Grinder gearbox lubrication

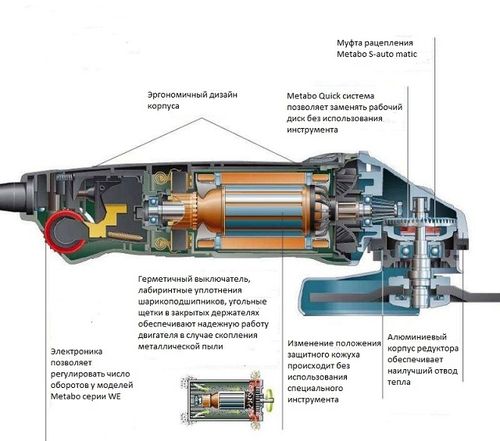

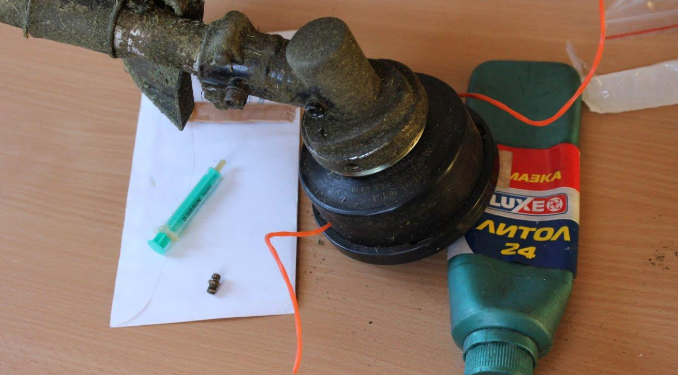

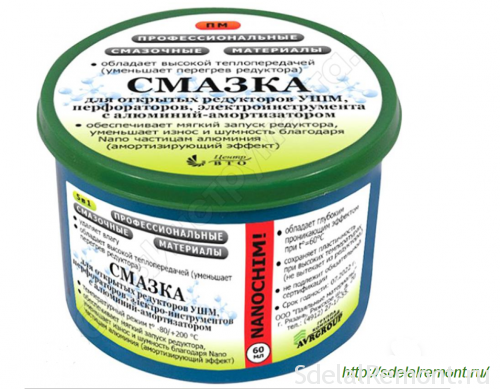

The angle grinder works under extreme conditions and under heavy loads. Due to this, periodic lubrication of the grinder's gearbox is necessary, since high lubrication requirements are imposed on the moving parts of the power tool. Otherwise, if there is a shortage of lubricant, increased wear will occur and the service life of the power tool will be reduced.

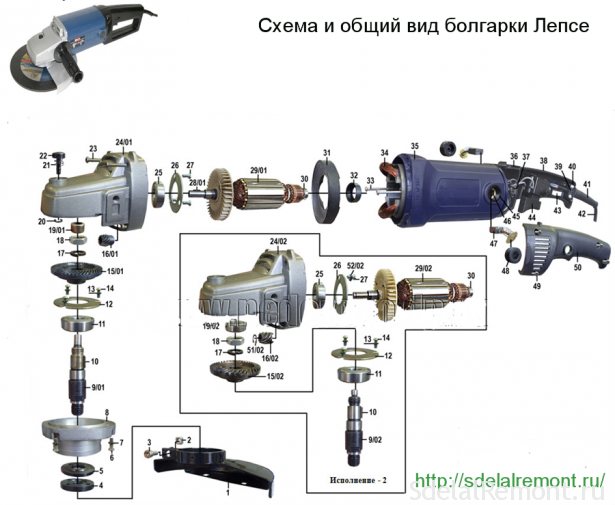

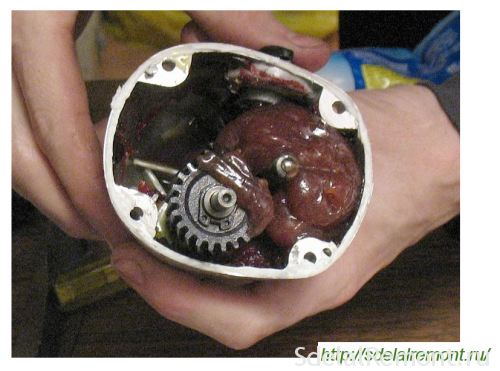

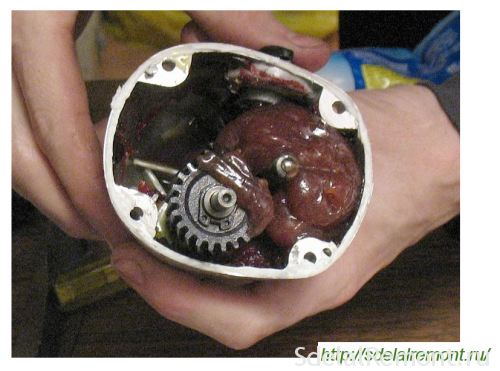

The LBM gearbox is designed in such a way that the grease of a pair of gears under the influence of centrifugal force moves to the walls of the housing. A sign of "draining" the gearbox is increased noise during the operation of the grinder. Opening the gearbox housing makes the problem obvious. All factory lubrication is on the walls of the housing, the helical gears are practically dry.

