Protection standards

Masks

In Russia, the requirements for medical masks are collected in the national standard “Medical masks. Requirements and test methods ”(GOST R 58396), introduced in March last year. The document is based on the German national standard of the same name (DIN EN 14683: 2014), therefore the Russian labeling has a direct correspondence to European goods. America has its own system developed by the Centers for Disease Control - CDC.

It is the filtering ability of the masks that is tested in laboratories. Fitting to the face or air suction are not evaluated in principle. To assess the effectiveness of the filters, Staphylococcus aureus bacteria are used - an aerosol with an infection is passed through a mask, and then the number of bacteria that has broken through is determined. Based on this, the type of mask is determined - I, II or IIR.

Type I masks are for patient use only. They filter at least 95% of bacteria from the inhaled air and do not protect against splashes. Such masks should not be used by nurses and doctors.

Types II and IIR are acceptable for use by medical personnel. Both will filter out at least 98% of bacteria and aerosol droplets. The types are splash-resistant, the letter R indicates an additional layer. Therefore, masks II are usually used by nurses and ordinary doctors, and IIR - by surgeons and operating nurses.

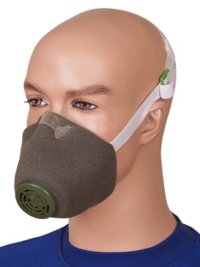

Respirators

The classes of respirators are described in another document - the interstate standard “filtering half masks for protection against aerosols” (GOST 12.4.294-2015). The standard is based on European EN-149: 2001 and uses European markings.

The standard provides for the assessment of filter efficiency, air leakage, dust and fire resistance. Based on the results, the respirator is assigned a class: FFP1 means low efficiency, FFP2 - medium and FFP3 - high.

Unlike masks, respirators are tested on volunteers. Subjects exercise, talk, and simulate work. This helps to assess the fit of the respirator to the face and the reliability of the protection in general.

It is important to understand that filter performance is not evaluated for viruses. For tests, aerosols from a solution of sodium chloride and paraffin oil are used.

The particle diameter of the salt solution is about 600 nanometers, and the oil droplets are about 400. This is several times larger than the diameter of the current coronavirus - for the Chinese SARS-CoV-2, sizes from 80 to 120 nanometers are characteristic. But since viruses are transmitted by small water droplets, the effectiveness of the filters correlates with the degree of protection against infection.

FFP1 class respirators retain at least 80% of aerosol droplets, FFP2 will protect against 94% of particles, FFP3 - from 99%.

Some European manufacturers indicate the type according to the EN 143: 2000 standard, it corresponds to the Russian GOST 12.4.246-2016. These documents provide for a slightly different typing system. Half masks are also divided into three classes, they are called P1, P2 and P3. Penetration tests are carried out in the same way, the first and second classes in the standards are the same. Only the requirements for the last class differ, here they are much stricter: P3 must filter out 99.95% of particles.

If we draw an analogy with American standards, then the FFP2 and P2 class are closest to N95, FFP3 to N99, and P3 to N100.

Why is it important? Clinical studies of the effectiveness of respirators have been conducted in the United States, Canada and Australia using American protective equipment: N95 surgical respirators

How to choose?

When choosing respirators for painting, one has to take into account not only the type of product design and the method of applying the compositions, but also the list of substances from which a particular model protects better. Modern industry offers a wide range of products, among them there are not only comfortable, but also beautiful models, while they fully meet all safety requirements.

The main criteria for the selection of PPE in each specific case should be considered in more detail.

Construction type. It depends on the working conditions. For home painting work, a half mask will be enough with a brush or roller. When spraying substances dry or wet, it is best to choose the option. covering the entire face, with an eye shield. When working with particularly toxic materials in closed rooms, models with an autonomous oxygen supply or a breathing apparatus are used.

Multiple use. Disposable masks, as a rule, have the simplest design, they are disposed of after completion of work. Reusable respirators have a replaceable filter and valve system - they are changed after each use or according to the equipment manufacturer's recommendations. Such products are relevant if the work is performed systematically.

Principle of operation. Filter masks for painting are more like classic gas masks. They prevent contact of the respiratory system with dust, volatile substances, fine particles, and eliminate odors. Isolating completely eliminates the possibility of potentially hazardous chemicals entering the body. These are self-contained breathing systems with a hose or a special apparatus for maintaining the pressure of the environment.

