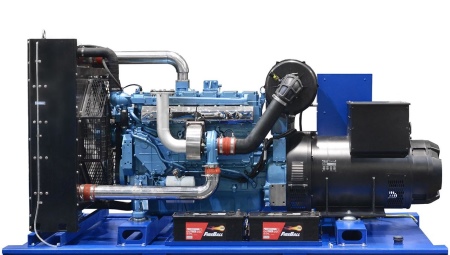

Reasons for the breakdown of the diesel power plant

In order to eliminate the malfunctions associated with the operation of the engine, it is necessary to establish the causes

The specialists of our company pay special attention to diagnostics when performing repair work, because the information obtained during the check can not only indicate the cause of the malfunction, but also warn of possible malfunctions in the future. Among the most common causes of a malfunctioning diesel generator set are the following.

- Lack of fuel supply to the engine due to a breakdown of the fuel pump;

- Paraffinization of fuel in the cold or simply poor quality diesel fuel;

- Starter rotation with insufficient frequency;

- Wear of graphite brushes or breakage or burnout of the windings;

- Clogged fuel supply system;

- Dirty air filter;

- Nozzle wear;

- Worn piston rings and rod seals;

- Failure of bearings, valve springs, camshaft;

- Incorrectly adjusted motor.

The importance of timely diagnosis and elimination of defects

Regardless of the cause of the DG malfunction, it is necessary to promptly identify and qualitatively eliminate the defects that have arisen, including defects in the generator fuel system. The duration and safety of the subsequent operation of the unit depends on how timely and competently the problem is identified and the repair is performed. In the case of scheduled work in a serviceable generator, preventive replacement or restoration of worn out elements and assemblies is carried out, or emergency, carried out when a particular malfunction is detected. By the scale of the actions carried out, current and major repairs are distinguished. In the first case, we are talking about several problem details, while in the second case, large-scale work is being carried out to restore the operating life of the diesel generator to at least 80% and to avoid common problems in the near future.

Overhaul stages

As part of the overhaul of the diesel generator, the following types of work are performed:

- Complete disassembly of the unit;

- Flushing and cleaning of all parts and assemblies;

- Defect detection of a diesel engine;

- Restoration of individual elements and details;

- Replacement of irreparable parts;

- Obligatory replacement of consumables - pistons and pins, filter elements and sleeves, hoses, rings and gaskets;

- Rewind of the electric motor;

- Assembly of the unit, testing in practice and running-in

Formation of the cost of repairing DG engines

The total cost of services depends on the list of work performed and replaced parts and the power of the generator. Below is a price list for the repair of diesel generators from the PetroMotors company.

| Basic work |

Price, rub |

Price, rub |

Price, rub |

Price, rub |

Price, rub |

Price, rub |

| Up to 40 kVA | 40-80 kVA | 80-160kVA | 160-300 kVA | 300-800 kVA | Above 800kVA | |

| Dismantling | 3000 | 4000 | 6000 | 8000 | 16000 | 24000 |

| Disassembly / parts washing / fault detection | 16000 | 24000 | 32000 | 36000 | 48000 | 56000 |

| Block head repair (without replacing saddles) |

4500 | 6300 | 8500 | 12000 | 24000 | 36000 |

| Assembly | 24000 | 36000 | 46000 | 56000 | 72000 | 108000 |

| Radiator wash and DGU buildings |

6000 | 8000 | 12000 | 14000 | 18000 | 24000 |

| Mounting / centering on the frame | 4000 | 6000 | 8000 | 10000 | 20000 | 28000 |

| Start-up / check in operation | 1500 | 2500 | 3000 | 4200 | 5600 | 8200 |

| Cargo handling | 1500 | 2000 | 2200 | 2600 | 4200 | 6700 |

| Total, rub: | 60500 | 88800 | 117700 | 142800 | 207800 | 290900 |

Emergency generator start

Sometimes it happens that the generator needs to be started urgently, and the manual starter failed at that very moment. If necessary, there are several ways to emergency start.

The methods listed below are not safe!

