How to glue a mirror to a wall

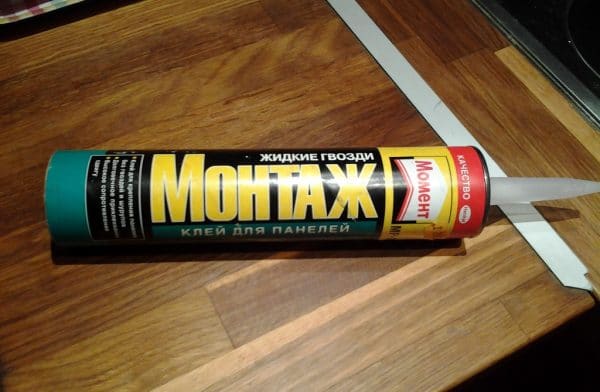

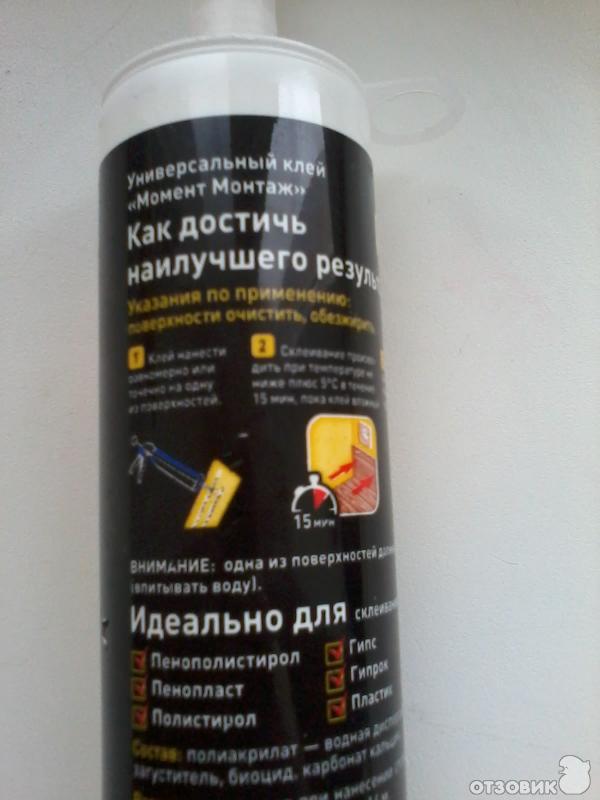

You don't need a hammer or nails to attach the mirror to the wall. We will use the "Moment montage" glue. It does not damage the amalgam coating of the mirror, waterproof, suitable for interior use.

We also need:

- assembly gun,

- stationery knife,

- stool,

- foam or other soft surface (we will put a mirror on it while applying glue),

- mirror.

Sticking is done only if both the wall and the mirror itself are dry.

Operating procedure:

- Cut off the spout from the tube of glue with a clerical knife.

- We turn the mirror over and put it face down on a stable surface (for example, a stool), after placing a soft material under it.

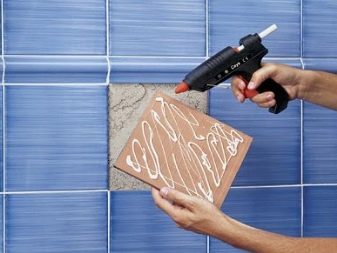

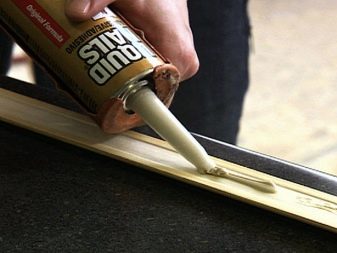

- We install the glue in the assembly gun and apply the composition to the mirror in strips over its entire surface.

- We press it against the wall and immediately tear it off. We are waiting for 3-4 minutes. This technique allows you to speed up the gluing process. It can be used with all solvent-based assembly adhesives.

