How concrete gets into the formwork

One of the most crucial stages in the construction of monolithic reinforced concrete structures is the delivery of concrete from the mortar-concrete unit to the place of its laying.

How concrete is delivered to the place of laying The days when the concrete mixture was delivered to the construction site by dump trucks are already gone, now the concrete is transported by domestic and imported concrete trucks of various capacities. The use of this delivery method can significantly increase the life of concrete, since throughout The mixing drum of the concrete truck rotates slowly (3 - 4 rpm), mixing the mixture, and practically fresh concrete comes to the site. However, now the concrete mixture delivered to the construction site must be fed into place and poured into the formwork. There are two main methods of conveying concrete: • the traditional method: "crane-bucket", in which the concrete delivered to the construction site is poured into a rotating bucket, laid in a horizontal position with a closed gate. The construction crane turns the filled bucket into a vertical position, lifts it and carries it to the place of pouring into the formwork, where the gate opens and the concrete is poured into the formwork; • a relatively new method of placing concrete using a concrete pump. In this case, the concrete mix from the truck is poured into the receiving hopper of a mobile (trailed) or mounted on a truck chassis concrete pump, which feeds the mix directly into the formwork via concrete conduits. The power of modern concrete pumps makes it possible to deliver the mixture to a height of up to 100 m and a distance of up to 300 m. Both of these methods are used on domestic construction sites with equal success, and each of them has its own characteristics and, accordingly, the field of application.

Concrete pumps are high-performance modern equipment for placing concrete Undoubtedly, the use of concrete pumps significantly reduces labor costs during concrete work, but its high productivity (up to 80 m³ / hour) makes the use of such equipment economically justified only with significant volumes of concreting. At the same time, a situation may arise when it is necessary to concrete a structure, to which concrete cannot be supplied to which an existing crane cannot and it is necessary either to rent a crane with a long boom, which has a high lifting capacity with a large outreach, in order to supply a bucket of concrete to this place, or to use a concrete pump. In such a situation, an auto-concrete pump can be used, which, thanks to an arrow reaching a length of 60 m, will be able to concrete a structure in a short time that is inaccessible to a medium-duty construction crane. For the concreting of large floor slabs, mechanical or hydraulic mobile concrete distributing booms are used, allowing the mixture to be fed within a radius of 12 to 40 m from the boom installation point. At the same time, the use of concrete pumps has its own peculiarities, in particular, the pumped concrete mixture should not include aggregates with a fraction larger than 40 mm, in addition, concrete must have a certain plasticity (cone draft) and it must be supplied continuously, otherwise the concrete pipes must be regularly cleaned of the mixture remaining on their walls. Despite these features, the use of concrete pumps significantly speeds up the process of placing concrete and allows concreting structures of significant volume in a limited time.

Which method to choose? However, the bucket crane method, due to its simplicity and economy, is still successfully used on many construction sites, where the bulk is made up of structures with a relatively small volume, in particular multi-storey and individual residential buildings. For industrial construction or for the construction of unique public centers or shopping complexes, it is most often economically justified to use a concrete pump.In any case, the method of concrete delivery, as well as the equipment and accessories required for this, should be selected at the stage of developing a project for the production of concrete works, taking into account economic and technological factors.

xn --- ptbbjegddbnkmk.xn - p1ai

Purpose and construction of the concrete bucket "Shoe"

