Types of laser levels

If you look at the prices for these measuring instruments, you will see a very large run-up - from $ 20-30 to $ 850. As you can imagine, it’s not just that. A tool with different capabilities and accuracy cannot cost the same.

With such a device, many jobs become easier and take less time.

To choose a laser level, you first need to decide on the type of work for which you need it. Under these works and select a laser level. They are of the following types:

- Point (axis builders). Usually three to five points are displayed in different planes. No lines, no planes, they do not build. It will be possible to see only points, but at a great distance (to make it clearer, you can compare their principle with laser pointers). Used in large areas to transfer marks. Useful in repairs for marking lines for wallpapering, marking for fasteners for paintings, shelves, etc. In more serious operations, this type of tool is not used.

The simplest laser levels only give points in one or more planes. - Crossliners, line builders, line levels. Sometimes called plane builders, as they essentially form a plane of a certain size (depending on the sweep angle). When working with such a laser level, a straight line is displayed on any plane that falls into the laser range. This is used in construction and finishing works. The operating range is usually up to 20 meters, if necessary, it can be increased (if there is a mode of operation with the receiver). For repair and interior decoration of premises, it is convenient if the device can form vertical, horizontal lines, give a "cross" on the floor and on the ceiling. Due to the nature of the scanning of the rays, the line is displayed only on the part of the room into which the device is directed. For example, on one wall and part of the ceiling / floor. To get marks on another wall, the device must be turned around.

Linear laser provides one or more planes with a specific sweep angle - Rotary plane builders. The functions are the same as the crossliners, only the planes are rotated 360 °. For this, a complex system is used, which is reflected in the price. Tools of this type can only be justified by professionals (prices for this type of laser levels start at $ 400). For home use, they are useless.

Rotary laser levels rotate the plane 360 °

Now it is easier to choose a laser level, you already know what type of instrument you need. For most, it is a line / plane builder.

Best line laser levels

In this category, the leading devices are from the German manufacturer Bosch, the GLL 3-80 P model, capable of making projections of three full-fledged planes and the Chinese ADA - the 6D Servoliner and 3D Liner 4V devices, slightly differing from each other in functionality. In a sense, we can talk about the identity of the quality of all these devices, since the production facilities of the German brand are also located in the Middle Kingdom.

| ADA 6D Servoliner | Bosch GLL 3-80 P | ADA 3D Liner 4V | |

| Alignment type | automatic | automatic | automatic |

| Disable alignment | |||

| Self-leveling angle, degrees | +/- 3,5 | +/- 4 | +/- 3 |

| Measurement range with / without receiver, m | 50/10 | 80/40 | 70/40 |

| Tripod thread, inch | 5/8 | 1/4 and 5/8 | 5/8 |

| Number of batteries, pcs. | 4 | 4 | 3 |

| Beam color | Red | Red | Red |

| Accuracy, mm / m | +/- 0,1 | +/- 0,2 | +/- 0,2 |

| Beam direction | horizontal / vertical / vertical / down | horizontal / vertical / vertical | horizontal / vertical / vertical / down |

| Number of beams | 9 | 3 | 6 |

| Laser class | 2 | 2 | 2 |

| Wavelength, nm | 635 | 640 | 635 |

| Operating time on one charge, h | 10 | 18 | 8 |

ADA 6D Servoliner

Self-leveling laser designed for indoor and outdoor use. The best laser level in the line of its manufacturer - it produces 9 beams, 4 of which form a horizontal plane at 360 °, 4 show two vertical planes, showing the zenith at the intersection, and the plumb point - nadir. Self-alignment is realized not by a pendulum method, but by means of servo drives, which expose the planes with a device installation error of 3.5 °. If it is necessary to build inclined planes, the auto-leveling function is disabled.

+ Pros of ADA 6D Servoliner

- high accuracy of plotting planes;

- maximum number of lines;

- high-quality auto-tuning mechanism;

- manual adjustment allows you to set the cross exactly at the desired point;

- the ability to work from an outlet.

- Cons of ADA 6D Servoliner

- The battery life declared by the manufacturer is 10 hours, but in fact, users mark only 3-6 hours.

