Care rules

Proper care allows you to extend the life and protective properties of the product. Caring for welding leggings consists in performing simple actions.

- Clean or wash items regularly. Leather and suede leggings should be cleaned with products specially designed for these types of material. After cleaning, leather products are recommended to be lubricated with a special leather cream - to maintain their elasticity. It is especially necessary to process the areas between the fingers. Split leather models should also be cleaned with leather cleaners. Felt and canvas mittens are washable. Washing should be carried out as follows: first, the products are soaked for 45 minutes in a warm (with a temperature not higher than +40 degrees) solution of antibacterial soap to remove all dirt. After that, the mittens are thoroughly rinsed in cold water, and then dried well: they must be dry both outside and inside.

- It is required to store the products in a dry place, out of the reach of direct sunlight, avoiding contact with chemically active substances and away from the heating system (no closer than 1 m).

The following video provides an overview of welding gaiters.

Additional processing

It is important to note here that gray split leggings without lining, without any additional processing or impregnation, can be used in the following temperature range: from -10 to +45 degrees Celsius. However, in order to make them the most optimal for use by welders, they are most often treated with a special compound

Thanks to this action, the gloves become more resistant to splashes of sparks or even hot metal. It is also important to add that after an additional processing process, the temperature limit increases from 45 degrees to 100 degrees Celsius.

Kevlar thread is also used in the production of split leggings. It is used to sew seams on gloves. This material belongs to the para-aramid group. In other words, this thread adds a high margin of safety, and, by itself, has a high rate of fire resistance.

Use of gloves

The primary purpose of using gaiters is to completely protect the hands and forearms of the person working with the welder from flying sparks. This part of the workwear should be tightly fitted to the size of your hand. Otherwise, it may subside during operation, which is unacceptable. In addition, split leggings also protect against burns that can occur if a working technician accidentally touches a hot metal surface.

This type of gloves is also suitable for other, installation work associated with increased stress. In other words, in addition to welders, this type of leggings is suitable for specialists working in such fields as: steelworkers, blacksmiths, as well as all representatives of professions whose work is associated with an elevated temperature environment.

Advantages and disadvantages

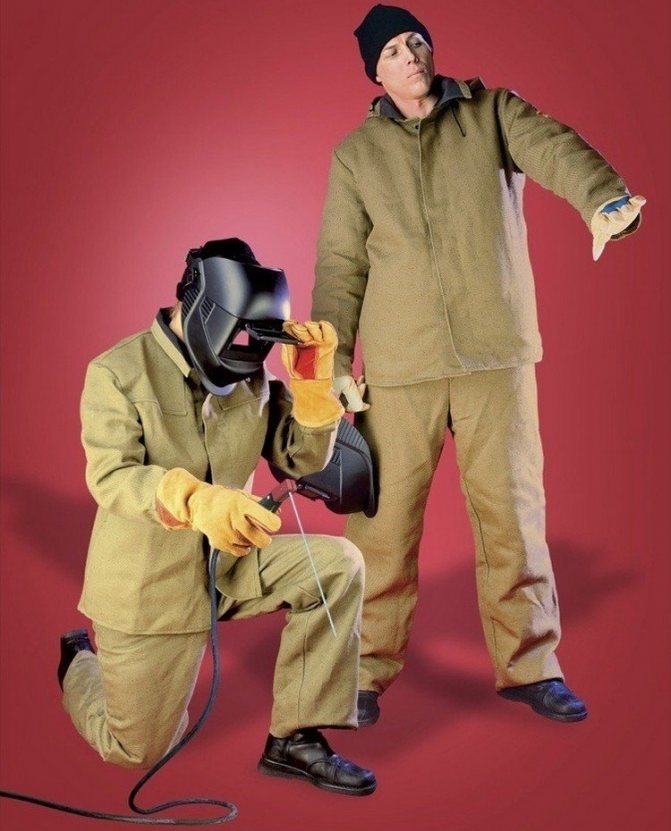

Split suits have advantages over other materials. They have many advantages:

- provide the highest class of protection due to heat resistance;

- high density (on average 550 g / m2) increases resistance to mechanical stress;

- withstand low temperatures, the influence of moisture, chemicals;

- have a long service life without degradation of performance.

However, there are also some disadvantages. Due to the high density of the material, there is no air exchange.The impervious one-piece suit makes the worker feel uncomfortable. In the constant presence of high temperatures, it will be hot, overheating may occur.

Views

The face split is rarely used for the manufacture of work gloves. The top layer is used to make expensive models of gloves from high quality leather. Working models from the front split file are sewn from waste received at the main production. Even the smallest flaps and pieces of genuine leather are used to make gloves.