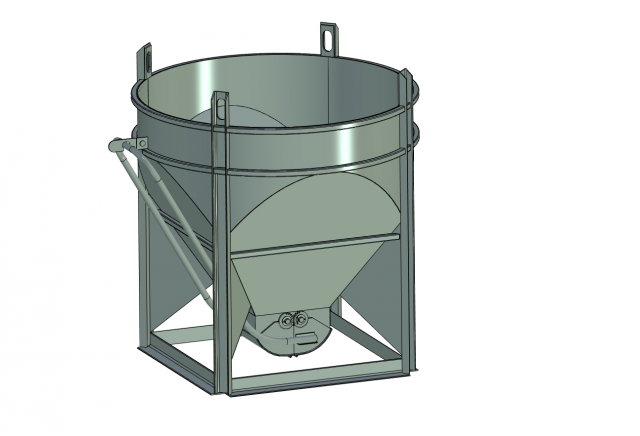

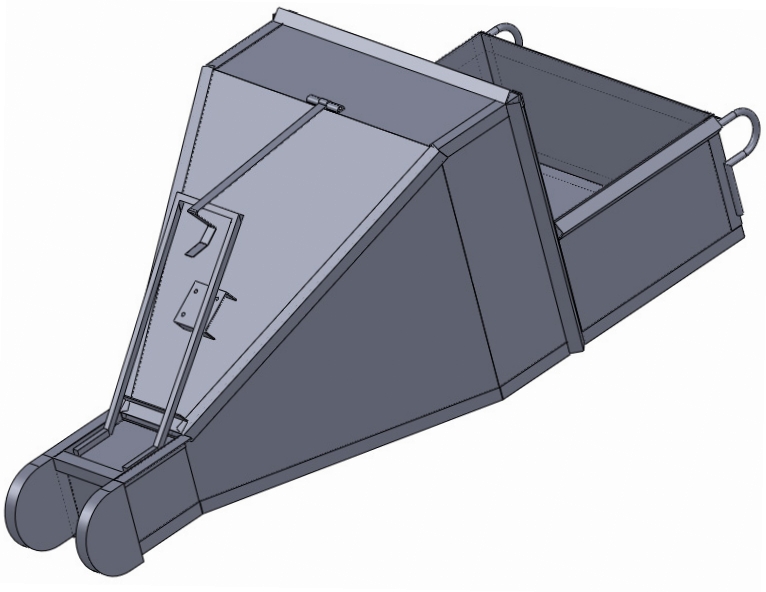

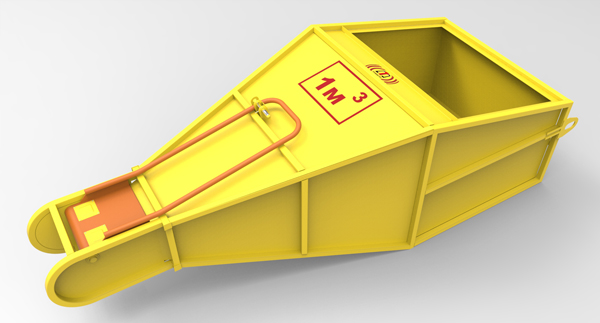

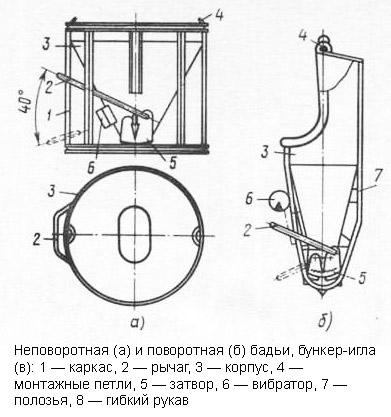

There are two forms of container construction: rectangular and conical. The first form is a tub "Shoe" for concrete, the second is a "Glass". In shape, the "shoe" is a rectangle that turns into a cone and really resembles this type of shoe. The bunker is loaded in a horizontal position with a closed and fixed shutter, and transported and used in a vertical position. Hence its additional name - rotary bunker. The turn is done using lifting mechanisms.

This device is opened in the lower part of the cone with the help of a lever system, which provides regulation of the dose of concrete solution. In addition, the locking mechanism has a lock that protects against spontaneous opening. A reclining gutter serves to direct the pouring; a rubberized hose is connected to deliver the concrete mix to hard-to-reach places.

