What is the material

Arbolite has been used in construction for a long time. Material requirements are established in GOST 19222 * 84.

For the production of wood concrete, a binder (cement) component, organic fillers and additives are used to adjust the characteristics. The material is used for the construction of structures for various purposes.

Arbolit (wood block)

The composition of the mixture (content of cement, water and chemical additives) for the manufacture of the material may vary depending on the type and fraction of organic matter.

In accordance with the current standard, manufacturers produce two types of wood concrete.

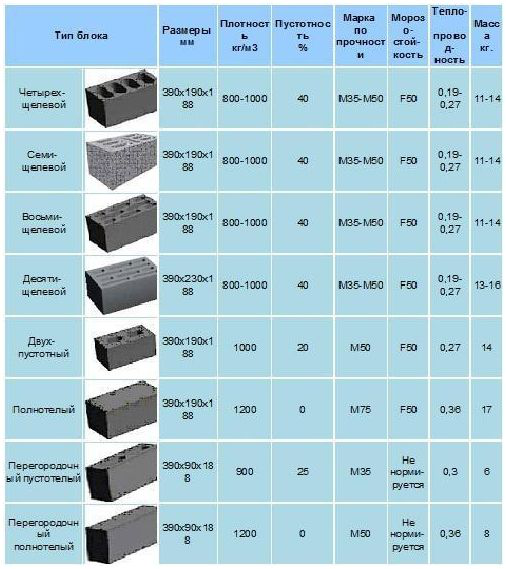

Table. Types of material.

| Material | Density, kg / m3 | Compressive strength, brand |

|---|---|---|

|

Heat insulating |

400…500 | M5, M10, M15 |

|

Structural |

500…850 | M25, M35, M50 |

The scope of application of structural wood concrete is the construction of low walls (2, 3 floors) and partitions, the arrangement of jumpers over openings and an armored belt. Thermal insulation material is needed for thermal insulation of walls and ceilings, as well as noise protection. The erection of load-bearing structures from products made of wood concrete with a density below 500 kg / m3 is prohibited.

Arbolite blocks masonry

Wood concrete type and characteristics

Relative humidity inside wood concrete buildings should not exceed 60%. Also, the presence of an aggressive gas environment is not allowed.

Blocks are produced from wood concrete, which are most in demand among consumers, and panels (they are mainly used for floor insulation).

Wall wood concrete panels

What are the characteristics of wood concrete blocks?

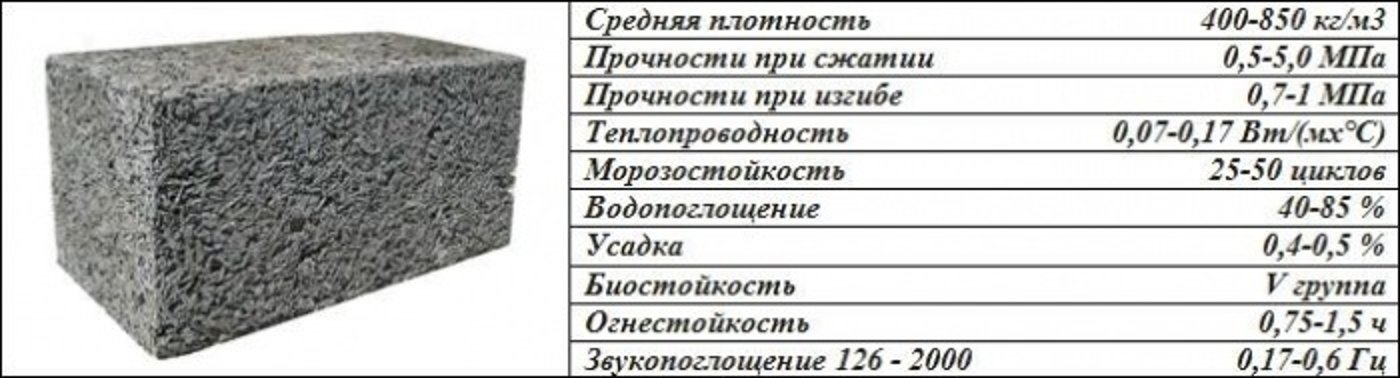

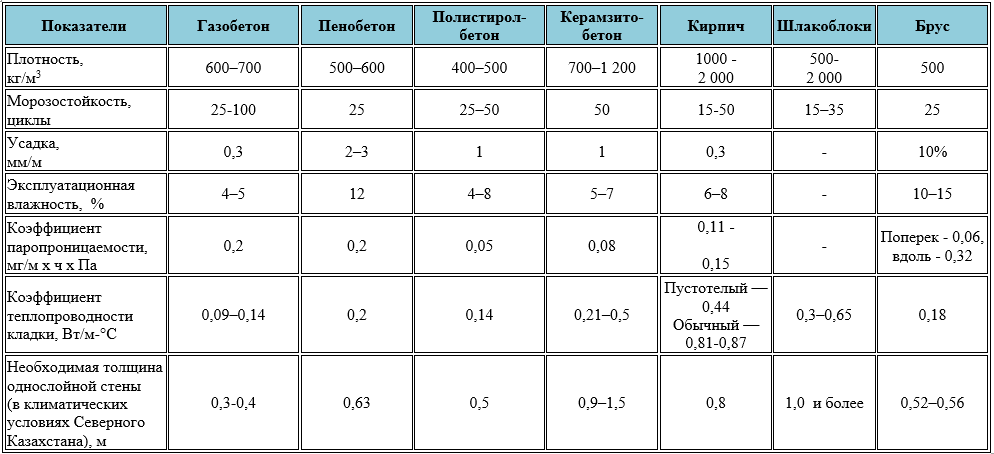

The coefficient of thermal conductivity of the material, depending on the organic filler, can be:

- 0.08 ... 0.17 W / (m × ° С) - for products with wood in the composition;

- 0.07 ... 0.12 W / (m × ° C) - for products with other types of filler.