- Put the mirror to the wall again. Since it is heavy, we use the "Super Tape Moment" for fixation. We glue several strips of tape along its surface, grabbing the wall. After a day, the tape can be removed.

VIDEO INSTRUCTION

How to glue a mirror to a cabinet door

What to glue the mirror to the tree? This question arises from the owners of cabinets who wished to attach it to the door.

The best results are obtained with a combination of silicone (or liquid nails) and double-sided tape.

You will also need to work:

- glass cleaner,

- clean cloth,

- 4 strips of fiberboard, 2-4 cm wide and slightly longer than the minimum size of the mirror.

Bonding procedure:

- Remove the door from its hinges and place it face up on the floor or table.

- We attach a mirror to the door and outline it around the perimeter. This is how we outline the place for gluing.

- We moisten the rags in a glass cleaner and wipe the door, then the back of the mirror.

- We glue strips of double-sided tape on the door with an indent from each other by 20 cm. The tape should not protrude beyond the applied markings.

- Between the strips of adhesive tape we lay the strips of fiberboard so that they do not touch each other. Apply silicone to areas free from adhesive tape and fiberboard.

- Remove the protective strips from the tape and apply a mirror.

- Independently or attracting an assistant, we hold him and take out the strips of fiberboard. We make sure that the mirror does not move out. It is more convenient to start pulling out the fiberboard from one side and move in order.

- We press it down so that the silicone spreads. We make sure that it is fixed.

- We install the cabinet door in place.

We glue the mirror on the tile glue

The question of how to glue a mirror on tile glue is asked by everyone who makes repairs in the bathroom.

- Before starting work, you need to choose a place where the mirror will hang.

- Next, it is carefully cleaned by removing the tiles in the area where the mirror will be located.

- At the next stage, this area is putty and leveled, then the bottom row of the border is glued.

- The adhesive is applied perpendicular to the curb to make the connection more durable. In thickness, it should match the thickness of the tile, on average it is 6-10 mm. Plastic crosses will help to make the seams even, which are fixed between the seams and left until the composition completely solidifies. Then the top row of the border is laid.

- It is recommended to nail a piece of wood to the wall to hold the top curb until the glue is completely dry.

- Then the side tiles are laid, removing excess glue from the surface.

- Now you can start installation.Be sure to leave a small gap between the mirror and the tile.

- The mirror is applied to the wall and pressed firmly. In this position, you need to keep it for about 15 minutes. After the adhesive has dried, grouting can be started.

If the object is heavy, tile glue is indispensable, liquid nails or glue and mirror sealant are needed. But not all are suitable, some corrode the amalgam, as a result of which spots and cloudiness appear on the surface.

A proven remedy is Multifix liquid nails, as well as PENOSIL Premium MirrorFix, which not only provide a strong elastic connection, but are also resistant to moisture.

Suitable mirror adhesives

A neutral silicone mirror sealant is a good option and is great for decorative fabrics.

It is only important to clarify whether there is a solvent in the product: some of them absolutely cannot be used for mirror surfaces, as they quickly destroy the reflective layer. Information on the suitability of a particular sealant is on the packaging.

As for the best brands of liquid nails that can be purchased for glueing mirrors, the following should be mentioned:

- MACROFLEX MF 930. Suitable for decorative, mosaic mirrors up to 6 mm thick when attached to concrete, glass, tiles. It is stable in a humid environment, tolerates temperature fluctuations up to -5 ... + 60 degrees, does not spoil the amalgam.

- KRASS "Liquid nails". Glues mirrors in any room, suitable for mirror tiles, including when attached to deformable substrates. It sets quickly, does not flow from vertical surfaces, has a high degree of adhesion.

- "Titanium for mirrors". Adhesive based on rubber, synthetic resins. It can glue mirrors of almost any thickness to drywall, wood, concrete, brick, metal. Does not provoke corrosion, does not spoil non-ferrous metal products. The elastic seam does not collapse from deformations, temperature changes.

