Which drill to choose for home + (Video)

Before you buy a drill for your home, it is important to pay attention to the following points:

1) If the drill is intended for doing work around the house or apartment, then it is best to purchase the household version. It has a low cost and can also be used as a versatile tool.

2) Manufacturer

It doesn't matter if you are planning to buy a drill for home use or for professional use, the main thing is to pay attention to the manufacturer's company. German firms are popular, which are characterized by the high cost of products. Russian models are the most popular, which perfectly combine "price and quality", but products from China often fail, although their cost is identical to domestic models

Russian models are the most popular, which perfectly combine "price and quality", but products from China often fail, although their cost is identical to domestic models.

3) When choosing, it is important to pay attention to the length of the cord for connecting to the network. If the living space is small, then the cord should be 2-3 meters

4) The presence of additional devices in the case. For a household drill, this is a very important point, otherwise, after purchasing a tool, you will need to constantly visit stores to pick up drills, bits and other replacement parts. The cost of the kit will be an order of magnitude higher, but all the components will be conveniently located together with the tool and you will not need to look for them to drill one hole

Please note that the kit contains a rich stock of accessories

In this article, we learned: how to choose an electric drill, what are the types of drills, the advantages of one drill over another

Now, choosing a drill for your home will not be difficult, because you know what to compare with and what to pay attention to. Therefore, summing up, it should be noted that it is better to overpay once and buy a high-quality drill than to skimp and change the tool every year.

What is the difference between a wrench and a screwdriver. The difference between a screwdriver and a nutrunner Selection of tools by manufacturer

Is a hand held power tool. It is designed for faster and more convenient tightening of various fasteners. The screwdriver is one of the specialized tools. Its main competitor, rechargeable drill-screwdriver on the contrary, it is considered a universal tool. The difference between them is that the cylindrical drill chuck is able to hold the tip of the drill (cylindrical shape), and bit shank (hex forms). The screwdriver is equipped exclusively with hex nests. It is because of its versatility that the cordless drill is used much more often. Manufacturers specifically provided for two speed modes in it: big (drilling) and small (tightening the fasteners). As you know, low speed creates high torque. The screwdriver is much less functional. For home use, it is better to prefer a drill - after all, it combines the functions of both a drill and a screwdriver. You should think about purchasing a screwdriver if you have to regularly deal with fasteners.

There are two main types of screwdrivers - rechargeable and network .

Battery: speed and compactness

The cordless screwdriver is small in size. Its design has a lot in common with a cordless drill.The screwdriver battery is located at the bottom of the handle. At the same time, it performs a supporting function. Many models are equipped with a special clutch that adjusts the maximum tightening torque.

For work with small fasteners or in tight spaces, a cordless screwdriver, a kind of screwdriver, has been created. Its main difference lies in its smaller dimensions. The power of the cordless screwdriver is also low. Its main advantages are compactness and high speed screwing fasteners.

Both cordless screwdrivers and cordless screwdrivers are applicable in industrial production and in households. Unsurprisingly, battery-powered tools are far more popular than their online counterparts.

Mains supply: power and reliability

The mains screwdriver is powered from the mains. Outwardly, it is almost indistinguishable from a power drill. Just like the battery counterpart, it is designed exclusively for use with fasteners. If a cordless screwdriver can be used both at home and at work, then power screwdriver intended only for professionals ... It is designed for long-term, trouble-free operation. No household needs to tighten many fasteners every day. Some network models are produced without torque adjusting couplings.

During work, difficult situations are often encountered when using only a wrench becomes clearly insufficient. Then you have to pick up special tools: they help in working with parts that have a thread. Among them are the screwdriver and the nutrunner. These technical devices serve one purpose - to speed up work associated with a large number of nuts, bolts and screws. At the same time, despite the similarity of the tasks being solved, they also have a number of significant differences. You can find out about this and which of the tools is better to use from the review below.