Protection class. There are 3 main groups: FFP1 - half masks capable of retaining up to 80% of potentially dangerous or harmful impurities, FFP2 have an indicator of up to 94%, FFP3 filters up to 99% of all possible sources of danger - this is quite enough for painting.

Workmanship quality

The respirator for painting has a long contact with the skin of the face, therefore it is very important that it is comfortable to use, meets the requirements for the area of contact and the density of contact. A properly selected mask or other protection system does not cause inconvenience, excludes the ingress of harmful substances or odors from the outside under its edges

Even when carrying out painting work in everyday life, you should think about buying a special respirator: paper and gauze bandages act as an exclusively mechanical barrier, not protecting the respiratory tract.

The type of substances to be filtered. It can be dust, gaseous (volatile) substances. A paint respirator can deal with one source of problems, or fix multiple problems at once. The second type is called universal, it is suitable if the master performs different tasks, works with dry substances and liquid paints and varnishes.

Individual protection means

Unfortunately, practically no filters, including charcoal ones, are able to 100% purify the inhaled air in the spray booth from all types of toxic components. Porous fillers are good at capturing aerosols, and charcoal neutralizes most toxins, but neither can filter out the most dangerous isocyanides.

Professionals use isolation systems consisting of ventilating masks with a sealed visor, a corrugated air supply hose, and a blower (compressor).

The system is adjusted so that the person inhales the required amount of fresh air and releases it through the valve to the outside.

Conventional respirator masks of the RPG-67 type will filter out part of the aerosols and, when a carbon cartridge is installed, will be able to neutralize up to 40% of toxins. However, everything else will have to be shifted to the protective functions of the body, and its resource, as you know, is not endless. Even one painting without full protection can cause an acquired disease.

Some painters use a conventional combined-arms gas mask. It is better than any half mask, but it is not suitable for constant work. The advantage of a gas mask over a half mask is that it provides complete tightness. However, it does not filter everything out.

Constantly working in a gas mask is rather uncomfortable. For some, talcum powder and rubber may in themselves cause allergies. And the purpose of the combined-arms gas mask is somewhat different. It is better for auto painters to use professional insulating systems: mask-coveralls with external air supply. Such systems are not cheap, but health is more expensive!

Unlike the result of painting, which can be corrected even with the most sad outcome, it is not easy to restore a person's health, and sometimes impossible. Tons of paints and solvents pass through the spray booth, most of which actively interact with air - the protective material of a respirator for painting a car separates the painter from all this chemistry. By the way, sanitary norms and standards for personal protective equipment were developed back in 1974 by employees of the Institute of Labor Protection of the All-Union Central Council of Trade Unions. Since then, the "Sanitary Rules for Painting Works" have undergone minimal changes.

Classification

The classification of personal protective equipment for the respiratory system is carried out according to several criteria:

- according to the basic principle of action;

- by the method of air supply;

- according to the conditions in which they are operated;

- according to the specifics of the appointment.

RPE: classification, scope and device - this is a topic for a whole dissertation, in this article it is briefly covered, only the main points necessary for the correct use of technical means are given.

By the principle of action

Types of RPE according to the principle of action:

- insulating. As the name implies, insulating RPE prevent harmful substances from entering the human lungs, that is, they completely block the access of air from the outside, isolate the lungs from hazardous substances. Clean air is supplied from a cylinder;

- filtering, that is, devices equipped with special filters. The filtering breathing apparatus has a specific principle of action: polluted air passes through filters and is purified before entering the lungs of a person. If the inspector who came with the check asks: "Specify the filtering RPE" - show him respirators and gas masks without cylinders and hoses.

Selecting the type of RPE

| Characteristics of the conditions of use | Type of RPE |

|

the composition of hazardous substances is unknown the air is not breathable oxygen content less than 16% the duration of the remaining RPE is not enough to complete the assigned tasks |

insulating |

| presence in the air of hazardous vapors (organic compounds, mercury, ammonia, hydrogen sulfide, etc.), gases, aerosols and dust | filtering |

These two types are indicated in GOST, that is, this classification is official, the rest are set out in the scientific literature.

Under what conditions is it forbidden to use filtering RPE:

- when the oxygen content in the air is less than 18%;

- when there are substances, the protection against which is not indicated in the instructions of the protective devices, or substances in such quantities that are not provided for by the instructions;

- when low-boiling and poorly absorbed substances are present: ethane, butane, propane, methane, etc .;

- if there are unidentified, unknown substances in the air.