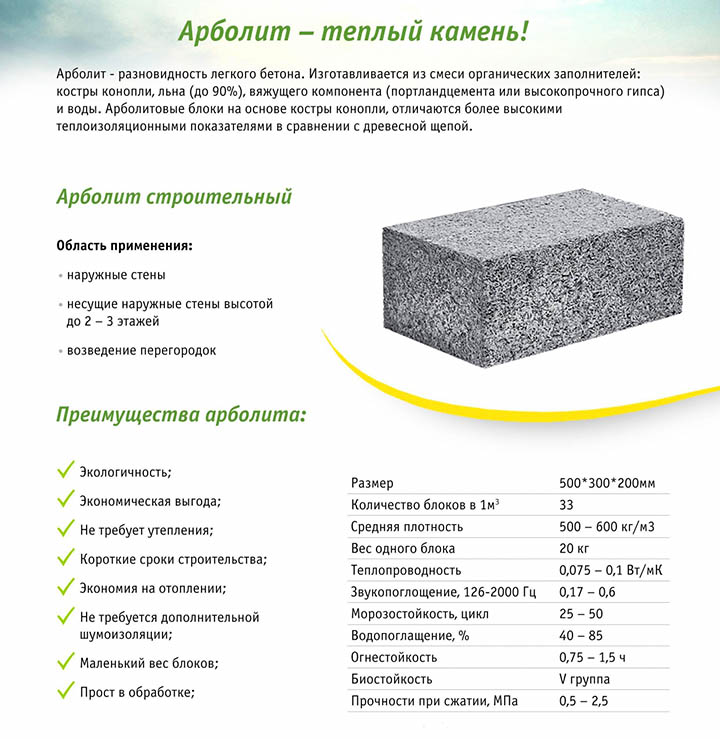

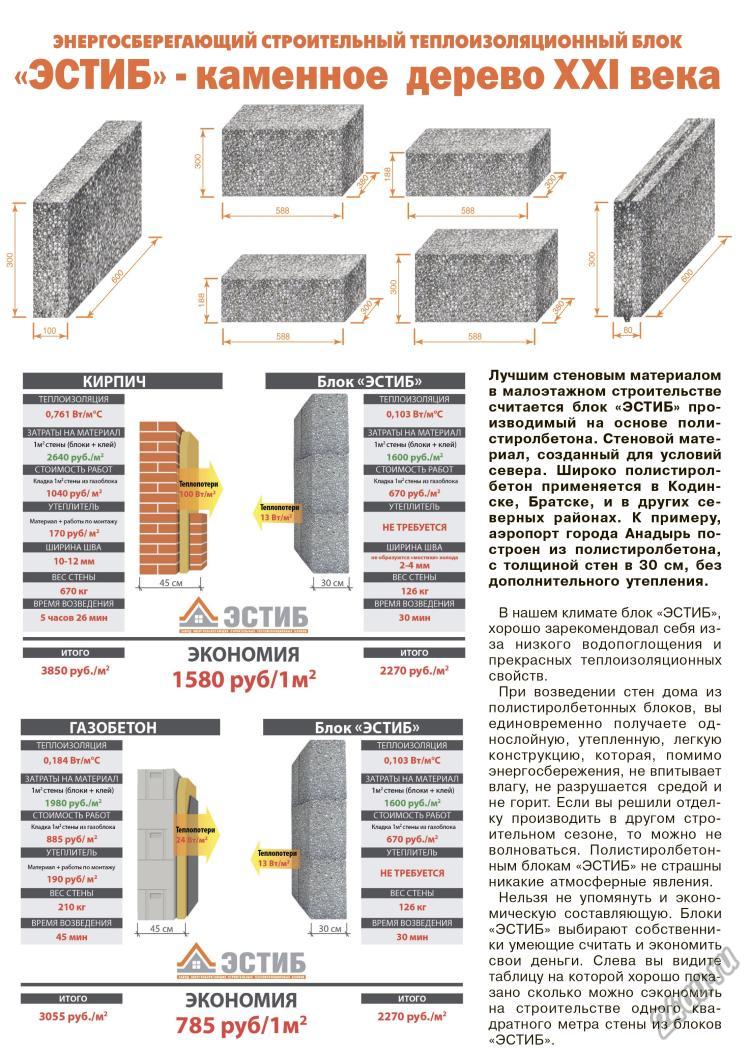

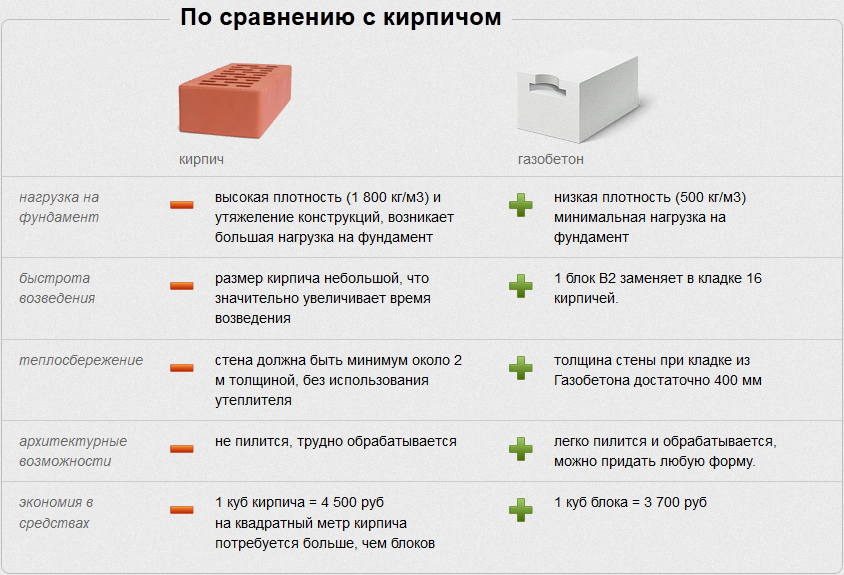

This heat-insulating ability of the material allows a wall with a thickness of only 30 cm to resist the penetration of cold as effectively as a meter-long brick.

When shipped to the consumer, wood concrete should not have a moisture content exceeding 25%.

The frost resistance of the material can be F 25 or F 50. In terms of resistance to biological damage, it belongs to the V group. Arbolite can withstand exposure to fire for up to 90 minutes.

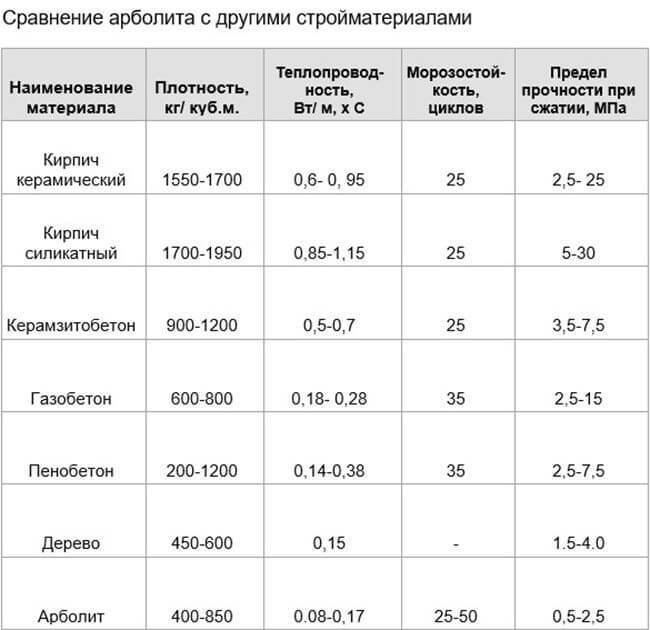

Comparison of wood concrete with other materials

Arbolite blocks can be reinforced. In this case, welded mesh or steel bars with a coating that protects against corrosion are used. The thickness of the concrete layer to the reinforcement should not be less than 1.5 cm. Embedded parts can also be installed in the wood concrete.

How is the reinforcement of wood concrete blocks carried out?

Advantages and disadvantages of wood concrete blocks

It should be noted that in the last century, wood concrete was used not only for the manufacture of wall blocks, but also in the form of sheets, which were used for insulation and sound insulation of floors.

Today, wood concrete is practically not used in this capacity, because its main advantages are revealed when erecting low-rise buildings. Let's list them in more detail.

- Low thermal conductivity

Wood concrete wall blocks belong to the category of effective heat-insulating materials. This is evidenced by the following fact: a wall made of wood concrete with a thickness of only 30 cm retains heat as well as a meter-thick brickwork.

Therefore, in the reviews of the owners of houses from wood concrete blocks, first of all, significant fuel savings are noted even in the coldest winters.