B7000 glue - what is it

Glue b 7000 is a Chinese product, an updated version of the adhesive composition, based on epoxy resin, has a gel structure. It is chosen for repair work on touch screens of phones, it can also stick a new screen when replacing. In addition, they are glued to the details of display modules on smartphones. B 7000 transparent glue glues like double-sided tape, it has better fixation, but at the same time, if necessary, removing parts is simple.

But the application is not limited to the repair of gadgets, the B 7000 glue is widely used to glue ceramic, glass, leather, metal, wood and other materials.

The glue is chosen for repair work on touch screens of phones, it can also stick a new screen when replacing.

Where used, features

Glue B 7000 instructions for use say that the glued part will hold for a long period of time. This is a universal product, the required time for setting is 10-15 minutes, complete drying occurs in a day.

The composition is produced in several versions, differing in the volume of the tubes; containers with a volume of 15 to 110 milliliters can be found on sale. The tip is made thin, which is especially practical when working with small elements. To ensure reliable sealing of the tube, there is a special rod, this helps to prevent premature drying of the solution.

Description of the characteristics of the adhesive solution includes the following information:

- The glue seam is soft and elastic;

- Anti-vibration property;

- The characteristic viscosity avoids runoff of the product;

- Ease of use;

- B7000 glue, according to the instructions, quickly sets, it takes 3-7 minutes, complete drying occurs in a day or two;

- It has a low consumption, on average a 15 mm tube is enough for gluing 3 phones.

The tip is made thin, which is especially practical when working with small elements.

The tip is made thin, which is especially practical when working with small elements.

The composition can be used for a variety of bonding options, but it has found great popularity in the following areas:

- Repair work with touch screens of various gadgets. Experts note its convenience, and the ability to be easily dismantled; good adhesion to metal, plastic, glass materials is also appreciated;

- In the electronic field, it reliably glues wires, metal, plastic. At the same time, it does not conduct electricity, creates a sealed layer, is convenient for applying to small elements;

- In needlework, it firmly fixes various rhinestones, stones and other elements of jewelry;

- The elasticity and water resistance function allows the composition to be used in the shoe industry.

Also effectively copes with gluing neoprene, leather, bamboo, rubber, paper, cardboard, fabric, stone products.

The composition can be used for a variety of bonding options.

The composition can be used for a variety of bonding options.

Advantages and disadvantages of glue

It is easy and convenient to work with B7000 glue; a beginner can also handle this process. The solution is characterized by increased adhesion to completely different types of materials. Thanks to its thin tip, it is easy to apply to the smallest parts, so it is in demand for gluing elements that are small in size. You can also note a few more positive properties of the glue:

- Productivity. In case of an error, the layer can be easily removed; when heated to 80-100 degrees, it acquires a plastic property;

- Safe composition, no toxic substances are used in production;

- Easy to remove from skin, unlike the popular super glue;

- Does not spread;

- Anti-vibration property;

- The resulting layer is soft and elastic.

Of the negative qualities, it is possible to note the need to comply with safety measures; when working, you should wear a respirator and gloves. When heated, epoxy resin exudes harmful substances; after drying, the layer is absolutely harmless to human health.

The solution is characterized by increased adhesion to completely different types of materials.

The solution is characterized by increased adhesion to completely different types of materials.

How to use liquid nails: complete instructions

Regardless of the type of product, it is a viscous mass that is distributed over the surface. This can be done in two ways. Let's take a closer look at both.

We use a construction gun

This is the name of a special device into which a tube with an adhesive mixture is inserted. The task of the tool is to ensure that the paste is evenly and continuously applied to the substrate. Depending on the method of pressure on the paste, three types of assembly guns are distinguished:

- pneumatic;

- electrical;

- mechanical.

Instagram mironova_m_olga

The most convenient way to apply the glue is with a special gun.

