, use a dispenser

It is important not to overdo it here: too much paint will be expensive and can lead to a deterioration in strength. And if you put a little dye, then the products will turn out pale and ugly

Sometimes, in order to save money, only the front layer is stained on both sides.

The main colors in which silicate bricks are painted are presented below:

Views

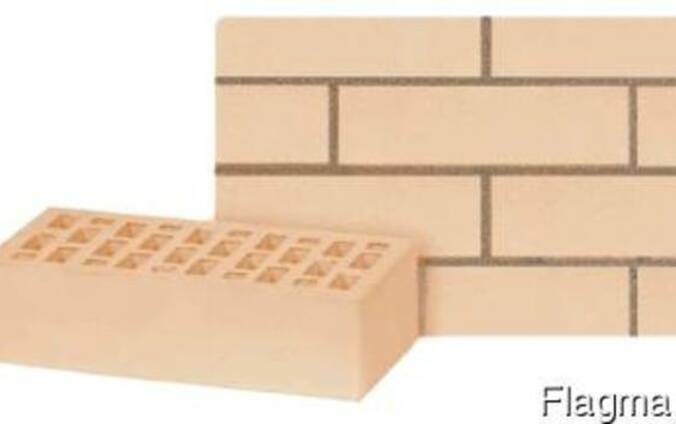

Such products are mainly used for cladding houses. Manufacturers produce a variety of blocks that differ in some parameters:

- texture;

- thick;

- form;

- material.

To create a hyper-pressed material, the latest technological processes are used. These products are distinguished by a high strength factor. Such blocks are designed for a long service life. The material feels great in areas of seismic instability.

White clinker material differs from analogues in its positive characteristics. It retains its original properties even in unfavorable climates. Houses from this material receive excellent thermal insulation, as well as a high level of sound insulation. The increased wear resistance allows this material to be used for a long time. One and a half clinker block is considered a universal option used for cladding buildings.

Fireclay white material is considered a refractory building product. It is used for cladding stoves, it is used to line fireplaces at home, and with its help they are used for facing the facades of buildings. The modern market presents facing products of European and domestic standards. All products are subdivided into two subgroups:

- NF - normal (240x115x71 mm);

- DF - thin (240x115x52 mm).

The second group meets the requirements of the architectural classics. When choosing such a material, make sure that all blocks are of the same standard. Otherwise, it will be very difficult to create a beautiful cladding.

Varieties of forms of facing bricks

It is by cladding that you can magically transform the house, which is an ordinary rectangular "box". By doing something exclusive, original and impressive. And to make it easier to cope with this task, manufacturers produce a special facade brick - figured. With it, even laying out a complex pattern is not a problem.

Shaped ceramic bricks

Such products beautifully decorate the space around doors with windows, process corners, cornices, and veneer columns. The front side and sides usually differ from the standard form. Next, we will describe the main varieties.

1. Brick, which instead of one corner is smoothly rounded with a radius of 5.5 centimeters.

2.It has one rounding of a much larger radius (15.5 centimeters).

3. One corner of this product is cut off (45 degree angle, 5.5 cm head).

4. A 45-degree cut is designed so that the brick takes the shape of a trapezoid with an upper side of 12.5 centimeters.

5. A product beveled in length at 9 degrees and has a rounding of one corner with a radius of 30 millimeters. In addition to the standard length of 24 centimeters, it can be 28 centimeters long.

6. Brick similar to the previous type. But he still has a special protrusion for attaching to the window frame.

7. The side is cut at 30 degrees on both sides - an angle is formed.

8. The jab is cut at 30 degrees on one side.

9. Brick one third of which is bent at an angle.

10. Has two fillets with a radius of 5.5 centimeters (both on the long side).

11. Brick for cladding with 45 degree cuts on both sides. The heads remain at 5.5 centimeters.

12. Brick used for cladding. Has a convex long side (radius 36.7 centimeters).

13. The spike and spoon parts of the brick are connected by waves.

14. Brick with rounded butt and one spoon part.

15. Radial solid brick.

16. One corner is cut at 45 degrees. Used for outside corners.

17. A brick in which one corner has a concave rounding. Its radius is 5.5 centimeters. The head remains 6 centimeters high.

