Varieties of electric hacks

Depending on the power source, electric hacksaws are divided into:

Network. They are characterized by versatility and ease of use. This type of tool is equipped with an electric cable.

Rechargeable. The rechargeable electric hawk is used in cases where it is impossible to connect to the mains. A similar device can be used for harvesting firewood in forest plantations or for sawing off branches in a garden area.

Other classification of electric hacksaws:

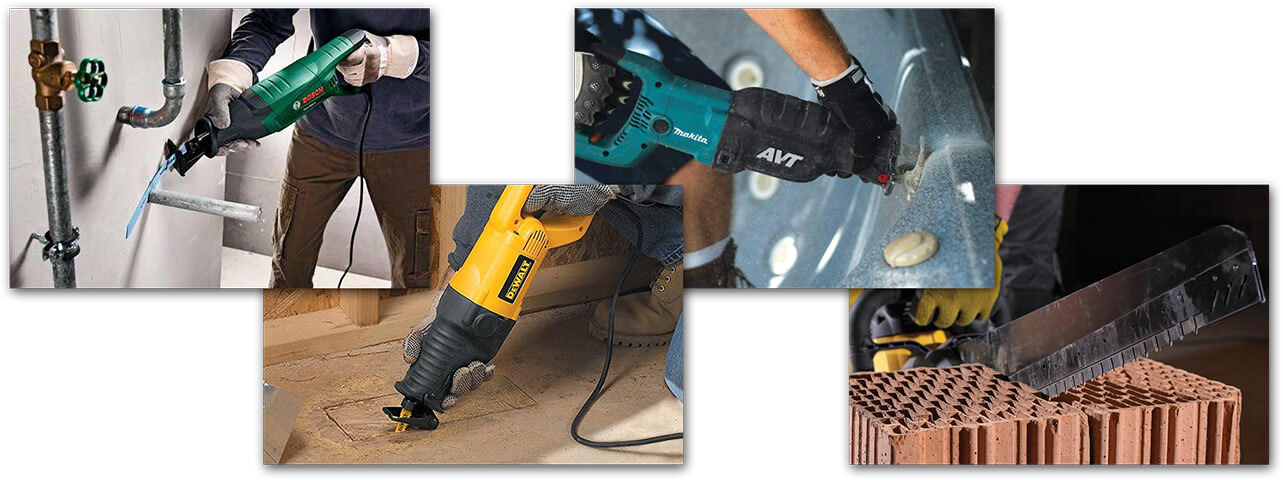

- The electric wood chopper is the most common option for use in everyday life - in the country or in a private courtyard. It allows you to work with different types of lumber, chipboard and fiberboard, as well as parquet and laminate. You cannot do without such equipment when installing flooring, when repairing cabinet furniture, etc.

- The electric metal hammer is an excellent tool for processing metal products, cutting pipes and profiles. It is also used when installing various metal structures.

