Distinctive features

When deciding whether to choose a shock or shockless model of a screwdriver, first you need to figure out how they differ.

Many consumers who have managed to evaluate the work of the striking mechanism will say that it is such a unit that is better, and that is how they are ready to substantiate their point of view.

- Directional impacts increase the torque of the percussion tool to a range of 80-250 N / m, making it possible to break through the most difficult obstacles. It is significant that in the process there is not even a need to firmly press the case against the wall - the tool will bite into it even without significant pressing.

- Without the need for constant physical effort applied to the tool, the wrist and hand of the master are much less tired, which allows them to increase the same productivity.

- Considering that even a solid wall is not able to successfully withstand the onslaught of such a tool, it usually does not deform the fasteners, which in the future will allow it to be removed without additional efforts. Moreover, many models also provide for the reverse function of extracting old fasteners from the walls, even those that have experienced strong deformation due to long-term use.

- The screwdriver works not only with bolts, but also with nuts, in each case achieving the most tight tightening. A smart car usually automatically switches from shockless mode to shock mode when it senses that the nut has become tighter at a certain moment.

Unfortunately, this solution also has certain drawbacks, which, perhaps, will never allow it to completely supplant unstressed models. Thus, an impressive twisting speed is observed only in the unstressed mode; when switching to impacts, it significantly decreases.

Chucks for such a tool are not suitable for any - you need strictly hex. Most models do not have a limiting sleeve, so the degree of twisting must be carefully monitored by the operator, otherwise damage to the wall or parts will not be done. Finally, at high speeds, such a unit is capable of producing deafening construction noise, therefore constant work with it requires the mandatory use of protective equipment.

Best Impact Drills

Such devices, having the main function of drilling, are also equipped with an impact option, thanks to which they can be used to work not only with wood and metal, but also with stone, concrete, and other high-density materials. To understand which drill is better, a comparison of the most functional and popular devices on the market will help:

| SPARKY BUR 150CET KL | Bosch GSB 1600 RE | Makita HP 2051 F | |

| Power, W | 13 | 13 | 13 |

| Chuck type | quick-clamping | quick-clamping | quick-clamping |

| Max. chuck size, mm | 600 | 700 | 720 |

| Number of speeds | 1 | 1 | 2 |

| Reverse | |||

| Backlight | |||

| Max. drilling diameter in wood, mm | 25 | 30 | 45 |

| Max. drilling diameter in metal, mm | 13 | 12 | 13 |

| Speed control | |||

| Spindle speed, rpm | 500 — 2500 | 0 — 3000 | 1st speed: 0 - 1200; 2nd speed: 2 - 2900. |

| Impact frequency, beats / min. | 37500 | 25000 | 1st speed: 0 - 1200; 2nd speed: 0 - 2900. |

| Constant rpm support | |||

| Automatic shutdown when brushes are worn | |||

| Weight, kg | 1,5 | 1,9 | 2,3 |

SPARKY BUR 150CET KL

The Bulgarian model has a power of 600 W, and is produced with classic and keyless chucks with a diameter of 13 mm. The maximum dimensions for drilling wood, metal and concrete are 2.5, 1.3 and 1.5 cm, respectively. In shock mode, the frequency is 37,500 beats per minute, while the spindle speed reaches the limit of 2,500 rpm.

+ Pros of SPARKY BUR 150CET KL

- Light weight (1.5 kg) and comfortable design allows you to work for several hours without feeling tired.

- Reverse functions for unscrewing fasteners and adjusting rpm and speed allow repair tasks to be completed quickly and effortlessly.

- High torque ensures long service life of the device.

- Low noise level during operation.

- The function of maintaining the rotation speed during drilling facilitates the operation of the tool.

- Reliable build, durable body and internal parts.

- Cons of SPARKY BUR 150CET KL

- Cartridge beating after prolonged operation in impact mode.

- Slow start.

- Lack of case included.

Bosch GSB 1600 RE

It is a professional tool for stone work, metal, wood, ceramics and other materials; the power of the model is 700 W, the maximum number of revolutions is 3000 per minute, in the shock mode the drill provides up to 25,000 beats / min. The model has the functions of adjusting the speed and number of revolutions, reverse for unscrewing fasteners, the maximum diameter when drilling brick, metal and wood is 1.6, 1.2 and 3 cm, respectively.

+ Pros of Bosch GSB 1600 RE

- Reliability of assembly, strength of the body and main mechanisms, which provides the tool with a long service life.

