How to make a homemade gearbox for a walk-behind tractor

For self-assembly of the converting device on the walk-behind tractor, you need to stock up on the following tools:

- vernier caliper and metal ruler;

- a set of screwdrivers of different sizes, including oblique;

- pliers and wire cutters;

- saw for metal;

- electric drill with a set of drills for metal;

- vice;

- hammers - big and small;

- rubber gaskets.

Also, with the help of preliminary calculations, you can estimate the dimensions of the future transmission device.

To make the correct calculation, decide on the parameters of your engine. For calculations, it is necessary to clarify several data:

- Engine speed. However, this value is not constant: it is necessary to "add gas", and it will increase significantly. Therefore, the calculations are based on the basis - the number of idle revolutions plus 10%.

- Estimated number of revolutions for the suspension axle. It is calculated taking into account the diameter of the wheels to determine the run-out per full revolution. Based on this, you can calculate at what speed the axis should rotate in order to ensure the most comfortable speed of the walk-behind tractor. This is an average of 3 to 5 km / h.

Consider a simple example: the engine idling power, taking into account an increase of 10%, is 600 rpm, and to achieve a speed of 3 km / h, a rotational speed of 200 rpm is required. Therefore, the design gear ratio is 3: 1. In other words, in order to decrease the speed of rotation of the axle by three times, in order to ensure the speed of movement of 3 km per hour, the torque is increased three times.

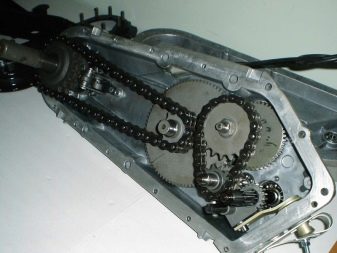

Step-by-step instructions for assembling a chain reducer

If you have certain skills, you can make a gearbox of any type with your own hands, but the easiest way is to assemble a small-sized mechanism with a chain drive. Materials for it are easier to find, they are reliable in work.

To make a homemade chain mechanism, stock up on the following parts and materials:

- sprockets with the required number of teeth;

- driven shaft;

- cylindrical and eccentric bearings;

- protective cover;

- fasteners for connecting parts of the casing;

- chains with the required number of links.

An old gearbox housing of a suitable size can be used as a protective cover by drilling holes in it for fastening.

- The manufacture of a homemade gearbox for a walk-behind tractor begins with a drive sprocket fastening to the output shaft of the engine. A key or flange can be used to secure it. Even spot welding can be used depending on the design of the output shaft.

- The driven shaft should be turned on the machine. The asterisk is fixed on it in the same way as on the drive shaft.

- A more reliable way is to make a shaft from two semiaxes, at the ends of which flanges are machined. The driven sprocket is fixed between them, fastening the entire structure with bolts. In this version, the second stage sprocket will be fixed more precisely and securely.

- To protect the gearbox mechanism from dirt and mechanical damage, it is placed in a protective case, which also serves as a reservoir containing liquid lubricant for moving parts.

- In the protective casing (crankcase), holes are drilled for installing support bearings. The driven shaft is mounted on cylindrical bearings, and the driving shaft is mounted on eccentrics. By changing, due to its design features, the position in the seat within a radius of 15 °, the eccentric bearing also changes the position of the drive shaft, thus adjusting the chain tension.

If the calculation of the gear ratio is done correctly, then the gearbox, carefully assembled taking into account all the design features of your walk-behind tractor, will ensure the smooth operation of the mechanisms no worse than its industrial counterparts.

Category: Homemade

Equipment

Converters are collapsible and non-collapsible. Basically, the latter type can often be found in the configuration of budget motoblocks. They feature inexpensive parts that cannot be replaced. In the event of a breakdown, there is only one way out - to replace the entire gearbox. The service life of such models declared by manufacturers is 1-2 seasons, provided that they are used correctly.

More expensive equipment can "boast" with a collapsible gearbox that can be repaired: failed parts can be replaced with new ones. Therefore, the term of use is several times longer than that of inexpensive devices.