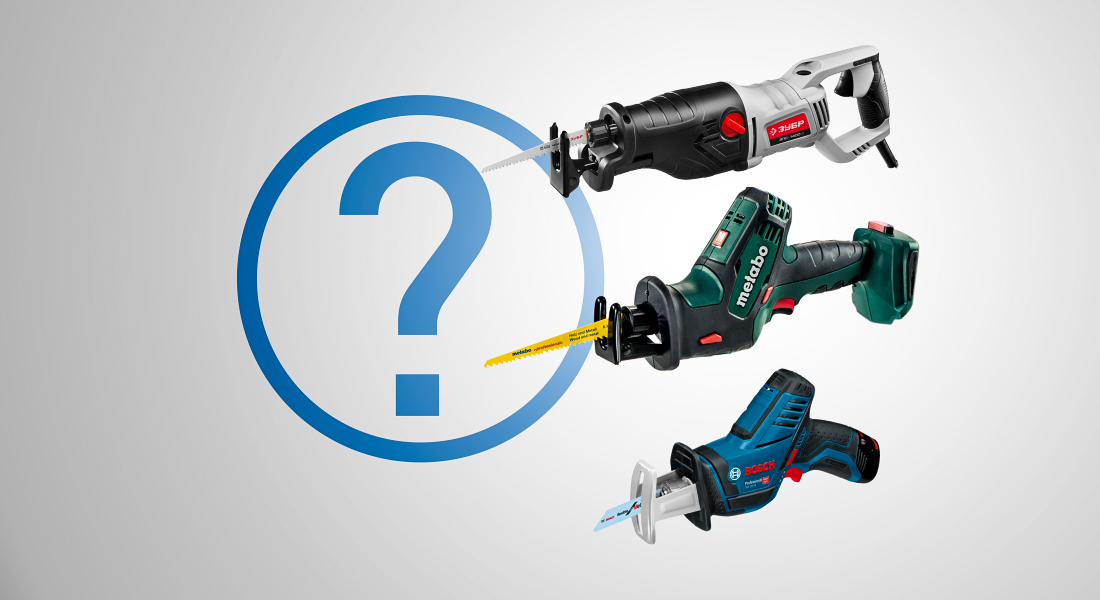

How to choose a reciprocating saw

To choose the right reciprocating saw, you need to compare the parameters and functionality with your prepared answers

It is important to pay attention to the following points.

Power

Power determines all other parameters of the device. This is a key characteristic. It should be powerful enough to work with the materials and thicknesses of your choice. In principle, the higher the power, the higher the productivity, the depth of cut, the wider the range of available materials and thicknesses, the longer the continuous work time and resource.

However, it should be remembered that a device that is too powerful for occasional home use will also have a lot of weight, dimensions and power consumption, and most importantly, a high price.

Speed regulation

Stroke frequency control is present in the most budget models. If you plan to cut one type of material, then you can get by with the simplest adjustment - according to the degree of pressing the power button.

If a frequent change of material and its thickness is expected, then it is better to consider devices with two-stage adjustment: limiting the maximum frequency with a slide or rotary switch and a set of revolutions with the power button, but not more than the limit set on the switch.

Pendulum stroke

The pendulum stroke is designed to speed up cutting and increase the blade resource. If you have a lot of work ahead of you, this is a must-have option.

Reciprocating Reciprocating Saw

If you plan to cut out extremely complex curvilinear contours from a relatively thin sheet, then the pendulum motion will be superfluous, it will still have to be turned off.

Support shoe

The support shoe should be. It increases the convenience and safety of working with a reciprocating saw. If you plan to saw objects of complex shapes in hard-to-reach places, then it is better to choose a shoe with several degrees of adjustment - reach, tilt, turn.

Blade replacement system

On modern models, a system of quick replacement of canvases is used. Different manufacturers promote their own designs, but all of them must provide one-handed blade replacement, and preferably without removing gloves.

High-quality models ensure that the stem stops in the extreme extended position; on budget models, you need to be prepared for the fact that you have to turn the saw on and off several times before you can catch the position to change the saw. The blade cannot be pulled out by hand.

Smooth start

The soft start system must be installed on powerful devices. This will protect the mains power supply from current surges, and will also ensure an accurate start of the cut. If the operator does not have great physical strength or experience, it is better to consider such a system for household-class devices.

Cutting depth

The cutting depth is related to the engine power. This parameter determines how thick the material you can cut. If the vending reciprocating saw does not cope with those boards, beams or sheet material with which you plan to work, you will have to choose a more powerful one.

Ease of use

It is very important that the device lies comfortably in the hands, the power cord does not interfere with the work, the weight of the device should not tire the operator's hands. Some craftsmen, before buying, rent several different models in order to evaluate the usability in practice and buy the most suitable one.

Type of food

Rechargeable type of power supply it is best to choose if you plan to use the device outside the home, in the garden or on a construction site where there is no constant power supply. The rechargeable device is also handy when you need to do small amounts of work in different places on the construction site - then you save time dragging and dropping extension cords and reconnecting cables.

Saw with mains supply

The mains type of power supply is more convenient if many operations are performed close to each other, and the amount of work is large, for example, in a carpentry workshop. In this case, time will be lost just on recharging the battery. The mains supply is also convenient when a constant cutting speed is required - with battery-powered devices, the power drops due to the discharge of the battery.

Additional characteristics of chain saws

Any chain saw, whether electric or gasoline, has several elements that you should pay attention to when choosing: oil reservoir for saw lubrication, bar length, chain type, chain tensioning mechanism

Chain lubrication

Each chain saw has an oil reservoir to lubricate the chain during operation. Oil is consumed quickly enough

It is very important that it is convenient to pour oil into the tank and simply control its level. For this purpose, a transparent insert is often made into the body, like on canisters, or a probe is provided.

