Lopper and pruner: what's the difference?

The pruner and the delimber are designed for essentially one task: pruning branches and twigs.

However, they are two different tools.

Pruners are similar to scissors, have short handles and are effective where you can freely reach with your hands, that is, for pruning low-growing branches, young shoots.

The lopper has much longer handles, which makes them perfect for working in hard-to-reach places, such as dense bushes.

Rod options even allow you to cut branches at a height of up to 6 m, depending on the length of the rod itself and the height of the gardener.

As a result, the only actual difference between the two tools is the length of the handles.

Accordingly, the pruning shears can be used with one hand, because it is small enough to fit in the palm of your hand.

With a lopper, regardless of its model, all work is done with only two hands.

Rod loppers from other manufacturers

In addition to the listed manufacturers, there are also such as: - Palisad, whose products are similar in design and functionality to Fiskars products, but hardly similar in quality. At least an external examination did not reveal any similarity in quality. - ARS (Japan) is an exotic instrument in our country, which I saw only at a garden exhibition, but did not work with it. - Others (mainly "Far Eastern" manufacturers) that produce delimbers with a fixed cutting unit, which I, again, do not recommend buying.

This is interesting: How to choose a robotic lawn mower: we study in order

How to choose a lopper?

The purchase of a delimber should be treated with special attention.

It is important to take into account the amount of work to be done, the size of the cultivated area, the nature of the plantings and your own capabilities.

When choosing a delimber, you must focus on the following criteria:

Branch diameter. This parameter is indicated in the characteristics of the tool. If you have to work only with bushes and young growth, then a 25 mm model will do. With a predominance of mature plantings, the delimber should cope with a diameter of 50-55 mm. It is always best to choose a model with a margin.

Tool weight. The range of loppers is wide, with one model weighing as little as 0.2 kg and the other weighing 2 kg. The instrument will have to be kept suspended, lifted above the head, so after some time every gram will be felt. When choosing, one should be guided by the physical strength and endurance of the operator. Women and seniors should look for lighter models.

Handle length. You need to focus on the height and length of the user's arms with the tool, as well as the height of the plantings

If you have to work with tall trees, then you should pay attention to the rod or telescopic model. It is better to choose a lopper with a stepless length adjustment.

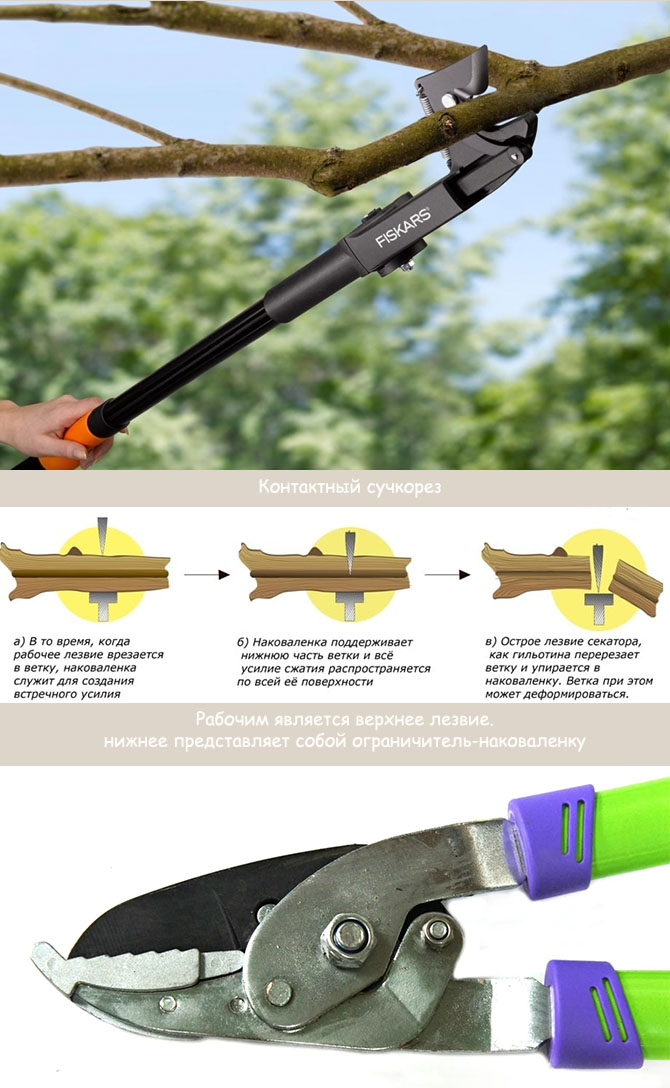

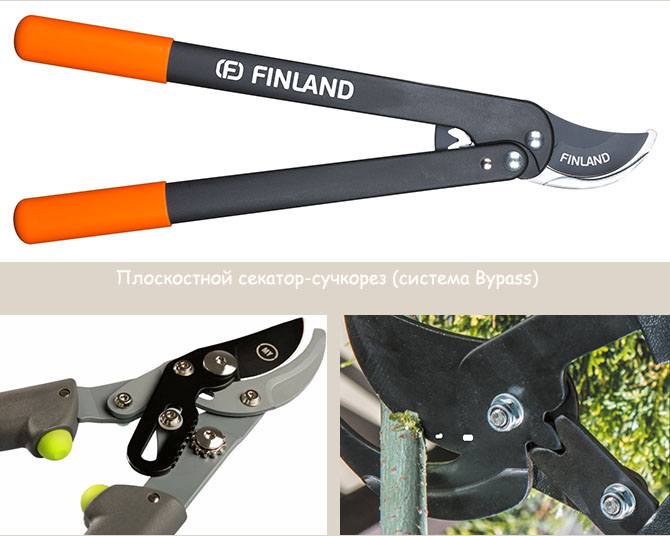

The principle of operation of the delimber

If you have to process fresh young shoots, then a plane lopper is suitable, and for dry and old branches it is worth choosing a contact one.

