Types of circular saws

First, let's figure out how a circular saw differs from a circular saw. In fact, there are practically no differences, both names are used in parallel to denote the same class of instruments. But still, a circular saw is more often called an apparatus on which, instead of a headset with teeth, you can install a smooth circle for cutting metals.

Such work is often performed using an angle grinder (in everyday life - "grinders"), but the device in question does it better:

- you can cut metal at an angle;

- the workpiece does not heat up;

- productivity, quality and cutting speed are higher.

Now about the types of saws:

- Stationary "circular" (circular machines)... Not so long ago, it was the only type of device in this class. They are table-mounted and designed for large volumes of work. Cutting is done in the same way as on a stationary device. They are used in professional activities.

- Also professionals use table saws... They are attached to the table with clamps and can be transferred to another surface. Such devices take up less space and are often used in production where there is a lot of sawing wood to be done.

- Circular saws... Held in the hands. They are used both by professionals and in everyday life. Their purpose is to cut small-sized wooden products in moderate volumes. Also, you cannot do without such a tool when preparing sheet materials.

Separately, it is necessary to consider the types of circular saws of a submersible type. They differ in that before starting work, the disc is raised above the surface to be treated and covered with a casing. You can set the cutting depth in advance and start working. The plunge-cut saw is convenient to use when cutting out windows, making blind cuts.

Sometimes novice carpenters ask the question - what is parquet? This name is used (but not often) for the class of plunge-cut saws - with their help you can perform parquet work.

By the type of drive, all considered devices belong to the class of power tools. Most of them are powered by 220 volts. There are also rechargeable models. They are more mobile, but have

reduced power and run time limited by battery capacity

Mobility is not the most important quality for such tools, so you need to choose battery devices only when you plan to work in the absence of a power supply

Advantages and disadvantages

A circular or circular hand saw is not the only way to cut various sheet materials, however, it is she who is considered one of the best solutions, competing with jigsaws and even more so with classic hand saws, driven by manual power.

This in itself indicates certain advantages of using it, however, let's take a closer look at what exactly such a tool is better than alternative options.

- The tool is powered by an electric motor, it relies relatively little on manual force, which is needed only for holding. This increases productivity and reduces operator fatigue.

- Unlike most other saws, the cutting edge of a circular saw is shaped like a disc that is sharp around the entire circle. Thanks to this, the unit has no return movement - absolutely all efforts are spent on useful work.

- Originally developed specifically for cutting wood, circular saws can now be created for other materials as well. Although the list is not limitless, there are still options for tiles and some soft metals.

- The hand saw can be equipped with a battery and work from it, which significantly expands the scope of potential use. Rechargeable models are able to do without an outlet for several hours, therefore they can be used in any working conditions, whether it be construction without supplied communications or the roof of a building.

- Compared to the same jigsaw, the circular saw has a significantly increased productivity - in the same period of time it is able to cut much more lumber.

- Unlike a chain saw, a circular saw is good in that it allows you to make a cut even, and does not tear it, therefore, it is better suited for cutting decoration materials.

- Most hand-held circular saws offer built-in safety measures that classic hand-operated saws certainly do not have. Moreover, the presence of special nozzles allows even a vacuum cleaner to be connected to many models, thereby achieving cleanliness in the workshop and safety for the health of the operator.

Of course, with all its positive qualities, a circular saw is still not uncontested - which means, at least in some situations, it cannot show itself perfectly. Perhaps, in your conditions, nothing else is required, but it is worth knowing about this and possible pitfalls in advance, therefore, we will separately consider the possible disadvantages.

- The operation of the device is impossible without electricity, which means that you either have to be near the outlet if the device is powered, or do not forget to charge it in time if it is rechargeable. At the same time, some batteries assume certain specific requirements - for example, popular lithium-ion batteries tend to discharge much faster at subzero temperatures.

- A circular saw is absolutely not intended for a figured cut, the cut will always and in any conditions be strictly straight, except with slight deviations. There is not a single way to perform figured cutting using such a unit - in this one it can only be replaced with a jigsaw.

- Battery models are good for their mobility, but an increase in their functionality, performance or autonomy will inevitably lead to an increase in the weight of the unit. Because of this, a truly powerful tool on batteries simply does not exist, and the thickness of the cut of the same wood in such a device is usually limited to 7-8 centimeters.

- A circular saw is not that expensive, but still significantly more than a classic one. In practice, this means that if there are doubts about the regularity of using the instrument, its purchase may be impractical.

