Caliber PTE-1400 / 210M The most popular tool of domestic production Country: Russia (made in China) Average price: 5360 rubles. Rating (2020): 4.8

The domestic manufacturer Caliber relies on an affordable and reliable tool. The interest of summer residents and homeowners in the products of this brand is constantly growing. Miter saw Caliber PTE-1400 / 210M is designed for straight and side cuts in wooden products. Engine power is sufficient to ensure high performance. The model is equipped with a dust collector, vertical clamp, two additional supports.

Users note the need for some refinement of the product, for example, fine-tuning of the sawing. But the lightness of the saw, its compact size and ease of use pleases. On the plus side, the brush assembly is available for ease of maintenance.

Popular miter saw manufacturers

Despite the wide variety of presented cross-cutting machines, among them one can single out the products of manufacturers who are most popular with consumers. We are talking about companies such as Bosch, Metabo, Hitachi, DeWalt and Makita. Apart from them, many interesting solutions can be found in the line of the Corvette manufacturer.

Professional unit Makita L. S. 1040

Many owners of this cut-off machine call it a very effective tool for making precise and clean cuts. Among the distinctive features should be highlighted the high power indicators (1650 W) and the speed, which is 4600 rpm. Woodworking equipment meets all safety standards, which is greatly facilitated by the presence of a protective casing made of transparent plastic.

Many owners of this cut-off machine call it a very effective tool for making precise and clean cuts. Among the distinctive features should be highlighted the high power indicators (1650 W) and the speed, which is 4600 rpm. Woodworking equipment meets all safety standards, which is greatly facilitated by the presence of a protective casing made of transparent plastic.

As follows from the reviews, many owners have been using such trims for many years and do not complain about a decrease in their quality characteristics. This model is also suitable for those who are looking for a mobile version of the woodworking tool, because it has a small size and weighs no more than 11 kg.

The model is designed to work with a disc with a diameter of 26 cm.This is the ideal value for a consumable to effectively perform with its help trimming flat workpieces with a width of 13 cm.When using the tool at an angle of 45 degrees, you can cut to a depth of 67 mm, and at a straight line - 95 mm. Many users note the high level of quality of the working units of this saw model. The unit is equipped with a broaching mechanism, which was positively noted by users who are forced to work with wide wooden blanks.

Features of trims from various manufacturers

Of the features of the miter cuts that Makita produces, a small cutting width should be distinguished. All models are supplied with a broaching mechanism. In the equipment of these end faces there are two special rods for reliable holding of the block. This is the design of one of the popular LS 0714 models. The LF 1000 saws are ideal for large workpieces and are supplied with auxiliary supports that greatly simplify the operation.

Of the features of the miter cuts that Makita produces, a small cutting width should be distinguished. All models are supplied with a broaching mechanism. In the equipment of these end faces there are two special rods for reliable holding of the block. This is the design of one of the popular LS 0714 models. The LF 1000 saws are ideal for large workpieces and are supplied with auxiliary supports that greatly simplify the operation.

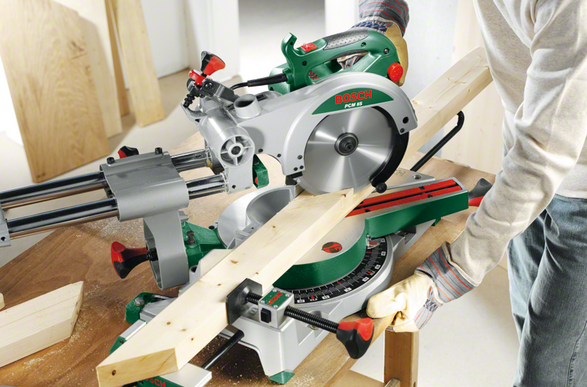

The Bosch product range also includes many models of wood-pulling miter saws, equipped with auxiliary supports and frames, which are made of aluminum and magnesium alloys. Many owners find this solution to be the right solution as it increases the strength and mobility of the trims. One of the most popular models of the manufacturer is the GCM 10 trimmer, the working weight of which is 15 kg.

Sawing devices manufactured by Corvette are equipped with a special mechanism for longitudinal broaching. Among other structural elements, there is a special laser pointer. Users have appreciated this innovation, which improves the accuracy of cuts.

The solutions offered by Dewalt stand out from the competition using the XPS system. A similar mechanism can also be found in the Corvette trims, however, the device introduced by Dewalt has an offset function with a shadow that is projected from the saw blade. Many consumers call this system very convenient due to the increased cutting accuracy.

The solutions offered by Dewalt stand out from the competition using the XPS system. A similar mechanism can also be found in the Corvette trims, however, the device introduced by Dewalt has an offset function with a shadow that is projected from the saw blade. Many consumers call this system very convenient due to the increased cutting accuracy.

Hitachi products are equipped with working blades ideal for cutting at 30 and 15 degrees. Previously, no one had ever produced such trims on the market, since all previously offered devices could only work at a standard 45 degree angle.

The cut-off saws from Metabo have pivoting and tilting saw blades. Consumers are generally satisfied with the trims produced, calling them easy to use.

Where are Japanese trimmings made

The line of edging saws from this manufacturer includes about 450 different types of devices. 8 enterprises are engaged in their production. Enterprises located in Germany, Great Britain and Romania are involved in the manufacture of trims. There is one plant on the territory of each of these countries. There are an additional 5 factories located in Japan.

How to choose?