The handle for opening the hopper is displaced and this allows visual control of the concreting process. The design is stable in any position. If necessary, an electric vibration motor is installed on the "shoe" in the area of the cone. Then the bucket can be used to transport hard concrete and dry mixes. The advantage of this design is that the loading height in the horizontal position is low and it is possible to load concrete from any type of concrete mixer.

Manufacturing

The process of preparing the mortar is a laborious construction operation. That is why the trough for preparing the batch must be highly durable and easy to use.

Let's consider one of the possible design options. For manufacturing, you will need the following materials:

a metal sheet. It is advisable to use sheet steel with a size of 1000x2000 mm, a thickness of at least 1 mm, with a zinc coating. The dimensions of the steel sheet may vary. The main thing is that the volume of the container corresponds to the tasks set;

Making a container for preparing a solution from sheet metal

- coniferous wood in the form of boards with a thickness of 30 to 50 millimeters. Prepare one board with a length of about 6 meters, which will make it possible to make a trough with dimensions of 1x2 m;

- nails for the manufacture of a wooden frame or self-tapping screws for fixing the steel sheet to the boards.

When making a concrete trough with your own hands, do the work in the following sequence:

- Cut a solid six-meter board into 4 pieces: two pieces 2 meters long and two pieces 1 meter long.

- Round the edges along the radius on two-meter workpieces by sawing off the corner fragments.

- Nail a galvanized steel sheet to the straight sections of the prepared planks using nails.

- Bend the edges of the sheet at the level of the radius part and, using self-tapping screws, fix the meter-long boards.

- Additionally, fix the structural elements with self-tapping screws, which will increase the service life and ensure tightness.

Considering the small overall dimensions and weight, it is not difficult to transport such a container for concrete. The radial shape of the sheet at the ends facilitates the extraction of the ready-made mortar and cleaning. The tightness of the structure is achieved after the initial mixing, when the cement mortar seals the small cracks. After the concrete mass has hardened, water will not be able to flow out.

After the first kneading, the trough will become practically airtight due to the filling of the gaps with concrete.

This design option is simple and allows the use of available building materials.Such a trough is a fully-fledged device for preparing concrete.

Some features of the operation of construction devices

As noted above, it does not always make sense to purchase a bucket, sometimes it is much easier to rent it or even use the services of transporting concrete, since doing the work with your own hands will require too much effort.

This applies to a lot of work, for example, cutting reinforced concrete with diamond wheels without special equipment will take too much time and money, and diamond drilling of holes in concrete is an absolutely impossible task without expensive devices. It is much easier to use the services of professionals who will quickly and efficiently carry out the work.

The paint must be periodically renewed, as the layer is severely damaged during operation.

Criterias of choice

From the description it follows that the simplest, therefore the most inexpensive, but rather capacious design are all types of "Boxes". At the same time, the most convenient (from the point of view of transportation, loading and unloading and the possibility of moving bulk materials) tub is considered a swivel "Shoe". It is recommended to use "Glass" in combination with small-scale mechanization means: chutes, concrete pumps and feed hoses.

In general, it makes sense to have at the construction site: "Shoe", "Glass" and several "Boxes" of various capacities and designs, depending on the scale of the construction site and the volume of planned concrete work.

Advantages and disadvantages of designs

Each model has its own characteristics, pros and cons. Some models of the fixed type use both vertical and horizontal methods of loading concrete. There is a tray at the bottom of the hopper, it is usually made in the form of a cone. Despite the identical dimensions, the pyramidal capacity is higher, but it is more difficult to clean the inner surface of the solution residues.

In smaller designs, the bottom tray is most often opened manually. In large containers, lock connections are used.

Swivel models are more expensive, but also more comfortable to use. When using a "shoe", the supply of the solution requires fixing the structure at the desired angle to the support, this facilitates the work. There is a possibility of adjusting the feed rate of the mixture from the container. This type of construction is more versatile, with increased convenience provided by the large cross-sectional area for the funnel.