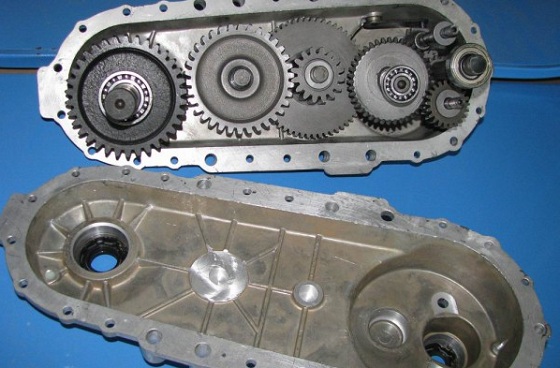

The complete set of converters consists of:

- Cases - collapsible or not.

- Rotor shaft - responsible for the torque.

- Gears of different sizes.

- Chain or belt - depends on the type of gearbox. In the case of a chain drive, the movement occurs due to sprockets - star-type discs. If the transmission is belt, then the equipment has pulleys on which the belt is put on.

- Bearings - Reduces friction between rotating elements and allows them to rotate freely.

Through these components, the movement is transmitted from the motor to the attached parts. Belt converters are weaker and more unreliable. If the torque is large, then the belts begin to fly off the pulleys. But such a structure has a positive effect on the engine shaft. This situation can be avoided by replacing them with toothed ones. But then the pulleys will have to be changed.

All parts are located inside the case. In addition to the installed set of components, you can also add elements for lubricating the bearings inside the device. These include an oil pump or cooling apparatus.

Chain or gear

The chain drive is a mechanism for transmitting motion using gear sprockets and chains. The mechanism has its own advantages:

- transmits movement over long distances;

- one chain is capable of twisting several shafts;

- high transmission stability and efficiency.

The disadvantages include:

- increased noise level;

- intensive chain wear;

- gradual pulling of the chain;

- high price.

There are roller, sleeve and gear chains.

The gear reducer is more complex than all the others. During operation, it reduces engine speed and increases the power output of the unit. A good walk-behind tractor is equipped with such an air-cooled gearbox. It can have a reverse, allowing the walk-behind tractor to move back. Disassembling and replacing gears is not difficult. In installations made in China, non-separable gearboxes are used. In the event of a breakdown, you need to change the entire body together with the filling.

Model overview

In order to get some idea about motoblocks with a power take-off shaft, you need to familiarize yourself in more detail with the characteristics and features of some models.

NEVA MB-Compact S-6.0

The walk-behind tractor of this model is considered a real find for adherents of professional technology. The unit has great functionality, despite its compact size. Almost the entire range of attachments can be connected to the PTO shaft, from the plow to the snow plow rotor.

The manufacturer specifies the following specifications:

- weight - 70 kg;

- power - 6 liters. with.;

- low noise level;

- fast start-up and flawless operation in cold weather;

- cultivation depth up to 20 cm;

- high engine resource;

- capture width - 86 cm.

In addition, some modifications of the Neva can be equipped with an electric starter.

Agate (Salute) 5P

The walk-behind tractor is mainly used for agricultural work in small farms.With the help of additional accessories, this machine can be used as a small tractor.

Has a downshift function. When transporting cargo weighing up to 500 kg, it develops a speed of 10 km / h.

Technical details:

- weight - 78 kg;

- power - 5 liters. with.;

- plowing depth 25 cm;

- adjustable processing width up to 90 cm;

- the steering column is equipped with two position switches for comfortable control.

Belarus 09N-01

The model is designed for versatile soil cultivation on an area of up to 5 hectares. The unit is distinguished by unpretentiousness to working conditions and reliability. Thanks to the weight, it provides traction and excellent handling. It belongs to the heavy type.

From the above characteristics, it can be noted:

- unit weight - 176 kg;

- developed power - 9.38 liters. with.;

- the capture width is adjustable from 45 to 70 cm;

- number of gears - 4/2;

- carrying capacity - 650 kg;

- speed up to 11 km / h.

Profi 1900

Motoblocks were specially developed by German manufacturers for agricultural operations in areas with heavy soil and poor maneuverability. Thanks to its power of 14 horsepower, this machine is able to provide easy working conditions where significant efforts must be made with a conventional walk-behind tractor. For evening work, these models are equipped with a headlight.

Attached specifications:

- motoblock weight - 178 kg;

- power - 14 liters. with. (in some models up to 18 liters. from.);

- captured processing width - 80-100 cm;

- plowing depth - 15-30 cm.

In addition, the walk-behind tractor is equipped with a cold start mechanism and a vibration damping system.