A screwdriver is an electric tool, the main purpose of which is to carry out work on screwing or unscrewing various screws, bolts and self-tapping screws. One can only imagine how long it will take to screw in a few hundred screws by hand when assembling, for example, a regular built-in cabinet for things or shelves for tools. With this device, all work will take a few minutes. In addition, this power tool has several other additional features:

- use as a cordless drill;

- replacement using special nozzles of conventional hex keys;

- backlight function in poor visibility conditions.

An electric screwdriver is also convenient in that it can drive screws to a given depth. Therefore, all screw heads will be located in the same plane, which will give the work a beautiful and finished look.

Choosing torque, impact and drills for a drill driver

Is it worth taking a powerful device or is it better to save money, you need a blow or not, why do you need to work with large drills at all? Now we will tell you how to choose a cordless screwdriver for your home, relying on its characteristics and numbers, which are written in the technical data sheet of this product.

"Why does a goat need a button accordion" or why does a cordless drill have a kick function? This question is asked by many, since there are always doubts about the relevance of loading light hand tools with such technologies. You pay extra about 1000 rubles and you already have an impact screwdriver. It is heavier, more massive, but it still will not be able to make many holes in concrete, for this you need a puncher, and constantly depriving yourself of comfort for the sake of a couple of holes is a dubious pleasure.

Photo of impact drill-screwdriver

Now about the torque - this is already important.14-24 Nm is suitable for the installation of lightweight structures made of plasterboard, plywood, OSB boards

If you need to work with thick boards, drill ceramics or concrete with a crown, then it is better to take 36 Nm. If you doubt which is a good screwdriver and which is not - judge from the torque, it decides a lot. If it is more than 36 Nm, then it is suitable for drilling metal and working with large drills.

Now a little about the diameter of the drills. Even if you bought a cordless screwdriver with the characteristics of a cordless drill, it will not replace it. You should not take tools with a torque of 80-120 Nm in the hope of working with 10-12 mm drills in metal - it will still not pull, besides, its cost will be 5 times more than a simple cordless screwdriver and a simple power drill combined ... Is it worth it?

As for the rpm, this is not so important, since the standard 1400 rpm is enough for everyone, and professional models that run at 2400 or more are already overkill and are necessary only in very specific situations when the tool is used for non-standard solutions. We told you which cordless drill to choose and what characteristics you need to look at

But there is one very important point. Where is the confidence that the numbers are correct? Many Chinese and even European manufacturers overestimate the data to make the instrument more attractive to the consumer. As a result, you read a lot of literature, ask a neighbor or friend how to choose a drill-cordless screwdriver, buy equipment with KM 80 Nm, shock, cool battery, high speed, and you get a useless piece of iron. To do this, you also need to get acquainted with the manufacturers

We told you which cordless drill to choose and what characteristics you need to look at. But there is one very important point. Where is the confidence that the numbers are correct? Many Chinese and even European manufacturers overestimate the data to make the instrument more attractive to the consumer. As a result, you read a lot of literature, ask a neighbor or friend how to choose a cordless drill / screwdriver, buy equipment with KM 80 Nm, shock, cool battery, high speed, and you get a useless piece of iron. To do this, you also need to get acquainted with the manufacturers.

Choosing a battery for a screwdriver

Now let's talk a little about the power source, since it is very important and the duration of operation, comfort at the construction site, and the weight of the device depend on it. Of course, you can buy several batteries at once and change them, but the issue of battery longevity, voltage, frost resistance and self-discharge has not been removed from the agenda. What are the parameters for choosing a cordless screwdriver and a battery for it in this case? Consider the main types of autonomous power supplies.

Nickel cadmium batteries. The advantages include their maximum resistance to full discharge - they can be stored for a long time and nothing will happen to them. It is very convenient to take it with you on departure, where there may be no electricity for 2-3 days and there is nothing to charge (summer cottage). They can also be in the cold and are inexpensive, which makes them attractive to the consumer, but there are also disadvantages:

- Batteries last no more than 1000 cycles and have a small capacity.