We check the degree of wear of a pair of gears, and damage to the teeth. Replace the gears if necessary.

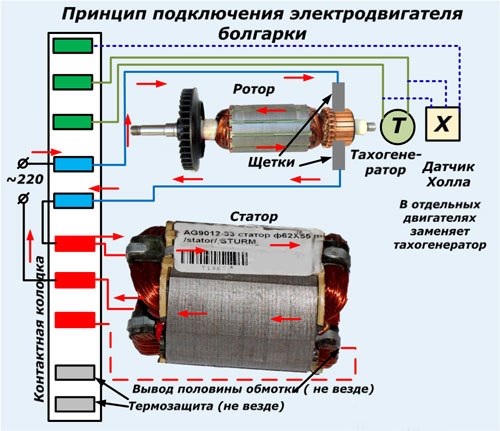

We clean the surface of the gears from mechanical dust. We lubricate the closed bearings of the motor rotor and the gearbox working shaft with liquid engine oil. We turn the rotor vigorously, for uniform penetration of the lubricant into the bearing. Remove excess liquid lubricant with a clean cloth. If this is not done, it will mix with the gear grease and make it thinner. The oil will not adhere well to the gear teeth.

We clean the surface of the gears from mechanical dust. We lubricate the closed bearings of the motor rotor and the gearbox working shaft with liquid engine oil. We turn the rotor vigorously, for uniform penetration of the lubricant into the bearing. Remove excess liquid lubricant with a clean cloth. If this is not done, it will mix with the gear grease and make it thinner. The oil will not adhere well to the gear teeth.

If the factory grease for the grinder in the gearbox is of normal quality, we apply it to the teeth of both gears as thick as possible. If there are signs of grease aging, we flush the gearbox with kerosene or other penetrating liquid, and replace the grease.

If the factory grease for the grinder in the gearbox is of normal quality, we apply it to the teeth of both gears as thick as possible. If there are signs of grease aging, we flush the gearbox with kerosene or other penetrating liquid, and replace the grease.

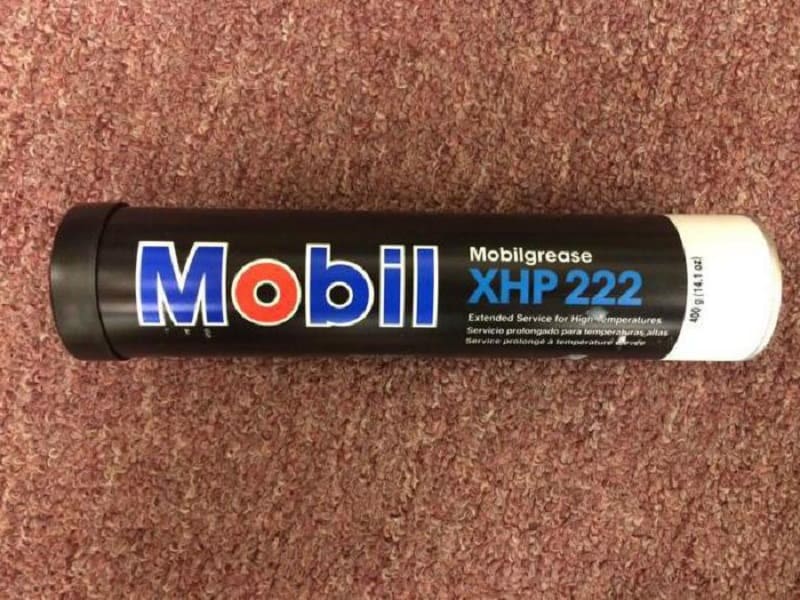

On the question of how to lubricate the grinder's gearbox - any high-temperature grease is suitable, for example, for lubricating CV joints and car wheel bearings. Do not forget to apply it to the shaft support bearing.

We assemble the gearbox by carefully tightening the fasteners. If you leave play in the gear pair, the gearbox can jam.

We assemble the gearbox by carefully tightening the fasteners. If you leave play in the gear pair, the gearbox can jam.

Also, when servicing the angle grinder, it is necessary to lubricate the second bearing of the rotor and check the condition of the motor brushes.

Depending on the intensity of use, a similar procedure (lubricating the grinder's gearbox and checking the condition of moving parts) must be performed regularly. This will extend the life of your power tool.