It is important to ensure that the paste is evenly and continuously applied to the substrate. In everyday life, where the volume of work is small, mechanical equipment is used

The solution is supplied by pressing the piston by hand. When working with such a tool, you need to ensure that you press the piston evenly. Otherwise, the glue layer will be of different thickness. It is also important to correctly install the tube into the gun. This is done in the following sequence:

In everyday life, where the volume of work is small, mechanical equipment is used. The solution is supplied by pressing the piston by hand. When working with such a tool, you need to ensure that you press the piston evenly. Otherwise, the layer of glue will turn out to be of different thickness.

It is also important to correctly install the tube into the gun. This is done in the following sequence:

- We press on the locking lever located on the body of the device.

- The rod holding the cartridge is pulled back as far as it will go.

- We insert the container into the base of the instrument.

- We fix it in place with a locking lever.

- We install the dispenser on the neck. We cut off its tip at an angle of 45 °.

- We press several times on the button to start the mechanism. We do this until the mixture appears in the dispenser.

The gun is ready for use. An important point. There are three types of tools, so liquid nails in suitable packaging are selected to work with them. It can be soft or hard.

Instagram stors_3

Instagram stors_3

Construction gun cartridges. To work with the device, select liquid nails in suitable packaging

We work without special devices

For various reasons, it may not be possible to use a construction gun. You can do without it. But one must understand that it is unlikely that it will be possible to apply the drug evenly. And the process itself will be complicated. If the packaging is rigid, in the form of a tube, we proceed as follows:

- We select a round flat object of diameter suitable for the bottom of the cartridge, for example, a bottle cap. We will use it as a piston.

- We put our device on the bottom of the tube.

- Install the dispenser in place, if required, and open it.

- We take the handle of a hammer or something similar and press on the homemade piston, squeezing out a portion of the solution.

You need to act very carefully so as not to crush the walls of the cartridge. They can be made of plastic or cardboard. The latter option is especially fragile. If the walls are damaged, further use of the tube is impossible. If the packaging is soft, you need to carefully make a hole through which to squeeze the paste. In this case, it is impossible to regulate how much mass comes out of the container. The seam is very uneven.

Instagram budni_gaechki

Such packaging of liquid nails does not require special application devices. If the packaging is soft, you need to carefully make a hole through which to squeeze out the paste.

To properly connect surfaces with an adhesive mixture, regardless of the method of application, you need to follow the instructions:

- The parts to be glued are thoroughly cleaned of dust and dirt, degreased with any suitable means.

- Glue is applied to the base. It is applied with a mesh, dotted, snake or solid canvas.

- We give the processed elements the required position and strongly press them against each other. We hold in this state for about two to three minutes.

- Leave until complete adhesion. On average, it takes a day.

You can find out exactly how long liquid nails dry by looking at the information on the cartridge. Here, the manufacturer indicates all the features of using this particular type of mixture. Therefore, before starting work, you should always read the recommendations and follow them. In any case, mechanical action must be completely excluded, especially with effort until the composition is completely cured.

Instagram stroysmatom

Instagram stroysmatom

You can work with glue outside, but only at a positive air temperature

Advantages and disadvantages of liquid nails

What is guaranteed with the correct use of liquid nails:

- Reliable adhesion of the same and different materials.

- A wide range of gluing surfaces: ceramics, metal, wood, plaster, plastic, glass, polyethylene, brick.

- The adhesion of the surfaces to each other is very tight, this cannot be achieved with ordinary nails. The paste fills in gaps if the surfaces are not completely adjacent to each other.

- Organosoluble varieties withstand moisture, high temperatures and physical activity well (up to 90 kg per 1 cm2).

- The material is equally successfully used in construction, repair work and everyday life, as well as in creativity.

- Over time, the appearance of the glue line remains neat.

- Affordable price comparable to the result.

Disadvantages of liquid nails:

- Organically soluble formulations give off a strong and unpleasant odor. It provokes a headache, the composition can damage the skin.Always wear protective gloves, do not neglect a respirator!