- Durability

The strength of wood concrete blocks directly depends on their density. For structural and heat-insulating wood concrete with a density of 600-650 kg / m3, it ranges from 20 to 35 kg / cm2.According to this indicator, arbolite practically does not differ from its main competitors - foam and aerated concrete.

An important plus is the plasticity of this material. This fact is explained by the fact that wood chips are included in the wood concrete blocks, which reinforce this material. Therefore, under load, wood concrete does not crack, but only slightly deforms without loss of integrity.

When building a house from wood concrete, you do not have to spend extra money and time on pouring a reinforced concrete belt, which is necessary for fragile walls made of gas and foam concrete blocks.

- Frost resistance

Arbolite has frost resistance (the number of freeze-thaw cycles in a water-saturated state) is from 25 to 50. In practice, this means that a house made of this material will stand for at least 50 years (confirmed by studies of existing buildings). In foam blocks, the resistance to freezing and thawing does not exceed 35 cycles.

Speaking about the advantages of wood concrete, it should also be said about its low carbonization shrinkage. This term denotes the process of loss of strength of cement stone due to reaction with atmospheric carbon dioxide, as a result of which soft chalk is obtained.

- Good sound insulation

For wood concrete blocks in the acoustic range from 125 to 2000 Hz, the sound absorption coefficient is from 0.17 to 0.6. For a brick, this indicator is almost four times worse. For wood, it is in the range from 0.06 to 0.1, which is also significantly less than that of wood concrete.