Fig. 6. The convenient location of the filler hole for chain lubrication and the presence of a window for monitoring the lubricant level greatly facilitate the operation of the saw.

Chain and Bar for Chainsaw

Another important question associated with the choice of a chain saw is what length of the bar to choose for the chain saw. The length of the chain saw bar can be from 20 to 50 cm. The longer the bar, the more expensive the chain saw and the more expensive it is to replace the chain and bar.

The length of the chain saw bar affects the size of the tree trunk to be cut. On the other hand, a chain saw with a long bar is less convenient to operate as the saw becomes larger. Therefore, if you do not plan to cut down century-old trees, then a bar length of 30 - 40 cm will be enough for household needs, and 15 - 20 cm for a cordless chain saw.

On saws from different manufacturers, the chain saw guide may be different, and chains with different sizes are also used. This is due to the different performance of the saw on different types of wood. Over time, the bar and chain for your chainsaw will wear out and need to be replaced. To avoid problems in the future, you should choose a chain saw with the most common type of chain.

The most common chains that will perfectly cope with their task at their summer cottage have a pitch of 0.325 and 3/8 inches.Chainsaws with this type of chain have good performance and are excellent for both wet and dry wood.

Chain tensioning mechanism

The chain tensioning mechanism is one of the most important elements of a chain saw. Correct chain tension affects performance and safety. It is necessary to check the chain tension not only before starting work, but also during work.

The chain can be tensioned with a special wrench or without an auxiliary tool. Naturally, the latter option is preferable, since it is much more convenient to use the tensioner without an auxiliary tool.

Fig. 7. During continuous operation, the chain must be re-tightened regularly. Tightening the chain with a special wrench takes a lot of time and effort. Therefore, if the saw has a chain tensioning mechanism without a key, then this greatly facilitates work with it.

Smooth start

The best electric chain saw always comes with a soft start. A soft start is provided by a special electronic circuit that does not allow the motor to be overloaded during start-up. Of course, the cost of a chain saw increases with this device, but the likelihood of an electric motor breakdown is sharply reduced. This significantly extends the service life of the saw.

How to choose: 12 practical tips

When choosing, you need to immediately imagine the purpose of the saw - with what materials, how often you will have to work, what should be the cutting depth, etc.

It is important to pay attention to the consumer characteristics of the model, compliance with safety requirements

Power and other power characteristics

For household purposes, devices with a power of 0.9-1.2 kW are mainly suitable.

Among other characteristics, you need to pay attention to:

Saw blade material

When buying, it is important to pay attention to the markings that indicate the composition of the metal and the types of materials with which you can work with such an electric saw

| Marking | The composition of the canvas |

What materials can work |

| HCS | high carbon steel | wood, plastic |

| HSS | tool steel | metals |

| Bim | combination of the first two | wood, plastic |

| HM / CT | hard alloy | hard materials and abrasives - steel, tiles |

Speed regulation

The speed can be adjusted in all modern models of reciprocating saws, however, this function is implemented in 2 main options:

It is worth paying attention to the presence of speed control, blocking, and the mass of the tool also plays an important role.

Tool weight

For amateur saws, it ranges from 3-5 kg. The less weight, the more convenient it is to work with the tool, but on the other hand, the lower its performance.

Therefore, it is important to pay attention not so much to the weight as to the power characteristics of the tool.

Blocking

The mechanism is started by pressing the gas and releasing the lock

The latter function is not implemented in every model, but the presence of such a button is important from a security point of view. If there is no built-in lock, there is a risk of accidental starting of the tool.

Safety clutch

This is another element for safety at work. It protects the operator from kickback that can occur when the rig is jammed. The clutch is not present in all models, but its presence is desirable.

Isolation of live nodes

Used in advanced models, designed to prevent electric shock to the operator. Allows you to work with the tool even in rainy weather and also increases the service life of the mechanism.

Do you already have a reciprocating saw in your toolbox?

Naturally, no, but it will be!

Support shoe

It is not present in all models, but it is also desirable. The shoe allows you to rest the saw directly on the workpiece and stabilize its position relative to the working plane.As a result, the accuracy and speed of the cut are increased and the operator fatigue less. The shoe is especially necessary when performing a large amount of work. It can be bundled or sold separately.