- short cord of the "native" charger.

Bosch GLL 3-80 P

A tool that allows you to build 3 fully enclosed planes. One horizontal and two vertical, at right angles to each other. The operating range is up to 40 meters without a receiver, and with it it doubles - up to 80. The device is equipped with an auto-leveling function that compensates for incorrect installation within +/- 4 °. If necessary, this option can be disabled. The arrangement of the lasers makes it possible to build reference planes practically close to the existing ones. Zenith and nadir are shown not as a dot, but as a cross of lines above and below.

+ Pros of Bosch GLL 3-80 P

- construction of three closed planes;

- the ability to disable and enable any plane as needed;

- small size and weight - compactness;

- the ability to build a plane 1.5-2 cm from the wall or ceiling.

- Cons Bosch GLL 3-80 P

- no fasteners with magnetization - the device must be installed on an additional stand;

- if the setting is lost, then even after auto-leveling, the sound signal must be turned off manually;

- all three lasers are on different bases and axes - potentially a high risk of misalignment.

ADA 3D Liner 4V

The six-beam plane builder allows you to simultaneously display the projection of two vertical planes, the lines of which intersect at the zenith, one horizontal, capturing the opposite and part of the side walls, and also shows the plumb point (nadir).

The self-leveling angle is +/- 3 ° - if the device is not able to self-calibrate, the laser beam starts blinking and a beep sounds. Also, the signal is triggered when the device is idle for a long time - if you forgot to turn it off, this saves battery power. The instrument is equipped with a built-in tripod and bubble level for easy surface presetting.

+ Pros of ADA 3D Liner 4V

- the accuracy of the construction of planes due to the fastening of lasers to one base;

- bright rays, lines do not thicken with distance;

- light weight - 900 grams.

- Cons of ADA 3D Liner 4V

- does not work from an outlet - it is advisable to purchase an additional set of batteries in reserve;

- it is impossible to turn on each line separately;

- horizon only 160 °

- if a beam receiver is needed, then it must be purchased separately;

- the auto-align function is not disabled.

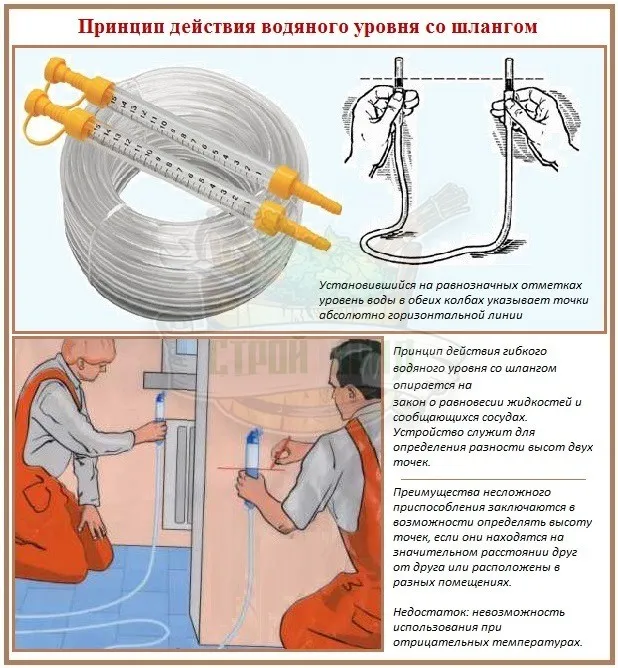

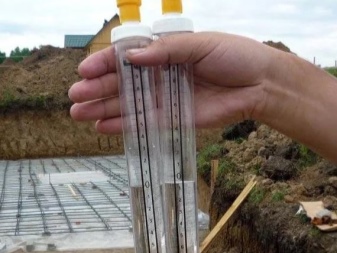

The simplest water level

The device consists of two flasks of equal volume, interconnected by a flexible thin hose. It is used for marking horizontal lines if the stakeout needs to be done in different rooms or at large distances. Those. where the use of a laser level is impossible, unprofitable or meaningless.

The principle of operation of an elementary device is based on the law of communicating vessels. The water level in both communicating vessels will always be at one absolute mark, for fixing which there are risks on the flasks.