- A light weight

1 m3 of blocks made of structural and heat-insulating wood concrete weighs almost 3 times less than brick and almost 1.5 times less than expanded clay concrete. This allows you to significantly reduce the cost of building foundations for wood concrete walls.

- Environmental friendliness and durability

Timber concrete is one of the most environmentally friendly building materials, since it contains only natural ingredients - cement stone, wood chips, water, calcium chloride (used in the food industry) or ordinary milk of lime.

In the wall, this material behaves excellently, since it does not rot, is not afraid of mold and does not burn. In addition, wood concrete breathes well and regulates the air humidity in the room, absorbing excess moisture and giving it back in case of lack.

- Non-flammability

Arbolit belongs to the group of low-combustible materials (flammability group G1). In addition, wood concrete is hardly flammable (flammability group B1) and low-smoke material (D1).

- Ease of processing

Wood concrete can be easily processed with any mechanical tool. It can be sawed and drilled and holds nails and screws well. The rough surface of the blocks is an ideal base for applying plaster mortars without the use of reinforcing meshes.

The disadvantages of wood concrete blocks include the low accuracy of geometric dimensions. Therefore, walls made of this material require leveling with plaster solutions or sheet finishing materials (drywall, magnesite, lining, siding).

Since the technology of wood concrete production is based on the use of wood chips - a rather expensive material, the cost of wood concrete blocks exceeds the price of aerated concrete by an average of 15-20%.

Negative properties of wood concrete

Despite the abundance of useful qualities and properties, arbolite also has negative qualities that you need to know about in order to be able to take them into account. So, questions and doubts when choosing a building material can be caused by the following facts:

The presence on the market of a large number of low-quality products. The quality and objective characteristics of the material produced in artisanal conditions can neither be guaranteed nor even evaluated accurately, since it is very difficult to fulfill all the regulatory requirements for the technological process outside the factory production, while in the regions it is not always easy to find factory products on sale, since its volumes are not very large.

Instability of the geometric dimensions of the blocks. Inaccurate correspondences of the sizes and orientation of the surfaces of wood concrete blocks often cause problems during masonry, force an increase in the thickness of the seams, and this leads to excessive consumption of material, a decrease in the speed of work, and also deteriorates the general properties of the finished structure.The reason often lies in the use of manual labor in production. It is still possible to counter this drawback: it is recommended to use warm perlite mortars for laying, at the same time manufacturers are working to improve the accuracy of the geometry of the blocks by milling their surfaces.

Moisture permeability of unprotected surfaces There is an unconfirmed assumption that masonry made of wood concrete blocks, not covered with any protection, can be permeable even to high winds

But you can easily protect the structure from external influences by making an external surface finish.

Block price Since the production process of wood concrete blocks usually combines a not very high volume of production and a low degree of automation of the process, the cost of finished products can exceed that for foam concrete and aerated concrete blocks by one and a half times.

Limited choice of finishes. In fact, when working with structures made of wood concrete blocks, it is important to observe only one rule: to combine exclusively "breathing" finishes with wood concrete masonry.

What problems may arise during construction

- Strong, durable structures can be erected using only high-quality material produced according to Gost standards, in compliance with all production instructions. Unfortunately, the market is overflowing with goods of not very high quality, among which it is rather difficult to choose the right one.

- Lack of highly qualified specialists. An illiterate approach to construction and ignorance of the characteristics of the material negates all its positive characteristics. Using such blocks in construction, a bricklayer must observe many nuances that determine the quality of his work. For example: wetting the surface before applying the mortar, perfectly fine and even joint. It is difficult to find such a master. The demand for highly qualified professionals is great, and sometimes you have to postpone the construction time, just to wait for the right person or team.

- The impossibility of erecting a building from wood concrete slabs in conditions of high humidity without erecting a basement or pile foundation.

Starting construction in a lowland or on swampy soils, wood concrete houses must be raised above the soil level.

Comparison of the characteristics of wood concrete blocks with other building materials

In order to understand whether wood concrete blocks are suitable for construction, it is worth making a comparative analysis of the properties of the most popular building materials.

Comparison of the properties of wood concrete, timber, aerated concrete and brick:

| Material property | Brick | Cellular concrete | Wooden beams | Arbolit |

| The degree of difficulty of attaching a home structure to the wall | Special fasteners | Expensive special fasteners designed for work with fragile materials | Perfectly fastened with screws, nails, ordinary dowels | Excellent fastening with screws, nails, ordinary dowels |

| Construction and commissioning period | A long and expensive process, since insulation and finishing are required | Rapid wall erection. A lot of time is spent on external insulation of the facade. This is a time consuming and costly process. | Due to the shrinkage of the material after a year after construction, finishing work will be required | Fast wall erection, add. no insulation is required, finishing can be done immediately |

| Foundation cost | Expensive, massive | Expensive massive monolithic strip foundation | Economical, lightweight | Lightweight, economical |

| Microclimate at home | The organization of forced ventilation of the room will be required | Weak breathing | Removes increased humidity, breathes | Removes increased humidity, breathes |

| Flexural strength | Fragile, does not work on bending | Deprived of plasticity, brittle, gives massive cracks during foundation vibrations, does not tolerate transportation | Works well for bending | It works well for bending, does not crack when the foundation vibrates, it tolerates transportation perfectly |

| Biostability | Biostable | Biostable | Rots | 5 group of biostability |

| Fire resistance | Non-flammable material | Non-flammable material | Flammable | Fire does not support |

| Thermal conductivity, Watt / (m × ° С) | 0,560-0,850 | 0,140-0,320 | 0,150 | 0,07-0,17 |

| Density, kg / m³ | 1150-1950 | 200-1200 | 450-600 | 400-850 |

The vapor permeability of wood concrete blocks is only slightly less than that of wood. Thanks to this property, the humidity level in houses made of wood concrete is always optimal. The strength of wood concrete blocks does not depend on the degree of absorption and evaporation of moisture, therefore, during its transfer, the walls are not destroyed.