- It must be completely discharged, otherwise it will work much less the next time it is used.

- Self-discharge is high. In 5-7 days, the battery runs out completely, be prepared for surprises.

Batteries remain popular only due to the fact that their cost is one level lower, but if you need a reliable professional screwdriver, then this option is clearly not for you - too often it fails. In addition, the weight also leaves much to be desired.

Nickel metal hydride batteries.The advantages of this type of batteries are: high capacity, small dimensions of products, practically no memory of the charge (can be recharged in half) and environmental friendliness. It would seem that a reliable home screwdriver can already be with such a power source, but now let's consider the disadvantages:

- funerals can be organized after just 500 recharging cycles;

- the cost of a screwdriver with a nickel-metal hydride battery will not please you;

- it also discharges quickly, about 10% of the charge is lost within 1 day;

- it is impossible to store a "killed" battery, it must be charged;

- this "Chinese comrade" is very afraid of frost, apparently they did not count on being exploited in Russia.

Fortunately, it is quite difficult to find such a battery now, so even an inexpensive and reliable screwdriver already comes mainly with lithium-ion sources, and these "miracles" have faded into the background.

Lithium-ion batteries. Traditionally, let's start with the advantages of these products: the specific capacity at a height, in comparison with the previous models, can be recharged whenever you want, regardless of the residual battery charge, they also do not discharge almost (no more than 20% can go away in one year). Despite this, the batteries charge very quickly, depending on the model, from 30 minutes to about 2 hours. The shelf life is about 2000-3000 cycles, although it is rather difficult to measure - tenacious. If you are looking for the most reliable and inexpensive screwdriver, then it will definitely be on a lithium-ion battery, although cost is already the second question. Disadvantages:

- Doesn't like big frosts (actually, nothing likes them ...).

- It is worth a level more expensive than its predecessors.

- There must be a minimum charge control system, otherwise it will be impossible to charge when fully discharged.

Now let's answer the question, which is better to choose a cordless screwdriver. If you drill a lot - overpay and buy a lithium-ion battery, this is definitely better, but if you take it for a house to twist something or make a ceiling one-time - get a lithium-cadmium battery, it is much cheaper. As for the capacity, everything is individual. Some 1.3 Ah is enough, others need more power to drill for 5-6 hours, but then you will have to carry a heavy tool. Our advice: it is better to buy a spare light battery if 1.3 Ah is not enough.

Pros and cons of a wrench

A significant advantage of the nutrunner lies in its ability to tighten fasteners with increased force and untwist rusted joints. This tool becomes an excellent assistant when working with large equipment. Unfortunately, the increased power of the instrument makes it more noisy. If you can work quietly with a screwdriver after rebound, then the wrench will quickly make itself felt.

To twist small elements with a wrench, you need to have a certain skill, otherwise there is a high risk of damage to the material. With a screwdriver in this regard, everything is much more convenient, albeit longer. The tuned ratchet mechanism will not allow you to twist the self-tapping screw, setting its head exactly on the surface of the material.

Summing up, we can say that the impact wrench is a powerful and noisy tool designed for tightening large fasteners. Suitable for domestic needs, but not everyone needs it. The screwdriver works at a lower speed. At the same time, it is very easy to use and does not require special skills and adapters.

Output: The wrench is needed for those who know exactly where they will use it. The screwdriver is suitable for most household jobs.

Cordless impact drill

Probably, many have an idea of what an impact drill is. A conventional drill is a tool designed to drill holes in tough materials. It can be manual, pneumatic or electric. Among the home craftsmen, the most common device is with an electric drive.Today, these drills have the additional battery and impact capacity that should help or accelerate the drilling of a hole in a stubborn wall. With the help of special nozzles, this electrical appliance can unscrew or tighten fasteners, which include bolts, nuts, screws or self-tapping screws. However, this is not easy to do because the machine torque is too high, even if the rotational speed is set to low.