Chinese agricultural machines are mainly distinguished from other brands by their low price. It is good if the cost reduction is achieved by increasing the quantity of products. But sometimes manufacturers from this country reduce the cost of goods by installing low-quality components.

One way or another, it is worth considering the most popular models.

Forte 105

It is positioned as a multifunctional unit for performing agrotechnical operations on plots with a total area of up to 1.5 hectares. It is used for cultivation, harvesting root crops, sowing seeds and many other tasks. The walk-behind tractor is able to withstand high loads for a long time.

Some technical data:

- the average weight of the unit is 105 kg;

- power - 7 liters. with.;

- processed width - 105 cm;

- processing depth - 35 cm;

- developed speed - 8 km / h;

- loading weight - 350 kg.

Weima WM1100BE

The motoblock, made according to Western models, belongs to the units of the heavy class. A powerful engine is able to fully provide high-quality functionality and performance of all tasks. The presence of a power take-off shaft allows the unit to operate with implements for various purposes throughout the year. An electric starter is installed on this modification, which makes it easier to start in severe cold.

Specifications:

- unit power - 9 liters. with.;

- weight - 140 kg;

- processed depth - 30 cm;

- capture width - 80-130 cm;

- carrying capacity - 300 kg;

- developed speed - 11 km / h.

You will learn how to make a power take-off shaft in the next video.

DIY gearbox for walk-behind tractor

Enthusiastic farmers ask themselves: how to make a geared walk-behind tractor with your own hands? The question is relevant, since making such a miracle from materials and parts available on the farm is sometimes easier and cheaper than purchasing a regulator assembled by a manufacturer at a factory.

Indeed, in the "invention" of the converter there are no super-complicated manipulations, and a tool made on a walk-behind tractor with your own hands always serves correctly, however, first of all, you should acquire some tools:

- screwdrivers (straight and oblique type);

- hacksaw (for metal);

- pliers or pliers;

- vice;

- some other tools and consumables, the presence of which one way or another may be needed during the assembly process.

The assembly, or rather, the preparation of the converter begins with welding the body. It can be made of metal plates. Sometimes they use a housing from the Ural shaft with its subsequent revision.

DIY motoblock gearbox

For gears, you can turn to the Druzhba chainsaw (4). In this case, an end is cut off in one of the shafts and a hole of the required diameter is drilled, while a second shaft is installed on the opposite side of the future gearbox, and with it - bearings, a cage. The output shaft must be fastened to the pulley.

Oil in the gearbox of the walk-behind tractor

Just like any mechanism, the lubricant being poured in individually fits the gear motoblock. Its quality directly affects the work of the cultivator. Depending on the conditions of use, you should choose the oil individually, but fortunately, universal brands, like Motul, save you, when buying which the user will not be mistaken.

Prices

However, there are also much more expensive models.

What matters is how pricing is built. And, above all, the price depends on the number of functions that the converter is equipped with.

It is impossible to ignore the quality of its assembly - it also greatly affects the cost. And also power and the ability to use reverse are important.

These are general characteristics of the gearbox, but there are many more. From which it follows that the gearbox for the walk-behind tractor is a complex mechanism, in the choice of which you should not be mistaken.

Self-assembly of the travel reducer

Having all the necessary parts, you can start assembling the travel reducer with your own hands. In order for the finished design to cope well with its functions, one should act clearly according to the algorithm described below:

- First, do all the necessary calculations so that the result of the work is a well-balanced structure. As a generator, you can take an element from the domestic Ural motorcycle;

- The main thing that is required from the device is high power and stable torque;

- Next, start cutting out the shell of the two bearings that will be required for the drive shaft. It will start the gear. When working, take into account the diameter of the gearbox;

- Then you need to decide on the bearings. The flange must be on the opposite side of the gearbox. There should be a metal washer inside it;

- Next, install the driven shaft on which the gear will stand. The product must be connected to the shaft of the rotary generator and the transmission mechanism;

- At the end, you will need to secure the pulley with the driven shaft using a spring nut and washer.

Having made a creeper, it will need to be tested. To check the device, it should be connected to the implement hitch, and the wheels for the cultivator should be installed. If you did everything correctly, then the wheels will turn slowly, while the cultivator itself will be pressed to the ground.