Comparison of wood concrete with other building materials

Helpful advice! When choosing products, pay attention to the sides of the products. If one of their ends is smooth, and all the others differ significantly from it, it is better to refuse to buy the proposed batch, since this sign indicates that the technology for the production of wood concrete was violated, and the cement simply flowed down

The quality of wood concrete is significantly influenced by the degree of sawdust drying. If only dry chips were used, then the value of the internal humidity of the blocks will never become critical, therefore, the wall erected from them will not be afraid of frosts. When wet sawdust was used, it is possible that after a few winters the wood concrete will begin to lose strength. After all at negative temperatures the water will freeze, increasing in volume, which, in turn, leads to the destruction of the binder.

Of the other practical properties of this material, it is worth highlighting:

- tensile loads are not terrible;

- mold and rot resistance;

- not afraid of fire.

Arbolite blocks can have a variety of shapes, so that during construction, you can do without adjusting and cutting conventional elements

Due to the latter property, the degree of fire hazard of wood concrete houses is closer to this indicator of stone and brick buildings than wooden structures. However, if a large-scale fire occurs inside a building, or it ends up in a large fire zone, the walls will lose a significant part of their strength. Reinforced concrete, stone and brick are less prone to such consequences, which cannot be said about other types of lightweight concrete.

Building material advantages

In Russia, the characteristics of wood concrete blocks are spelled out in GOST 19222-84 "Wood concrete and products from it". This document provides for the production of two types of blocks - thermal insulation (density up to 500 kg / m3) and structural (density 500-850 kg / m3). Chips are used for manufacturing softwood and hardwood, flax, straw. The general properties of wood concrete blocks, more often called simply wood concrete, are as follows:

- low thermal conductivity - 0.07-0.18 W / m;

- compressive strength grade - for heat-insulating wood concrete В 0-В 1.0, for constructional В 1.5-В 3.5;

- frost resistance - 25-50 cycles;

- flammability group G1 - slightly flammable, does not support combustion;

- plasticity - due to the high content of chips, the block does not break when bending, it is capable of restoring its original shape;

- vapor permeability;

- light weight - 3 times lighter than a brick of the same volume;

- environmental friendliness - does not emit harmful substances;

- resistant to decay and mold;

- low cost - up to 90% of the block weight is chips.

The technology for the production of wood concrete is quite simple, therefore, blocks of our own production are often used for the construction of individual residential buildings.

For the manufacture of blocks wood chips up to 40 mm long, 5-10 wide mm and thickness up to 3-5 mm are treated with additives to improve adhesion (water glass, calcium chloride or nitrate, aluminum sulfate), dried for a month or two, stirring regularly. Dry shavings are mixed with cement grade not lower than M 400, then poured with water and thoroughly mixed.To obtain chips of the required size, a special device is required; to obtain a high-quality mixture, a concrete mixer is used, for molding - a vibrating table and split forms.

The finished mixture is poured into a mold. By loading the form, you can achieve a more correct and uniform geometry of the products. After 3 days, the block is taken out and sent to ripening in a dry heated room. Blocks are easy to cut, sawn and drilled, hold nails perfectly.

Attention! It is allowed to build houses from wood concrete up to 7 m high, as a rule, this is a 2-storey or one-storey house with an attic.

To ensure the normalized resistance to heat transfer of enclosing structures, a wall with a thickness of 380 mm is sufficient, but in fact, masonry with a thickness of 300 mm is more often performed, with protection of the outer and inner surface of the wall with warm plaster on porous fillers.

The blocks are produced in several standard sizes, the most commonly used dimension is 500x250x300, the masonry is carried out with the dressing of the seams of each row. In addition to corpulent ones, they produce hollow products, products with a front finishing layer, and profile blocks for lintels.

Arbolit: what is it?

Wood concrete (wood concrete) is an arbolite, the name of which comes from the French word "tree" (arbre). The material is made of three components - from wood chips (spruce, larch, pine), cement and chemical additives. The fourth irreplaceable component is water.

Wood chips

90% of the composition is wood processing waste. The strength of this building material is to a greater extent depends on the type raw materials used for the production of wood concrete blocks. Wood chips must be properly dried and of a certain size. If we talk about the maximum, then these characteristics are as follows: thickness 5 mm, width 10 mm, length - 40 mm. However, the best indicators are 3-5 mm, 5-10 mm, up to 25 mm, respectively.

Coniferous trees are used more often, deciduous ones - less often. Flax fire, straw, cotton stalks, shavings or sawdust are raw materials that are undesirable for making wood concrete. The ideal is wood chips without the addition of leaves, bark or other similar impurities. The presence of the first 2 ingredients is permissible (5% leaves, up to 10% bark), but it is still not welcomed by builders.