By air supply method

This classification is relevant for respiratory isolating PPE. According to the method of air supply, insulating PPE for respiratory organs are:

- hose-type, where the supply is carried out using a hose from a stationary source under pressure, on demand or continuously. They are used in painting booths, for sandblasting abrasive processing, the set includes: mask, helmet, hood and suit;

- autonomous, where a source of clean air is included in the set of the device, that is, a person brings it with him. The duration of such protection is short. If the device is a closed circuit, the exhaust air can be recycled with a carbon dioxide adsorbent and used a second time.If an open circuit is used, then the exhaust air cannot be reused, as it is released into the atmosphere. Respiratory PPE with autonomous air supply are used in mine rescue operations, in conditions where low oxygen content threatens human health and life, in underground mines.

Other classifications

There are disposable or reusable devices designed to protect against specific substances, their use is due to the instructions. Filtering devices are also divided into anti-aerosol and anti-gas, combined. Anti-aerosol respiratory protective equipment is designed to protect against smoke, mists and aerosols. They contain filter material that prevents hazardous substances from entering the lungs. Gas masks protect against gases and vapors, while gas molecules break down, falling into a gas mask when interacting with a sorbent. The combined ones can protect against both threats, that is, it is an anti-aerosol and gas mask PPE at the same time.

In case of fire

Respiratory personal protective equipment in case of fire are the so-called self-rescuers. The skin is protected by fire-resistant capes. They can also be insulating and filtering. When choosing a product, one must take into account not only the instructions, but also the tightness of the fit, the correspondence of the mask to the shape of the face. The degree and quality of protection will depend on this.

Occupational diseases

The profession of an auto-painter can definitely be called one of the most harmful. Previously, people who worked with paints were given milk for being harmful. Today no one gives milk, but, as it turned out, it does not help much after inhaling with acetone. Moreover, there is no effective pharmacological protection against solvent-borne paints.

Particles of organic solvents in the form of vapors enter the mucous membranes of the respiratory tract. Molecules of corrosive substances easily penetrate the thinnest shell, the thickness of which is measured at the level of atoms. Acetone and other organic solvents are strong poisons. They penetrate the gaps in the protective mucous membrane and poison the body.

The occupational diseases of auto-makers include:

- diseases of the central nervous system;

- respiratory tract diseases;

- liver disease;

- skin diseases (allergies, chemical burns).

Frequent inhalation of solvent vapors can cause bronchial asthma, severe allergies, and nasopharyngeal diseases. Once in the blood, solvents cause dizziness, nausea and vomiting. First of all, the brain, liver and kidneys are affected. Over time, if you work without personal protective equipment, regular inhalation of solvent vapors can even lead to cancer.

Varieties of respirators

Many different types of painting respirators are produced, as well as various painting masks. To make the application of paints and varnishes safe, you need to choose a respiratory model that can protect against the fumes of those chemicals that boil at temperatures below 60 degrees.

What is the best mask to choose? There are several excellent options, for example, PPM-88 and RU-60M are very popular, they are used mainly for protection against paint fumes. These models are not suitable for use in the paint and varnish shop, in complex technological production, as well as during the manipulation of various building mixtures.

A 3M respirator is perfect for repair, construction and finishing work. This device protects not only from paint fumes, but also from dust, gas and particles of various substances. 3M products are of high quality, reliable devices that effectively protect breathing over a long period of time.These respirators for painting and for other work meet all modern safety requirements, they fit quite tightly to the skin of the face, therefore, during inhalation, dust particles and paint vapors do not penetrate the respiratory system, and therefore do not harm human health. The cost of 3M respirators is relatively low, affordable to everyone.

If you have to apply paint containing many toxic substances, then a mask will not effectively protect the respiratory tract. And if a person has to work in a room in which the concentration of dust is several times exceeded, then an ordinary protective mask will not give the necessary protective result. In such situations, a special protective suit is suitable for applying paint or other finishing materials.

Special items of personal protection are produced for applying paint to cars. Such a mask provides reliable protection against harmful, toxic substances, for example, xylene, toluene, benzene, various carbon disulfide compounds. To paint the body or car parts, you need to purchase a special filter respirator for paint fumes.

It is unacceptable to apply paint on a car indoors without a respirator or use a paper mask. Some in workshops use simple foam rubber bandages for workers, which are fixed with ordinary ties; it is very harmful to breathe toxic paint fumes through such devices.