Expert opinion

Vasily Kuznetsov

When buying, you need to pay attention to the lightness and tightness of fastening the shoe to the surface - even a minimal backlash is unacceptable.

overheat protection

A number of models of electric saws are equipped with an automatic system that turns off the tool when a certain temperature is reached. This saves it from overheating and failure.

Smooth start

The saw must be protected not only from temperature, but also electrical overload. In the presence of a soft start system, the blade accelerates without jerking, which increases the service life of the mechanism and provides additional comfort when working.

Tool-free saw blade replacement

Many models are equipped with a convenient system for changing the blade - for this it is enough to turn the locking lever or slide the locking ring. However, for some saws, similar actions have to be performed with a wrench or a screwdriver, which is uncritical, but less convenient.

Vibration damping

Only advanced electric saws are equipped with this system. Allows you to work comfortably with dense materials - composites and metal, as well as heavy wood. However, for domestic purposes, vibration damping is not always necessary, therefore, this criterion is not considered by buyers as the main one.

It is also useful to study if there is overheating protection, soft start, vibration damping, toolless replacement of the file on your future tool

Power features

Electric hawkers work from electric energy. However, they can be powered either through the network or from the battery. Reciprocating saws of the network type are equipped with a special cable and plug for connecting to the network. They are quite convenient and versatile to use.

The second type - rechargeable electric chewing machine - has greater mobility and is indispensable in the absence of mains power. For example, it is actively used in garden manipulations.

For such a tool, the life of the battery, the characteristics of the battery, including the duration of the recharge, the time to retain the charge, and the cost of updating, are important.

Popular models

A number of companies are leading in the market of construction and repair equipment, which have in their assortment saber plates for metal products.

The firm offering the most budgetary products is Elitech. A significant plus will be the low price of consumables for the tool. Saw weight does not exceed 2 kg

However, when working with metal products, you need to proceed with caution, since such devices have mostly low power.

Among the heavy-duty reciprocating saws are Makita tools. They are often equipped with a vibration-reducing system

Perfect for metal products, creating a cut with a depth of 13 cm. The device switch has four positions and is very convenient to adjust. The high price of the products is justified by the available advantages.

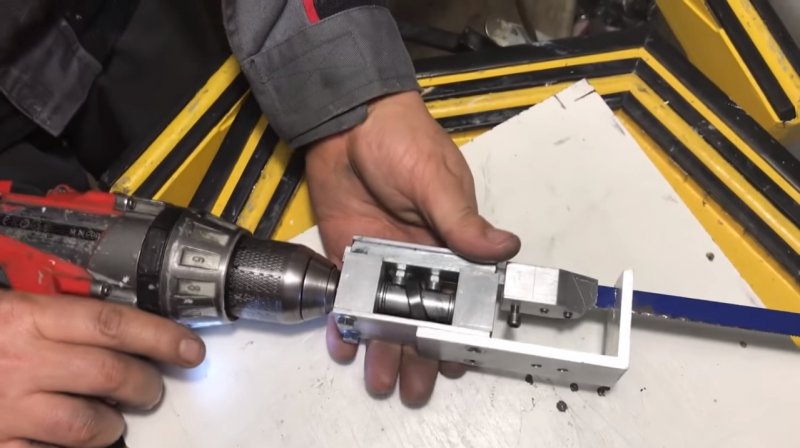

How to replace the stem on a stable saw, you will learn from the following video.

Let’s block ads! (Why?)

Principle of operation and device

The design of the electric hacker is quite simple and similar to the device of many power tools. It includes:

- electric motor;

- reducer;

- pusher, which is connected to the eccentric gearbox.

The pusher converts rotary motion into reciprocating motion. Some models have a so-called pendulum motion. Its distinctive feature is to raise the file during the reverse stroke. This movement is provided by a pendulum mounted on needle bearings. The main task of the manufacturer is to fine-tune the pusher travel.

2> Repair of reciprocating saws

What can you say specifically about the repair of a reciprocating saw? If you are a non-specialist in this matter, then you should not open and disassemble the tool. Take it to the service center, where the professionals will do it. The only thing you can do with your own hands is to change the canvas if it breaks from the load.

Graphite brushes

The main reason why the saw stops working:

- burned out electric motor;

- the graphite brushes are worn out.