Among the disadvantages of the "shoe" it is worth noting the possibility of loading concrete only in the horizontal plane by two methods - with the involvement of a dump truck or special vehicles. Thus, the “bell / glass” design is simpler and cheaper, while the “shoe” is functional and comfortable, but it costs more. The first option is suitable for small volumes of work, the second is relevant when performing large-scale fillings.

The concrete pumping bucket is a convenient and functional device that greatly simplifies and speeds up the pouring of concrete on objects. Provided the correct choice and professional operation, the bunker will serve for a long time and faithfully.

Criteria for the selection of containers for concrete

To ensure optimal performance of construction work, adherence to technology, usability of the container, a number of the following factors must be taken into account:

the dimensions must be suitable for carrying out all the necessary manipulations in specific conditions;

the capacity should be optimally matched to the scale of the concreting work in order not to cause delays and to exclude idle time of the finished mixture;

when choosing a shoe, you need to make sure that it is possible to use the required equipment, equipment, as well as how to attach the sleeve or funnel;

it is important that the lifting capacity is sufficient to ensure increased safety on the construction site, but taking into account the characteristics of the crane used;

it is recommended to choose a branded manufacturer that guarantees high build quality, durability and reliability of the structure (you should pay attention to Zitrek products).

Renting or buying?

- a large amount of work;

- tight or round-the-clock work schedule that does not allow downtime;

- you need to make some changes to the scheme, for example, to strengthen the frame;

- you are engaged in commercial activities and often perform work related to concreting: pouring sites or erecting multi-storey monolithic buildings.

If you decide to buy a new tub, you will get the following benefits:

- the design will fully meet the declared characteristics: no hidden or obvious defects, deformation of the container;

- it will be possible to maintain the ideal condition of the metal by ensuring gentle operating conditions and timely maintenance;

- loading the exact volume of the solution, since there will be no adhering dry concrete on the walls.

Buying a used bucket is an excellent alternative to purchasing a new one due to the following benefits:

- at the same price, it will come out to get large container sizes;

- instead of a non-rotating one, choose the optimal shoe and improve work productivity;

- abandon Chinese equipment in favor of branded equipment, for example, Zitrek;

- operation at maximum technical capabilities with minimal financial investment.

Used equipment that has been in use for a year has a cost that is 1.5-2 times lower than new equipment with similar characteristics. Therefore, from a financial point of view, it is the most profitable. There are such risks:

- the ideal external condition is the result of the hiding of critical defects, for example, rusted sheets or a supporting frame;

- inside steel structures, as a result of improper operating conditions, fatigue deformations have formed, which, under certain loads of the concrete mixture, are partially or completely destroyed by the bucket;

- there must be a mandatory technical passport.

In the case of a limited budget or a one-time concreting, rent is beneficial. Its cost depends on the service life of the equipment, its condition, design features and equipment. If there is a long distance to the construction site, then it is necessary to assess the possibility of acquiring, since sometimes transportation costs can make the lease financially unprofitable.

Prices for new and used concrete buckets

| Type of service | Type of | Volume | Carrying capacity, t | Dimensions, m | Price, rubles |

| Purchase (new) | Fixed with discharge tray and funnel clamp | 0,5 | 1,12 | 1.50x1.50x1.46 | 18900 |

| 1,5 | 3,75 | 1.52x1.52x2.00 | 29950 | ||

| Fixed with tray | 3 | 4,5 | 1.57x1.57x2.85 | 48800 | |

| Swivel with a platform for installing a vibrator | 1,6 | 4 | 3.60x1.60x0.89 | 36900 | |