An impact drill has the same properties as a conventional drill, but has the ability to move the rotary body along its axis. This means that when drilling materials such as high-strength concrete, this function must be applied, and then the drill not only rotates the drill, but also makes a large number of hits with it.

What is an impulse screwdriver

Many screwdrivers have a pulse mode of operation. It is expressed in the fact that the twisting occurs intermittently, tangential impacts or measured jerks. This makes it easier to drill holes on smooth and hard surfaces, because the drill will not go to the side. With the help of such equipment, it will be possible to easily unscrew or screw in a screw that has a damaged slot.

The impulse mode is found not only in screwdrivers, but also in impact wrenches, as well as screwdrivers, which are specially designed to create a tangential impact. The impulse screwdriver is able to work equally effectively with nuts and rusted bolts, as well as parts made of soft materials such as brass.

If we consider the diagram of such devices, then it almost does not differ from standard electric drills. There is a motor and a gearbox with the help of which the equipment transmits torque in the process of unscrewing the screws to the chuck. The same applies to conventional drilling. At the moment of increasing resistance to rotation, the equipment switches to the shock-impulse mode automatically, where the impact mechanism is used. A feature of the shock-impulse mode is that with the help of frequent and sharp impulses it is possible to reduce inhibition. The torque increases, while the rotational speed of the chuck decreases.

The impulse screwdriver allows you to solve a wide range of problems, while it is possible to achieve high speed and efficiency. But this tool also has some drawbacks. They are very noisy, which is especially true for 18-volt screwdrivers, because their operation is accompanied by a rapid rotation of the chuck. Quite often, when choosing a screwdriver, home craftsmen wonder how a percussion instrument differs from an impulse one. The latter was discussed above. As for the impact mode, it features an axial impact rotation, which is similar to an impact drill. With this technique, you can more effectively drill holes in brick, concrete and other building materials.

Comparing screwdriver and drill

Screwdriver

In a screwdriver, one of the most important parameters is the maximum torque.

High rotational speed is not required.

Under normal conditions, two to three hundred revolutions per minute are sufficient.

Sometimes a gearbox is installed to reduce speed and increase torque.

This is done using a special regulator.

They are given the force required to tighten a specific type of screw or screw, to avoid their deformation.

A screwdriver usually has a reverse to unscrew screws or free from jamming.

It can have multiple speeds, overload protection. There are screwdrivers on sale, supplemented with a drilling function. The main thing that distinguishes a screwdriver from a drill-screwdriver is the presence of a release clutch, which regulates the twisting force, it does not allow you to tighten the screw deeper than you need to.

The difference is also in the holder.If the screwdriver assumes the use of a bit of the desired size with a hex shank, then a keyless chuck for a round drill is used in the drill.

The drill, regardless of the presence of adjustment, cannot ensure the accuracy of tightening, as a result, the head of the fastener or the screwing nozzle itself may be damaged.

The most common electric screwdrivers and drills can be powered from the mains and the battery. More powerful drills use mains electricity. Especially when it comes to a tool with an impact function, where rotary and reciprocating movements are combined.

When using cordless power tools, the advantage of screwdrivers is clear. With the same charge and voltage, they show an advantage over a drill. This is determined by their technical parameters, primarily the maximum torque.

Most often, household products have nickel-cadmium batteries. Their peculiarity is that they need to be discharged "to zero" and charged to full charge.

Advantages and disadvantages of an impact screwdriver

Advantages

So, let's start with the advantages of an impact screwdriver, and there are many of them:

- Directional impacts of the tool create a torque of up to 80-250 N / m, which allows the drill to go through a difficult area in a wall, for example, drill through a stone. At the same time, the screwdriver is compact, and it is not necessary to press on it, unlike an impact drill.

- The impact driver easily drives long self-tapping screws and screws even into dense woods, without pre-drilling. Thus, the productivity of the work is obviously increased.