The first one cannot be repaired. It is changed to a new one. The latter also change, but this is a simpler operation, which includes disassembling the saw body, removing old brushes and installing new ones. The brushes are inserted into special grooves, inside which they are pressed against the conductive plane of the spring. Each brush has a shank in the form of a stranded copper wire, it is connected to the electrical part of the device with a regular screw. Therefore, replacing brushes is straightforward.

The main thing is not to overload the saw

Related article:

Features and functions

The main characteristics of a reciprocating saw are:

- Engine power.

- The frequency of the rod movement (usually 2500-3000 strokes per minute).

- Working stroke length (20-30 cm).

- Maximum cutting depth in mm for various materials.

Power is the parameter that determines all other possibilities. The more power, the greater the capabilities of the device.

The most important function is speed control. It is implemented in two ways:

- Smooth, carried out by the power button, depending on the depth of pressing. This method requires a certain skill.

- Stepped. One of the modes of limiting the maximum frequency of the rod movement is set using a slide or wheel regulator on the saw body, and by pressing a button, the frequency is adjusted within the specified limits. With this method, exceeding the maximum speed is excluded when the power button is fully pressed.

Reciprocating saw for metal

Also important are the functions of the electric reciprocating saw, such as:

- Pendulum function.

- Blade change mechanism. Different manufacturers and different models may call it differently, but the meaning should be preserved - the blade changes with one hand, without removing work gloves.

- Ergonomic Both the overall usability and the availability of switches and controls.

- Vibration isolation. An extremely important function, when cutting thick materials or metal, the saw without vibration isolation will shake so that it will break out of the hands.

There are also a number of very useful features:

- Frequency stabilization under load.

- Overload protection - automatic shutdown of the motor when the blade is jammed.

- Electrodynamic brake for instant stop of the stem.

- Illumination of the working area with a LED lamp.

Manufacturers add other sometimes exotic functions as well. Not all of them stand the test of time.

Reciprocating saws: review and comparison of popular models, approximate prices

Bosch

Among the well-known manufacturers of saber electric hacksaws, Bosch products rightfully occupy a leading position. The tools are distinguished by the following features:

- excellent performance;

- high operational safety;

- convenience and ease of use.

In addition, power tools can completely replace counterparts with disc attachments, which greatly simplifies the work of operators. Regardless of the type of saber hacksaws, electric motors provide a large supply of torque.

Bosch cordless electric hack model

It is also worth noting that when cutting various materials, a minimum amount of dirt and dust is formed. In addition, the revolutions are steplessly regulated (the operator must take into account the characteristics of the workpieces being processed). Among the range of cordless and cordless saws, PSA 700 E, GSA 1100 E, GSA 1300 PCE, GSA 18 V-Li C Professional, GFZ 16-35 AC, KEO should be distinguished. The cost of power tools varies in the range of 13-28 thousand rubles.

Makita

The range of Makita saber electric hacksaws is an excellent alternative to circular cutting tools. Sawing equipment Makita is characterized by a high operational life, provides high quality work and a high degree of safety.

Electric hawk network Makita

Amateurs and professionals can choose both high-quality budget models of electric saws (Makita JR 3050 T, JR 3070 CT - 8-14 thousand rubles), and high-performance powerful counterparts (Makita JR 3060 T - 13.5 thousand rubles). Among the battery models, the DJR 186 RFE and JR 100 DZ are worth highlighting. Their cost varies in the range of 4-23 thousand rubles. If you are interested in a high-quality and inexpensive electric wood-cutting machine, the price for it will be 9.6 thousand rubles - this is the DJR 181 Z model.

Cordless reciprocating power saw Makita JR 100 DZ

Interskol (Interskol)

Among domestic manufacturers, the company "Interskol" should be highlighted, which offers consumers high-quality power tools. Among them there is the only model NP-120 / 1010E. If you need a reliable saw for aerated concrete, wood and plastic, Interskol will perfectly cope with the tasks.

Saw network Interskol

This model belongs to the products of the budget segment and meets all the parameters necessary for operators to perform work. The tool can be used with a variety of hacksaw blades to handle a wide variety of materials. You can buy a hacksaw for 5.7 thousand rubles.