The angle grinder works under extreme conditions and under heavy loads. Due to this, periodic lubrication of the grinder's gearbox is necessary, since high lubrication requirements are imposed on the moving parts of the power tool. Otherwise, if there is a shortage of lubricant, increased wear will occur and the service life of the power tool will be reduced.

The LBM gearbox is designed in such a way that the grease of a pair of gears under the influence of centrifugal force moves to the walls of the housing. A sign of "draining" the gearbox is increased noise during the operation of the grinder. Opening the gearbox housing makes the problem obvious. All factory lubrication is on the walls of the housing, the helical gears are practically dry.

We check the degree of wear of a pair of gears, and damage to the teeth. Replace the gears if necessary.

We clean the surface of the gears from mechanical dust. We lubricate the closed bearings of the motor rotor and the gearbox working shaft with liquid engine oil. We turn the rotor vigorously, for uniform penetration of the lubricant into the bearing. Remove excess liquid lubricant with a clean cloth.If this is not done, it will mix with the gear grease and make it thinner. The oil will not adhere well to the gear teeth.

If the factory grease for the grinder in the gearbox is of normal quality, we apply it to the teeth of both gears as thick as possible. If there are signs of grease aging, we flush the gearbox with kerosene or other penetrating liquid, and replace the grease.

If the factory grease for the grinder in the gearbox is of normal quality, we apply it to the teeth of both gears as thick as possible. If there are signs of grease aging, we flush the gearbox with kerosene or other penetrating liquid, and replace the grease.

On the question of how to lubricate the grinder's gearbox - any high-temperature grease is suitable, for example, for lubricating CV joints and car wheel bearings. Do not forget to apply it to the shaft support bearing.

We assemble the gearbox by carefully tightening the fasteners. If you leave play in the gear pair, the gearbox can jam.

We assemble the gearbox by carefully tightening the fasteners. If you leave play in the gear pair, the gearbox can jam.

Also, when servicing the angle grinder, it is necessary to lubricate the second bearing of the rotor and check the condition of the motor brushes.

Depending on the intensity of use, a similar procedure (lubricating the grinder's gearbox and checking the condition of moving parts) must be performed regularly. This will extend the life of your power tool.

Do-it-yourself grinder grease

A do-it-yourself grinder gear lubricant consists of a base and a thinner. The basis of a homemade lubricant is usually a CV joint with molybdenum disulfide or Tsiatim-221. They have a second viscosity according to NLGI, therefore, for use in the gearbox of an angle grinder, the base must be thinned. As a diluent, it is best to use a simple industrial mineral oil, which, for example, is I-20 oil. To obtain a viscosity of NLGI 0, you will need to mix approximately 70 percent base and 30 percent thinner. The resulting mixture is thoroughly mixed and ready to be applied to the gears and bearings of the angle grinder.

Making grease with your own hands

Timely maintenance of any electrical tool is the key to its long-term and trouble-free operation. A properly working tool is also a guarantee of safety for the person using it. Using the tips given above, everyone can choose the right lubricant for the angle grinder gearbox and replace it without resorting to the help of expensive power tool service centers.

Gearbox maintenance

Having chosen, and also prepared for this process, the mechanism, you can start servicing the tool. The product must be mixed thoroughly. It is applied in a thin layer to the gearbox parts. The mass is applied to the bearings using a packing method.

If the product is packaged in a tube, its neck is placed on the side of the bearing cage. The composition is poured inside until it flows out from the other side. The gearbox is filled with enough grease to cover the gear teeth. The surplus will flow out during the operation of the grinder. Lack of lubrication leads to increased heating and friction inside the mechanism.

Experts recommend putting in such an amount of the substance so that it takes up almost half of the space in the gearbox housing. In this case, the operation of the tool will be correct. The manufacturer may indicate in the operating instructions some of the nuances of this process. They should also be taken into account in the process of servicing angle grinders.

The correct process of stuffing the mast in the cutlery machines

Stuffing mastic in the university of an angle grinder has its own rules. The demand of the nobility is not only the order and application, more and more words, and where to put it.

If there is little mastilo in the grinders

Mastilo on the grinders changes according to the plan of technical service to the tool, when replacing the gearbox parts they went out of tune with the bearings of the rotor.

The old mantle was dark dark color. Tse vіdbuvaєtsya through a potlane in some side parcels of metal or a saw.

Yak correctly see the old mastilo in the grinders

It was old enough to see it all over again in the country.The details are not to blame for the slides of the old mastic, but in the empty bodies of the particles of sharpened details.

To see the old mast, it is possible to vykoristovuvaty zimyvayuchi rіdini, zastosovovanі by motorists for mittya motor and th parts. At home minds, it is recommended that you turn off the gas or gasoline.