Remove the starter cover. A flywheel with a cooling impeller is located under it, pulled to the crankshaft by a nut. To make it spin, you can:

- With a rope wrapped around the flywheel, use it in the same way as a recoil starter rope.Note that if it snags on the fan blades, this rope will turn into a whip whip when starting the motor, so be careful. Stand so that the rope cannot get caught in your hands or head.

- Low-power engines can also be started manually: with the ignition off, turn the crankshaft several times, turning the pulley by hand in the desired direction. In this case, the gas valve must be open, and the shutter of the starting device must be closed. After that, turning on the ignition, bring the crankshaft to the compression TDC (you will feel an increase in the effort on the flywheel), and then turn the pulley with a sharp jerk so that the spark energy is enough to ignite the mixture.

- A powerful cordless drill and an extension head from the tool kit are a good replacement for a quick electric starter. Clamp the extension in the chuck, put a head of a suitable size on it and unscrew the crankshaft by the flywheel nut. True, in this way it will be possible to start only a low-power generator - for a large-volume engine, the drill torque is not enough to turn it on the compression stroke.

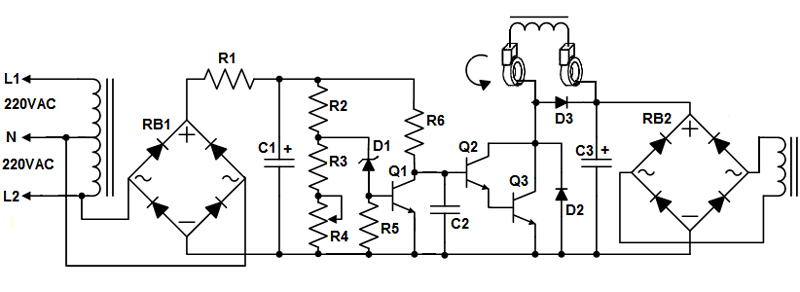

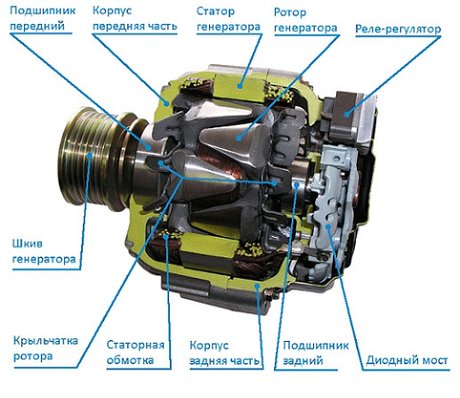

Breakage of the excitation winding

Breakage of the excitation winding most often occurs in the places where the ends of the winding are soldered to the slip rings.

In the event of a break in the excitation winding, an EMF of no more than 5 V is induced in the stator winding, due to the residual magnetism of the rotor steel. In such a case, the battery will not be charged. To determine the break, it is necessary to disconnect the end of the field winding from the brush, and then connect the wires from the battery to this end and to the terminal Ш of the generator through a lamp or voltmeter.

In the event of a break in the winding, the lamp will not light up, and the voltmeter needle will not deviate. To find a coil with a winding break, wires from the battery terminals are connected to the ends of each coil. After that, the place of soldering of the connections and the output ends of the field winding coils are carefully checked. The detected breakage point is eliminated by non-acidic soldering using soft solders. When a break occurs inside the coil, it is replaced or rewound.

Alternator repair kits

To eliminate the indicated malfunctions of the generator, it will be necessary to carry out repairs. When you start looking for a generator repair kit on the Internet, prepare yourself to be disappointed - the kits offered usually contain washers, bolts and nuts. And sometimes it is possible to return the generator to working capacity only by replacing - brushes, diode bridge, regulator ... Therefore, a brave man who decides to repair makes an individual repair kit from those parts that fit his generator. It looks something like the table below, using the example of a pair of generators for the VAZ 2110 and Ford Focus 2.