Hilti

The Hilti brand presents on the market a range of electric saws for professionals. The prices for the products are quite high in comparison with analogs, which is compensated by the highest build quality and excellent performance. They fluctuate in the range of 17-56 thousand rubles.

Using a Hilti electric saw when dismantling a window sill

AEG

The AEG brand certainly deserves the attention of users, as power tools are of high build quality, reliability and affordable prices. Models with lithium batteries BMS 18C LI and BUS 18-0 can be bought inexpensively - 6-8 thousand rubles.

AEG Chain Saw

Saws AEG US 1300 XE and US 900 XE cost about 9.5 thousand rubles. The models are safe in operation and are characterized by a large production resource.

Metabo

Compact and ergonomic, easy to use and productive - this is how Metabo products can be characterized. Cordless models of saber hacksaws, which are widely used in everyday life and on a personal plot, are very popular with operators.

Cordless hacksaw Metabo

Prices for the model range vary between 6.5-17 thousand rubles. The blades on the tools are easily changeable, making it possible to perform various types of material handling tasks.

De walt

Among the leaders in the manufacture of sawing power tools, it is worth highlighting the products of the De Walt brand. Consumers have the opportunity to purchase network and battery hacksaws at optimal prices.

Alligator Saw De Walt

In the Devolt model range, you can choose an alligator saw, which is ideal for cutting aerated concrete, aerated concrete, as well as drywall sheets. The cost of production varies between 11-28 thousand rubles.

Appointment

A reciprocating saw of this type is used mainly for cutting strong metal, which includes structures such as steel profiles, various pipes, fittings and non-ferrous metal products. Since a wide range of different blades can be found for this tool, the range of materials for which it is used is also very wide:

- stainless steel;

- aluminum;

- hot metal.

The purpose of the saw can be classified according to the type of work.

- Cutting metal by weight. It is the reciprocating saw that is convenient, since its design minimizes the load on the hands, unlike other types of devices.

- Before collecting any structures, it may be necessary to cut the metal parts.

- The tool is used to create curved cuts.

- For the safety of operation, the aesthetic appearance of structures and other purposes, the ends of the parts are rounded with the help of a saber electric saw.

- Repair work, during which it is necessary to dismantle metal structures, for example, radiators.

Usage Tips

Experienced craftsmen believe that working with such a unit as a saber electric saw is not difficult, and everyone can learn it. However, there are a number of recommendations that allow you to master this skill with minimal negative consequences.

- Before cutting the main parts, be sure to try the operation of the equipment on a rough surface. These may be unnecessary pieces of metal. This procedure will help not only to check the tool for quality and the presence of defects, but also help a novice user to fill his hand and get used to the electric hack.

- One of the preparatory work will also be the adjustment of the support shoe. It is recommended that the length of the head extending beyond the blade is kept to a minimum.

- And also when working, you need to clearly follow a simple algorithm of actions. To start cutting for metal, you first need to press the start button in a smooth motion and bring the saw to the area where the cutting will be carried out.

- After that, it will only be necessary to correctly direct the unit, the blade of which will independently plunge into the metal.

- Blind cuts are not recommended. This can lead to damage to the gear units.

- Be careful when cutting metal, sometimes the tooling may begin to bend. A peculiarity when working with metal parts is that this process usually takes place not at the beginning of work, but closer to the middle of it.

- When working with blades that show signs of deformation, the risk of tool wear increases. Therefore, it is recommended to choose a metal with a minimum number of defects.

- As a regular maintenance procedure, the instrument should be lubricated and cleaned.

What are they?

An electric hacksaw for metal can be of several varieties. The first feature underlying the classification of instruments is their power. According to this parameter, 3 types of reciprocating saws are distinguished.

- With motor power from 400 to 600 watts. Such a unit is most often used for simple locksmithing work.

- A higher indicator - from 700 to 1000 watts - is typical for a tool used for a wider range of domestic purposes.

- If the electric saw motor has a power of 1200 watts, then this tool is able to cut the most durable metal materials. Moreover, it is characterized by a long service life.

Electric reciprocating saws for metal also differ in the number of blades. In most models, it is presented in a single copy, but there are variations with two blades with an oncoming trajectory. For certain types of work, mini-units are used that have little power. The stroke rate of such a device is usually adjustable. This option is especially useful for working in confined spaces.