It is not always that manufacturers engaged in the manufacture of wood concrete blocks without "interrupting production" (at sawmills, in other woodworking companies) strictly monitor the composition of products. Some of them add what is available to wood concrete blocks, so the quality of such building materials is often much lower than required.

Cement

For any construction work, it is recommended to choose sufficiently high-quality cement grades: at least M400. The reason for this is the loss of some of its properties during the storage period. Therefore, even the products coming from the factory, to some extent, do not correspond to their strength characteristics.

The requirements for the components of wood concrete, which is a light type of concrete, are stricter. In order for the building material to meet all the requirements, it is made from M500 cement. Such products guarantee sufficient strength.

Mineral supplements

In the production of wood concrete, it is allowed to use water glass, lime, aluminum sulfate (alumina sulfate, aluminum sulfate), lump silicate, calcium chloride. Mineralization is necessary to protect the material from biological threats, from the effects of moisture, to increase the adhesion of such dissimilar components.

Mineral additives are added to the water in advance. First, the liquid is mixed evenly with the chips for 20 seconds. Then cement is added to the semi-finished product, which is mixed with chips for longer - for 3 minutes.

Big difference: sawdust concrete and wood concrete

Some people call wood concrete sawdust concrete, but these are completely different materials. The main component of wood concrete is chips, and the second contains sawdust, which does not have reinforcing properties.

For this reason, products made from small waste are quickly deformed and destroyed. Another disadvantage of sawdust concrete is the addition of a larger (than necessary) proportion of sand. This violation of technology is the secret of unscrupulous manufacturers. The logical result of this "crime against humanity" is the crumbling walls of the house.

Arbolite blocks, price per piece of the most demanded types

Modern industry produces two types of wood concrete - structural and heat-insulating. The material of the second type is not used in the construction of external and internal walls, since it is characterized by a relatively low density and relatively low weight. It is successfully used to insulate buildings, residential buildings built of bricks, expanded clay concrete, as well as other building elements.

Structural-type blocks are required to create load-bearing walls. Their strength and density indicators are higher than those of similar products from heat-insulating wood concrete.

Comparative characteristics of heat-insulating and structural wood concrete:

| Wood concrete type | Application in construction | Compressive strength class | Strength, kg / cubic meter | Density, kg / cubic meter |

| Heat insulating | Wall insulation | B 0.35-1.5 | M5, M10, M15 | 400-500 |

| Structural | Erection of load-bearing walls | B1.5-B3.5 | M25, M35, M50 | 500-700 |

The most popular types of these products include wood concrete blocks of the following types:

Large wood concrete blocks are used for masonry walls subject to severe stress

small wood concrete blocks. They are mainly used for laying insulating rows and for erecting non-load-bearing lightweight walls. Block size - 190 × 190 × 300 mm. Grades - D500, D600. As for the price of wood concrete blocks of this type, it fluctuates around the mark of 60 rubles / piece.

Arbolite blocks: price depending on the scope

The cost of the product in question is also influenced by what it is used for, as well as the configuration of a single product.

Helpful advice! Buy wood concrete blocks, on the surface of which there is no white bloom. This is evidence of the addition of glue, which is not allowed by the technology.

Scheme of wood concrete blocks intended for insulation of wall structures

Consider the data on brands of wood concrete products with an indicator of 600-650 kg / m³. The indicators presented in the table are indicative, since they may differ in different regions of the country.

The cost of different types of blocks and their characteristics:

| Type of | Price for 1 cubic meter, rub. | Number of pieces in 1 cube | Approximate weight pcs / kg | Dimensions, mm |

| U-shaped block for with a recess for armpole or window lintels | 4900 (148.48 per 1 piece) | 33 | 12 | 500×200×300 |