Generator VAZ 2110 - KZATE 9402.3701-03 for 80 A. It is used on VAZ 2110-2112 and their modifications after 05.2004, as well as on VAZ-2170 Lada-Priora and modifications

| Generator KZATE 9402.3701-03 | ||

|---|---|---|

| Detail | Catalog number | Price, rub.) |

| Brushes | 1127014022 | 105 |

| Voltage regulator | 844.3702 | 580 |

| Diode bridge | BVO4-105-01 | 500 |

| Bearings | 6303 and 6203 | 345 |

Generator Renault Logan - Bosch 0 986 041 850 at 98 A. Applies to Renault: Megane, Scenic, Laguna, Sandero, Clio, Grand Scenic, Kangoo, as well as Dacia: Logan.

| Alternator Bosch 0 986 041 850 | ||

|---|---|---|

| Detail | Catalog number | Price, rub.) |

| Brushes | 140371 | 30 |

| Brush holder | 235607 | 245 |

| Voltage regulator | IN6601 | 1020 |

| Diode bridge | INR431 | 1400 |

| Bearings | 140084 and 140093 | 140/200 rubles |

Possible malfunctions and their elimination

Determine what caused the failures before repairing. It is possible that the problem is due to improper use of the generator. Always start your renovation from simple to complex.

ICE breakdowns

First, consider the malfunctions of the internal combustion engine. Checking the condition of the fuel system should be started from the gas tank to the injectors:

- the system must be sealed, air and fuel drips are not allowed;

- make sure that the fuel comes from the tank to the coarse and fine filters;

- check the booster pump;

- make sure that fuel is supplied to the high pressure fuel pump (injection pump);

- check the correct operation of the injectors.

To check for air, unscrew the supply tubes and pump the fuel with the hand pump. There should be no air bubbles in the liquid stream. Inspect the nozzles. If there is carbon build-up, try removing it with rubbing alcohol.

Starter malfunctions include:

- poor electrical contacts - they must be clean and shiny;

- malfunctions of the retractor relay - it must be replaced;

- burnout of the winding - the starter must be changed.

If the engine stalls, take the following actions.

- Check the control system - one of the sensors could be broken there. Sometimes a faulty electronics is checked by a tester, so to check it, it is better to replace it with a known working one.

- Dirt can accumulate in the tank and fuel lines, especially during the cold season. The blockages must be removed.

To clean up stubborn rust inside the tank, remove it and pick up a handful of small stones. Next, fill in some oil or solvent. Shake the tank vigorously so that the stones have removed all dirt. After that, remove this substance and rinse the inner cavity.

If there is a high oil consumption, the piston rings must be replaced.

If the color of the exhaust gases has changed, the probable cause is the ingress of coolant into the combustion chambers. To fix, do the following:

- check the injection pump and injectors;

- replace piston rings;

- check the cylinder head gaskets and the cooling system.

If the engine speed is unstable, it is necessary to inspect the injection pump and the power system. Do the same if after a while the engine stops by itself or the color of the exhaust gases turns black. The normal exhaust color is clear. It sets in after a while when the condensate evaporates. If there is too much smoke, you need to inspect the piston group and check the compression.

If there is a lack of power, then, most likely, the matter is in the power system. Possible reasons:

- the timing of fuel injection is incorrect;

- clogged filters;

- malfunctions of the injection pump;

- the gap in the valves is lost or they are burned out;

- injectors are faulty;

- a foreign object has entered the exhaust system.

Inspect the muffler periodically. Due to the high temperature of the exhaust gases, it can burn out or become cracked.

If the engine overheats, check the cooling system radiator. Over time, it becomes clogged with deposits, therefore, it must be cleaned or replaced.

Electrical faults

If the generator does not produce the desired voltage or it "jumps", inspect the sliding contact. Over time, graphite brushes wear off, they must be replaced with similar ones.

Oiling of brushes occurs when antifreeze or oil gets on them. For repair, they need to be removed, degreased and reinstalled. If this happens frequently, check the tightness of all pipes. Over time, the springs that press the brushes against the rotor also weaken. They need to be changed or tightened.

The rotor must be firmly seated in the bearings and rotate without wobbling. If there is, the repair must be started immediately, otherwise the bearing will break the seat. Then you have to change the side cover.

If the winding is short-circuited, it must be rewound. This can only be done in a service center, as the procedure is very complicated. The integrity of the windings is checked with a multimeter. The resistance of all phases should be approximately the same.

Pay attention to spark plugs. They need to be periodically cleaned of carbon deposits, just like the nozzles.