Type of drive. A mechanical tool will cope with a small volume, in other cases, electric or gasoline models are optimal. When choosing an electric lopper, you need to pay attention to the length of the power cord - if it is not enough, then you will have to additionally use extension cords. When buying a cordless tool, it is better to choose a model with a removable battery, then purchasing a second battery will allow you to work continuously. If there is no electricity on the site or the mains voltage is unstable, then it is better to purchase a petrol lopper. If there is no gas station nearby, then you will always need to have a supply of fuel on the site.

Blade holder. This option is a safety issue, so it is better to purchase a model whose blades are fixed when closed.

Ratchet mechanism. This option provides fast and high-quality pruning of thick branches, the cut line is smooth.If the branch was not cut off the first time, then you can loosen the pressure and squeeze the handles of the tool again - at this time the blades will remain in the wood.

Precision sharpening. This formulation in the characteristic of the delimber means a high sharpness of the cutting edges, that is, a greater efficiency of the tool.

Teflon coated. This provides the blades with extra protection. Thanks to it, the friction of the blades is reduced, so wood does not stick to them.

How to make a DIY garden electric shredder

A shredder for summer cottage needs can be made independently. This will not present any difficulty for an experienced locksmith. To do this, you need to purchase the following constituent elements:

Electric motor with a power of 1.5-2 kW.

A cutter with coarse teeth or circular saws in the amount of 10 pcs. with a diameter not exceeding 200 mm.

A finished axle or a steel circle with a diameter corresponding to the size of the seat of the circular saws.

A set of washers for separating discs with a thickness of 5-7 mm.

Belt for transferring torque from the engine.

Angle or channel for the bed.

Steel sheet with a thickness of 5 mm for the production of a working hopper, and with a thickness of 2-3 mm for creating a guide bell.

A set of wheels from a conventional trolley.

To complete the work, you will need a drill, a grinder, a welding machine, a set of fasteners and other tools.

In the case of chopping grass and small branches, you can make a shredder of a primitive design, in which the cutting mechanism will resemble a knife system for chopping cabbage. An old saucepan or metal bucket is suitable for the work hopper.

A purchased or self-made shredder makes life much easier for the gardener

For the knife mechanism, you can use a metal disc with knife slots, or sharpened plates. Once in the slots, the debris is crushed and thrown into the side opening. The feed socket must be designed in such a way as to keep fingers away from the knives.

If thick, coarse wood is to be used for processing, the shredder must have a more massive and stable structure. As a grinding mechanism, you will need a cutter with large teeth, which can be purchased at a mechanical engineering plant or grind yourself. The hopper should be made of 5 mm thick sheet steel. A powerful motor of more than 2 kW is required here.

An important part of the entire structure is the adjustable base plate, which facilitates the grinding of branches. It can be used to adjust the size of the crushed chips.

The entire powerful and rather heavy structure of the device must be located on a solid stationary base without wheels.

The cutter width can be different. But it should be remembered that with its increase, it is necessary to use a more powerful engine. If you cannot find a sufficiently wide cutter (40-50 cm), you can put several cutters of the same size and shape on the shaft.

DIY garden shredder

A good owner in his garage will surely find many components for making a shredder on his own from scrap materials and a grinder. This can save you a lot of money, and great results will be the reward for your hard work.

Before you buy a garden shredder with an electric motor, you should decide on the amount of work that it will perform. Then you should carefully read consumer reviews for specific shredder models. Here you can get the maximum of useful information that will dispel all doubts and help in making the right choice. It is worth taking a closer look at domestic grinders, which are no worse than their European counterparts, and their price will be much lower.Having bought a good shredder once, you will get a reliable assistant for many years.

What you need to know about delimbers?

Despite the fact that a mechanical lopper is a constructively simple tool, there are still rules for its operation and maintenance:

- When using the tool, protect yourself by wearing protective goggles and gloves. Work clothes should not hinder movement.

- Before starting work, it is necessary to conduct a visual inspection of the delimber, check the reliability of its fasteners, and the serviceability of the tool. It is recommended to perform a couple of test presses.

- To avoid injury, manipulate the instrument in a stable position.

- Upon completion of work, the delimber must be cleaned of dirt and wiped dry from adhering tree sap.

If the tool is made of metal subject to corrosion, it must be periodically disassembled, cleaned the internal surfaces of dirt, and then lubricated with oil. Otherwise, it may reduce the efficiency of its work.