Peculiarities

All models of MATRIX jacks and service accessories are made of high quality, high strength metal.

Among the car jacks of the MATRIX brand stand out:

- pneumohydraulic;

- hydraulic;

- movable;

- rack;

- stands and wheel chocks.

Automobile rack jacks MATRIX - lifting devices for servicing vehicles, which are particularly durable and reliable. These are devices suitable for operation even in the most difficult conditions - they are not afraid of temperature extremes, dust, high humidity. Among other things, this technique is safe and durable. To select a specific model of the jack, you need to decide on its use in the future.

Rack jack models are represented by the High Jack series (505155, 505175, 505195) with a lifting capacity of 3 tons.

Popular models of Matrix jacks and their characteristics

The reliable German manufacturer Matrix offers proven models of equipment for cars, among which you can choose a mechanism for any situation and type of car.

Important!

It is recommended to purchase only branded products. The most important thing that can be counted on in this case is the full compliance of the parameters specified in the accompanying documents with those that the mechanism will show in reality. Manufacturers who care about their image, without fail, carry out the necessary tests, so you can be sure that if a lifting capacity of 2 tons is indicated, this is exactly how much the jack will lift .. MATRIX MASTER 50750 is a bottle-type hydraulic jack capable of lifting a load weighing up to 2 tons. tons, which is enough for all passenger cars in the sedan or hatchback body, as well as for some light SUVs and compact crossovers like the Renault Duster

The body is made of steel and cast iron. The working stroke is 116 mm. This model is capable of lifting loads up to 345 mm. It is light enough - just over 3 kg, comes with a plastic convenient case, so the mechanism does not take up much space in the trunk

MATRIX MASTER 50750 is a bottle-type hydraulic jack capable of lifting loads weighing up to 2 tons, which is enough for all sedan or hatchback cars, as well as for some light SUVs and compact crossovers such as the Renault Duster. The body is made of steel and cast iron. The working stroke is 116 mm. This model is capable of lifting loads up to 345 mm. It is light enough - just over 3 kg, comes with a plastic convenient case, so the mechanism does not take up much space in the trunk.

Price - RUB 1122 *

MATRIX MASTER 50756 is another bottle-type hydraulic model, but with a carrying capacity of 5 tons, while other characteristics are also better here: working stroke - 127 mm, maximum lifting height - 413. Naturally, this affected the dimensions: the unit weighs almost 5 kg. MATRIX MASTER 50756 is ideal for vans and trucks up to 3.5 tonnes GVW, as well as for SUVs with high ground clearance (lift height 216 mm too big for most passenger cars). Price - 1634 rubles.

MATRIX MASTER 50737 - the most powerful hydraulic bottle jack "Matrix": can lift a load weighing 50 tons to a height of 356 mm. Such characteristics make this model not only relevant for drivers of heavy vehicles, but also for those who are engaged in construction and repair work. Such a unit weighs a lot - 28.6 kg, so it is better to carry it together. Price - 8195 rubles.

MATRIX MASTER 50737

MATRIX MASTER 50737

Quick Lift. MATRIX 51047 is a hydraulic trolley jack with a reinforced structure, belongs to the professional model. It has a switch for lifting and lowering modes installed on the handle, as well as a removable support heel, instead of which it is possible to install additional devices, for example, a sliding stop bar. The lifting capacity of 3 tons allows you to use this jack for servicing all types of cars. Convenient for owners of cars with low ground clearance, as the pickup height is only 130 mm.Price - 8510 rubles.

Note!

The Matrix hydraulic trolley jack is the most popular option today. Its advantages include high reliability, large lifting height and small pickup height, ease of use

It is these jacks that are used in auto repair shops, so the manufacturer positions them as professional tools.