- When tightening the fasteners, the impact screwdriver does not deform it, which will allow later to unscrew the fasteners without any problems.

- An impact screwdriver, when changing a nozzle, turns into a rather powerful nutrunner, which is capable of unscrewing even a stuck bolt or nut. In this case, the percussion function on some models turns on automatically when the instrument encounters difficulty in movement.

Disadvantages of an impact screwdriver

Unfortunately, this tool has some drawbacks, however, they are not so significant:

- The high speed of the screwdriver is possible only in the shockless mode, with the blows the revolutions are significantly reduced.

- The chuck for the impact screwdriver is not required anyhow, but only a hexagonal one.

- Cheap models are usually not equipped with a force limiter, therefore, when screwing in fasteners, you have to be careful not to twist or tighten a self-tapping screw or screw.

How to make a wrench from a screwdriver

Save this page in your social. network and return to it at a convenient time.

In some everyday situations, it is quite difficult to get by with a wrench. Then devices come to the rescue that help to assemble and disassemble threaded devices. One of those is a wrench. They have one task - to help when working with fixing parts - but there are also a lot of differences. We propose to consider the main differences between the devices, find out which is more convenient to use, and how you can upgrade an old screwdriver to a nutrunner.

A wrench, unlike a screwdriver, is considered a more professional tool. By method of application mechanism for nuts happens: gasoline, pneumatic, hydraulic and work from the mains. It is designed for screwing in or out bolts or nuts. Unlike a screwdriver, a chuck is not attached to the nutrunner. A rod with a nut head is installed in its place.

The second difference is in the twisting power, here the wrench has an advantage. With it you can “master” any crafts.

Another difference lies in the volume and weight of the mechanisms, for example, not every person can lift some wrenches. Also, screwdrivers are able to regulate their work process, while another representative of mechanics does not have this opportunity.The nutrunner copes with complex tasks no faster than the screwdriver, which creates a lot of noise during operation - this fact is the key difference. In such a situation, equipped with a 3-speed gearbox, the screwdriver in light tasks is able to replace any device for tightening nuts.

In terms of operational capabilities, the nut mechanism has serious limitations. Good to use when drilling. So, for soft wood, it is not necessary to use a professional mechanism; you can get by with a tool for screwing in screws.

What is better wrench or screwdriver?

Given the many functions of a screwdriver, it performs a wider range of work, which is what wins over a nutrunner. In many cases, it replaces the nut device, performs the simple work of a wrench. The screwdriver works even more accurately: the tangential impact of a professional wrench, although it works quickly, the screws do not withstand the stress and can fly out of the building material.

Advice:

From the outside, the nut mechanism looks like a conventional drill, and its holder is equipped with an extension attachment.

The impact wrench becomes indispensable during large construction works, when working with cars, ships, airplanes and other units. A device for screwing in self-tapping screws and screws is often used at home for furniture repair. Since such a mechanism is free of mains power, the use of a wrench is often grown up.

Benefits of an impact screwdriver

By purchasing this power tool, you greatly facilitate your work at home or in the workshop, and on a production scale it is simply irreplaceable.

Let's consider the main advantages of the tool:

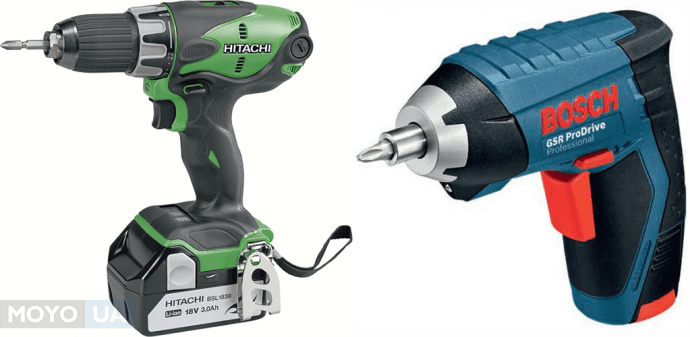

Impact drill screwdriver HITACH

- it completely replaces the screwdriver;