The use of a water device allows you to correctly beat off the horizontal lines regardless of the real position of the surfaces of the floor, ceiling, parapet, etc. No digital apparatus has yet been able to replace it. Note that the reference horizon is bounced off by the water level, from which the heights indicated by the project are then deposited. With its help, they do not directly mark future planes formed by a suspended ceiling, logs or a screed with a finish, mounting points for plumbing fixtures, etc.

For marking with a water level, we will invite an assistant, we will act like this:

- On the wall, mark an arbitrary point at a distance from the floor, convenient for making markings;

- We apply one of the flasks to a point, fix and remember at what mark the water level is established;

- We send the assistant to the desired point. By moving his flask up / down along the wall, he must find a position in which the water level is established at an equivalent mark.

Weighty advantages of the device: low cost, simple operation and accuracy. Cons: inability to break down at negative temperatures, limited use, the need to wait until the level is established in both flasks.

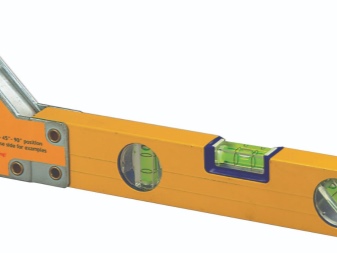

Best Stanley Bubble Levels

Stanley Torpedo FatMax Pro Box XTHT0-42495

Stanley Torpedo FatMax Pro Box XTHT0-424

Stanley Torpedo FatMax Pro Box XTHT0-42495

Small bubble level. In the case of extruded aluminum, twenty-three centimeters long, there is one horizontal capsule and two vertical ones. The right container has a 360-degree swivel mechanism.

Outside, the body is molded with rubberized plugs that do not leave marks when in contact with the surface. The measurement accuracy in both planes is half a millimeter.

The building level is suitable for home repairs, window installation, consumer electronics or headsets, small-sized carpentry work.

Stanley STHT1-43111-60

Stanley STHT1-43111-60

Stanley STHT1-43111-60

Medium spirit level with a magnetic substrate made of rare-earth metals. With a length of sixty centimeters, it includes two tanks for determining the horizontal or vertical tilt with an error of half a degree.

The body is lightweight, made of an aluminum box-section profile. Around the acrylic tanks and at the ends are treated with rubber plugs that protect against deformation during impacts.

The level can be used in decoration works, furniture production, doors or windows installation. It is poorly applicable for metal structures, because there are only two small magnets in the case, deeply recessed in the case.

STANLEY FATMAX XL 0-43-681

STANLEY FATMAX XL 0-43-681

STANLEY FATMAX XL 0-43-681

Two-meter building level with three measuring capsules in three solid acrylic blocks. Larger center tank for accurate horizontal angle measurement. The measurement error varies within half a millimeter per meter. It has through slots for hand gripping, treated with a soft sealing material. The ends are treated with a cast protective compound that increases wear resistance.

The tool can be used for carpentry, flooring, renovation, gardening or landscaping, paving stones and paths. There are no magnets in the case, so it is impractical to use on metal surfaces.

Latex paint or acrylic: what is the difference and which one is better to choose for different types of work (Photo & Video) + Reviews

Diagonal ampoule

If everything is immediately clear with horizontal and vertical ampoules, then "oblique" is a kind of stumbling block for beginners. There are no difficulties here - this is a diagonal running at an angle of 45 degrees. It is necessary in places where you need to draw a clear bevel between two specific points. Replaces the protractor in this case - you do not need to first cancel the value in half a right angle.

A level equipped with such a goniometer is called a goniometric level.

Follow the steps below to set the desired angle.

- Turn the swivel flask to the desired mark by loosening the fixing screws on the instrument.

- Set the ampoule to the desired angle using a ready-made scale. When turning the ampoule, hold it at each degree for increased measurement accuracy.

- Place the level gauge on a surface such as a pipe at a specific angle. In this case, the air bubble should be in the middle of the ampoule - that, in turn, is located horizontally.

After setting the desired angle, draw a guide line. A pipe or structure will be led along it, the angle for which has already been selected.