Or change. A symptom of a malfunction - the engine does not start the first time with a working power system. Sometimes the control system also gets lost, then you need to reset the settings. In expensive models, a computer is connected to the generator, with the help of which a reset is performed.

Still, a malfunction is easier to prevent than to fix.Now we will talk about preventing breakdowns.

Where can I find parts and consumables?

- ZIP-365 - spare parts for Caterpillar motors;

- DieselSnabGroup - sale of spare parts, repair of diesel generators;

- Volga Nord - spare parts for sale.

Prices for work (repair of diesel generators):

| the name of the operation | Price | Duration of execution |

|---|---|---|

| Power plant inspection / diagnostics | from 2000 rubles | from 1 hour |

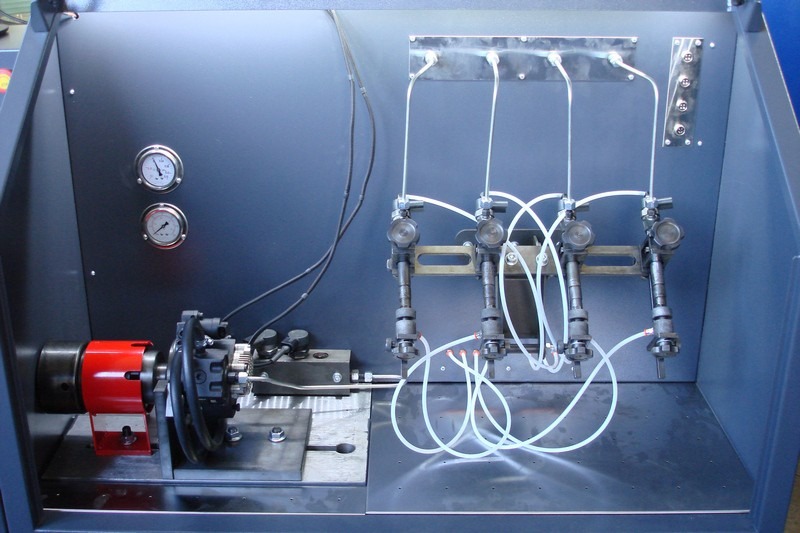

| Fuel system / injection pump / injector test (excluding the cost of repairing the injection pump) | from 15,000 rubles | from 1 day |

| Replacing the control panel | from 4000 rubles | from 2 hours |

| Alternator replacement | from 15,000 rubles | from 1 day |

| Alternator Voltage Regulator Replacement | from 2000 rubles | from 1 hour |

| Replacing the coolant heater | from 2000 rubles | from 1 hour |

| Replacing the charger | from 2000 rubles | from 1 hour |

Malfunctions of diesel generators appear as a result of violation of operating rules or due to aging of equipment.

For a reliable repair of the station, it is better to resort to the services of professionals.