- Organosoluble glue is flammable both during operation and after hardening.

- Often a pistol is required for neat work - an expensive repair technique.

- Water-soluble liquid nails do not tolerate freezing and thawing, as well as high humidity.

How to choose?

The choice of liquid nails is recommended according to the following criteria:

Composition

Depending on the purpose of the composition, you should choose acrylic or rubber liquid nails. The former are optimal for lightweight materials used indoors at normal humidity. In all other cases, it is better to opt for a rubber-based analogue.

Scope of use

This criterion is largely related to the previous one. For domestic use, general purpose liquid nails are usually sufficient. For bathrooms, kitchens and other rooms with high air humidity, as well as for outdoor use, only moisture-resistant compounds should be selected.

Special glue is also required for fixing the expanded polystyrene. Other types may contain additives that destroy the material.

Setting speed

In most cases, this criterion is not the main one when buying liquid nails. However, when it comes to gluing tiles to ceilings and similar surfaces, it is better to choose an adhesive with a higher setting speed.

Type and weight of glued surfaces

Universal compositions are suitable for solving most construction and repair tasks, but in some cases it is better to use specialized analogs, taking into account the characteristics of the material of the elements

It is important to take into account the weight of the products, correlating it with the strength of the glue. The greater the mass of the products to be glued, the higher the load-carrying coefficient should be.

When choosing liquid nails, it is important to pay attention to material compatibility. So, water-soluble polyurethane-based compounds are not recommended for gluing polyethylene and Teflon surfaces. Acrylic compounds are best used on porous substrates.

When buying, you should pay attention to the shelf life and storage conditions. The first usually does not exceed 12 months if stored at a temperature of -5 ... +30 degrees. Do not allow freezing of the product, its contact with water. When exposed to direct sunlight, the composition stratifies

Acrylics are best used on porous substrates. When buying, you should pay attention to the shelf life and storage conditions. The first usually does not exceed 12 months if stored at a temperature of -5 ... +30 degrees. Do not allow freezing of the product, its contact with water. When exposed to direct sunlight, the composition stratifies.

Choosing reliable glue liquid nails - an overview of proven options

When choosing the most suitable brand of adhesive, consider the following:

- What materials need to be glued;

- What kind of load will the glue line experience;

- In what conditions will the glued product be used (inside or outside the room).

Today, the most popular among professionals is liquid nails from such manufacturers as: Moment (Henkel), Titebond, Makrofix, TYTAN, Krass, Kim Tec, Liquid Nails, Kraftool, Titebond, Quadro.

The following brands enjoy a very good reputation:

Glue Moment Installation MV 50 liquid nails - universal moisture-resistant express glue based on water dispersion (polyacrylate).

Perfect for joining different surfaces (wood, styrofoam, metal, plastic, ceramics, chipboard, MDF, cork coverings, polystyrene, gypsum, etc.) when carrying out installation work inside and outside the room.

Ideal for gluing plastic and wooden skirting boards and other decorative elements, various profiles and panels indoors.

Adhesive liquid nails Titan Professional 901 - heavy-duty construction and assembly adhesive based on hydrocarbon solvents.

Provides fast and durable bonding of various types of surfaces (wood, metal, ceramics, concrete, plastic, stone, etc.). Resistant to temperature extremes, high humidity.

Suitable for outdoor use (frost resistant). Titanium Professional 901 is suitable for bonding heavy decorative elements and building materials.

Krass Extra Durable - specialized liquid nails for quick installation of plastic and tiles.

It is considered one of the best options for mounting heavy and light elements made of plastic (polystyrene, PVC), chipboard, MDF, ceramics, plaster, plywood, stone, metal.

Suitable for use in damp rooms, has excellent adhesion.