Types of harmful substances

- When applying paints and varnishes, starting with a primer and ending with a finishing coat of varnish.

- While drying the coating. At this stage, the solvent evaporates.

In addition, in the process of applying paint to the car body, micro drops of paint float in the air, which can also enter the respiratory system. As you can see, a respirator is needed at all stages of painting with a car.

Among the most harmful types of substances that are released in the air are:

- vapors of isocyanates.

- carbon disulfide.

- xylene, toluene (benzene derivatives).

- benzene.

If the concentration of these substances in the airspace of the working area is exceeded, they become dangerous to the human body.

Personal protective equipment for painter

The basis of the respiratory protection means of the master is the filtration of the air entering the lungs using special systems. And practically all devices and protective masks have a different system, but they are all aimed at eliminating the ingress of harmful substances into the human body. In its shape, a respirator is a mask that covers all the respiratory tract, and includes filters to clean the incoming air. There are anti-dust, universal and gas filters.

We do not recommend using the simplest means of protection for the painter like a paper or gauze mask, since the effect of them is minimal.

Respirator options with integrated filters

Experienced painters advise using RU-60M only with original filters, since otherwise it will be difficult to guarantee an adequate level of protection. Therefore, when purchasing this respirator, consider the cost of components for it.

Each respirator you choose must meet one of three standard groups. The document has the title: "The European quality standard for respirators for painting works is EN-149: 2001".

- FFP1 limit value for the concentration of harmful substances more than 2 mg / m3. m. The concentration of the dispersed phase does not exceed 8 mg / cu. m. This category includes plastering work, the release of non-toxic dust into the air.

- FFP2 with a limit value for the concentration of harmful substances above 0.05 mg / m3. m and a dispersed concentration below 0.5 mg / cubic meter. m.This group includes coal and asbestos dust, as well as toxic air components during welding, soldering and simple car painting.

- FFP3 limit value for the concentration of harmful substances below 0.05 mg / m3. m and the concentration of the dispersion does not exceed 1.5 mg / cubic meter. m. It is necessary to carry out protection against lead, cadmium and antimony released into the air during painting and soldering with lead and acid.

Respiratory tract isolation

Before using any respirator for painting a car, you should carefully study the instructions and filtering capabilities of this device. It so happens that even the most expensive options do not solve the issue of protection against harmful substances of interest to you, and can pass poisonous particles of material or gases. For example, using a charcoal respirator, you protect the body from many harmful substances, but at the same time, this type of device allows isocyanides to pass through.

If you are painting automotive work in a poorly ventilated garage, it is best to use an insulating type of respirator that will exclude all harmful types of fumes from entering. Their cost is high, but some masters rework the RPG-67 respirator by connecting a hose with the required diameter and supplying it to a compressor with clean air.

There is such a definition as the expected degree of protection - NEO (the permissible range is from 50 to 10,000). For self-contained respirators, this figure is maximum. And filtering protective masks work in the OSO range from 5 to 50.

Do you use protective equipment when painting your car? Write your comment below.

Species overview

All respirators used for painting work can be conditionally divided into partial (half masks) and full, providing isolation of the entire face. In addition, there is a division into professional and household product segments. The simplest classification of PPE is presented below.

Standard products. The classic respirator has a built-in polymer-based filtration system. The degree of protection allows filtering out both organic vapors and particles of fine aerosols.

Also, all respirators are divided into filtering and insulating. The first type in the classic version protects only against dust. Replaceable filters help to improve its protective properties - they are selected depending on what kind of sprayed substances you have to work with. The most popular filtering respirator option is RPG-67. In the domestic version, models with a charcoal filter are suitable for staining and whitewashing, have the form of a half mask that covers the nose and mouth.

Insulating models are aimed at maximum protection against all types of substances: gaseous and dust particles, chemical reagents. They use an autonomous oxygen supply system to prevent contact with a potentially hazardous environment.

What is the principle to choose?

Only an experienced painter can give a confident answer to the question of how to choose a respirator for breathing protection. If you have never experienced a home renovation, you can get into serious difficulties. Nevertheless, we will try to figure it out.

The face shield has many varieties:

- half masks;

- covering the entire face;

- on the whole face with an oxygen supply device;

- on the whole face with a breathing apparatus in which high pressure is constantly maintained.

Face shields can be disposable or reusable.