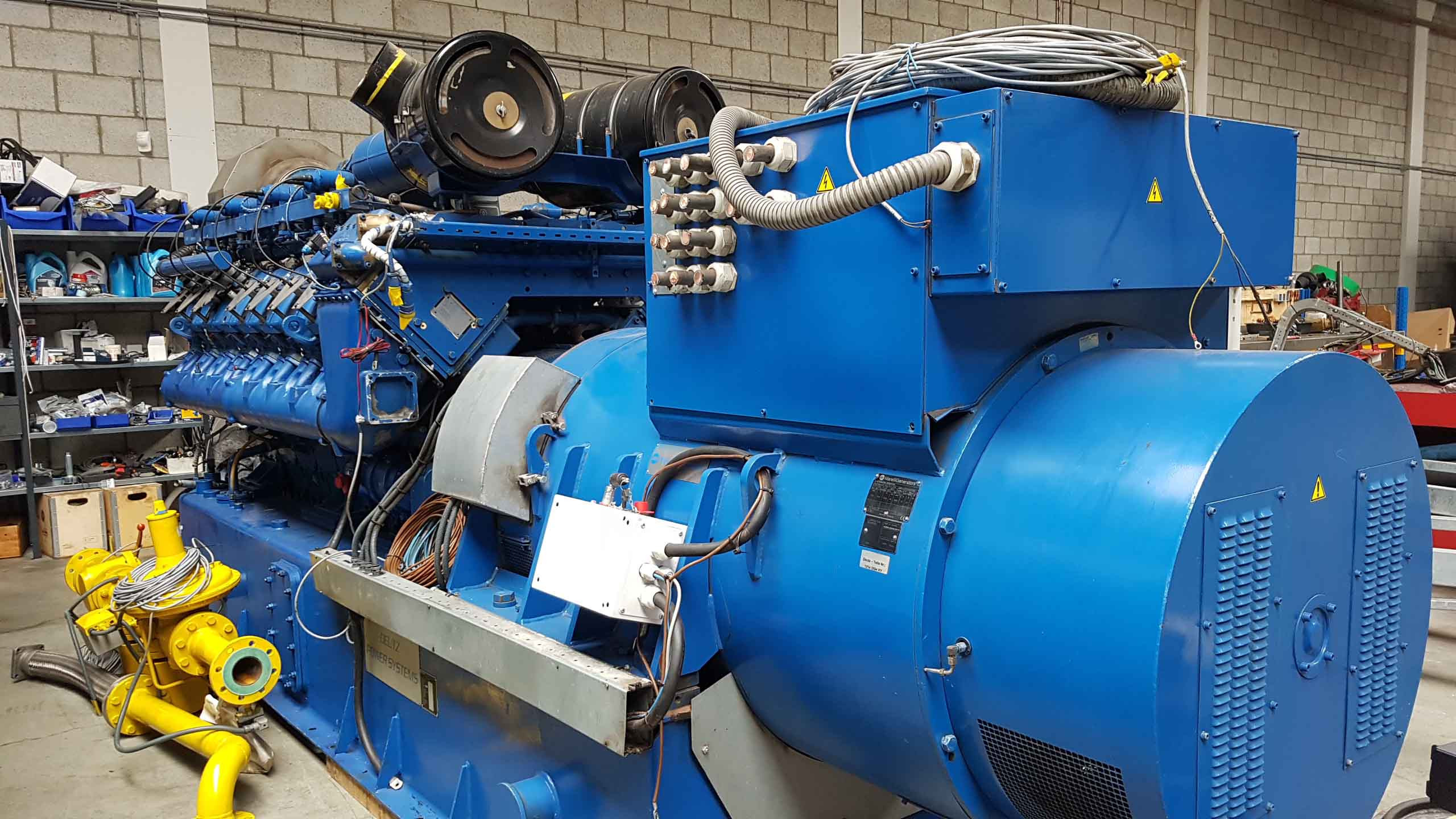

Repair of diesel power plants

At the time of the loss of a diesel power plant, it is not always possible to determine the cause of the breakdown on its own and decide what type of repair is required: replacement of individual parts of the diesel power plant or, for example, a complete overhaul of the engine. It is often possible to find out which parts or assemblies need to be repaired only after thorough diagnostics or fault detection of the power plant.

Prices for the repair of diesel power plants and generators

| Name of works | Price |

| General inspection of the power plant to identify the unit requiring repair | from 2,000 rubles |

| Testing the fuel system, including removing the fuel pump and injectors, testing at the stand and installing it back (excluding the cost of repairing the injection pump) | from 15,000 rubles |

| Repair work on replacing the control panel (control panel) of the diesel generator | from 4000 rub. |

| Repair work to replace the alternator, alternator (not including the cost of the generator) | from 15,000 rubles. |

| Repair work to replace the alternator voltage regulator | from 2000 rub. |

| Repair work to replace the coolant heater | from 2000 rub. |

| Repair work to replace the charger (charger) | from 2000 rub. |

| Diesel engine repair, engine replacement, piston group repair, engine overhaul, alternator repair | depends on the power of the diesel generator |

Terms of repair of diesel power plants and generators

| Name of works | Repair terms |

| Initial diagnostics, replacement of the alternator voltage regulator, replacement of the coolant heater, replacement of the charger | from 1 hour |

| Repair work on replacing the control panel (control panel) of the diesel generator | from 2 hours |

| Testing the fuel system, including removing the fuel pump and injectors, testing at the stand and installing it back (without the cost of repairing the injection pump), replacing the generator (alternator) | from 1 day |

| Replacement of a diesel engine DGU, repair of a diesel engine, repair of a piston group, engine overhaul, repair of an alternator | depends on the power of the diesel generator |

GENERAL-ENERGO's repair specialists go to inspect and diagnose malfunctions of diesel power plants throughout Russia. If simple repairs can be carried out directly on site, then for serious work it may be necessary to deliver the power plant to our repair base. If necessary, GENERAL-ENERGO can provide a backup diesel power plant for the period of repair work in the service center of power plants, and you do not have to disconnect electricity consumers.