18. Brick with a surface profiled on one side. The protrusion is rounded with a radius of 2.75 centimeters. It is used for finishing cornices.

Almost all popular forms of ceramic bricks are provided above, but depending on the manufacturer, they may differ.

Hyper-pressed figured bricks

Hyper-pressed bricks also boast a huge variety of shapes.

1.With one cut corner.

2. With two cut corners.

3. With one rounded corner.

4. With a profiled surface.

5. Short figured cornice.

6. Rounded corner, shortened.

7. Semicircle.

8. The "drop" shape is shortened.

9. Eaves smooth.

10. With one rounding of a large radius.

11. The "drop" is internal.

12. "Cornice" inner.

13. Inner semicircle

14. "Cornice" outdoor.

15. Brick of the "semicircle" shape

16. Outside drop-shaped brick.

17. One corner is cut for 45 and the texture is rock.

18. Brick with the texture "rock" with cut corners.

Material characteristics and advantages

"Straw" facing brick got this name for the characteristic shade of straw. Today it is the most popular and demanded finishing material in individual construction. Moreover, this shade is used in combination with other colors of this brick, allowing to emphasize the architectural expressiveness of the building. For example, the combination of "straw and chocolate" is used not only in the decoration of private houses, but also in the manufacture of gazebos, small buildings on the territory of a suburban area, fences and even in interior design.

This building material is made of natural light-colored clay mixed with sand. After firing, the product acquires a number of outstanding characteristics and advantages:

- The significant strength of the product is due to the fact that clay itself is a fairly durable material. And due to mixing with sand and exposure to high temperatures, the strength of the material increases even more. Such a brick is practically not subject to deformation under the influence of constant loads.

- This facing material is resistant to all weather conditions. It easily withstands temperature fluctuations, its extreme values, the effects of water and strong winds.

- Due to the voids in the structure, the material has excellent sound and heat insulation characteristics. In the heat, it does not allow the house to heat up, in the cold it retains heat inside the room, additionally insulates it from the noise coming from the street.

- All houses made of “straw” bricks, photos of which can be found on the web, retain their brightness and richness of color for many years, without changing the shade under the influence of sunlight, high humidity, frost or strong winds.

- Due to the voids inside, the specific gravity of the material is small, which saves on its transportation to the place of laying.

- This is an environmentally friendly material that is made only from natural ingredients. It does not emit harmful impurities during operation.

- The product does not burn.

- Long service life. The material can last up to half a century without losing its technical characteristics.

- If we compare a hollow brick with a solid product for masonry walls, then its cost will be lower due to the lesser need for material. In addition, due to its high thermal insulation characteristics, the thickness of the walls can be reduced, reducing material costs. And if you use a double hollow brick, then you can save on mortar.

- The material is highly resistant to cracking. This is achieved due to the presence of air inside the product. Bricks, in which the ratio of raw materials and cavities is 1 to 1, are especially high crack resistance.

- The most important advantage for which this brick is so valued is its decorative qualities. If the joints when laying the walls are done accurately and efficiently, then the house does not need additional finishing work.

- Straw-colored brick houses are not the only example of the use of this cladding material. There is a large assortment of colors and textures of such products, allowing to bring to life any ideas of architects and designers. The range of colors is so wide that it allows you to choose elements for restoring the lost details of the facades of buildings of past eras.

Conclusion

No matter how beautiful and durable the building is, over time it will require finishing work. To "refine" the old building, give it a beautiful appearance, reliably protect it from atmospheric influences, you can use brick cladding. It is considered the most reliable and also the simplest finishing method. This will help carry out restoration work, turn the old house into a modern one, and significantly insulate it. After such finishing, the building will stand for many more years, attracting passers-by with its beautiful appearance.

For the secrets of working with white facing bricks, see the video below.