For an overview of the Stabila and Kapro building levels, see below.

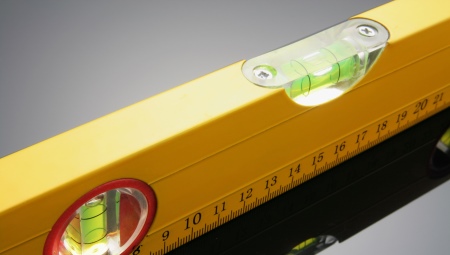

1.Bubble building level

This is the most common type of building level. It is a very simple, but quite functional device.

Design

This is a rectangular frame, most often made of aluminum and hollow inside, with a transparent bulb in the middle. It is the measuring flask, sometimes called the "peephole", that is the most critical part of the level. The flask is filled with liquid, industrial alcohol is most often used for these purposes, since it has a lower density compared to water, and the air bubble, due to this, reacts more sensitively to deviations and moves faster inside the flask.

Often, the liquid inside the flask is tinted, and in modern levels fluorescent particles are also added to it to facilitate work in the dark. Lines perpendicular to the body of the level are applied to the flask, which serve as the permissible limits of deviation. That is, looking at the flask, you will see two thin lines, an air bubble and again two thin lines. If the bubble is clearly in the middle between the lines, then the surface is perfectly flat.

An important point - the larger the bubble itself and the less space remains from it to the lines on both sides, the more accurate the device will be and the smaller its error. By the way, there are levels with the ability to customize. The bulb at such levels is attached with fasteners, which makes it possible to adjust it at any time. The most common type of bubble level is a level with two flasks. One is used to control the deviation from the vertical (90 degrees), the other - from the horizontal (180 degrees). They are located perpendicular to each other on different planes. If you see three cones, then the last one is used to measure 45 degrees from the horizontal plane or is rotary, to measure any angle of the surface. There are also levels with a large number of flasks, which duplicate horizontal and vertical flasks, such levels are used for very important work, since they have a higher measurement accuracy. Modern levels are additionally equipped with various useful functions:

Stiffening ribs are a very important element, the presence of which will make the level body more durable and protect it from deflection, which is especially important when using long levels.

The markings made on one of the surfaces of the level can be used as a ruler, which makes it possible to refuse additional tools and free your hands.

A milled surface, often located on the opposite side of the measuring flask, prevents the level from sliding off the working surface and facilitates the force that must be applied to hold the level with one hand.

The striking pad is necessary for adjusting the test surface by applying moderate hammer blows.

The groove for pipes is a very convenient additional function when working on the distribution of sewer pipes, which prevents slipping from the radius surfaces.

Magnetic side - there is a magnet at one end of the level, which allows it to be fixed to metal surfaces for hands-free installation.

The length of the bubble levels starts at 20 cm and reaches 3-4 m, which makes them versatile for any application. For example, for simple DIY repair work, a level 30-40 cm long will be enough, for laying tiles, you should choose a slightly longer length - 40 cm-1 m.And if you are planning to make a screed, or to decorate the walls, then here you need a level with a length from 2 meters.

Bubble Level Benefits

- Quite high structural strength, especially in the presence of stiffening ribs

- Very easy to operate, no special skills are required to use it

- Suitable for both home use and more precise work

- Available in various sizes, which makes it possible to choose the tool that is most convenient for you and most suitable for a specific task

- Affordable price

disadvantages

- If you get a low-quality level of dubious production, then it will go wrong very quickly.

- Bubble levels fear drops and bumps

- If you have chosen a bubble level with the ability to adjust, then remember that they go astray more often, and to adjust them you will need a flat surface that is not always at hand.

Description and purpose

The building level is a measuring device used to control the installation of materials and structures in the horizontal and vertical planes. The main parameters of any level are:

- measurement accuracy - the larger the tool dimensions, the lower the error will be.

- impact resistance - in most cases, the building level assumes a hollow body, while its wall thickness can reach 100 mm in order to withstand mechanical shock;

- resistance to bending and twisting.