Before purchasing a miter saw, you need to know its basic specifications. The fundamental condition is the purpose of the tooling. If the operation of the saw is expected in very rare cases for economic purposes, in this case it is worth purchasing a trimmer with a typical set of options. For frequent use of a device for sawing products of different widths, it is appropriate to buy a multifunctional miter saw with a broach, which expands the range of possibilities of the device. It is the broaching option that is used to work with objects of very large thickness and makes it possible to increase the cutting width, the parameter of which is not large enough for ordinary modifications, which also increases the functionality of the tool.

The next aspect is the safety of the instrument. Regardless of the price of the equipment, its structure must have a protective casing and a function to block the accidental start of the device.

When choosing a tool, you need to take into account its size and weight. It should be flexible and comfortable

When working at height, it is advisable to use a small and lightweight device rather than a bulky heavy unit. The depth and width of the cut determines the purpose of the rig, specifies what it can do. For high-quality work, it is necessary to select a saw blade with a size of at least 20 centimeters. The larger this parameter, the easier it is to use the device. When looking for a specific modification, it is necessary to take into account the quality indicator of the material from which the bed and the swivel block are made.

How to choose

The miter saw is a design based on a commutator or asynchronous motor. It is electrical and the cutting is done using a rotating disc. The saw is powered by a starter.

Both brushed and induction motors have positive and negative sides. The first version of the motor is able to rotate the cutting element at high speeds, and the second one provides ease of use and durability. The negative side of the collector motor is the need for periodic maintenance, and the asynchronous one is the lower speed and its large dimensions.

One of the most important selection criteria is the location of the engine.It can be located to the side of the cutter bar or behind it so that the work area is more open. This is great if you want to cut at a specific angle.

When purchasing a bed, you need to pay attention to the material from which it is made. Experts recommend making your choice in favor of magnesium and aluminum alloys.

These are fairly light metals, therefore, the total weight of the structure will be much less. This will not affect the strength in any way, but the unit can be transported without much effort.

Try to purchase a saw with a rotary top table. More on this will be discussed below.

It is important that the instruments are capable of making an incision at an angle of 40 to 60 degrees on both sides. Therefore, carefully study the technical specifications.

You will have to overpay a little for this function, but it greatly facilitates the sawing process.

Another selection criterion is the maximum possible cutting depth. On the miter saw market, you can find models with various bells and whistles: neon lights, speed control and others. If you are going to use this device at home, then you should not overpay for these add-ons.

Before purchasing this device, always pay attention to its maximum power. Many parameters depend on it, for example, the diameter of the cutter and the size of the surface with which your tool can work.

The smallest power required for the normal operation of the saw is 0.8 kW, and the maximum is 1.8 kW. In the Russian market, designs in the power range from 1.6 kW to 1.8 kW are especially popular. They are compatible with 2.4cm discs, great for home use. The models are small.

TOP 7 band saw blades

Saw bands are manufactured by both saw manufacturers and narrow-profile companies involved in the production of parts. When buying branded tools, it is recommended to purchase canvases from the same company.

Pilana tools

Pilana tools company is engaged in the production of cutting tools for metal.

The firm manufactures products that work with a wide variety of materials:

- Stainless steel.

- Non-ferrous metal profiles.

- Non-ferrous metals.

- Thick-walled tubes.

- Tin plates.

Lenox

Lenox is an American company that specializes in saws and related equipment. The advantage of this manufacturer's canvases is a protective coating called "Armor". Thanks to it, the strength and wear resistance of the tool are increased. Lenox canvases stand the test of time and cope with any stress. The disadvantages of saws and blades from this manufacturer include the high cost.

Arntz

Arntz cutting tools and saw blades are manufactured in Germany. This large company has retail outlets in most countries. The manufacturer specializes in the manufacture of tools from carbide materials. In Russian stores you can find Arntz bimetallic and carbide band saws.

Forezienne

Forezienne is one of the leading suppliers of saws for woodworking. All canvases produced by the company are made of steel, which is produced from beneficiated ore. As a result of careful hardening, the canvases acquire reliability. The disadvantage of Forezienne products is their inaccessibility.

Lennartz

The German manufacturer Lennartz specializes in the production of canvases made from composite alloys. The uniqueness of the cutting tools of this company lies in the innovative approach to the manufacture of parts. The saw blade is made of high speed hardened steel. The serrated edge is made individually and then attached to the web.

Lennartz products are used to process the following materials:

- Aluminum and alloys based on it.

- Ferrous metals.

Wikus

Wikus has been manufacturing carbide saws and related equipment since 1958. Manufactured tools have a universal focus. They handle the processing of metal and wood blanks.

In addition to carbide models, the company manufactures the following saws:

- Diamond.

- Bimetallic.

Doall

The American company Doall has been producing saws and band saws for 100 years. The company pioneered the production of titanium-nitrogen coated saw blades.

The manufacturer specializes in band saws and has a wide range, consisting of the following items:

- BI - METAL Silencer 101.

- BI-METAL TIN Penetrator.

- BI-METAL Invader-X.

- BI-METAL PMP 2000.

Saw bands are presented in Russia by American, German and French manufacturers. There are other small firms specializing in the production of materials for cutting units. For the correct choice of a saw blade, it is necessary to take into account the characteristics of the machine and the parameters of the material being processed.

- Types of jigsaw files: types, types, classification with characteristics, marking, an overview of popular manufacturers and models, their pros and cons

- Discs for angle grinders: how to choose, types and classification, characteristics, marking, popular models, their pros and cons, care and storage features

- Drill types with characteristics and purpose

- Types of wood cutters for a hand router: their classification, purpose, characteristics, features, pros and cons, recommendations on how to choose the right option