The choice of design for the intended purpose

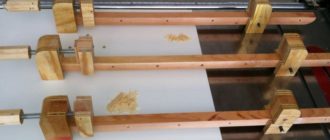

Homemade clamps in their functionality are no different from those made in production. They can be used for gluing boards, assembling furniture, gluing panels. Various tools are used for carpentry, including clamping, F-shaped, table clamps. Depending on the purpose, it is worth choosing the right unit, taking into account its design features. For example, for frames and for an echo sounder, furniture and eccentric clamps will differ from each other. Each of them is designed to fulfill a corresponding task and is not a universal tool.

If you plan to fix large workpieces, then a pipe structure will be the best option. Its advantage is that the length can be easily changed. However, such a unit has a complex operating mechanism. In carpentry, the angular version of the tool is often used. With its help, it is easy to bring together wooden blocks at right angles. Sometimes these clamps are used for laminate flooring. Carpenters also use tape tools.

In their appearance, the spring units resemble a hitch. With this type of clamping clamp, the force is generated by the installed spring. It is very easy to work with such a tool without using the other hand. The unit is used in the case when a large compression is not required, and on the contrary, this condition must be met, otherwise the workpiece may suffer, since it was made of a brittle material. There are clamps with a clip and an automatic type. It is difficult to make one yourself, but it is possible if you have the skills to work with electronics. This type is referred to as quick-clamping structures. The principle of operation of the unit is simple and straightforward.

It is very important for the guide bar with what force the compression is produced. Poorly made and inexpensive instruments have weak fixation

End models have found their application in the furniture industry. There they are used when working with overlays on tabletops. There is another budget option for the clamp - G-shaped. To work with such a unit, it will first need to be fixed on a tabletop or any other plane. The clamp will become an indispensable assistant when working on gluing, grinding or sharpening workpieces.

Varieties

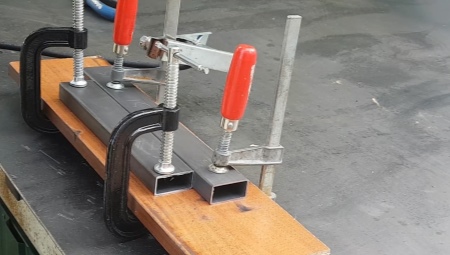

Using clamps in your work, it is worth remembering that they are much weaker than a vise, therefore they cannot be considered a reliable lock. In addition, its clamping capabilities are limited by the dimensions of the clamping frame. Therefore, for reliable fixation of the workpiece, it is necessary to use several clamps at once. If you need to glue the joinery board, then this will require more than a dozen devices.

The clamp can be made of wood or metal. Metal models are much more durable and last longer than their wooden competitors, and they are also not afraid of moisture. Metal fixtures can not only fix the workpiece, but also press with the required force. This point is very important when working with cladding parts, where dents are unacceptable.

There are many different clamps:

- F-shaped;

- G-shaped;

- for corner joints;

- for end fit;

- spring mechanisms;

- screw;

- pipe;

- lever;

- automatic;

- tape.

Each type of clamping tool performs a certain type of work. There is no one very good kind of clamps that will suit all occasions.As with any device, you need to know how to use clamps and know their purpose.

Design and principle of operation of the tool

The clamp is an analogue of a vice, only its main difference is that it belongs to the category of mobile tools. Its main feature is its low weight and simplicity of design. The tool is arranged by analogy with the fastening of manual meat grinders fixed to the table before starting work on the processing of meat and other products.

Metal, plastic and wood are used for the production of the clamp. Tools made of plastic and wood have low strength, so such devices are produced in small sizes for fixing small parts. Structurally, the tool is based on a frame or base in the shape of the letter "P". A movable screw with a lock at the end is attached to one edge of the frame, through which the part is fixed. The second side of the frame is equipped with a thrust heel, which is a fixed part.

Above is the design of a conventional or classic clamp, but few people know that these tools are available in different types. The varieties of clamp designs depend on the scope of their application, as well as on the characteristics of fixation. Before choosing a clamp, it is recommended that you understand their varieties in order to understand which option is best for performing the planned actions.

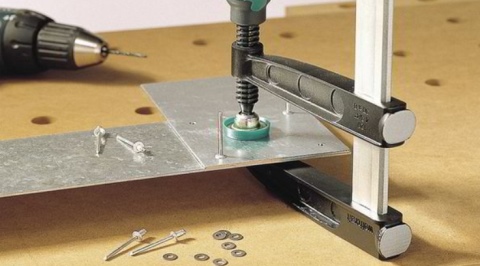

Making a clamp for metal

Clamps for working with metal must also be made of metal.

What you need to work

To work, first of all, you need to decide which clamp you will have to make. Although this is not a very complex product, it is advisable to at least make a sketch drawing and apply the basic dimensions on it. After that, you can pick up materials.

You will need ordinary locksmith tools - a workbench, a vice, a hammer, a drilling machine, taps and dies for threading, emery.

Manufacturing technology

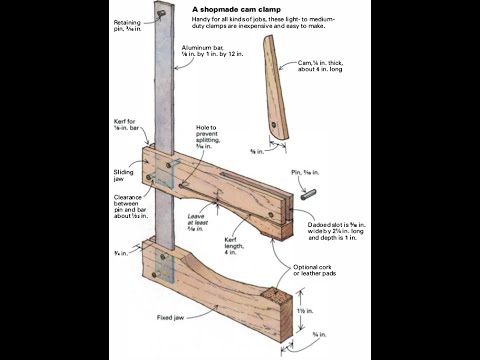

For homemade clamps, a simpler design is usually chosen. As a rule, they are required to solve immediate problems. The very process of making such products will be more accessible. Of course, the options for foundry technologies are unacceptable for the DIYer. He will not make a forged bracket. And a milling machine is not available to everyone. The easiest way is to make a C-clamp and even several pieces of different sizes.

For this, a strip of steel is taken with a width of 150-200 mm, a length of 350-400 mm and a thickness of 10-12 mm. A hole is drilled at a distance of 15 mm from one of the ends and an M8 thread is cut. Here, for strength, a nut with the same thread should be welded. The strip is bent in a vise in the shape of the letter "P". Then take a stud or bolt with an M8 thread and a length of 100 mm and screw it into the threaded hole on the bracket. At the outer end of the hairpin, you need to make a knob, and at the inner end, a rotating stubborn "heel". The clamp is ready. To create more or less forces, the size of the device must be increased or decreased.

Homemade clamp

Homemade clamp