All the details and empty parts are guilty and can be viewed and hung.

The procedure for applying mastic to the grinder gearbox

Nova mastic should be mixed and applied with a thin ball before being applied. In bearings, the mast should be applied with a padding. If it was milled in a plastic tube, then the neck of the tube should be attached to the bichesky separator of the bearing and be seen to turn from the revolving side.

Yaka a lot of mastila treba vikoristovuvati when replacing in the gearbox of the UShM

If the number of marsh in the bearings is controlled by the way of the turn of the head, then the number of marsh is stuffed into the gearbox of the USHM. Zayva will be very successful in the process of robots. And a little bit of it will not take care of the gearbox robot.

In the gearbox, you need to fill in the mastheads, but you will need to use them for the teeth of the gears.

For maintenance, put on a layer of mast, which took less than half of the empty gear box.

Control of the correctness of the application of mastic into the gearbox of the angle grinder

The control of the ossuary stuffed into the gearbox will help to test the switching on of the grinder for a non-trivial hour at idle mode.

If the gearbox is starting to get dry, from the gaskets and gaskets, it appears as the mastication is running, then the closure is obvious. Wee changed the mast. Open the gearbox housing and see any excess mastic. All surplus mastic will grow on the rings of the gearbox housing. The lack of a lot of mastic in the gearbox is caused by the noise of the gearbox robot.

With trivial robots, the angle grinder milled in the gearbox to grow on the walls of the case and, as a result, consumes its power.

Having opened the gearbox cry, respectfully look at the mill, the gear tooth profile. as soon as you are, turn the ball to the contact of the gears

The presence of parts of dry or dry mastication in the area of the gearbox, or on the case, talk about those that the hour of the mast has come.

The better to lubricate the angle grinder

Any power tool contains rotating parts that are subject to increased wear as a result of friction. It is possible to prevent their premature destruction and extend the service life of the tool if the rubbing parts are prevented in a timely manner. In the grinder, the gears of the reducer are subject to the main wear. The harmful effects of friction can be reduced by applying lubricants to the surface of parts. Consider which lubricant for the grinder gearbox is better to buy.

When a lubricant change is required

With intensive daily use of the grinder, the lubricant in the gearbox should be replaced at least once a year. Often, users do not adhere to certain periods of preventive maintenance of the tool, and routine maintenance is carried out after the appearance of extraneous sounds during operation. This is a completely inappropriate method of caring for the gearbox.

Preventive inspection of the gearbox begins with the separation of its casing from the rest of the grinder. To do this, it is enough to unscrew the four fixing screws.

The next photo shows that there is grease in the case, but it has gathered on one side of the case, and it is not enough.

This is because the angle grinder (angle grinder) operates at high speeds. Under the influence of centrifugal force, oil particles tend to move away from the axis of rotation. With prolonged operation, the surfaces of the gears become completely dry, and without lubrication, the metal is erased. In this case, it is enough to lubricate the gear teeth with the existing composition, then close the gearbox and work until the next maintenance.

Often, you will notice grains of oil mixed with dust in the gearbox. During operation, the grinder heats up, and these grains are sintered, solid particles interfere with the operation of the mechanism. This grease must be replaced.

How to lubricate the gearbox

The choice of lubricant for the gearbox has some peculiarities. The rotational speed of the angle grinder is high, the liquid oil will simply fly away from the rotating parts. The thick composition must withstand a fairly high temperature and not bake.

Ready grease

You can buy such funds, but their cost is quite high, and the costs are not always justified. Firm "Interskol" is more democratic to the type of materials used. What is the best lubricant? Lubricant for the grinder gearbox must meet certain requirements:

- the viscosity of the composition does not exceed 800 Pa * s;

- the temperature of droplet separation from the bulk is not less than 120 ° C;

- homogeneous composition without the presence of mechanical inclusions;

- resistance to moisture.

The industry produces many types of lubricants, including special formulations for use in gearboxes. The best results are shown by mixtures containing molybdenum disulfide as an extreme pressure additive. If we talk about foreign manufacturers, Castrol and Mobil have proven themselves very well.

From domestic brands MC-1000, Limol can be noted. The use of solid oil, lithol or Tsiatim-221 does not give the desired result.

Homemade mixes

If the necessary lubricant is not available for sale, or if the user considers the price of the product to be unreasonably high, you can try to make the lubricant mixture yourself. There are several formulations using different bases. One of them is the widespread Tsiatim-221.

Another base can be grease for SHRUS in combination with MC-20 liquid oil.