| Partition | 5100 | 53,3 | 11,5 | 150×250×500 |

| 5000 | 40 | 15 | 200×250×500 | |

| Stenovoi | 4300 | 26,6 | 22,5 | 300×250×500 |

| 4200 | 20 | 30 | 400×250×500 |

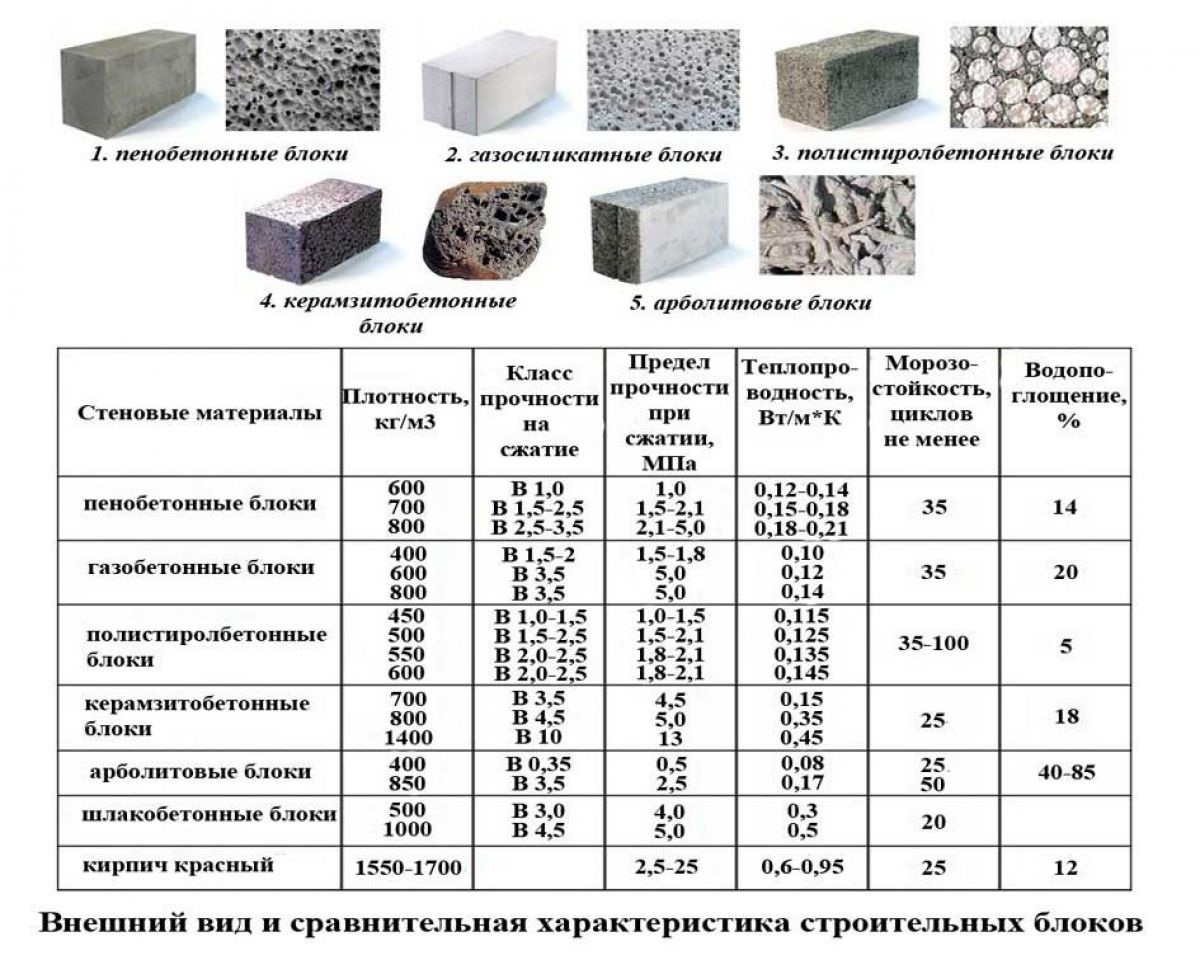

Specifications and comparison with other building blocks

Arbolit guarantees quite understandable disadvantages and advantages - the only unexpected moment may be the low quality of the material itself. If the blocks are made according to technology, from correctly selected components and in compliance with proportions, then all properties are quite predictable.

Basic technical characteristics of wood concrete:

- Density - in the range of 300-850 kg / m3 (depending on the type, because arbolite can be structural and heat-insulating): the higher the indicator, the higher the bearing capacity and the lower the thermal insulation indicator.

- Strength - depends on the density: for wood concrete with a density of 400-500 kg / m3 it is equal to B0.35, for 700-850 kg / m3 - B3.5. This is quite enough for the erection of load-bearing structures of a 2-3-storey building.

- Thermal conductivity - also directly depends on density, increases proportionally: for blocks with a density of 400 kg / m3, the indicator is 0.06 W / m K, at 850 kg / m3 the thermal conductivity coefficient is within 0.17.

- Water absorption - for heat-insulating blocks, the parameter is 85%, for structural blocks - 75%.Arbolite absorbs and gives up moisture during drying, but it is not recommended to use it where constantly high humidity is noted (or each wall of arbolite will have to be carefully plastered and covered with insulators).

- Fire resistance - the material is considered to be hardly combustible with a G1 index (capable of withstanding an open flame for an hour and a half without changing the geometry).

- Frost resistance - F50, which is equal to the number of freeze / thaw cycles.

- Resistance to stretching - when the foundation moves, it demonstrates the susceptibility to the appearance of deformations and cracks by 0.4-0.5%.

- High level of sound absorption.

- Good indicators of vapor permeability - wood concrete can be used for the construction of a sauna, bath.

If we compare wood concrete blocks with other building materials, then all the advantages and disadvantages become more obvious. Some parameters are indicated in the table:

Comparison of wood concrete with some materials:

Brick is more dense in structure and therefore more compressive strength. But wood concrete retains heat better: the indicators of a wall 50 centimeters thick are equal to the thickness of a brick wall in the region of 120 centimeters. At the same time, the dimensions of wood concrete are larger, so the laying is faster and easier.

Wood - the materials are similar in thermal conductivity and density, but natural wood is much more expensive, more difficult to transport and install, and requires more careful care. In addition, the wood rots and burns.

Foam concrete - the foam block also has a low weight and density, but due to the porous structure it implies additional costs for reinforcing the masonry, making the construction process longer and more complicated. The thermal insulation of wood concrete is 75% higher.

Additionally, you can see the parameters here:

Arbolite blocks production technology

Arbolit refers to lightweight concrete, the technology is almost standard, with the exception of some nuances: the need for pressing and using not an ordinary gravity concrete mixer during mixing, but a forced one. It mixes chips better with the rest of the components.