| 2 | 5 | 3.70x2.10x1.14 | 45400 | ||

| Purchase (used) | Swivel | 0,5 | 1,12 | 3.1x1.27x0.7 | 15500 |

| 1,6 | 3,75 | 3.10x1.27x1.20 | 16000 | ||

| 2 | 4,00 | 3.60x1.27x1.34 | 19500 | ||

| Fixed | 0,5 | 1,25 | 1.25x1.25x1.27 | 10000 | |

| 0,75 | 1,88 | 1.25x1.25x1.68 | 14500 | ||

| 2 | 5 | 1.58x1.58x2.45 | from 19000 | ||

| Rent | Swivel | 1 | 2,5 | 3.17x1.27x0.72 | from 800 per day + 12000 deposit |

| 2 | 5 | 3.64x1.27x1.34 | |||

| Fixed | 0,5 | 1,5 | 1.25x1.25x1.27 | from 500 per day + 10000 deposit | |

| 1 | 2,5 | 1.25x1.25x1.86 | |||

| 2 | 5 | 2.00x2.00x1.75 |

Purpose and varieties

The bucket may be needed when the volume of loading and unloading concrete is very large. When pouring monolithic foundations and other structures, the bunker makes it possible to significantly reduce the cost of delivering the finished mixture, abandoning the services of the plant and providing the supply of the solution directly to the site. Ready concrete can be stored in the tub for some time.

Different models of tubs are suitable for the implementation of certain tasks, therefore, it is advisable to study the features of each option before choosing.

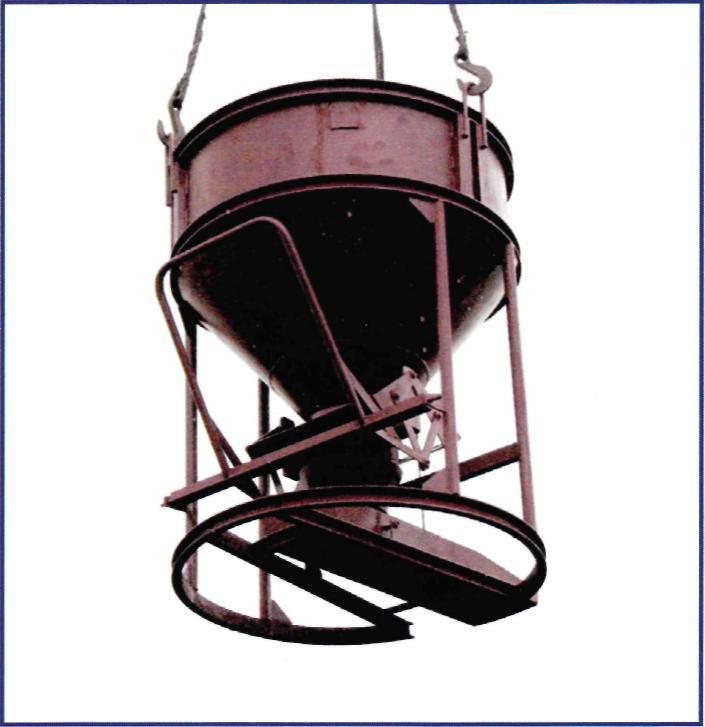

Glass or bell

This is a model of a non-swiveling tub of cylindrical shape with a cone. The hopper carries out vertical concrete feeding. The stability of the structure is achieved through the presence of a support system in the format of wide rings. The rings are different, the configuration is different in the case of a filled and empty container.

The concrete solution is loaded into the bucket from the top from the dump truck. The easiest way is to work with understated models. The standard equipment assumes the presence of jaw-type tool joints, which are located in the lower part of the cone. Also, to simplify the supply of the solution, mechanisms are used: a trailed tray, a funnel, fasteners for flexible hoses.

The bell model is used to load concrete mortar into single-type / monolithic building structures. Such a bucket is relevant when working with very hard mixtures. Additional functionality is provided by removable trays and special hoses, without which concrete can only be fed in a single direction.

"Shot" is the simplest and most inexpensive version of the bucket, the capacity varies in the range of 0.5-3 cubic meters (in Moscow you can find more, but rarely), the average carrying capacity is 2500 kilograms.