The face layer is highly valued for its main quality - the ability to restore its original shape after various types of deformation. In addition, this layer of the skin is characterized by firmness, elasticity, high strength, excellent air permeability, but retains water. When dry, after getting wet, the material may shrink slightly. In the insulated version, this type of gloves becomes an integral attribute of the builder for winter work.

Gloves made from a medium cut, which has the characteristics of increased durability, are the most common among builders. The products are used to work with heavy metal and wood parts.

They are reinforced in the palm area, which increases their strength and extends their service life.

Welding all-split leggings are made of a fleece layer. They are not afraid of open fire sources and high temperature conditions.

Bakhtarma is the layer of animal skin that protects internal organs and tissues from external thermal shock. The bakhtarmya layer is inferior to the middle layers of leather in terms of strength, and it has no equal in terms of thermal insulation properties.

The product's ability to withstand high temperatures is not affected by the cut layer. Usually, for the manufacture of products for working with fire, a layer with a thickness of 0.6 to 1.2 mm is used. The main quality characteristics of the split are density, wear resistance. All these properties depend on the manufacture of the leather and its quality.

Grade is very important for five-fingered gloves. It is established based on the presence of defects and the basic properties of the material. With a weak or destroyed structure of the split, a decrease in the breaking resistance is observed. The reason is a violation of the processing technology. For working models, one of the main quality indicators is tensile strength.

For different types of layers, this strength indicator has different requirements. The lower the strength, the lower the level of wear resistance, resistance to cuts, tears and punctures. To date, materials are not tested for tensile strength, since it is excluded from mandatory certification. Therefore, experts recommend checking split gloves for compliance with EN 388, and for welding models also for compliance with EN 407.

Species overview

Welder's leggings are of several types. The division is based on the features of their design.

Five-fingered. As the name implies, these leggings have a separate hole for each of the fingers. This type of gloves is optimal in terms of comfort and convenience. Five-fingered leggings do not reduce the mobility of the fingers and are considered universal - they are suitable for all types of assembly and welding work. In accordance with the requirements, leggings are made of split leather with additional leather inserts. The inside of the glove is covered with an airtight fabric or fleece. Length according to GOST - 35 centimeters.

They have special textile inserts on the palms and on the back of the hand. The lining for them is made of cotton fabric, and the reinforcement is made of double split leather or tarpaulin. It is worth noting that now most of the welding gloves are combined. Although, of course, you can find simpler options.

- Extended sleeve length.

- Expanded socket, for putting on over a winter jacket or overalls.

- Insulated lining made of fur or reinforced fabric.

All this allows you to work comfortably even in very low temperatures.

How to care?

To keep welding gloves made from this material in good condition, there are some important care guidelines to follow. So, remember that it is recommended to regularly process them using special water-repellent compounds.

You can also apply special aerosol solutions to them to help prevent material contamination. Before cleaning gloves, if necessary, it is better to dry them completely at room temperature.

The material itself can be cleaned with a rubber brush.

You can find out how to extend the service life of welding leggings in the video below.

Peculiarities

Split five-fingered leggings are working overalls. They are designed to protect the hands and forearms from harmful and dangerous influences arising in the working area.

They do not look like regular work gloves, as they have:

- increased resistance to punctures, tears, cuts;

- protect from sparks;

- protect hands from burns in case of accidental contact with hot metal surfaces;

- high abrasion resistance, at least twice as high as that of similar canvas gloves;

- softness and elasticity, allowing the worker to freely use all five fingers without loss of sensitivity.

Split leather gloves are used by blacksmiths and steelmakers, as well as other workers in the so-called hot workshops. They work in insulated five-fingered leggings even at low temperatures. As a rule, a special impregnation is applied to the crag material, which significantly increases the ability to withstand thermal loads. For example, gray leggings not treated with impregnation, on which there is no lining, are operated at a maximum temperature of +45 degrees.

Gloves that have undergone the processing process are guaranteed to protect hands from heat reaching +100 degrees. Strong material requires the same threads to connect the individual parts. Workwear manufacturers use fire-resistant Kevlar threads for sewing. The seams of the leggings are very strong.

Selection Tips

When choosing leggings for work, you must, first of all, take into account the nature of the activity. When it comes to welding, then you need to choose gloves made entirely from split leather. It will be useful to look for a model impregnated with a refractory composition.

If we are talking more about installation work, then here the main attention should be paid to the thickness of the protective layer. The best, of course, would be the combined A-class models.

Now, with regard to the type of gloves. If you know that you have to do fine work, where fine motor skills are required, then you cannot do without five-fingered gloves. However, if the nature of the future work is rather rough, then it is quite possible to get by with three-toed or two-toed models. They are not so convenient, but they are cheaper.