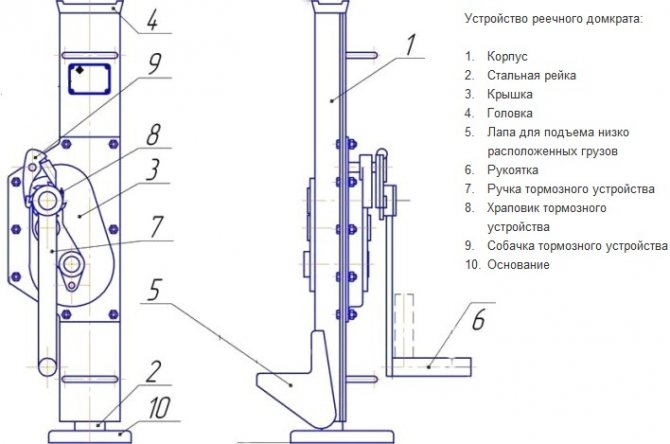

HigH Jack. MATRIX 505175 is a mechanical, not a hydraulic rack-and-pinion jack with a lifting capacity of 3 tons. The maximum lift height of 1016 mm makes the mechanism very popular with motorists who often travel into hard-to-reach places where the machine can seriously get bogged down in mud. Like any rack jack, Matrix 505175 is quite heavy - 14.2 kg. It has a hooking loop at the end of the carrier rail, which allows the mechanism to be used as a winch. Price - RUB 4866

Jacks Matrix: description of the manufacturer and its features

There are a lot of companies on the market that are engaged in the production of car jacks. Among them, leaders have emerged who produce high quality products, and Matrix belongs to them. It is a relatively young company founded in Germany in 2003. Through the use of innovative technologies in the production of products, the brand quickly gained popularity in both North America and Europe. At the moment, under the Matrix brand, torque wrenches, power tools, fasteners, goods for carpenters and locksmiths, and many others are produced. dr.

Matrix logo

Matrix logo

Features of jacks "Matrix" on the example of the most common hydraulic varieties:

- Modern, stable design - due to the special shape of the base, the device does not move when the vehicle is lifted.

- Easy Lift - Hydraulic drive that raises the platform with a load, operated by light movements of the handle. At the same time, due to the presence of a rubberized coating, slipping of the hand is excluded.

- Long stroke - allows you to use the jack to raise vehicles to the desired height for various jobs: from changing wheels to inspecting the suspension, exhaust system and other parts. The size of the working stroke can be 135-300 mm or 140-800 mm.

- Reliable load fixation - a wide support heel with grooves serves as a good support for the underbody of the car, therefore, when lifting, there is no displacement and the possibility of a breakdown of the load is excluded.

Today Matrix jacks are produced with a carrying capacity of 2 to 50 tons, so you can choose a model for servicing cars and trucks, for construction work. For cars with low ground clearance, a device with minimum pickup height 95 mm, and the maximum value for this parameter reaches 220 mm.

Note!

The type of packaging for Matrix jacks can be of two types: an ordinary cardboard box or a plastic case, which is more convenient for storage and transportation.

Rules of work and safety precautions with jacks "Matrix":

- It is not allowed to support the load in the process of moving the load with a jack for a long time.

- Before lifting a load, make sure that the weight is evenly distributed over the center of the supporting surface of this unit.

- The weight of the load must not exceed the value indicated by the manufacturer on the jack. For example, a rolling jack "Matrix" 3t is not designed to lift a load weighing more than 3000 kg. Failure to do so can lead to rapid failure of the hoist.

- In the process of moving the load, the tool must be placed on a horizontal, level and solid surface.

- To support the weight after lifting the load, you need to use special stands.

- Before starting work, you should carefully read the operating instructions for the device.

- The design with a safety valve is designed for lifting weights up to 10 tons.

Using the "Matrix" jack for lifting a car

Using the "Matrix" jack for lifting a car

Possible breakdowns and how to fix them yourself

Any mechanism can break, especially for hydraulic models, which have a much more complex design than mechanical ones. Basically, the device fails when lowering or raising the stem. Oil leaks are common. If such problems arise, the fixture should be repaired. If, after carrying out repair work, the device again does not work in normal mode, then you will have to completely disassemble the structure.

In the process of disassembling the device, specialists take out the pistons and check the parts for corrosion. If there is contamination in the pistons, then the affected elements are thoroughly cleaned. The next step is to check the stock. If it is deformed, it will have to be replaced. Clogged valves are an equally common cause of device failure. These elements are responsible for the extension or retraction of the working rod of the mechanism.

Change of oil

Important!

Having identified the cause of the breakdown, it is better for the owner of the jack to contact professional specialists who will carry out repair actions.