When choosing wheels for a cultivator that will work in tandem with a travel reducer, you need to pay great attention to their diameter. You do not need to choose too large parts so as not to load the motor of the unit

Wheels with a diameter of 25 to 30 cm will be optimal.

If home-made devices are planned to be used in tandem with other attachments, for example, for a plow, then creepers must have sufficient power to press the equipment to the soil. Be sure to take this into account when preparing spare parts for the manufacture of the device.

The creeper for a motor cultivator is used at a high speed of the motor cultivator, when it is necessary to reduce it to the speed effective for cultivating the land. Creepers are best used when working with additional trailed equipment, a trailer, hilling the ground and clearing snow.

Varieties

The gearboxes that the walk-behind tractors are equipped with seem to be the same only at first glance. In fact, these devices can be divided into three groups. The differences lie in the design features of the gearboxes. Let's get acquainted with the representatives of this family in more detail.

Angular

Angle-type gearboxes are elementary structures that serve to dock the transmission with the power plant of the unit.

The device of this node looks like this:

- Mechanism body.

- Belt pulley with fastening.

- Rotor shaft.

- Flange with mounting and bearing.

- Washer and retaining key.

Gear

This is a more complex mechanism, which cannot be recreated at home without special skills and knowledge.

Gear reducers are called reduction gears. Due to its design features, the mechanism reduces the number of engine revolutions, simultaneously increasing the output power of the walk-behind tractor.

Such gearboxes have a long service life, therefore, they are suitable for various jobs, and do not receive mechanical damage even at peak loads.

Reversible

This mechanism is based on a clutch that moves freely between bevel gears.

Such gearboxes enable the walk-behind tractor to move in reverse, which has a positive effect on the maneuverability of the equipment.

However, this comes at the price of a drop in performance and maximum speed. Therefore, it is up to each farmer to decide whether to install a reversible gearbox or not.

Reducers installed on walk-behind tractors from different manufacturers have practically no structural differences. Therefore, disassembling the unit and replacing defective parts will not cause difficulty.

Types of mechanisms

According to the way of work and action, all converting mechanisms for walk-behind tractors are divided into several types:

- angular;

- downward;

- reversible with reverse speed (reverse gear reverse gear);

A bevel gear (bevel gear) is used to redirect rotational energy from the vertical drive to the horizontal plane.

Reducing the number of revolutions and increasing the power of the drive mechanism is provided by reduction gear reducers, or creepers for a walk-behind tractor. They are considered the most reliable for the operation of an air-cooled diesel or gasoline walk-behind tractor. This allows them to be used for particularly heavy work - for example, for plowing heavy soil or harvesting potatoes using a potato digger.

How to maintain motor cultivators yourself (at home)

Service of a cultivator at home is quite a feasible task, it is within the power of those consumers who have at least a little technical knowledge and skills in stock.

By its design, a motor-cultivator is not something unimaginably complex. It has a motor, gearbox and frame. These are the main parts. There are also handles for holding during operation and a control system. And now let's dwell in more detail on each part of the mechanism and understand their service.

The frame is the most robust and therefore reliable part of the cultivator. It holds the motor and gearbox, as well as the control and carrying handles. It is advisable to put the frame in order after each operation and remove parts of the soil from it, then the material will deteriorate much less. Care should be taken to install protective guards on the frame. Thanks to them, you will be protected from possible injuries, for example, a pebble accidentally bouncing off the cutter or a suddenly torn gear belt. Even during operation, the earth from the cutter flies both to the frame and to the engine with a gearbox, and this is fraught with breakdown.

The reducer in the cultivator can be worm or chain (in walk-behind tractors it is gear).Any gearbox uses liquid lubricants

In order for the gearbox to work smoothly, it is necessary to pay attention to the joints on the housing so that oil does not leak, if such a nuisance exists, it is worth tightening the fasteners. Do not forget to change dirty oil for clean oil every two seasons.

After using the equipment, it is necessary to clean the gearbox and its breather (a unit for removing excess pressure to the atmosphere). You need to move the equipment vertically, then the lubricant will not leak from the gearbox (through the breather).

The motor transmits rotation to the chain reducer in the way of a belt drive, so watch its belt, as soon as you see hanging threads or cracks on it, change it without slowing down. And when changing the belt, clean the grooves (with gasoline) the belt landing pulleys. We recommend installing a cover on the gear itself for protection.

