Selection Tips

Before deciding on the choice of such a tool, it is necessary to outline a construction work plan. The SDS-plus drill will help out both the professional and the one who has just encountered the construction industry.

The first thing to look out for is the surface to be drilled. Depending on the technical characteristics, you can get rid of unnecessary noise, speed up the work and make it better.

And also it is worth deciding on the purpose of drilling. For example, to install switches and drill holes for a future picture, you will need different attachments.

When buying, it is advised to correlate price and quality. First of all, it is recommended to proceed from the tasks facing the construction work. Often, such a tool pays for itself in the first few weeks, so it is worth looking closely at more professional solutions.

The following video provides an overview of BOSCH SDS-plus drills.

Important parameters

Construction and repairs are impossible without drilling holes in various surfaces. And if an ordinary electric drill is quite suitable for making a hole in a structure made of wood materials, brick and drywall, then only a perforator is able to cope with a concrete structure. The peculiarity of this equipment is that it can not only drill the surface to be treated, but also exert an impact load on it, that is, it can function as a jackhammer. Naturally, for installation on a perforator, you must use a special tool - a drill. From a conventional drill for metal, it differs in a number of parameters.

Boers differ among themselves by design features, among which should be highlighted:

- execution of the spiral part;

- the presence of a special cavity in the inner part;

- material for manufacturing the working part, which can be used as a hard alloy;

- number and geometrical parameters of cutting edges.

The main parts of the drill

Drills are also distinguished from conventional drills by the shank design, which allows them to be securely fixed in the chuck of the equipment used. The most common types of concrete drill liners and chucks used with rock drills are as follows.

SDS +

SDS-plus drills, as well as cartridges of this category, are designed for installation on rock drills of medium and light series. It is devices of this type that are most often used by home craftsmen to perform various repair and construction work. SDS-plus shank diameter cannot exceed 18 mm.

Drills with this shank are designed for light construction punchers

SDS-max

The drills with SDS-max shanks intended for processing concrete (the diameter of their fastening part exceeds 18 mm) are used in the complete set of the professional series rotary hammers.

SDS-max system with increased wedge contact area for heavy rock drills

The main manufacturers of SDS-plus concrete drills (the most popular category) are Chinese companies. As a rule, the parameters of such products meet the requirements of GOST, so it can be installed on any perforators. Meanwhile, you should not try to insert a tool for working with concrete into an ordinary drill, since it will not work even with considerable effort.

To choose the right drill for a hammer drill, you should take into account such parameters of the working part as:

- length, on the value of which depends how deep the hole you can drill;

- diameter.

Drill bit operating parameters

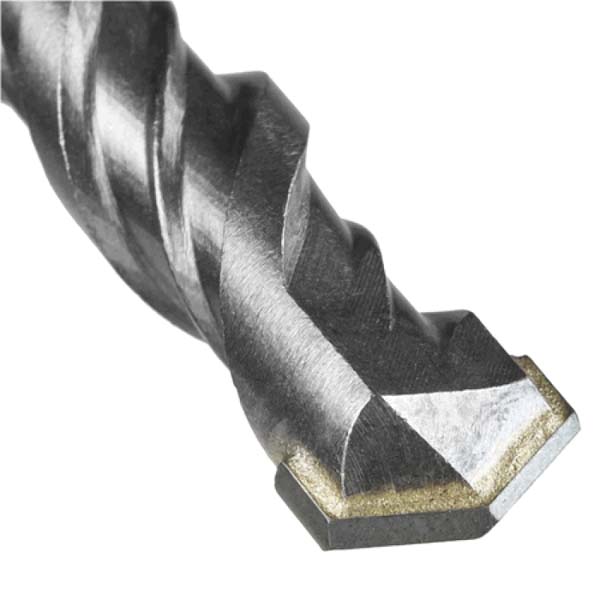

Taking into account the fact that drills for a perforator are used in work with especially durable material (concrete, natural and artificial stone), their design has a reinforced design, and the working part is made in the form of a double spiral.This is what makes it possible to use drills for a perforator when working with concrete and other materials for a long time, without worrying about their technical condition. Many models of concrete drills for rock drills are equipped with a tip made of the strongest alloy of the VK8 grade, which allows them to be successfully used for processing materials that are particularly strong.

It is not difficult to choose tools of this type: all their most significant parameters are indicated in the marking. For example, if you have a concrete drill in front of you marked 6x160, then this means that it has the following dimensions: working diameter - 6 mm, length - 160 mm. It should be borne in mind that the marking of the tool indicates its working length, which is slightly less than the dimensions of the working part.

The diameter of the working part of concrete drills mounted on a perforator can be in the range of 4–30 mm. The most popular sizes are in the 6-10 mm range. Using a concrete drill of this size, it is possible, in particular, to make a hole for placing a dowel.