GENERAL-ENERGO carries out repair of diesel generator sets (DGU) of any complexity.Simple repairs are carried out on site, in other cases it is necessary to transport the unit to our repair shop.

GENERAL-ENERGO carries out repair of diesel generator sets (DGU) of any complexity.Simple repairs are carried out on site, in other cases it is necessary to transport the unit to our repair shop.

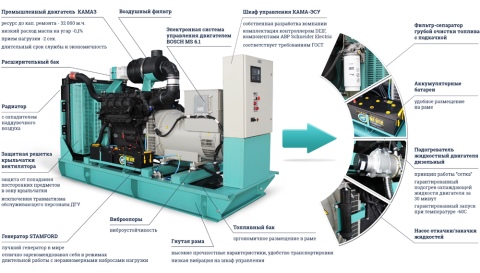

Repairing a diesel power plant may include:

- Preliminary diagnostics of the power plant... General inspection of the diesel unit to identify components requiring repair. Testing the fuel system, including removing the fuel pump and injectors. Checking the health of the cooling systems. Diagnostics of the electrical part of the diesel power plant and storage batteries.

- Extended fault detection of the power plant and drawing up a troubleshooting plan.

- Repair or replacement of faulty units and parts of the power plant (control panel for diesel generator, alternator (alternator), alternator voltage regulator, coolant heater, charger, etc.)

- Power plant test... Test run of all units and mechanisms, including under load using GENERAL-ENERGO load modules.

Call +7 (495) 21-21-554

Your equipment - IN SAFE HANDS!

Preventive measures

The main cause of malfunctioning diesel generators is improper operation and starting errors. To avoid breakdowns, it is not allowed to start devices with a damaged case and loose parts, or with a connected load higher than the standard. It is not recommended to use low quality oil and fuel, mix or fill in different brands unsuitable for the season. Each model has clearly specified maintenance periods, with intensive operation they are carried out more often.

Climatic conditions are taken into account, in particular the need for sealed protective covers, thermal insulation and ventilation systems. Humidity is controlled - exceeding above 60% leads to ignition of contacts and wiring

During operation, fuel and oil consumption is monitored, attention is paid to the noise emitted by the generator and exhaust gases. If extraneous sounds or black exhaust appear for a long time, unscheduled diagnostics should be carried out

The degree of clogging of the air and oil filters is constantly monitored, if necessary, they are cleaned or replaced.

Closing the "plus" terminal of the generator to the case

The shorting of the "plus" terminal of the generator to the case occurs due to the destruction of the terminal insulation or the insulation of the wire connected to this terminal. With such a generator malfunction, the current in the stator winding and in the diodes of the rectifier unit sharply increases, which leads to thermal destruction of the winding insulation and breakdown of the rectifier unit diodes. After the breakdown of the diodes, a short circuit occurs in the battery, as a result of which a deep discharge of the battery occurs and the insulation of the connecting wires is destroyed, and the ammeter also fails.

The defective clamp insulation is restored. The damaged stator windings and the rectifier diode unit are replaced with serviceable ones in a repair shop.

Troubleshooting

On modern cars, the use of the "old-fashioned" diagnostic method by throwing off the battery terminal can lead to serious damage to many of the electronic systems of the car. Significant voltage drops in the vehicle's on-board network can damage almost all on-board electronics. That is why modern generators are always checked only by measuring the voltage in the network or diagnosing the removed unit itself on a special stand. First, the voltage at the battery terminals is measured, the engine is started and readings are taken while the engine is running. Before starting, the voltage should be about 12 V, after starting - from 13.8 to 14.7 V. A deviation to a large side indicates that you are "overcharging", which implies a malfunction of the relay-regulator, to a smaller one - that no current is supplied.Lack of recharge current indicates a malfunction of the generator or circuits.