It is important that the mask for painting has replaceable filters and valves, and its protective layer consists of high quality material that does not cause allergies. When wearing such a mask, the worker should not experience discomfort.

From a technical point of view, there are two groups of respirator masks for protection against chemicals, coarse dust, fine dust particles, odors:

- Filtering.

The air is purified through special filters, according to the principle of the device, such designs are similar to gas masks. - Insulating.

The respirator contains an oxygen mixture that is supplied through a hose or separate breathing apparatus.

The most important characteristic for anti-dust, anti-aerosol respirators and filters is their protection class. There are three main classes: FFP1 (class 1 filtering type half masks)

- trap more than 80% of airborne impurities

FFP1 (class 1 filtering type half masks)

- trap more than 80% of airborne impurities.

FFP2 (filtering type 2 half masks)

- more than 94% of impurities are retained.

FFP3 (class 3 filtering half masks)

- trap more than 99% of impurities.

Classification

The grouping of respirators depends on:

- From their purpose, that is, from what harmful substances it is necessary to protect the respiratory organs: dust, gas, or both together. Respirators of this category are used for painting works, including when painting cars.

- From the design. Depending on the specifics of the work, a respirator is chosen, in which there is or is not a breathing valve.

- Disposable or reusable masks are distinguished from the period of use. In respirators of the first type, the filter cannot be removed, it is firmly fixed. Dispose of the entire mask after clogging. Reusable models are better, since the filter must be replaced if it gets dirty.

- On the type of protection mechanism.

You need to purchase it personally, so as not to be mistaken. A preliminary measurement of the face is taken from the largest depression on the bridge of the nose to the lowest point on the chin. After selecting a model, the mask is examined for defects. If everything is in order and there are no faults, fitting is done.

The edges should fit tightly to the face without causing discomfort. Buckles fixing the position of the respirator on the face must have normal tension. It is better to choose a model where they will be regulated

It is important that moisture does not accumulate inside the mask, since there is no way to weather it. If this happens during the production process, you need to get out of the danger zone, remove the respirator from the face, remove all moisture with a soft cloth, put it on again and only then return to your workplace

What respirators are

According to the latest WHO data, COVID-19 is spread by airborne droplets, airborne dust and contact-household routes. And the diameter of the viral particles of the coronavirus, according to virologists, is only 0.125 microns. Before choosing the appropriate antiviral agent, let's figure out what breathing masks are.

Medical half masks can be:

- disposable;

- reusable.

All of them are designed for an individual barrier between the respiratory organs and particles of gas, dust, aerosols and in contact with dangerous pathogens such as tuberculosis, SARS, bird flu, COVID-19.

By way of protection

According to the method of protection, breathing apparatus are divided into the following groups:

- filtration (the design provides for special filters that are capable of cleaning polluted air);

- insulating - do not depend in any way on the quality of the ambient air, oxygen is supplied from the supplied external source.

By type of pollution

According to the type of contamination from which it is necessary to protect the respiratory tract of a person, medical masks are divided into:

- anti-aerosol (protect against pathogens of various infectious diseases that spread from a sick person to a healthy person by airborne droplets: when sneezing, coughing, talking, as well as when spraying hazardous substances with an aerosol method);

- gas respirators are used to maintain a high concentration of gaseous substances;

- gas and aerosol breathing masks - a universal device blocking the ingress of combined particles, with a built-in filter.

Photo: respirator with valve and mesh

By level of protection

Disposable medical masks are classified according to the level of protection and are designated by the abbreviation FFP - filtering half mask. According to the level of air filtration, disposable breathing apparatus are divided into 3 types, each of which has its own protection factor:

- FFP1 - provide 80% filtration of solid and liquid particles, nominal protection factor - 4.

- FFP2 - provide filtration of solid and liquid particles by 94%, nominal protection factor - 12.

- FFP3 - provide filtration of solid and liquid particles by 99%, nominal protection factor - 50.

How to choose the right respirator to protect against coronavirus

When choosing a breathing apparatus, do not hesitate to try it on. First of all, you should be comfortable in it. The store will help you choose a protective device so that it fits your face in shape and size.

- After trying on a breathing mask, check if there are any gaps between the mask and the face allowing outside air to enter.

- Spray an aerosol air freshener in front of your face if you smell or taste in your mouth, then the mask does not fit tightly to your face. It is necessary either to choose another instance, or to tighten it by means of ties, increasing the number of filtering layers.

- If the mask slips, choose a smaller size.