How to lubricate the gearbox

It is impractical to add the missing amount of oil to the gearbox housing: a good composition is mixed with an already used one, and the new grease loses its effectiveness faster. Therefore, when the gearbox housing and gearbox housing and cover are removed, the remnants of the old grease are removed. First, dry rags are used, and then the traces are washed out with gasoline or kerosene. After the parts dry, new grease is applied to them, while the gearbox housing is filled with grease to 2/3 of its volume.

After assembling the grinder, its shaft is rotated several times by hand to evenly distribute the oil. The rotation should be uniform, without jerking or jamming. After making sure that everything is fine, plug the device into the network and get to work. With timely prevention, the tool will last a long time.

When you need to change the lubricant in the angle grinder

The term of the next lubricant change depends on the loads and the intensity of the use of angle grinders. Usually it is equal to 12 months. With everyday use of the grinder with frequent overheating, the frequency of the change is significantly reduced, at least to six months.

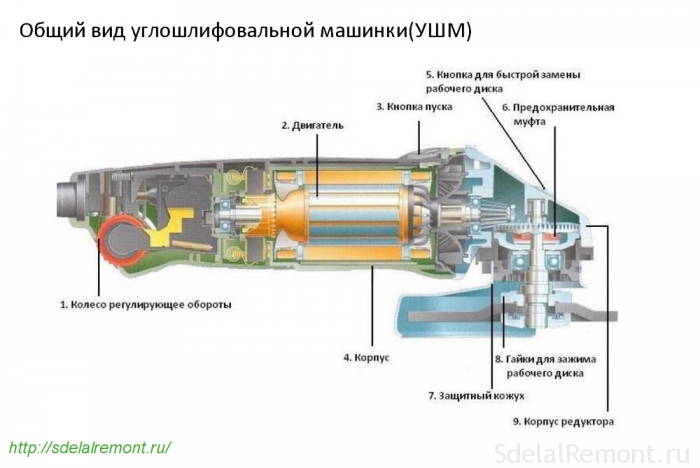

To make sure it is necessary to add a new amount of grease, the gearbox must be disassembled by unscrewing the screws on its cover. Inside is a pair of helical gears. The small one is placed on the anchor and is used to drive the large one located on the secondary shaft. A grinding or cutting disc is attached to this shaft.

During operation, the lubricant, when the gearbox moves, scatters along the walls of the case, drying out over time and forming large lumps. The material used for a long time overheats, becomes liquid and flows out of the housing. Therefore, its volume in the gearbox decreases. If there is only a thin layer of lubricant on the gears, add lubricant.

Grease for the gearbox of the Makita grinder (Bosch)

For the reason that the grinder is a high-speed, powerful and very hot tool in operating mode, the question of what kind of lubricant to use for the grinder's gearbox is very important.Immediately we want to highlight the types of lubricants, the use of which for the gearbox (bearings and gears) of the angle grinder is not recommended by specialists. It:

- grease;

- lithol.

When choosing which lubricant to lubricate the grinder's gearbox, it is worth listening to the opinion of professionals in their repair or just long-time users of this tool. Although their opinions will be far from unambiguous.

So, widely known among motorists, the CV joint grease is equally persistently recommended and rejected by specialists. Moreover, both sides give quite convincing arguments for and against the use of CV joints.

We can say with confidence that the lubricant for the gearbox of an angle grinder must meet the following requirements:

- Be heat resistant and do not leak out of the gearbox as it heats up;

- Increase sliding;

- Reduce the force of friction between touching, moving parts of parts;

- Evenly redistribute the heat load while simultaneously performing cooling functions;

- Protect metal parts from corrosion, penetration of dirt and dust into the mechanism.

As it should be, tool manufacturers advise using only their own, native spare parts, consumable parts (brushes) and lubricants.

We lubricate the gearbox of the LBM Makita and Bosch with our own hands

An action that does not require much effort and cost. It is made according to the following scheme.

- According to the instructions, we disassemble the grinder into its component parts.

- We open the gearbox housing.

- We remove dirt and dust, as well as the remnants of the previous grease.

- We distribute the new grease evenly throughout the gearbox.

- We bring the grinder to its original state.

- We start the engine at idle speed for a while to warm up the lubricant and distribute it evenly over all parts.

Video instruction on changing the lubricant in a Makita angle grinder.

For good work, the grinder needs a lubricant that will not leak out under heavy loads and long-term operation, but will reliably lubricate the part over its entire surface during the entire operation time. It must also be environmentally friendly.

Pay attention to well-known and already proven lubricant manufacturers such as Lubcon

,Hammer ,Makita ,Hitachi ... Experts advise, whenever possible, to choose a lubricant of the same company as your tool.

When deciding how to lubricate the grinder, pay special attention to materials based on silicone or silicone oil. These lubricants are excellent for tools that operate at a range of speeds from slow to high and under all loads.