Generator repair

There are many different designs of mini power plants. For this reason, it will not be possible to repair any of them in the same way. But in general, every power plant contains two main elements: an internal combustion engine and an electric generator. Therefore, in the event of a breakdown, you will have to repair either one or both of these elements.

Electric generators in all power plants are most similar in their design. Therefore, if in any power plant the engine is working properly, and the voltage at the rated load does not correspond to the norm, or there is no problem in the excitation of the generator.

An asynchronous generator with capacitor excitation is checked for the serviceability of a capacitor, which, for one reason or another, has lost its original parameters:

- the capacity has significantly decreased;

- the capacitor is broken - the plates are short-circuited or open-circuit.

If it is possible to disassemble the generator with your own hands, remove and replace the capacitor, you need to do this. In the three-phase version, there are three capacitors, in the single-phase version - one.

|

|

Three-phase asynchronous power generator |

If the excitation is valve, a punctured or broken valve is determined using a tester, which is replaced with a new one.

Synchronous generators with rectifiers in the excitation system may also not work due to a malfunction of the rectifier diodes. A defective diode, if there is access to it, is determined by the tester and replaced with a new one. A rotor with rings and brushes can have a problem with the wear of the brushes, which have become like resistors. They must be checked with a tester for resistance and replaced with new ones.

If the capacitors and semiconductors turned out to be safe and sound, then the worst happened - an inter-turn short circuit or a winding break. With such a breakdown, it is at least very difficult to rewind the windings on your own. It is better to contact the service department and solve this problem with its specialists.

If a generator with an inverter breaks down, the presence of high-frequency voltage at the input of the inverter and the absence of voltage with a frequency of 50 Hz at its output at rated load indicates a breakdown of the inverter. Usually its parts are not available for replacement and are filled with a special compound. Therefore, the entire inverter unit will have to be replaced.

If permanent magnets create a magnetic field in an electric generator, it is possible that they are demagnetized and, as a consequence, a decrease in the power of the power plant. This malfunction will also require replacement of the part with magnets through the service department.

Common battery malfunctions:

- short circuit of the electrodes / plates of the battery;

- mechanical or chemical damage to the battery plates;

- violation of the tightness of the battery cans - cracks in the battery case as a result of impacts or improper installation;

- chemical oxidation of the output terminals of the battery. The main reasons for these malfunctions are:

- gross violations of operating rules;

- expiration of the product's service life;

- various manufacturing defects.

Of course, the design of a generator is more complex than a storage battery. It is quite reasonable that there are many times more generator malfunctions, and their diagnosis is much more difficult.

It is very useful for the motorist to know the main causes of generator malfunctions, ways to eliminate themas well as preventive measures to prevent breakdowns.

All generators are classified into AC and DC generators. Modern light vehicles are equipped with alternators with a built-in diode bridge (rectifier). The latter is necessary for converting current into direct current, on which the car's electrical consumers work. The rectifier, as a rule, is located in the cover or housing of the generator and is one piece with the latter.

All electrical devices of the car are designed for a strictly defined range of operating voltage currents.As a rule, operating voltages are in the range of 13.8-14.7 V. Due to the fact that the generator is "tied" by a belt to the engine crankshaft, it will work differently depending on the speed and speed of the vehicle. It is for smoothing and regulating the output current that the voltage regulator relay is intended, which plays the role of a stabilizer and prevents both surges and dips of the operating voltage. Modern generators are equipped with built-in integrated voltage regulators, in common parlance referred to as "chocolate" or "pill".

It is already clear that any generator is a rather complex unit, extremely important for any car.

Generator self check

The easiest way is to check the fuse. If it is working properly, the generator and its location are inspected. Check the free rotation of the rotor, the integrity of the belt, wires, housing. If nothing aroused suspicion, the brushes and slip rings are checked. In the process of operation, the brushes inevitably wear out, they can jam, warp, and the grooves of the slip rings become clogged with graphite dust. A clear sign of this is excessive sparking.

Cases of complete wear or breakdown of both bearings and stator breakdown are not uncommon.