- using an impact screwdriver, you can tighten or unscrew any nuts and screws;

- if necessary, drill wood or even metal or concrete;

- the device is much more compact and easier to use than, for example, a drill;

- this type of power tool is equipped with an adjustable clutch, which allows you to limit the torque and avoid damage to the fasteners;

- there is no need for strong pressure when tightening self-tapping screws or screws, which allows you to save their caps and then it will not be difficult to unscrew them if the need arises;

- high wear resistance of the tool;

- the possibility of installation in hard-to-reach places, due to the compactness of the device.

Additional functions

Reverse function, i.e. backstop, allows you to unscrew tight screws and pull out stuck drills. To turn the reverse on or off, there is a button, which is usually on the handle, which is very convenient. The essence of the reverse stroke is to change the positive and negative fields in the electric motor.

You can choose a model with functions that will greatly facilitate the work and reduce the time allotted for repairs. For example, a drill / screwdriver with a tape for feeding self-tapping screws. A tape with self-tapping screws is attached to the bottom of the case, which are fed automatically.

There is also a magnetic holder under the cartridge, a backlight and an indicator showing the battery charge.

What is the difference between a wrench and a screwdriver

During work, difficult situations are often encountered when using only a wrench becomes clearly insufficient. Then you have to pick up special tools: they help in working with parts that have a thread. Among them are the screwdriver and the nutrunner. These technical devices serve one purpose - to speed up work associated with a large number of nuts, bolts and screws. At the same time, despite the similarity of the tasks being solved, they also have a number of significant differences.You can find out about this and which of the tools is better to use from the review below.

Why do you need a cordless impact screwdriver?

Compared to other rotary devices, the cordless impact driver has the following advantages:

- high maximum torque;

- reduces the load on the hand of the master;

- does not require increased downforce;

- has the ability to drill holes;

- automatic switch from normal to shock mode;

- long operating time without recharging.

The disadvantages include the following:

- lack of manual torque control;

- the need to use special bits;

- drills holes in fragile substrates, such as wood.

An impact driver is a versatile tool for any home DIYer, often referred to as an impact drill driver. However, when purchasing it, it is not so easy to make the right choice. Before you pay money and take the screwdriver home, you need to analyze the device according to the following criteria:

- maximum operating time without connecting to the network;

- Li-Ion battery type;

- power of the tool, which varies from 24 to 36 V;

- torque not less than 70 Nm;

- comfortable feeling;

- weight no more than 1 kg;

- a proven brand (Bosch, Makita, Metabo).

What is it and what is it for?

An impact screwdriver is a special power tool that allows you to most efficiently drill walls in order to drive screws and install other fasteners. Unlike bumpless models, this relative novelty in the domestic market makes a hole not only due to the rotation itself, but also with the help of directional blows. The latter usually do not have a permanent character - the corresponding mode is turned on at the request of the operator or automatically if the drill runs into an obstacle of particular hardness. In a way, it's a small jackhammer.

Impact screwdriver - the device itself is more complex and "smart", therefore, a certain versatility should not be surprising. This means that the tool, as a rule, is fully compatible with various attachments, due to which the scope of its potential application significantly expands - instead of a drill, you can attach, for example, a hole saw or a mixing attachment.

It is logical that such a tool is somewhat more expensive than non-impact models, but its purchase is often justified even at home - the external, load-bearing walls of multi-storey buildings are usually distinguished by the highest strength, which only an impact screwdriver can overcome.

The device is also appreciated by professionals who drill walls or various parts on a daily basis - according to them, for all its assertiveness, the drill of an impact screwdriver usually does not cause significant damage to the fasteners, increasing their durability. This characteristic is especially valuable in the context that the same tool is often used to assemble furniture.

Specifications

Knowing what work is to be done, you can choose a drill according to the technical characteristics. Let's dwell on them in more detail.