They are highly resistant to oxidation, protect against corrosion, and are easily combined with plastics and elastomers. The composition contains only silicone and a lithium thickener, which makes them environmentally friendly. The consistency is maintained at temperatures from -50 to +190 degrees Celsius.

How to lubricate the gearbox of LBM Makita, Bosch, Interskol and not only

How to lubricate. Most manufacturers insist on the use of lubricants produced under their brand. The list of recommended lubricants is usually given in the operating instructions. Listen to the opinion of the author, purchase a tube or jar of the original material in advance.

If the manufacturer is so democratic that the instructions are limited to the instruction to use "intended for this" formulations, the decision "how to lubricate" is made by the owner of the grinder. And he buys - as an analogue - a universal grease from another manufacturer. Or, remembering the video he saw on YouTube, he says to himself: “Somewhere in my garage I have the same bank, I’ll have to - I will grease it”. Decide for yourself, the original or the analogue. Or take the dealer's advice. Or take advantage of someone else's experience. The options “Make a lubricant yourself or use a surrogate” are not recommended.

The right amount of grease.Having started a new power tool, it is advisable to know how much lubricant is to be put into its gearbox during maintenance, the need for which will arise sooner or later.

Remove the cover with your brand new angle grinder and look into the gear case. A conscientious assembler must put in such an amount of grease so that it covers a thin layer of the gearbox housing and the drive gear, completely fills the teeth of the driven gear and the volume of the cover under the driven gear. Take that amount as a benchmark and stick to it.

Reference. Authorized dealers of "Makita" claim that the lubricant should occupy no more than 50% of the gearbox volume.

Therefore, it is very useful, when purchasing a grinder, to buy a tube of lubricant at the same time. Original or similar.

Lubrication intervals

Some sources claim that the grinder's gearbox should be lubricated once a year, others - "as needed."

The lubrication intervals depend on the class of the tool. A professional angle grinder that works “without interruptions, for a long time with full load,” simply will not live up to one year of age without lubrication. Try to independently determine the need for lubrication of the gearbox using the simplest diagnostic methods.

If in doubt, open the gearbox for inspection. It is easier to add fresh grease in five minutes than it is for the entire weekend to "take out for repair" the required power tool. The actual lubrication replacement technology can be viewed on YouTube:

Important. On some models, the gear cover is secured with Torx 3.5 or Torx 4.0 cap screws. Save such a bat in advance

Watch the video of the process itself and the sequence of operations for changing the lubricant. Do not listen to recommendations like "eternal grease for the grinder gearbox". The eternal lubricant is intended for use in perpetual motion machines only.

After opening, carefully inspect the grease in the housing and gear cover. If it is translucent, of the original yellowish or blue-green color (depending on the brand), does not have inclusions of dirt and wear products, the grease should not be replaced. It is enough to replenish its quantity.

Old grease is plastic enough - remove it with a soft cloth (rag). If it has turned into lumps of dirt (low temperature sludge), after removing it, rinse and dry the gearbox.

When cleaning and flushing the gear housing, be careful with the rear spindle bearing. If it is needle-shaped, do not rinse or lubricate. The needles can fall out of a worn out cage (or outer cage, if such is the design) and you will get a lot of problems, up to replacing the bearing.

When the spindle is seated in sleeve bearings, do not overwhelm them. The porous bronze-graphite material of the bushings is saturated with grease and does not need to be "degreased".

When flushing the gearbox housing, hold the grinder with the engine upwards so that the dirty solution does not flow along the rotor shaft into its bearing and electrical giblets.

Use clean gasoline or white spirit and a stiff bristle brush to rinse.

Sections: Grinder, How To

It is interesting: Lubrication for a hammer drill gearbox - types, selection features, how to lubricate

Homemade lubricant for the LBM gearbox

Where did the popular belief come from that modern lubricants are not very good, even unsuccessful? Who said that lubricants for gears of hand-held power tools produced by dozens of enterprises and research and production associations are of such poor quality that it is necessary to immediately invent and manufacture a new lubricant?

In videos posted on the pages of some sites of unknown qualifications, experts question the quality of existing lubricants for bevel gearboxes of spur, helical and hypoid gearing used in the design of angle grinders.Having scolded, for example, the Bosch VP729 grease, the specialist immediately, before your eyes, prepares his miraculous composition with incredible properties.

Bosch brand grease

At the same time, the entire technical arsenal of his research laboratory is used: a workbench in the garage, plastic and tin cans, a wooden popsicle stick. The recipe is simple and accessible to every gullible user. It is suggested to take some kind of grease and make it "thinner" by mixing with some kind of oil.

Components are off-the-shelf materials produced by the industry. Mixing equipment - jar and stick. The stability of the required temperature is ensured by the candle. The quality of the product is assessed by organoleptic methods. There are no test benches due to the lack of tests.