- The compact size and convenient structure, combined with a low weight (1.9 kg), make the work process easier for the master.

- Electronic control of the frequency of impacts in the punch mode ensures maximum accuracy in tuning.

- High power allows you to easily handle surfaces of different density and hardness.

- Compatible with various attachments, quick-release chuck with a maximum diameter of 13 mm.

- Relatively low price.

- Cons Bosch GSB 1600 RE

- Lack of case and backlight.

- Jamming of the drilling direction adjuster during intensive work.

- During long-term operation, there is a significant backlash of the drill along the axis, due to which the runout effect occurs.

Makita HP 2051 F

Equipped with a 2-speed gearbox and keyless chuck, this Japanese-made percussion model has 720 W of power, RPM control, hammer mode, and allows you to drill holes in brick, metal and wood up to 2, 1.3 and 4 cm in size.

+ Pros of Makita HP 2051 F

- Long service life without the need for service.

- Robust metal housing to protect the gearbox from mechanical stress.

- Bright backlight for comfortable work in all conditions.

- Electronic speed control to make drilling or punching operations easier.

- Comfortable grip, long electric cord (2.5 m), good balance of the body.

- Cons of Makita HP 2051 F

- Difficulty holding the drill in the chuck under strong mechanical pressure.

- Lack of mechanical adjustment of the frequency of revolutions and speed.

- High price.

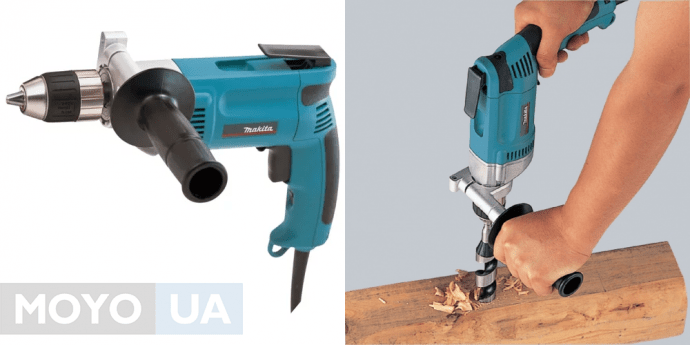

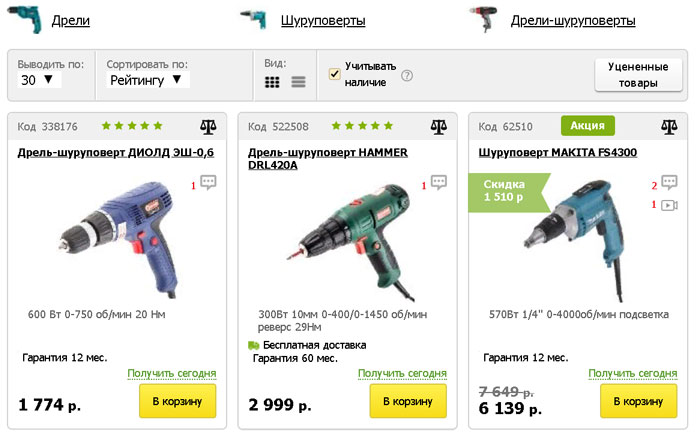

Best Hammerless Drills

These devices have a limited area of application: they can only be used for drilling wood, metal and plastic, so shockless models are purchased mainly for small household chores.

| Hitachi D 10 VC 2 | DeWALT DWD115KS | Makita DP 4700 | |

| Power, W | 460 | 701 | 510 |

| Max. chuck size, mm | 10 | 10 | 13 |

| Chuck type | quick-clamping | quick-clamping | quick-clamping |

| Reverse | |||

| Rotation frequency | 0-2300 | 0-2500 | 0-550 |

| Max. drilling diameter in wood, mm | 25 | 25 | 36 |

| Max. drilling diameter in metal, mm | 10 | 10 | 13 |

| Speed control | |||

| Weight, kg | 1,3 | 1,9 | 2 |

Hitachi D 10 VC 2

The tool is equipped with a quick-change chuck, which allows you to quickly change the drill, has the function of adjusting the speed, reverse for unscrewing fasteners, is lightweight (1.3 kg), which makes it convenient to use for a long time. Drill power is 460 W, maximum dimensions for drilling in wood and metal are 2.5 and 1 cm, respectively.