Typical levels represent a rectangular cast body, the lower edge of which is milled. Usually they are made from strong, but at the same time, lightweight materials (for example, plastic, wood, as well as polystyrene or aluminum with an anti-corrosion coating). Depending on the ultimate measurement accuracy, a certain number of glass flasks are provided in the body, inside which an alcohol-containing liquid with an air bubble is poured. If there is only one flask, a similar level can be used exclusively for a horizontal guide, a pair of flasks allow measurements to be made horizontally and vertically, and three or more are used for complex work when it is necessary to measure the slope parameters.

Risks are applied on the surface of the tool - dividing lines, eyes for alignment have special reflectors, and plugs are made of plastic. On the ends of the tool there are pads that protect the mechanism in case of accidental fall. For the most comfortable bubble control for the eyes, the liquid may contain fluorescent components, so that work can be carried out in the evening and at night.

Varieties

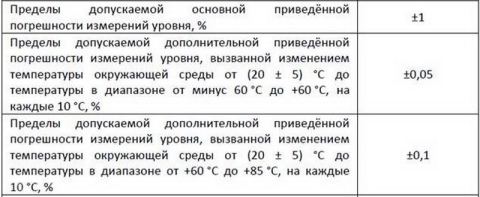

Bubble-type devices are most widely used, their design is simple, intuitive and versatile. The measurement error does not exceed 1 mm / m. This device is manufactured in strict accordance with the current GOST 9416-483. The body is of a simple design with strong stiffening ribs, the size of the tool varies from 30-50 cm to 5 meters or more. To reduce the weight of the structure, the level is made of aluminum alloys, and the ampoule is made of extra strong glass. A scale for measurements is provided near the base.

Magnetic bubble levels are mainly used to work with metal structures.Their characteristic feature is the presence of built-in magnets, which makes it possible to fix the device in an upright position on metal structural elements. Products with a reinforced monolithic body are more suitable for working with stone. If you are going to carry out complex measurements, you should give preference to combined products that combine the features of both types.

Electronic models with a goniometer are usually referred to as expensive measuring equipment; they have two or more cameras at once in order to assess the horizontal and vertical of the processed planes. Unlike typical standard products, these devices are characterized by a set of additional functionalities: one of them is a display that visually displays the size of the deviation of the measured planes with a high degree of accuracy. In addition, they provide the option to record the measured values. An audible indicator is provided in the electronic mechanism - it gives a signal when it reaches 0 or 90 degrees.

Some construction and repair work requires the use of a hydro level, it is needed to apply correct markings in a horizontal position on several objects located at a distance from each other. With the help of such a device, floor beating is carried out, the foundation is installed for brickwork, as well as the installation of metal structures in a single plane. The hydrostatic mechanism looks like a pair of vessels held together by a transparent tube. Before starting operation, the system is filled with liquid, no kinks and breaks of the tube are allowed - the liquid must flow freely from one container to another.

Laser models are better known as levels, they belong to the category of professional equipment. The cost of such devices is high, but they provide many additional advantages:

- increased marking accuracy - the error parameter does not exceed 1 mm / m, depending on the type of mechanism;

- technical parameters of laser levels allow measuring vertical, horizontal and inclined surfaces at a distance of up to several meters from the measurement area.

Diagonal, vertical, horizontal alignment

When performing even small construction work, it is very important to position the windows vertically and the floor horizontally. The work is carried out as follows:

- Horizontal alignment.

The lower plane of the level rail must be exactly concave. Its absence will cause a large error in measurements, which is unacceptable. It is applied to the surface measured by the device with this working side. The bubble should not go beyond the marks.

- Vertical alignment.

The level is applied to the wall, then you need to pay attention to the readings of the bubble: if it is not pushed back into the middle of the ampoule between the marks, then the wall is not even. The ampoule itself must be exactly at the top of the level when measuring

That is, if you turn the level over, the deviation in the measured surface will be very large.

- Diagonal alignment.

For the convenience of work, it is enough to set the ampoule, following the scale, to the required degree, turning it. And, having applied to the surface, it is necessary to carefully monitor the air bubble when setting the level. As soon as it settles in the middle of the marks, the required angle is found.

On sale you can find both fixed goniometers, and rotary ones, which allow you to set an arbitrary degree, both 45 ° and 68 °.