Shoe-shaped tub

This model is performed with a rotary structure, the geometry of which can be changed. The capacity is 1-4 cubic meters, the opening for receiving concrete is rectangular, the unloading of the mixture is carried out horizontally, which is a guarantee of comfort in operation and the stability of the bucket.

Externally, the model looks like a tapering and slightly truncated pyramid. The unloading funnel is closed with a special shutter, the body is reinforced with metal parts. The special frame provides additional protection and stability.

The main feature of the shoe model is the presence of a vibrator on either side of the bucket, which significantly extends the life of the solution and allows it to be stored for a short time. The mixture becomes more homogeneous and active, easier to serve.

Cranes are used to move the bucket and turn it into a vertical plane. Due to the rotary design, the task is greatly simplified. This is a more functional model in comparison with the previous one. An important advantage is the connection of a vibrator, which does not allow concrete to linger on the walls of the tank.

The unloading funnels in the models of the "shoe" type can be very different - starting with a slide gate and ending with two-section. A system of levers initiates control. Using a bucket, concrete can be prepared directly on site.

Criteria for the selection of buckets for concrete delivery

When purchasing a new product, pay attention to the following:

- To the desired capacity of the bunker: for BN series buckets it starts from 0.5 m3, for BP series buckets - from 1 m3. Volume gradation - every 0.2 m3.

- By the thickness of the metal of the hopper: sheet metal will significantly reduce the service life of the product, given the rather high density of concrete mixtures and the operating conditions of the products at the construction site.

- On the quality of painting of all surfaces: the use of weather-resistant powder paints not only ensures the tightness of the coating in any atmospheric conditions (for at least a year), but also guarantees the durability of the tooling.

- For the presence of additional options in the bucket design. In particular, the presence of a platform for installing a vibrator (for products such as a bell and a shoe) leads to an acceleration of the process of unloading concrete and will reduce the labor intensity of the subsequent cleaning of the inner surface of the bunker. For fixed designs, the convenience of unloading is also determined by the type of mechanism for opening the shutter jaws.

- The shape of the transport lugs. It should be convenient to use when transporting the bucket not only by cranes, but also by forklifts.

For periodic concrete work, the concrete pouring buckets are usually not purchased, but rented. The rented container should not have dents on the inner surface of the bunker, damage to the coating and defects in transport loops.

An overview of the most popular options and their advantages and disadvantages

As noted above, two types of structures are mainly used, and you need to decide which one is suitable for this or that construction object.

They differ in many characteristics, and it is important to choose the best option.

Wine glass design

A bucket for concrete glass belongs to one of the simplest types of products, which provides invaluable assistance in the process of work. But you need to understand that products of this type may differ from each other, and it can be difficult to choose a specific option, even if you do not buy, but rent a device. After all, productivity and usability depend on the right decision.

It was the appearance that determined the name of the glass (some call this type of bell)

Consider what criteria you should pay special attention to, whether it is the purchase of new equipment or used units:

The material of manufacture of the product, most often it is steel, must be very durable. Insufficient thickness does not provide the required reliability

If you choose a used bucket, then pay attention to the absence of damage, sometimes their removal will cost more than the product itself.

Also check other elements - each node must be strong and reliable.

If you need a device with a capacity of 1 m3, you should not purchase the option twice as large: it is much heavier, and it will be inconvenient to work with it.

A concrete bucket of this type consists of several main parts:

- The main container, made either simply in the form of a cone, or as a cone with a cylinder on top. The features of this system depend on the required capacity.

- The support system is also of great importance; it can be of a wide variety of configurations. The main requirement for it is the strength and stability of both empty and full containers.

- A very important part of the design is a shutter with a handle, with which the solution is discharged, the shutter must be strong, and the opening handle must be comfortable. (See also the article Facing aerated concrete: how to do it.)

A comfortable handle on the valve is an important part of the design

The lugs for attaching the structure to the crane and lifting it are very important, since the safety of everyone on the construction site directly depends on this.