+ Pros of Hitachi D 10 VC 2

- Compact size and light weight, thanks to which the device is convenient to hold and work for several hours with breaks of 5-7 minutes.

- Preset speed for use as a screwdriver.

- Rubberized, non-slip body with optional second handle for a more secure grip.

- Reasonable price.

- Cons of Hitachi D 10 VC 2

- Rigid electrical cable that requires replacement after several years of intensive use due to chafing or fractures of the inner core.

- Budgetary equipment.

- Weak chuck strength, which makes it difficult to work when drilling metal.

- Noisy gearbox operation.

DeWALT DWD115KS

This model has an increased power (701 W) and can be used for drilling in wood, metal or plastic. The diameter of the holes and the size of the cartridge is identical to the previous version, the weight of the drill is 1.9 kg.

+ Pros of DeWALT DWD115KS

- Increased power, thanks to which the performance of the drill allows you to work with wood and metal with the same comfort, and the resource is significantly increased.

- Comfortable design with a non-slip handle, the weight is distributed in such a way that the hand does not get tired of the constant load.

- The quick-release chuck facilitates drill change and holds the bit securely, which ensures accurate drilling even with strong vibration.

- The presence of overload protection: the drill does not overheat, does not break down during long-term operation.

- Soft start option, the presence of a reverse, due to which it is convenient and easy to operate the device.

- Cons of DeWALT DWD115KS

- Small chuck diameter.

- Rigid wire that can be damaged by extreme bending. In addition, it is long enough to interfere with your work.

- A small storage case where you cannot place additional items (attachments, spare drills, a pen, etc.).

Makita DP 4700

Manufactured and assembled in Japan, this model is equipped with a 13 mm chuck and can drill wood and metal with a maximum diameter of 3.6 and 1.3 cm respectively. The drill has a power of 510 W, is equipped with a keyless chuck and can be used for household tasks and small repairs. This device is the most expensive in the rating.

+ Pros of Makita DP 4700

- The device is on bearings, due to which the high precision of the drill is ensured and its service life is maximally extended.

- Durable case made of high quality plastic, resistant to scratches, cracks and other damage. The drill will not break if dropped, and the comfortable handle minimizes the risk of slipping out of your hand.

- Improved reliability and build quality.

- A quality keyless chuck that holds the bit securely in place.

- High torque (38 N * m) for easy reaming of metal.

- Ease of maintenance, minimal repairs.

- Cons of Makita DP 4700

- High inertia, which makes the drill stop taking a long time.

- Inconvenient dimensions of the additional handle and speed control.

- Lean factory equipment.

pros

Plastic materials (wood, plastic and so on) are "cut" with a drill. Stone, brick "give in" only with the participation of a mechanical impulse.

The advantages of an impact drill are that it is possible to work with any material.

Among the shortcomings, it should be noted: the drilling accuracy is noticeably inferior to a good drill. In shock operation, too much background noise is also observed. Household drills have low productivity.

For household work, the power of 560 W is quite enough, this is enough to drill even concrete with holes diameter 15 mm. Impact Drill Benefits:

- compactness;

- little weight;

- versatility of use in a domestic environment;

- convenient functionality;

- the ability to work with a variety of materials;

- the ability to work with various drills;

- ease of use and repair;

- long service life.