Electric motor power

The more powerful the electric motor, the more active, longer the drill works, and the tighter the obstacle can be overcome. It is suitable for drilling heavy structures, long continuous working period. The speed of rotation and the price of the product depend on the power of the motor. Those who are not financially constrained may decide that for household purposes, just in case, it is better to choose a model with a powerful engine, since you do not know in advance what you will need to do in everyday life. But such a tool will turn out to be quite heavy. When assembling furniture or doing home repairs with a drill, the load from a heavy tool can be felt very quickly. Therefore, it is better to choose the best option in terms of power and weight ratio.

Rotational speed

The more revolutions per second the drill makes, the faster it rotates and the more intensively it produces holes. If you have to make a lot of small holes while working with different simple surfaces, a high rotation speed will be very useful. The rotational speed of hammerless drills is 2500-3500 rpm. The higher the intensity, the better, but sometimes it is necessary to reduce the speed, for this purpose a speed regulator is provided.

Drill diameter and torque

To extend the life of the electric motor, do not violate the specified drilling parameters. The instructions should indicate the maximum sizes of drills intended for materials of different densities. An unforeseen drill diameter and material strength will increase the load on the motor and can damage it. And the torque characteristic is also important, which determines the screwing of screws into materials of different densities. If the drill is also purchased for construction mixes, a model with a higher torque should be selected.

Is it possible to make a wrench from a screwdriver yourself

Of course it is possible, with only one important caveat: it is unlikely that it will be possible to obtain the same power as a tool made in an industrial environment. But, very often too much power is not required

For example, if you have to change tires on a car. Many people know how long the process of unscrewing wheel nuts is. Of course, there is an opportunity to contact specialists, but it will cost money. If you have a screwdriver at hand, then it can be quickly converted into a wrench: this requires only an adapter with a head of a certain size, which must completely match the size of the wheel wrench. It remains to fix this adapter in the chuck and install the head. The screwdriver wrench is completely ready.

Of course, this will not be a full-fledged tool, since it will still be necessary to loosen the nuts manually, but the time spent on all wheels will be only one minute.

In a greater force of twisting with at the same time less force of pressure on the tool by the operator.

Many people often ask the question, what are the advantages and differences of an impact screwdriver (wrench) from a conventional one and who and why needs this tool? And here it is important not to confuse an impact drill with an impact screwdriver, which is sometimes more correctly called a wrench. An impact driver or wrench has a tangential impact (in a plane perpendicular to the axis of rotation), i.e.

the effort to tighten screws or nuts is not applied continuously, but by a high-frequency series of small blows, as if you put an open-end wrench on the nut and started tapping it with a hammer. The total applied force is calculated as the sum of the efforts of these blows per unit of time.

Based on this, one can immediately emphasize the advantages and disadvantages of tools of this class.

Benefits of Impact Screwdrivers (Impact Wrenches)

- High torque! For most cordless models, the torque range is between 80 and 250 Nm!

- Convenient for tightening nuts. At low loads, the tool operates in a shock-free mode with continuous force (quickly tightens the nut along a free thread), and with an increase in resistance, it switches to an impact mode (tightening with a high torque).

- There is no need to apply a large pressing force to the tool when tightening screws and self-tapping screws, thereby saving the caps from "licking". Also, with its help, you can unscrew those screws and self-tapping screws, the caps of which have already begun to bully.

- Reduces torsional stress on the operator's wrist.

Disadvantages of impact screwdrivers (wrenches)

- Low drilling speed when switching to hammer mode.

- Inapplicability of jaw chucks (only hexagons) with rare exceptions.

- Inapplicability of the torque limiting clutch, due to which the tightening process has to be monitored all the time independently, which is not always convenient at a high speed of rotation of the tool shaft.

- Increased noise in shock mode.

And in order to more clearly represent the difference between an impact screwdriver (nutrunner) and a conventional one, we will summarize their main technical characteristics in one table: