Varieties

Differences in tool configuration allowed axes to be classified

Considering the type of blade, they are:

- professional cleavers with a wide cutting area;

- tools with a medium blade width;

- axes with a small cutting element.

An ax knife for a butcher will be very weighty, as a rule, its weight is about 3 kilograms. Also on sale you can find a multifunctional version of a kitchen tool for meat - an ax hammer, which can perform several tasks at once. Such a product is not heavy, therefore it is suitable for use by housewives.

In addition, axes for processing meat products can be classified based on the type of handle with which the tool is equipped. Most often, a tree familiar to everyone is used for the handle, however, modern products for professional and domestic use for the most part have rubber or plastic handles that prevent the hatchet from sliding in the hand

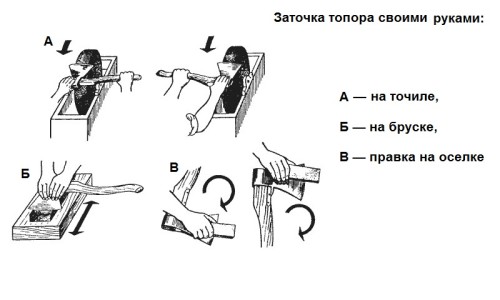

Manual sharpening option

There are also a lot of tools for manual sharpening of an ax blade. Their plus is that you do not have to spend a lot of money to buy the necessary device, and the small size will allow you to store it in any kitchen drawer. The downside is the duration of the sharpening procedure itself, especially if you are working with a meat hoe with a large blade (Figure 7).

To chop meat in one motion, use the following hand sharpening tools:

- Musat: as a rule, this tool is already used for the final dressing of the blade, and not for its direct sharpening. Externally, the musat is a long file rod with notches and abrasive spraying. Despite the limited functionality, it is still worth including musat in the arsenal of kitchen utensils, since it will help to correct the burr on the blade or give it sharpness in just a few movements.

- Bar or stone: it is already a more serious sharpening tool that is used to directly sharpen the blade of a kitchen ax or knife. If you want a really sharp ax, it is better to buy several stones at once with different grades of coating.

- Special sharpening kits: ideal for those who want to sharpen not only kitchen hatchets, but also knives, while not delving into the details of working with a bar or machine. As a rule, such sets include several coated stones of different grain sizes, a special fixing stand and additional accessories.

Figure 7. Tools for manual sharpening: sharpening kits, musat and bar

Figure 7. Tools for manual sharpening: sharpening kits, musat and bar

If you are not a professional butcher and use the ax infrequently and exclusively at home, hand sharpening tools are perfect for you. But for those who, due to their profession, often work with frozen meat or hard bones, it is better to give preference to sharpening the ax blade on special electrical appliances.

Sharpening a meat chopping ax

Even if sharpening an ax for chopping meat was carried out flawlessly by the manufacturer, the time comes when it is necessary to restore this parameter of the instrument.

Grinding work at home can be done with different tools:

- whetstone - the most accessible and simple, should have a rounded shape and bend, which will allow you to accurately maintain the sharpening angle;

- tape-type file - simplifies the sharpening task at times, implies manual work with a minimum of physical effort;

- grinder, grinding wheel - power tools that can only be operated with at least minimal experience.

Some people use a grinder to restore the sharpness of the ax blade, but this method has many drawbacks - sparks fly in all directions, the sharpening angle is not maintained, the metal overheats. This all at times reduces the quality of the blade and leads to the need to replace the kitchen tool soon.

How to sharpen a butcher's ax correctly

The grinding technology is identical for all types of cutting / chopping tools. Safety will be respected only if a person strictly adheres to some rules:

- You need to properly organize your workspace. Place the sharpening tool on a horizontal surface, make sure it is firmly attached so that it does not get pulled out of place during sharpening.

- The abrasive wheel should be checked for quality before use. On its surface there should be no cracks, notches, grooves.

- Be sure to wear protective goggles. The fact is that meat hatchets are made of high-quality steel and sparks fly in the process of sharpening, particles of an abrasive surface - injuries cannot be avoided without protection.

- The blade is held "away from you" towards the rotation of the circle, the blade is led parallel to the axis of the sharpening tool. You need to hold the hatchet with both hands, which will help maintain the correct sharpening angle.

It is important to remember that the blade should not be overheated, because this is how the metal deteriorates, becoming brittle. If a burr has formed on the surface of the blade, then you need to turn it over and start processing the other side

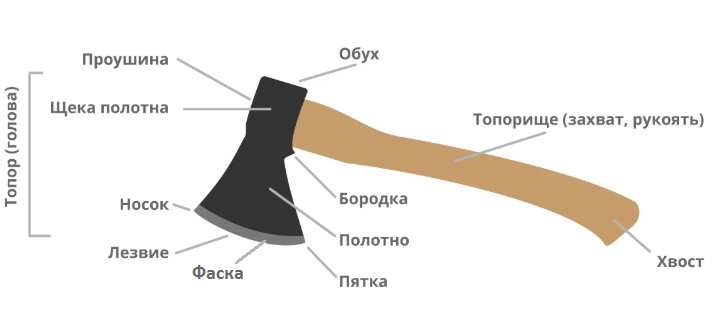

Chamfer width

Chamfer is the width of the plane between the two planes of the blade, the parameter can be one / two / three-sided. For kitchen axes, manufacturers maintain a two-sided chamfer width and do not change it in the process of self-sharpening. The optimum chamfer width is 18-20 mm.

It is allowed to change the width of the chamfer on one side of the blade, which makes it possible, if necessary, to change the sharpening angle.

Sharpening angle

This parameter varies within the range of 25-30 degrees, for compliance, you can cut out a template and already navigate along it. The sharpening angle directly affects the cutting / chopping characteristics of the product: the smaller this parameter, the sharper the blade will be.

Electric sharpening tool

You can use a special tool - an electric sharpener. It is distinguished by its impressive dimensions and rather high cost, but such a device allows you to work to restore the sharpness of the cutting edge not only of an ax for meat, but also of all other types of knives.

More often, a grinder with an abrasive wheel is used to sharpen a butcher's ax. It makes it possible to perform work at a professional level, but requires experience in operating machine tools.

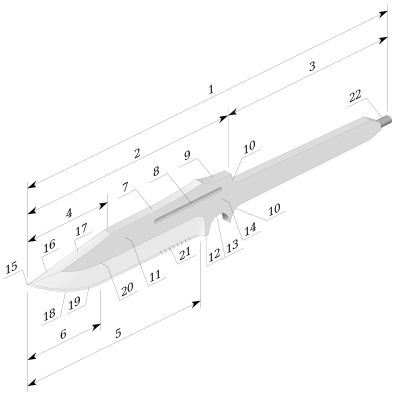

Sharpening an ax on a grindstone: 1 - stop; 2 - ax; 3 - grinding wheel; 4 - protective casing.

Sharpening an ax on a grindstone: 1 - stop; 2 - ax; 3 - grinding wheel; 4 - protective casing.

The disadvantage of using a machine with an abrasive wheel is the rapid heating of the blade metal, and this degrades the quality of the kitchen tool and reduces its characteristics.

Hand tool

Its advantages are its low cost, small dimensions - it can be stored in the kitchen, and no experience is required. But there is also a drawback to a manual sharpening tool - the work to restore the sharpness of the cutting edge will be long, especially in the case of a large / wide blade.

Effective hand tools for sharpening a butcher's ax are:

- musat - they are ruled, and not sharpened by a blade, they can also return the sharpness of an ax in just a few movements or quickly remove a burr on the canvas;

- bar / stone - you will need several types with different abrasive surfaces;

- special sets - can be used by absolute beginners, do not require independent setting of the sharpening angle.

Purpose and execution

An ax knife is the younger brother of an ordinary ax. Its structure is such that the blade has a shape that is vaguely similar to a real ax. It protrudes forward in the form of a square rounded at the edges, which allows you to wield such a product without intensive chopping movements with your hand. Unlike a conventional ax, the butt is thickened, but does not copy the clumsy one in shape. It is an indispensable tool for cutting both layers of meat, in which there are small and medium-sized bones, and chopping frozen fillets.

The hatchet knife is suitable for chopping meat and bones, cutting meat exactly "by the joints". It has a wide and heavy blade, which makes it possible not to shred meat, like a sausage, but to cut it in a structured and precise manner, preserving the fibers that hold their juices and liquids.

If you used an ordinary blade, which does not work like this, the cut meat would resemble a squeezed lemon in consistency. Chopping bones with a hatchet knife does not imply the formation of a bone crumb during cutting movements, which discourages people from eating a dish made from meat, in which such fragments are often found.

A hatchet knife facilitates the work of a chopper or a cook when cutting a large number of carcasses of livestock or poultry. This makes it possible to increase the labor productivity of people for whom meat cutting is the main responsibility at enterprises that manufacture finished meat or fish products.

Selection recommendations

According to experts, when choosing an ax for cutting meat, some nuances should be taken into account.

Blade characteristics

This detail is the most important in the whole design, a good blade will be thick and weighty. It is these properties of the metal element that determine the assignment of this device to the category of hatchets, since it is the balance between the mass and thickness of the metal that will be responsible for the chopping capabilities of the tool

As for the shape, it can be straight or rounded.

Product arm configuration

The optimal size of the handle will be the ability to operate the tool with one hand, that is, its length should be within the palm of your hand. In addition, it is best if it has a rounded shape with special grooves for a comfortable position of all fingers. This will prevent the tool from slipping out while cutting the meat.

Cutting edge type

The classic sharpening option is not suitable for an ax as it is important that the edge remains sharp in working order on each side. This feature will greatly facilitate further operation and maintenance of the ax due to the fact that it is this type of product that is easiest to sharpen by choosing the correct sharpening angle

The optimal angle is 40 degrees. Such a product will allow the instrument to cut fibers and bones as deeply as possible.

Type of steel used

As a rule, certified products, in contrast to handicraft products, will have a special stamp on the tool head. This abbreviation will contain data on the steel grade used for the production of the ax.

It is important to pay attention to the fact that it should be in the area where the handle contacts the cutting part.

Additional configuration nuances

Good and high-quality products should have a special tab on the case, which will allow you to properly store the inventory after use.

Place of purchase and cost

Often, the cost of the same product will differ significantly when comparing the pricing policy of supermarkets and markets.Therefore, you can safely purchase kitchen tools at retail outlets, which will save money, however, this will not in any way affect the quality of the purchased product. Also, for the rare exploitation of an ax, it is simply pointless to buy an expensive tool. Today, inventory from domestic and foreign brands is on sale, which, for the most part, have high quality indicators of the products sold.

Ease of use

It is best to choose a kitchen or professional tool yourself. Before buying, you must definitely test the cleaver, hold it in your hands, evaluate the comfort of the handle, weight and other characteristics of the product you like. Otherwise, there is a risk that even a high-quality and attractive tool will be simply unsuitable for a cook, butcher or housewife.

Step-by-step instruction

The algorithm for the independent production of a butcher's ax must be strictly observed:

- Material preparation. You can use a good piece of steel (high-carbon, with a high level of hardness) without preliminary hardening - if the metal is not processed with a file, this means that the indicators are suitable for making chopping kitchen tools. It will be necessary to clamp the material in a vice and use a gas burner to burn it, which will clean the surfaces of dirt.

- Next, annealing is required - the workpiece is placed in a "chamber" of refractory bricks and heated by a burner (it is better to use two at the same time) to a stable red color. After that, the metal must cool naturally - the longer this process lasts, the softer the workpiece will become. You can check the quality of annealing with a file - it should leave marks on an already cooled workpiece, even with the application of slight physical effort.

- Profile cutting. First you need to prepare a template of the desired shape on cardboard. Then it is applied to the workpiece and the cutting line is outlined with a marker. The latter is performed with the help of a grinder and a cut-off wheel, but some experience is needed - if the metal overheats, then it will be almost impossible to restore its softness. Experts recommend using band saws and hand-held metal saws to cut a profile.

After obtaining a rough profile, you need to modify it with a metal file: form a cutting edge, remove the remaining burrs. It is better to do this while holding the workpiece in a vice.

- Forming bevels. The meat ax should have steep bevels. First, the intended cutting edge must be divided into two halves along the length with a marker. Then the workpiece is clamped with a clamp, the formation of bevels begins - without haste, so as not to heat the metal, using a grinder with a grinding wheel. The bevels are made symmetrical, then they need to be finalized with a file, after holding a metal plate in a vice.

Sharpening of the cutting edge at this stage is not carried out, first you need to harden the workpiece. The bevels are formed one by one - first on one side, then on the other.

- Manufacturing of overlays. Two overlays are cut out of the board in the shape of the future handle. Holes are drilled in metal and wood to install pins. Then the handle of the meat ax is assembled: the overlays are installed, gluing together with epoxy glue, pins are inserted into the holes, the whole product is fixed with clamps. It is necessary to give 24 hours for the epoxy glue to dry completely and only after that work can be continued.

- Blade hardening. First, it is warmed up to red, then dipped in oil (the action is repeated 2-3 times). It is highly advisable to end the stage by heating the blade in the oven until slightly reddened, but if wooden overlays are already installed on the handle, then this cannot be done.

It remains only to decorate the handle - it is covered with several layers of varnish.The final stage is the sharpening of the cutting edge.

It is performed on any convenient device with an angle hold of 25-30 degrees.

Advantages and disadvantages

A kitchen hatchet makes carcass butchering a lot easier and saves time. Thanks to special hardening, it can be used for a long period without additional sharpening. Other benefits of the ax:

- made of durable steel;

- able to cut even the hardest parts of a carcass with bones and cartilage;

- maintenance does not require large costs;

- versatility - it can even be used instead of a meat grinder.