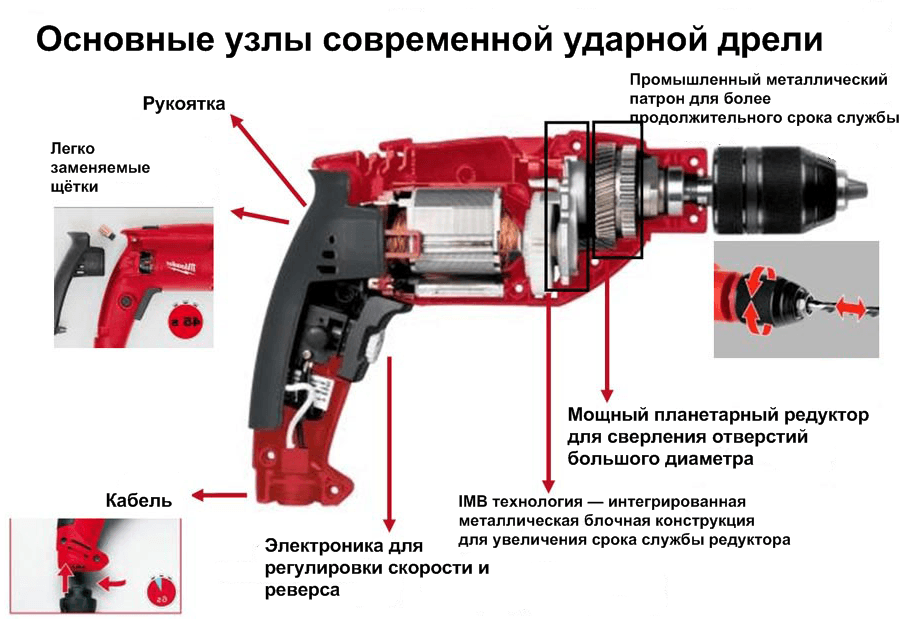

Criteria for choosing a drill for home use

Power

The motor power of modern electric drills varies from 500 to 1500 W.This important parameter determines the torque of the tool and the ability to machine dense materials. A weak motor will not crank the drill in steel, the grinding wheel will get stuck in birch plywood. The more power, the greater the weight of the tool. For household work, it is recommended to choose a drill with a 700-800 W motor.

Shaft speed

The engine rotation speed varies from 2000 to 4000 rpm. For each drill, the manufacturer selects the optimal rotation speed (it is called nominal and is indicated in the model's characteristics). The higher the speed, the more times the drill passes through the material, giving a cleaner surface. At high speeds, the risk of errors increases - the hand trembled, the drill went to the side, ruining the workpiece.

Drilling diameter

The Drill Diameter parameter defines the largest hole that the drill makes in different materials. Obviously, wood is very different in density from steel, so the manufacturer sets for his product the maximum hole diameter in wood and separately in steel. If the drill has an impact mode, then the diameter in concrete is also normalized.

Chuck type

The chucks in which the tool is clamped are of two types: with a key and a quick-release.

The main thing is not to lose the key to the cartridge.

The main thing is not to lose the key to the cartridge.

The chuck with a key has been known for a long time - in it the jaws are compressed using a toothed nut, which is turned with a special key. Advantages: secure drill hold even in the most difficult working conditions. Disadvantage: Drill change takes a minute, key is easy to lose.

Keyless chuck hand tighten

Keyless chuck hand tighten

Keyless chucks have appeared in recent years. In them, the clamping nut is turned by hand. The advantages and disadvantages are opposite to the key chuck - the tool changes in ten seconds, but the strength of the hands is not always enough for a strong clamping, for example, at the exit from the metal, the drill wedges, the shank slips in the chuck.

Equipment

The simplest set consists of one item - the drill itself. If the manufacturer offers additional items, this is a big plus. The kit may include:

- A small suitcase is an excellent packaging for storage and transportation. The tool and accessories are neatly stored and do not collect dust.

- The tool set is a basic set of the most popular drills for wood, metal or concrete.

- Laser level - attached to the impact drill, needed to mark wall holes.

- Nut Attachment - Clamps grinding and cut-off wheels.

- Additional handle - screwed to the body, by which the master holds the tool with his other hand, for example, when drilling concrete.

- Depth gauge - a pin with a ruler screwed to the body, will not allow the drill to plunge further than measured.

- Spare brushes. The collector motor is powered through moving contacts - carbon brushes. This part wears out over time. It's good if the manufacturer has prepared a replacement.

Additional functions

Engineers implement additional features in electric drills that make work convenient and safe. The most important features:

- Smooth start. The collector motor starts in short-circuit mode, which generates current surges in the network, the collector brushes burn out. The regulator will smoothly increase the rotation speed to the maximum, the tool will last longer.

- Automatic speed controller. The electronic circuitry maintains a constant rotational speed of the drill regardless of the applied load. The drill handles wood and metal equally smoothly.

- Locking the switch. If the drill is operated with a grinder or machine, the motor must run continuously. The button holder will free the hands of the master.

- Reverse engine. A convenient function that will help if the drill is jammed at the exit from the metal. The master clicks the lever, the direction of rotation of the drill is reversed (reverse) - the tool is released.

- Chuck brake.When the master removes his finger from the trigger, the cartridge continues to rotate by inertia, it is dangerous to touch it. The braking system instantly stops chuck rotation after the engine is turned off.

Other important criteria

When choosing an electric drill, take it in hand. In a good drill, the handle is equipped with rubber spacers and fits comfortably in the palm of your hand. Buttons and switches are easy to press, the chuck rotates smoothly, does not dangle in the longitudinal direction.