The most common mechanical problem with a generator is bearing wear. A symptom of this malfunction is a howl or whistle when the unit is operating. Of course, the bearings must be replaced immediately after inspecting the seats. Loose drive belt tension can also cause poor alternator performance. One of the signs may be a high-pitched whistle from under the hood when the car is accelerating or accelerating.

To check the rotor field winding for short-circuited turns or breaks, you need to connect a multimeter, switched to the resistance measurement mode, to both slip rings of the generator. Normal resistance is 1.8 to 5 ohms. The reading below indicates the presence of a short circuit in the turns; above - a straight winding break.

To check the stator winding for "breakdown to ground", they must be disconnected from the rectifier unit. With the resistance readings given by the multimeter, which are of infinite value, there is no doubt that there is no contact between the stator windings and the case ("ground").

A multimeter is used to check the diodes in the rectifier unit (after completely disconnecting from the stator windings). Test mode - "diode test". The positive probe is connected to the positive or negative of the rectifier, and the negative to the phase terminal. After that, the probes are swapped. If at the same time the readings of the multimeter are strongly differ from previous - the diode is good, if they do not differ, it is faulty. Another sign indicating the imminent "demise" of the diode bridge of the generator is oxidation of the contacts, and the reason for this is overheating of the radiator.

Diagnostic equipment

To diagnose diesel power plants, the following are used:

- Diagnostic computers with appropriate software packages that allow you to identify most of the malfunctions. They are connected to a special connector of the station.

- Stands for diagnostics of malfunctions of high-pressure fuel pumps and injectors.

- Fixtures for the repair of different injectors.

Diagnostic stands

The complexes are designed for diagnostics of electrical equipment. There are universal and highly specialized stands.

Generators are checked when operating at certain speeds, the unit must deliver such a current that will ensure normal charging of batteries and power supply to consumers.

The starter must start and work smoothly (without extraneous noise) when the voltage standard for this model is applied to its contacts.

Professional repair of diesel generators

Masters of the PetroMotors company have experience from 5 to 20 years in the repair of domestic and imported diesel generators and carry out repairs of any degree of complexity. Repairs are carried out on modern equipment, which eliminates errors in diagnostics and repair.We have our own spare parts warehouse, which allows us to reduce the repair time.

Conclusion

Most of the problems a generator owner will encounter can be remedied on site by himself. But you need to soberly assess your abilities - sometimes saving on contacting the workshop leads to unnecessary costs later.

In order not to waste time on old and non-working equipment, you can buy a new one at inexpensive prices with discounts.

Name For Price DDE GG950Z

Apparent power 0.72 kVA

Active power 0.65 kW

Displacement 63 cm3

Voltage 220 V

Tank 4.2 l

Working time 6 h

Engine: 2-stroke

Small electrical appliances with a total power of up to 0.7 kW: laptop, camera, lighting, screwdriver. A great option for hiking and fishing.

5869 CHAMPION GG951DC

Apparent power: 0.72 kVA

Active power: 0.65 kW

Displacement: 63 cm3

Voltage: 220V

Tank: 4.2 l

Working time: 6 h

Engine: 2-stroke

For electrical appliances up to 0.65 kW / Cope with a small 60W A + refrigerator, a 40W TV and several 40-50W LED bulbs. Excellent travel option 6150 DDE DPG1201i

Apparent power: 1.1 kVA

Active power: 1 kW

Displacement: 69 cm3

Voltage: 220V

Output current: 16A

Tank: 2.6 l

Working time: 4 h

You can connect devices that are demanding on the purity of the current: smartphones, laptops, computers with a power of up to 1 kW

8159 HUTER HT1000L

Apparent power: 1.1 kVA

Active power: 1 kW

Voltage: 220V

Tank: 4.8 l

Working time: 4 h

Engine: 4-stroke

You can use it as a backup source of electricity in the country, take it with you on a hike or on a picnic to power low-power appliances. For example: grinder for 1 kW, concrete mixer 140l, oil cooler 11100 HUTER DY2500L

Apparent power: 2 kVA

Active power: 1.6 kW

Voltage: 220V

Tank: 12 L

Working time: 15 h

Engine: 4-stroke

Can be used to power tools, street outlets, and as a backup power source. The electric kettle, wood splitter, drill will take turns pulling. Together will pull the refrigerator, TV, music center

14150