Shoe type construction

This is a more progressive option, but its price is also noticeably higher, the requirements for strength and quality of materials for such structures are similar to those discussed above. (See also the article Concrete Crushed Stone: Features.)

Instructions for checking the product with your own hands are as follows:

- First, all structural elements are carefully inspected for reliability and absence of damage.

- If the unit is used, then look inside the bunker: if it has not been cleaned, then a layer of hardened concrete can create a lot of problems for you.

This type of construction, due to external features, is called a shoe or galosh.

This option has a number of advantages:

- The design of the product is rotatable, which allows you to adjust the direction of unloading of concrete and increases the convenience of using the bucket. It is this advantage that determines the popularity of this type of product.

- The structure may have a platform for installing a vibrator, which significantly speeds up the unloading process and does not allow concrete to stick to the walls.

- Another undoubted advantage is the ability to load the solution, both from a mixer and from a dump truck, this can simplify the work and make it cheaper, since special transport is much more expensive than conventional trucks.

- With a large capacity and reliability of products, their unloaded weight is relatively small, which increases the convenience of transportation.

- It is much easier to load such containers, since this is done when the bucket is in a horizontal position (transportation is carried out in an upright position).

Convenience of loading capacity is another important advantage.

The device and principle of action of the bucket

As part of the structure:

- Pos. 1 - a reservoir in the form of a cone;

- Pos. 2 - gate;

- Pos. 3 - control handle;

- Pos. 4 and 5 - elements for fixing the gutter;

- Pos. 6 - chute for solution supply;

- Pos. 7 - funnel;

- Pos. 8 - a loop for transportation;

- Pos. 9 - visor.

Most often, the container is made in the form of a truncated cone, which is connected to a cylindrical shell. The gate serves to adjust the supply of the mixture by means of a handle with a lever mechanism.

When transporting equipment, the chute is fixed with a lock, pos. 4, and when pouring the mixture through the chute with a retainer, pos. 5. Through the chute pos. 6, the direction of the solution flow is ensured. Funnel pos. 7 with a flange prevents splashing of the mixture during mixing and when unloading the mixture.

Read also: Ohm's law for parallel connection of resistors

The container shown in the photo differs in the design of the case, which conditionally consists of three parts:

- Receiver of rectangular shape for concrete or mortar mixture;

- A bunker in the form of a truncated pyramid;

- A two-piece shutter, with the help of which the angle and intensity of the concrete solution are regulated.

The concrete receiver and the shoe hopper are usually made of rolled metal. To strengthen the body of the device, a longitudinal frame of channels is additionally constructed, which prevents the bucket from deforming when it is fully loaded.

The loops for transporting or unloading the container using lifting equipment are attached to the channels reinforcing the structure. On the reinforcing frame, special elements are additionally attached, which ensure the inclination of the container at the required angle when unloading the solution or concreting the area.

The shoe has a special shutter, in which both flaps have their own handles for control. This design allows you to adjust the flow of the mixture. Special safety rings on the handles provide protection of the bucket from accidental opening of the shutter.

When transporting the equipment, the lifting mechanism is attached to the bucket by the transport loops. For transportation of dry mixes and hard concrete, a mechanical vibration bucket is used. In this case, the tank is supplied with an electric motor mounted on a conical tank.

In addition, the container can have a technological platform designed for the operator and the delivery of technological equipment to the concreting area for lifting the bunker with concrete. The cone hopper is only used in an upright position. And its volume can be v = 0.75; v = 0.8 cubic meters

At the initial stage of construction work, when building a utility room, installing a temporary fence or repairing an existing building, it becomes necessary to mix a small portion of concrete solution in a special container. A concrete trough will allow you to prepare up to five buckets of concrete composition, using an ordinary shovel for mixing.

Consider simple options for containers for the preparation of a concrete composition, the necessary materials and technological features of manufacture.

Trough for manual concrete mixing