Brief description of the process: industrial oil I-20 is added dropwise to the plastic CIATIM-221. With continuous stirring with a stick. CIATIM-221 is made on a silicon-organic basis from silicone oil with a complex calcium thickener. I-20 oil is a mineral-based petroleum product. Mix more thoroughly to obtain a stable polymer-inorganic compound. If you succeed, you will not only have a homemade grinder lubricant, but also an international chemistry prize.

However, there are videos of a slightly different nature on the net. "When the question arose of how to lubricate the grinder, I remembered that in the garage I have an iron can left over from my father." The bank is on display. "It has an inscription: Grease 158". Close-up inscription. "I lubricated the gearbox with this grease ...". This is followed by pictures of the lubrication, and finally the pictures of the tests. "Now my grinder works like this ...". Indeed, the grinder works quietly, evenly, after turning off the spindle speed smoothly falls, the machine stops almost silently.

Please note: he did not invent anything, did not mix anything, he used a ready-made product, perhaps an analogue. He does not advise, but shares his experience

What prevents you from adopting this valuable experience?

Lubricants of domestic manufacturers for bearings and gearboxes of grinders

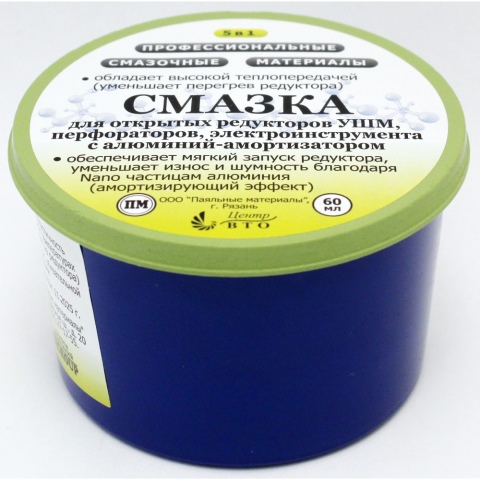

With the rise in prices for foreign lubricants, lubricants of domestic manufacturers have become especially in demand.

Russian lubricant manufacturers have learned how to produce high quality lubricants suitable for any tool.

Lubricants have been developed for reducers of grinders, perforators, and drills.

The most popular products are Nanotech Metal Plak Electra. The range of lubricants produced by this company allows you to select the lubricant required for each unit

Grease for bearings LBM

Three bearings are installed in the design of the angle grinder. Two bearings are mounted on the rotor of the tool, one bearing is mounted on the shaft of the driven helical gear with a larger diameter.

Bearings already filled with grease are used in angle grinders. But from improper operation, overheating of the tool, grease flows out.

How to choose the right grease for the grinder bearings?

Bearing grease must meet the following requirements:

- increase sliding;

- reduce friction between the component parts of the parts;

- evenly distribute heat and act as a coolant;

- prevent the occurrence of corrosion;

- protect from dirt and dust getting inside;

- work in the required temperature range up to + 150C;

The operating conditions of the bearings of an electric motor differ from the operating conditions of the gearbox bearing, not only because of the temperature requirements, but also because of the operating modes, load conditions, frequency and speed of rotation.

The lubricant for the bearings of the electric motor must have protective properties that prevent the ingress of dirt, dust and moisture onto the bearing parts.

The Russian market offers a wide range of foreign greases designed for bearings operating in different conditions. But their cost makes us look for cheaper, not inferior in quality, domestic lubricants.

Among domestic lubricants, we recommend paying attention to the Tsiatim-221, VNIINP-246 (GOST 18852-73), VNIINP-235 lubricants. Lithium greases are well proven

Lithium greases have proven their worth.

Possessing high water-repellent properties, they have a wide temperature range. The role of the thickener in them is played by organic and inorganic substances. For sealed bearings, it is best to use CIATIM-203, VNIINP-242 greases.

Among pigment greases for electric motor bearings, blue grease VNIIMP-246 and dark purple ointment VNIINP-235 have become widespread. The first lubricant, due to its high price, is less common than the second.

In today's Russian market, domestic manufacturers of lubricants are represented in a wide range of products.

Lubricant for the LBM gearbox

Grease for the grinder gearbox differs from grease for bearings in the main feature - increased adhesion. It should firmly adhere to the gearbox teeth when it rotates a lot.

In general, the lubrication process of the gearbox in angle grinders occurs due to the fine splashing of the lubricant and its suspensions. The gearbox operates as if in oil mist. Therefore, the lubrication requirements for gearboxes are slightly different.

In addition to increased adhesion, the gear lubricant must be highly heat resistant and not melt at elevated temperatures.

DIY grease for the grinder gearbox

Is it possible to make do-it-yourself lubricant for the gearbox of an angle grinder

And there is an affirmative answer to this question.