Composition

The wood concrete contains four components:

- high quality cement (M 400 or M 500);

- wood chips;

- water;

- chemical additives.

Wood concrete composition

The cement must be dry and fresh. Wood chips are of a certain size. The fewer the re-grading, the stronger the block will be. Chemical additives are calcium nitrate and chloride (food additive E509), water glass, aluminum sulphate and some other substances

Please note that they are first diluted in water and only then added to the chips, mixed. Any drinking water is allowed, but not technical, without contamination

After the chips are evenly wet, add cement. Another sequence is not valid.

Types and sizes of blocks

V density dependence wood concrete blocks are divided into thermal insulation (up to 500 kg / m3) and structural (from 500 kg / m3 to 850 kg / m3). For the construction of one-story houses, you can use the lightest of the structural ones with a density of 500 kg / m3. For detached houses with 1.5 and 2 floors, the minimum density is 600 kg / m3 and above.

The sizes of wood concrete blocks can be different. The most common - 500 * 200 mm and different thicknesses - from 100 mm to 400-500 mm. But different factories and workshops produce blocks of different sizes. Molds for them can be welded from ordinary sheet iron, so this is not a problem. The photo shows an example of the assortment of one of the shops.

Dimensions and weight of wood concrete blocks

As you can see, blocks of 600 * 200 mm and 600 * 250 mm also have a thickness from 100 to 500 mm. You can choose suitable for both load-bearing walls and interior partitions. Also, for self-production of wood concrete blocks, it will be possible to make a suitable shape. This is if you decide to do them yourself.

Proportions

Like any building material, wood concrete is divided into strength classes.For the construction of load-bearing walls of houses, the required strength class is B 2.5.

The number and proportions of wood concrete components, depending on the brand

The amount of materials required per cubic meter of wood concrete solution is in the table (photo above).

Pressing technology

All these components are mixed, from which blocks are formed. There are several technologies:

- just by pressing:

- manual on the floor (great effort required);

- manual rammer on a vibrating table.

- pressing with vibration on a vibrating machine.

The easiest way is manual pressing. But it is difficult to control the density and strength of the resulting blocks in this way.

Manual molding of wood concrete blocks

Normal production conditions

For the normal process of cement hydration, a temperature of at least + 12 ° C is required. There are no other conditions. The peculiarity of production is that after the block is formed, at least 2-3 weeks must pass before the start of its use. During this time, the cement will gain about 50-60% strength (depending on the temperature) and you can already work with the blocks. That is, the blocks must be made long before the start of construction. If we consider that the chips must be aged for at least 4 months before using them, then you can start a year before construction.

This is how you can store hand-made wood concrete blocks.

Another practical point: if you are going to make wood concrete blocks with your own hands, in addition to a platform for kneading and storing components, you need a platform for settling the blocks. The place should be covered, protected from rain and sun. There should be no drafts.

Properties and scope of wood concrete blocks

Arbolite blocks - a wall material of a group of lightweight concrete, used in low-rise (up to 3 floors) construction. Their standard size is 200x300x500 mm. Most manufacturers offer a wider range of sizes. Residential buildings, low-rise commercial buildings, technical buildings, and outbuildings are built from wood concrete blocks.

Residential buildings, commercial and technical buildings, outbuildings are built from wood concrete blocks.

Arbolite, as a building material, has a huge number of advantages:

- Low thermal conductivity;

- Minimum sound transmission;

- High vapor permeability;

- Biological resistance;

- Fire safety;

- Light weight;

- Convenient format;

- Environmental friendliness;

- Economy and ease of installation;

- Durability;

-

Low cost.

With the competent manufacture and use of wood concrete blocks, you will achieve savings on several cost items at once: a lightweight foundation, no additional thermal insulation, reduced heating costs, and a minimum of waste during construction.

The disadvantages of building materials include:

- The need for plastering walls, protection from water.

- The need to use special masonry compounds - "warm" perlite mortars.

- The ability to use only "breathable" finishing materials.

- Time required to manufacture a sufficient number of products.

-

Risk of damage to low-quality blocks by rodents.

What is the wood concrete made of?

For the production of wood concrete blocks, you will need the following components:

- wood chips;

- chemical additives;

- cement;

- water.

Requirements for the size of wood chips according to GOST - length up to 25 mm, width 5-10 mm, thickness 3-5 mm

You can take other size chips, shavings, sawdust. But remember that a too coarse fraction reduces the strength characteristics of the block, and a small fraction increases its thermal conductivity.

Usually the raw material is pure pine and spruce wood, sometimes deciduous species. Chips make up 80–90% of the total volume, so the material is often called wood concrete.

The wood concrete block is 80-90% wood, so it is easy to cut it with a chainsaw

The wood is well dried - moisture content no more than 23%. The inclusion of bark and wane up to 10% is allowed. Inclusion of leaves, needles, straw is undesirable.

A chemical additive is necessary for the mineralization of wood chips - the neutralization of sugars and resins contained in wood fibers. These natural substances interfere with the adhesion of the cement mortar to the wood and impair its bonding. For mineralization are used:

- sodium sulfate (liquid glass).

- sulphate aluminum.

- aluminum chloride.

- calcium chloride.

Chemical additives can be used individually or in pairs in a 1: 1 combination.

Cement should be taken only of the M500 brand, in extreme cases - M400. It has maximum binding properties, hydrophobicity and strength.