The most important nuance is the presence of a stamp on compliance with GOST standards. If there is no stamp, then you cannot be sure of the quality of the gloves, perhaps at the decisive moment they will let you down

Also, great attention should be paid to the manufacturer. According to user reviews, the highest quality is offered by Swedish manufacturers such as ESAB.

They provide the highest level of protection and comfort. However, many may be scared off by the price, which starts from 1,500 rubles per pair.

Russian-made gloves are also in great demand. The leader of the domestic market is the Bars company. Their products are also very comfortable and durable, and the inner lining is made of a pleasantly soft material. The only thing they are inferior to the Swedish models is in durability. Their lifespan is lower, but they make up for it with an affordable price.

Although the service life is a rather controversial issue. Despite all the indicators of split leather gloves, they also need to be looked after. With due attention to the condition of the gloves, they will last much longer. For example, they must be cleaned of contamination. They cannot be washed, either in a typewriter or by hand.

To clean, it will be enough to dry them, and then take a good walk with a dry brush or rag, paying special attention to the place of contamination. And if you do not take care of them at all, then an expensive model can begin to deteriorate after just a few uses.

It is also very important to choose the correct size of the gaiters. The glove should fit as tightly as possible on the hand

Under no circumstances should it slip off your hand. But do not overdo it, your hand should be comfortable inside the glove, including when bending your fingers and performing various hand manipulations. If you feel that the glove is squeezing your hand, it is better to choose a larger size.

An important point is the integrity of the protective layer of the cuffs. If there is a puncture or tear on the surface of the gloves, they will begin to let heat inside, and liquid metal, hot oil, or even fire from welding can also seep through it. It is very dangerous, therefore, it is imperative to check the integrity of the outer layer of the gloves before each use.

What models of split leggings are better to use, see the video.

Advantages and disadvantages

Regardless of what thickness the material is used, the products have certain advantages and disadvantages.

- Durability makes the gloves resistant to mechanical damage, punctures, cuts. These qualities are inherent in the middle layers of the split.

- Convenience and comfort are provided by products made of front layers. The products fit your hands nicely and serve as reliable protection against all kinds of external influences.

- Resistance to high temperatures, heat resistance is a prerequisite for models used in welding and associated with incandescent masses and fire. In the manufacture of such heat-resistant products, middle layers and a splint are used. Moreover, the indicators of the latter are much higher.

- Only products made from the top layer are moisture resistant. These gloves can be used in all weather conditions, even in heavy snowfalls or rains. For winter work, use insulated leather products.

Choice

When choosing this workwear, it is very important to understand for what purposes it will be used in the future. If it will be operated in an elevated temperature environment, it is best to purchase five-fingered welder split leggings, which have a refractory impregnation

The seam of the gloves will also be an important factor in choosing. This place is considered to be the weakest in all gaiters. The seam must be made of a special thread that will provide the required density, high strength, and the required heat resistance.

It is important to note that five-fingered gloves are also suitable for finer work. Split leggings of this model are almost universal, the only selection criterion is the length

It is necessary to choose so that when putting on the glove, it sits tightly, but at the same time does not hinder the movements of the fingers and does not squeeze the hand itself too much. But in no case should the glove slip off.

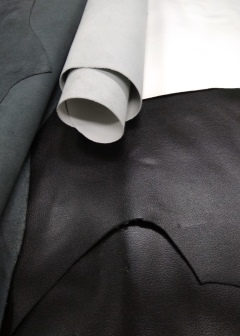

Materials (edit)

When creating split leggings, split is used as the main material. However, it, in turn, can be very different. The second and third layers of skin are usually much thinner than the first, which adds a number of additional features to them. Gloves made of thin split leather are much more comfortable and pleasant to the skin, and when creating them, no lining materials are required.

Split layers with a thickness of more than 1.2 millimeters are used to create class A leggings.Such leggings are very reliable: they are almost impossible to damage during operation and they can withstand temperatures up to 100 degrees Celsius. Grade A gloves can be a little restrictive, although the effect is almost imperceptible. In addition, the thick split leather is not very pleasant to the touch and can even irritate the skin, which is why such gloves always have an additional layer of fabric lining.

For fastening gloves, Kevlar thread is most often used. Lavsan threads can also be used, but in this case, the manufacturer will be obliged to strengthen the seam with an additional leather insert. Depending on what kind of leather was used for the production, the split can be of different colors. The most common are gray leggings, as well as various shades of yellow, orange and brown.

Some manufacturers coat their gloves with a coat of fireproof paint. It not only gives them a more presentable appearance, but can also slightly increase the protective properties. There are also leggings with a siliconized coating, which gives them full water resistance. These gloves are widely used for working with liquid nitrogen. There are also models that have increased fire resistance. They are impregnated with a special refractory compound.