Since the main technical characteristics of lubricants for LBM gearboxes are presented above, they can be taken as the basis for compiling a lubricant of the desired characteristics with your own hands.

Homemade gear lubricant should be based on a highly adhesive lubricant. It must hold firmly to the touching parts.

Grease for CV joints has increased adhesion. SHRUS is a joint in a front-wheel drive vehicle that operates in conditions of increased pollution, shock loads, temperature fluctuations and humidity.

Taking grease for CV joints as a basis, it is necessary to add liquid grease (MS-20) to give the mass the desired consistency. Oil MC-20 should be served dropwise, thoroughly kneading the mass using a homemade mixer.

Good results are obtained by a mixture of a mixture of Tsiatim-221 and TAD-17 lubricants, where Tsiatim is the basis.

Correct grease filling process in angle grinders

Packing grease into the units of an angle grinder has its own rules. You need to know not only the order of its application, but also how much, and where to lay it.

When to change the lubricant in the grinder

The grease on the grinder changes according to the tool maintenance plan, when replacing failed gearbox parts or rotor bearings.

Old grease is dirty and dark in color. This is due to the ingress of foreign particles of metal or dust into it.

How to properly remove old grease in a grinder

Old grease is always removed completely, regardless of its color. There should be no traces of old grease on the parts, and there should be particles of destroyed parts in the cavities of the body.

To remove old grease, you can use various flushing fluids used by motorists to wash the engine and its parts. At home, it is recommended to use kerosene or a solution of kerosene and gasoline.

All parts and their cavities must be thoroughly washed and dried.

The procedure for applying grease to the grinder gearbox

The new grease is thoroughly mixed before application and applied in a thin layer.The bearings are lubricated by packing. If the grease is in a plastic tube, then the neck of the tube is pressed against the side bearing cage and squeezed out until it flows out of the back.

What amount of lubricant should be used when replacing the angle grinder in the gearbox

If the amount of grease in the bearings is controlled by flowing it out from the reverse side, then a certain amount of grease is stuffed into the angle grinder gearbox. Excess grease will leak out during operation. And a small amount of it will not ensure high-quality operation of the gearbox.

Leave as much lubricant in the gearbox as needed to cover the gear teeth.

Apply enough grease as a guide so that it occupies slightly less than half the volume of the gearbox cavity.

Control of the correct application of lubricant to the LBM gearbox

Control of the amount of lubricant stuffed into the gearbox is carried out by testing the assembled grinder for a short time at idle mode.

If the gearbox begins to warm up, traces of grease leakage appear from the oil seals and gaskets, then the conclusion is clear. You have shifted the grease. Open the gear housing and remove excess grease. Any excess grease will be deposited on the gearbox housing covers. An insufficient amount of lubricant in the gearbox is determined by the increased noise of the gearbox.

With long-term operation of angle grinders, the lubricant in the gearbox is distributed on the walls of the housing and loses its properties from external influences.

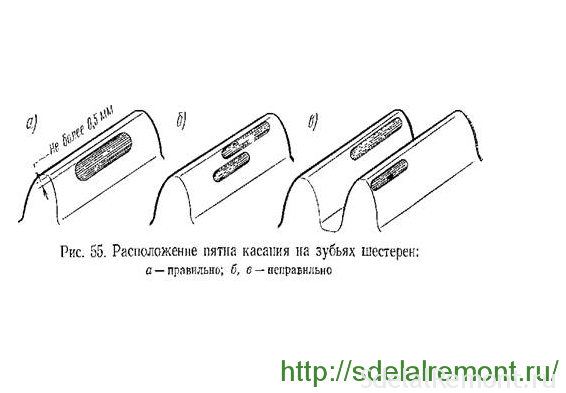

Having opened the gearbox cover, carefully inspect the condition of the lubricant, the tooth profile of the gears. If you can, check the contact patch of the gears.

The presence of dry or dried lubricant particles in the area of the gearbox or on the housing indicates that the time to change the lubricant has come.

Works performed by angle grinder

The grinder instantly gained immense popularity. Since, before its appearance, certain types of work required a significant application of both physical efforts and several tools in their type of purpose for performing one type of operation.

Being, in essence, a universal device for cutting products and materials of various hardness groups, as well as rough abrasive and grinding processing, an angle grinder easily performs the following types of operations:

- Cutting of ferrous and non-ferrous metals;

- Sawing of reinforced concrete, natural and artificial stone, ceramics and other materials of this group;

By replacing the saw attachment with the corresponding disc, the grinder can cut wood products and lumber from different tree species.

Also angle grinder is used for the following works after sawing:

- Removing scale and paint from metal and wood surfaces;

- Removal of burrs resulting from sawing materials;

- Fine grinding and finishing of surfaces and hard-to-reach places.