The biggest disadvantages of the product are its considerable weight and the need to use physical force for work. The wooden handle of the ax can deteriorate over time.

To prevent this, it is important to observe the recommended storage conditions, to carry out proper processing of the instrument.

How to choose an ax knife?

The correct choice of hatchet knives is based on several important parameters.

- The blade should be wide and thick. The optimal balance between weight and force applied to cutting is the main criterion when choosing a knife with the most efficient and convenient blade to work with. The length of the blade is most often 15-25 cm, but the width should be at least 8 cm, otherwise it is no longer a chopper, but an ordinary kitchen knife.

- A shortened handle with a transversely rounded shape, with depressions for holding the fingers of the entire structure. This allows you to achieve the most reliable coverage, significantly reducing hand fatigue while working.

- Double-sided sharpening. One-sided will lead the edge to the side, which makes cutting the product require noticeably more effort. Sharpening a blunted blade on both sides is easier - you will still sharpen the knife not one-sidedly, but in two ways. The sharpening angle must not go beyond 15-45 degrees: the larger one interferes with cutting the meat, the smaller one makes the knife unusually thin, like a razor blade.

- The quality of the steel - must be stainless, not carbon. The latter becomes covered with a brown coating, when the knife is not immediately washed, it quickly becomes thinner, it is more and more difficult to make it sharp again when it is dull from common bones, and food tastes like iron. Rusting products are cheap, but don't skimp on the price. Damascus steel or titanium is strong enough, the first requires special care, the second, on the contrary, is unpretentious in use and is noticeably lighter.

- The best choice would be a metal handle, not a wooden or plastic one. Metal will not burn or melt from high temperatures, such as when a knife is accidentally thrown dangerously close to a fire. A completely steel product is easy to wash, it does not retain foreign odors. A solid knife does not need rivets or bolts. Disadvantages - decent weight (over a kilogram) and high price.

- Finally, before buying a hatchet knife, check it for quality: no wear (numerous abrasions and scratches, indicating that the tool has been used for a very long time and has been sharpened repeatedly), chips, gouges and notches. The latter report that the knife was generally not used for its intended purpose, for example, with hammer blows on its butt, pieces of wood were pricked into chips.

Review of Mr. Blade Camp awaits you further.

Tool sharpening technology correctly

The technology of sharpening a professional meat ax is practically no different from a similar procedure for another piercing-cutting tool (Figure 5).

To carry out the procedure correctly, you must consider the following:

- The work area must be properly equipped. The sharpening tool must be firmly installed on the bed, and the bed must be fixed to the floor so that it does not move during operation.

- Before starting work, carefully inspect the abrasive wheel: it must be absolutely even, without beats and notches.Only in this case you will be able to sharpen technologically correctly and without harm to the blade.

- Take care of your personal protective equipment as well. First of all, you need to wear protective goggles. Kitchen hatchets are made of high-quality steel, and during the sharpening process, metal splashes and abrasive dust can fly in all directions and accidentally get into the eyes.

- The sharpening technology itself is as follows: the blade is held in the direction "away from you" towards the rotation of the circle and is parallel to its axis. It is advisable to hold the ax with two hands so that it is possible to accurately maintain the sharpening angle.

- In the process, try not to overheat the cutting edge. From this, the steel of the blade can become too brittle and will crumble during further use.

Figure 5. Correct sharpening technology

Figure 5. Correct sharpening technology

If during sharpening you notice that a burr has accidentally formed on the blade, do not despair. This does not mean that the instrument is damaged. To remedy the situation, simply turn the ax over and start sharpening it the other way. It is better to bring the cutting edge to the necessary condition on a fine abrasive wheel

At this stage, you need to be very careful so that the edge of the chisel does not break off, and the edge itself remains strong. The best way to do this is to use the double sharpening method.

At the final stage, you can check the sharpening angle of the blade using special templates and, if necessary, bring the product to perfection.

Sharpening angles

The sharpening angle of any ax is one of the key indicators necessary for the correct preparation of the tool for work. It is from this characteristic that the cutting ability of the tool will depend.

The choice of the sharpening angle is influenced by several points at once:

- The hardness of the processed material (bones, fresh or frozen meat);

- The moisture level of the material is an indicator that plays a greater role when choosing the angle of sharpening of a carpenter's ax, since dry wood pricks much easier than wet;

- The metal from which the blade is made also plays an important role. It is advisable to choose a product with the most durable steel. Of course, sharpening such an ax will present certain difficulties, but such a tool will be enough for a long time, even with constant use.

Typically, common kitchen axes have a sharpening angle of 25 to 30 degrees. But, in order to accurately determine this value, you can cut out a template from thin metal along the blade, attach it to the ax and check how much the assumed angle corresponds to the desired one.