Unlike hand-held hacksaws, the saber device can be battery-powered and pneumatic. The battery device has a removable part: the battery, which must be charged periodically by connecting to the mains. Depending on the capacity of the battery, there is enough charge for different times of use. Another type of device is pneumatic saws that work through an air compressor. Battery-free devices are connected directly to the mains using a cord. The disadvantage of these types of electric saws is the possibility of their use only in rooms equipped with electricity.Cordless devices can work without being connected to the mains.

The best household and professional models

Inforce 300 mm 06-08-12

The model is considered the best among the tools with a blade length of 30 cm and a tooth pitch of 24 mm. The blade is made of Japanese 65 Mn carbon steel. During operation, it does not deform and does not corrode.

Specifications:

- The average cost is 770 rubles.

- Weight - 610 gr.

- The blade installation angle is 90 degrees.

The Inforce 300 mm 06-08-12 has a two-component handle and can be used for household and professional work.

Advantages:

- ease of use, does not rub calluses on the palms;

- the ability to cut any kind of metal;

- simple system of tensioning and changing the blade;

- clean cut;

- secure grip on the ergonomic handle.

The disadvantages include inconvenient weight distribution and insufficiently rigid fastening of the canvas.

Owner reviews:

| Victor M. | Nikita S. |

| I bought a hacksaw for a summer residence. When the blade was tightened relative to the handle, the angle shifted. | I like the way the pen is in the hand. Does not slip during operation. Great canvas. The frame is rigid. |

Cobalt 246-517

The model is equipped with an aluminum handle and blade with a tooth width of 24 mm and a blade length of 300 mm.

Specifications:

- The average cost is 700 rubles.

- Weight - 530 gr.

- The blade installation angle is 90/45 degrees.

The rubberized handle of the model prevents the tool from slipping while working in the hand.

Advantages:

- ease of use;

- light weight.

Disadvantage - there are complaints about the cleanliness of the cut.

Owner reviews:

| Alexey M. | Sergey M. |

| The paint is peeling off the canvas. The handle has a rubber grip. She has good ergonomics. | Lightweight, handy tool. The design is quite reliable. |

Gross 77604

The canvas of the model is made of bimetal. The handle is metal, rubberized. The 300 mm blade has a 24 mm tooth pitch.

Characteristic:

- The average cost is 1570 rubles.

- Weight - 896 gr.

- The blade installation angle is 90/45 degrees.

The HSS blade allows for a clean cut. There is an additional function of changing the tension of the web.

Advantages:

- rigid fixation of the canvas;

- convenient and simple web tensioning system;

- two options for setting the angle;

- additional nozzle.

The disadvantage is a lot of weight.

Owner reviews:

| Andrey Ch. | Alexey S. |

| The hacksaw does not jump when sawing. Good grip angle. Comfortable handle, there is a place to put your left thumb. | Powerful, beautiful, comfortable. |

TOPEX 2500-300 mm

The length of the aluminum blade of the model is 250-300 mm. It has a pivot function. The model is designed for professional activities.

Specifications:

- The average cost is 320 rubles.

- Weight - 3.2 kg gr.

- Blade installation angle - 90/45 degrees

The handle has good ergonomics and is comfortable to grip. High-strength materials are used in the manufacture of the model.

Advantages:

- long service life;

- increased structural strength;

- ergonomics.

The main drawback is the absence of a rubber pad on the handle. The model is resistant to deformation.

Owner reviews:

| Evgeny R. | Mikhail J. |

| The tool has a great blade. Saws great. Very comfortable grip. | Ergonomic tool. It is convenient and safe to work with it. The saw cut turns out to be smooth. |

COBALT 150 mm 246-548

The model has an aluminum frame, which makes it very lightweight. The handle has a plastic cover. Blade length 150 mm

Specifications:

- The average cost is 185 mm.

- Weight - 200 gr.

- The blade installation angle is 90 degrees.

The 24-tooth hacksaw blade is rigidly fixed with an aluminum frame. Despite its small size, the model has a solid body.

Advantages:

- ergonomics;

- good performance characteristics;

- practicality and versatility.

The disadvantage is a little backlash. The model is intended for domestic use.

Owner reviews:

| Yuri U. | Mikhail F. |

| Lightweight, compact tool. Convenient and reliable at work.Copes well with work in everyday life. | The hacksaw has a comfortable handle. Copes well with cutting metal. |