Operation and maintenance

It is possible to use the tool for a long time and safely only if its instructions are constantly followed. First of all, you need to work only with the tool that is designed to solve exactly these tasks, it must be properly equipped and not be damaged. Failure to comply with the recommendations specified in the instructions, at best, leads to premature wear of the tool assemblies, at worst is fraught with injuries.

Attaching the anchor (in the case of network models) and setting it yourself up should also be carried out strictly in accordance with the instructions, otherwise you should not rely on the correct operation of the tool.

In addition, even when choosing a saw blade for wood, it is advised to select it by the number of teeth so that there are 2 to 4 teeth in the thickness at the same time, because a smaller amount negatively affects the stabilization of the tool position, and a larger amount provokes strong heating of the blade, clogging of the saw and dullness sharp edge. Based on this, we can conclude that neglecting even minor details is fraught.

Maintenance, like setting up the tool, in the case of most models is done independently, but it all depends on the specific situation.Most manufacturers are categorically negative for the consumer to disassemble the case on their own and make any changes to the design of the device. Accordingly, the scope of self-service usually includes only the replacement of a disk, while any breakdowns, according to the instructions, must be eliminated by the efforts of certified technicians.

For information on how to choose the right hand-held circular saw, see the next video.

Selection Tips

To choose a good circular saw, you first need to fully determine the tasks for the solution of which the tool is purchased, and then select a specific model with suitable technical characteristics. At the same time, a modern circular saw is a "smart" tool, in it, in addition to the above-described set of numbers, various additional functions are also important, whose presence can simplify the use of the device or extend its service life. To figure out what additional functions a circular saw can have and what they are for, let's study the topic in more detail.

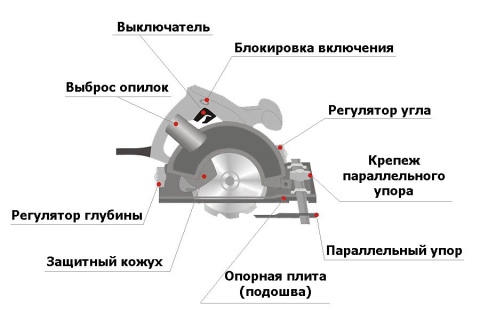

One of the most significant advantages of a good circular saw is the presence of a smooth start. With a sharp start from zero to several thousand revolutions per minute, the engine and other components of the mechanism experience tremendous overload, which often leads to premature wear of the unit. It's another matter if the speed is gained gradually - you will have to wait no more than a few seconds, but the purchase will last much longer.

The anti-jam function is very useful for the operator's safety. If at some point it suddenly turns out that the disc is not able to cut the material further, it will definitely be thrown back, because of which the master may even drop the equipment from his hands, it is also possible that the disc is deformed, which increases the risk of injury. It is impossible to completely prevent such a phenomenon, but modern models, at least, are able to weaken such a return blow.

In some cases, the engine, working for a long time with a fairly dense material, may heat up uncontrollably. An inexperienced operator is not always able to recognize the moment when it is better to turn off the device immediately in order to avoid damage to the unit. For this reason, the developers in the new models have provided for the protection of the electric motor, which reacts to excessive indicators and knows how to turn off the power supply in a timely manner.

Another important safety feature for the operator is the blade lock. It works instantly, as soon as the power button is released - the disk "wedges" instantly, that is, it does not continue to rotate at a reduced speed. This is done to ensure that the operator is not injured, for one reason or another, losing control of the tool. With such a function, it is no longer so scary to drop the unit from your hands, fall with it or lose consciousness during operation.

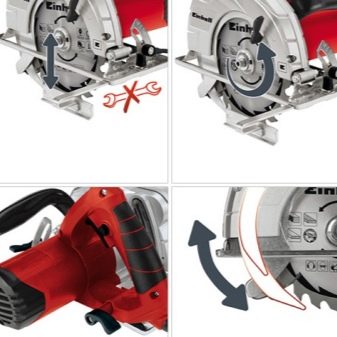

Adjusting the speed and cutting depth are two very similar characteristics of the tool, which allow you to adjust it as accurately as possible for a specific task. In the first case, it becomes possible to more accurately adjust the speed of the disc, in order, for example, to quickly cut wood, but not to melt the plastic with excessive haste. The second of the described functions is aimed at not completely cutting the workpiece, but delving into it only slightly.

Such a function as connecting a vacuum cleaner is also rapidly gaining popularity. When sawing wood, which the circular saw most often works with, a huge amount of sawdust is formed, which not only clogs the workshop, but can also enter the respiratory tract or eyes, posing a serious health hazard.The presence of the described function allows the vacuum cleaner to draw in all small particles already at the moment of their formation, therefore the workplace usually does not even require special cleaning.