Comparison table of popular brands:

| Glue brand | Volume | Advantages | Price |

| Moment Installation MV 50 | 125 grams.; 250 grams.; 400 grams. | quick-setting, solvent-free, white. | about 300 rubles for 400 grams. |

| Titanium Professional 901 | 380 grams. | strong initial adhesion, forms an elastic seam, suitable for gluing heavy products. | about 100 rubles. |

| Krass Heavy-duty assembly | 300 grams. | convenient to apply on vertical surfaces, elastic, non-shrinking, odorless. | about 200 rubles. |

Instructions - how to properly glue with liquid nails using the example of PVC panels

Most often, liquid nails are used to attach PVC panels to walls and ceilings.

This method of installation eliminates drilling; moreover, there are no traces of fasteners on the front surface of the panels.

How to glue PVC panels on liquid nails KRASS "Extra strong installation"?

For this you need:

- Prepare the surfaces to be glued beforehand - they must be clean, dry and free from grease.

- Remove the protective cap from the tube, cut the plastic tip closer to the thread.

- Insert the glue tube into the assembly gun.

- Apply glue to the material to be glued in thin strips of the same thickness with an interval of several centimeters (depending on the weight of the product) or pointwise.

- Lean the PVC panel against the wall / ceiling, press down and fix for a few seconds. To correct the position of the panel, do not peel off the material, but carefully move it. It is recommended to additionally fix heavy elements with support structures until the glue is completely dry (24-72 hours).

- Immediately after completion of work, the tools should be cleaned of glue with warm water.

VIDEO REVIEW

Frequently asked questions

How to use a glue gun for liquid nails?

This is not difficult. It is only necessary to insert the tube into the gun body, having previously pushed the rod outward, and cut off the tip of the tube.

When the trigger is pulled, the rod is set in motion, creating pressure on the piston inside the tube. The glue is squeezed out through the hole. The intensity of pressing regulates the supply of glue.

What is the consumption of glue liquid nails per 1m2?

Average consumption is about 200 grams of glue per square meter of decorative panels. When gluing narrow profiles and panels, the average consumption is 20-40 grams per meter.

How long does liquid nail glue dry?

The time for complete curing of the glue is usually 24-48 hours (depending on the thickness of the applied glue), the setting time is usually 20-40 minutes.

Appointment

Liquid nails are usually used for bonding metal, wood and chipboard surfaces, glass and mirrors, as well as plasterboard structures. You can connect both homogeneous and dissimilar, as well as loose-fitting bases.

Liquid nails are widely used in renovation work - heavy wallpaper (for example, bamboo or cork wallpaper, soft wall panels), ceramic tiles can be fixed on them.At the same time, the reliability of adhesion when using liquid nails will be higher than traditional masonry compounds demonstrate.

The only drawback is the higher cost of liquid nails, so they are best used for cladding small surfaces. For laying tiles on large areas, it is more rational, of course, to use classic masonry mixtures. Liquid nails are often used to glue ceiling panels, and can also be used to fix baseboards or moldings. For these purposes, it is better to use quick-setting plastic compounds.

Some manufacturers use liquid nails as a sealant to fill gaps in wall surfaces, between walls and floors, and in window and door openings. In principle, this is possible, however, sealants are elastic, which cannot be said about liquid nails. In theory, of course, you can use them as sealants. However, practice shows that it is undesirable to do this. Liquid nails are also suitable for mirrors, but they should not contain components that destroy amalgam. As a rule, these are silicone-based formulations.

Only neoprene liquid nails with increased strength are suitable for bonding metal and concrete substrates (they must withstand a load of up to 80 kg / m2). They are also used for fixing large or heavy wooden surfaces, for example, for gluing laminate to the wall. This is one of the technologies for zoning a room, obtaining the necessary visual effect.

For gluing some floor materials - linoleum, carpet, liquid nails can also be used. True, this can be too expensive, in addition, a special ultra-strong, vibration-resistant composition will be required.

Liquid nails are often used in combination with metal hardware and are even used to protect the latter from corrosion.