In general, Matrix jacks, whether hydraulic or mechanical models, are quite reliable, since the quality of materials and assembly is very strictly monitored, and it is not for nothing that this brand is popular not only in Russia, but also in the European Union countries, as well as in the USA.

* Prices are valid for December 2018

Criterias of choice

To determine the choice of a device, you need to know its further purpose and evaluate the capabilities of the mechanism.

- Plantar (support) size. The larger it is, the more stable the structure is.

- Carrying capacity. The main criterion, it should be several times more than the weight of the car itself.

- Pickup height. It is desirable that it be in the range from 135 mm to 155 mm.

The operational excellence in comparative analysis with other similar mechanisms is:

- step-by-step descent of the load;

- compactness;

- suitability for repair service;

- availability and ease of use;

- decent efficiency;

- cost (of similar devices of different brands).

An important plus is the availability of accessories.

The lineup

Rack and pinion jacks MATRIX High Jack allow their owner to smoothly raise the load to the desired height.

MATRIX High Jack 505155. Consists of a carrier rail with a hook loop that can be used as a winch. On any plane, it will provide stability and wide support. The lifting capacity of such a jack is 3 tons, the lifting height is 660 mm, and the height pickup is 135 mm.

The undoubted advantage of the MATRIX brand is the use of high quality metal with an anti-corrosion coating for its jacks. Transportation is carried out using mounting latches, which allows owners to place the mechanism even on the roof of the car. Quality such as ergonomics is essential to use the machine quickly and efficiently.

How to choose a quality tool

Before purchasing a jack, it makes sense not only to ask the seller about the specified product, but also to look at the instructions.

Initially, you need to pay close attention to the following indicators:

Lifting height. This characteristic will allow you to determine how high will be the ability to lift the load with a specific device. The height of the lift is measured from the position of the jack in an idle state on the surface to the critical height of the support.

Pickup height. Pickup is characterized by the minimum possible lifting of the machine above the surface using a specific jack.

Carrying capacity. Shows the maximum weight the tool can safely hold. When evaluating this parameter, it is imperative to compare the weight of the car and the capabilities of the jack that you will have to buy. It is better to choose a tool with at least a small margin of carrying capacity.

The size of the working stroke of the tool.The working stroke is the distance that the jack "travels" from the lowest non-working level to the maximum possible working

It is also important here not only the distance itself, but also how easily the jack overcomes this path. If this happens with effort, then, perhaps, the mechanism is faulty, and then, of course, it is not worth purchasing such a jack.

Weight and size

These indicators are important not only as part of performance, but also in terms of storage and ease of transport of the tool. The jack must be in the car at all times.

Hydraulic trolley jack "Matrix" in a branded box

Hydraulic trolley jack "Matrix" in a branded box

Most often, drivers choose hydraulic jacks, since they are easier and more convenient to use than mechanical jacks, they lift the load smoothly, without jerking, you do not need to exert a lot of physical effort, so even a fragile girl can use such a tool. However, hydraulics also have disadvantages. Many experts believe that hydraulic jacks lift loads too slowly. Raising the vehicle to a great height at one time is not possible.

In winter, with significant temperature changes, the hydraulics freeze. If a part fails, the repair is too expensive. The hydraulic device needs periodic maintenance: pumping, fluid replacement.

Review overview

According to the owners of the purchased MATRIX rack jacks, everyone liked the product. The main advantages that buyers highlight:

the mechanism is durable and of high quality;

easily replaces the winch, which is enough to lift and remove the engine for further repairs;

the mechanism is able not only to lift the load, but also to pull the car out of the off-road;

compactness and availability of spare parts;

the device has a constant amplifier, even people with a fragile physique can cope with lifting weights;

anti-corrosion protection, which is especially important for off-road driving enthusiasts in all weather conditions.

Of the shortcomings, users most often mention uninformative instructions (you have to spend time looking for the necessary information on the Internet), a relief platform, which in some cases can leave traces, and a breakdown, and not a smooth descent when working with loads up to 30 kg.

If you have to choose a jack, then you need only one mechanism. The rack jack of the MATRIX firm is an irreplaceable device, if it is handled faultlessly and correctly, it will save its owner from many troubles.

For information on what MATRIX rack jacks are, see the next video.