It is better to work in dry soil conditions, because when working with wet soil, the load on the cultivator is greatly increased, and this negatively affects the operation of the worm gear. If we take into account the fact that in motor-cultivators with such a gearbox, the frame is a housing from the gearbox, then the expenses for subsequent repairs can be equal to the price for a new unit.

The engine is one of the main parts of the cultivator, one might say its heart. Basically, four-stroke engines (gasoline) are mounted. They are assembled in a special way to provide easy access to all important control systems (requiring frequent maintenance): fuel system, lubrication system, ignition and cooling system. Engine maintenance is the most important point, so we'll take a closer look at it below.

Pens

Pay attention to the handles that you hold on to when driving, their rubberized pads wear out over time, so change or strengthen the old ones in time with electrical tape

Cable. All control devices must be carefully adjusted, if they cannot be adjusted, then you need to check the integrity and reliability of the drive connection (basically, this is a braided cable). If the cultivator is in places of moisture, then the cable may well lose its ability to move in a braid. Then the cable is replaced with a new one or the braid is disassembled, cleaned of corrosion and the cable is lubricated.

Views

Depending on the type of transmission used in the gearbox, converters are divided into several types. Different devices are used in the mechanisms of different fields of activity.

Chain

The name is due to the design of the gearbox, which is based on a chain as a transmission element. In one device, it can be more than one. The movement is provided by asterisks, the small one is the driving one, the big one is the driven one. The principle is similar to that of a system on a bicycle. Performance and reliability are highly dependent on the quality of the materials used to manufacture the main driving parts.

Among the negative points, the need for regular maintenance should be highlighted: chain tightening, lubrication. Unlike a belt drive, a chain drive does not allow slipping and lasts longer.

Reverse

The reversing mechanism provides the vehicle with the ability to reverse. In this case, the reverse rotation clutch is installed between the bevel gears, which are located on the main shaft.

Belt

The simplest gearbox available on the market is of the belt type. As a rule, budget models of gearboxes use just such a device. The belt serves as a transmission element that is attached to the pulleys. Under heavy loads, the belt slips or breaks.

Belt converters reduce aggressive action on the propulsion system by reducing jerking. Moreover, their construction is simple and repairs are easy.

Among the minuses, unfortunately, there are more factors.

- The belt stretches at high temperatures. This is what reduces grip.

- Rapid wear (abrades).

- Belt drive rupture due to kinks or twists.

- As the speed increases, the belt starts to slip.

- The pulleys must be in the same plane.

Gear

Gear reducers are most often used in heavy equipment engines. The transmission consists of a gearbox, differentials and governor, gears and belts. The design of the device is simple.

The gear transmission contains bevel or spur gears. Due to the fact that several of them can be placed on one shaft at once, the dimensions of the converter are reduced.

Among the advantages, one can also highlight the noiselessness of the engine on the specified type of gearbox.

Worm

The worm gear inverter is characterized by a long service life and a high degree of reliability. The design is considered not very complicated, requiring qualified maintenance. The worm gear is already angular. In addition, it has a reverse, which allows the technique to move not only forward, but also backward.

The gearbox got its name from the presence in its composition of a special worm gear wheel, which moves along a screw having a trapezoidal four or two-start thread. By varying the number of teeth, the rotational speed can be changed. All components are made of anti-friction steel, which is characterized by increased strength.

The converter consists of only two main components. In addition, it is quiet and smooth running.

Angular

One of the most efficient and reliable gearboxes. Therefore, it is used to equip production machines and equipment operating under heavy loads. In the automotive industry, this type of converter is also actively used.

Angle gearbox provides a connection between the engine and the transmission, which is designed for chain transmission

Please note that the magnitude of the load will depend on the quality of lubricants and temperature conditions.

Downward

The task of the reduction gear is to reduce the number of revolutions while increasing the power. This is achieved by using a gear system. As a rule, modern converters of this type are equipped with an air cooling system.

Frame

For the manufacture of the base, you will need a rolled channel. This material is able to withstand dynamic loads. Typically, the frame is a welded structure made of cross members and longitudinal spars.

It is better to immediately foresee the possibility of mounting the engine, supports of the rear and front axles, and the driver's seat.

Such structures are also made from a channel, but not a monolithic base is made, but two half frames. The structural elements are connected by a hinge, for this you can use the cardan shaft of a truck.

Frame for homemade tractor