How the motor pump works

At its core, a motor pump is a centrifugal pump powered by an internal combustion engine. The pump and motor are located on the same chassis, which makes the unit compact and mobile.

Gasoline or diesel engines can be used for the fire engine pump. Gasoline engines start better, give more revs. The gasoline engine is made with two or four strokes. Two-stroke models are less powerful, but more compact and mobile. They are used mainly in everyday life.

For production needs, models with a four-stroke engine are used. The gasoline motor pump creates less noise and is cheaper.

A diesel motor pump has a longer engine life than a gasoline one, fuel is cheaper, but a diesel model is more expensive.

Cooling of the motor pump is provided by an air or water system. Starting is done manually or with an electric starter. Some models have two options. The fuel supply is enough to work for at least 2 hours without refueling.

Modern models of motorized firefighters are equipped with a vacuum pump. Such a device simplifies operation. A vacuum is created at the pump inlet, therefore no preliminary filling of water into the pumping part is required.

This is interesting: How to combine wallpaper in the corridor is important to know

Using a motor pump when extinguishing a fire

Launch (MP-800):

- The pump is filled by pressing and holding the handle of the vacuum assembly away from you.

- The pressure gauge will indicate the presence of pressure.

- Open the valve of the outlet hose. After water enters it, turn off the vacuum blower (handle to the muffler).

- They press on the launch with their right foot, engaging the toothed sector.

- Slowly pushing the piston in to start, and quickly pushing the pedal down to start.

- They remove the leg, adjust the work with the carburetor handles.

In new models, starting can be easier with a starter button.

Application of motor pumps in a fire:

- the suction hose is placed in the water supply at least 200 mm;

- taps, plums are closed;

- the valve in the pressure hose is pushed back;

- MPa is raised gradually;

- in the process of using the rules are standard: fire extinguishing goes from the front edge inward, from top to bottom (openings on the contrary), to the hearth - at least 2 m.

Classification of motor pumps for fire extinguishing

MP options:

- types include: power plant options, blower power (high pressure motor pumps, conventional);

- types: by size, mobility (mobile on wheels, portable).

Fire pump types

The main task in the design of the MP was to ensure mobility. Motor pumps are subdivided into several options according to the type of transportation.

Portable motor pumps

Compact MPs can be moved manually. The body has handles, frame, wheels. The options are:

|

Type of |

Description |

|

Portable |

|

|

Mobile |

|

Handles, elements of portable MP frames are necessarily equipped with thick thermal insulation. In addition to these models, there are floating motor pumps on a plastic lining filled with air.

Trailed motor pumps

Features of MT on a trailer:

- often with a foaming agent system;

- high power, industrial use;

- are a pumping unit like a fire engine.

Trailed pumps (MP 20-80 Aquarius) are produced on a full-fledged trailer.Chassis with one (MP-1600), two axles.

Types of fire pumps

Options depending on fuel and engine:

- with internal combustion engine:

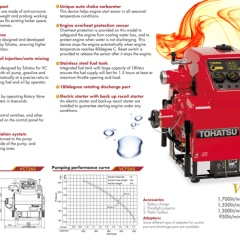

- gasoline (Tohatsu VC52AS);

- diesel (MP-500 Vepr);

- gas (Lifan 50ZB60-4.8QT);

- electrical;

- manual.

ICE requirements:

- speed limiter;

- smooth power regulator;

- protection against moisture, short circuits;

- cooling;

- muffler;

- for diesel internal combustion engines - spark arrester;

- a tank that excludes leakage during tilting;

- fuel tap, sump (filter);

- lubrication units, oil filling.

Petrol pumps

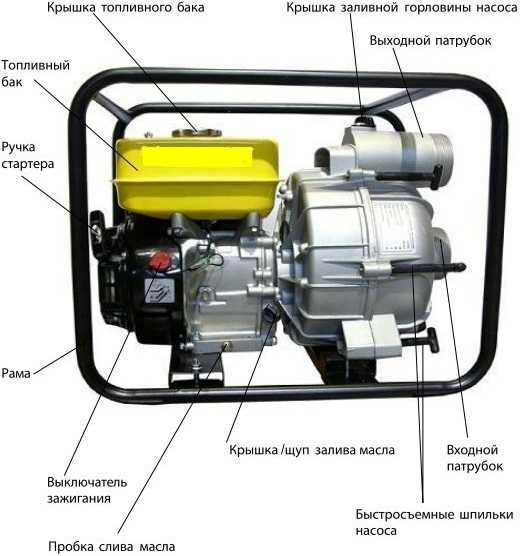

The standard device of the power section of a lightweight design gasoline pump (portable):

- engine:

- carburetor-injection;

- one (600 l / min.), two (800 l / min.), four-cylinder (1600 l / min.);

- one, two, four-stroke;

- starting system: lever with toothed segment or electric starter;

- battery ignition system or with a glow plug, magneto;

- exhaust windows.

A motor pump running on gasoline makes less noise, is cheaper than diesel ones, but the fuel itself is more expensive. There are powerful MPs with 4-stroke engines from VAZ. A 20: 1 mixture of gasoline and oils is often used as fuel for two-stroke engines.

Diesel motor pumps

Diesel pumps (MPDV-80) are equipped with engines similar to those of gasoline engines. Diesel MPs have a long service life (from 6 thousand hours), fuel is cheaper, but the pumping device itself is more expensive and noisy.

Electric pumps

Pluses of the electric pump:

- for premises:

- airless;

- with special conditions (high temperatures);

- closed, where the presence of exhaust gases is not allowed;

- work without a break for refueling;

- quick operation, high power.

Hand pumps

A hand pump is a mechanical unit with valves and pistons on a frame (sled) connected to a lever with two or one handles, like a railway bogie, raising and lowering which create pneumatic force. The head and length of the jet are weak in hand pumps. The standard sample is PN-100.

High-pressure motor pumps

According to GOST R 53332-2009, high-pressure motor pumps create a force of 2 MPa. The output is up to a maximum of 5 MPa. A larger nominal head is formed, which means the height of the rise (pumping) of the water column. The described indicator should not be confused with the length of the jet, and especially with the suction depth from the water source.

There are household high-pressure pumps (Honda WH-20) and for fire brigades (MP 16-80 Aquarius). High-pressure pumps are capable of delivering OTV to a height of 160 - 200 m and more.

For collecting dirty water

According to the standards, conventional pumps (Tohatsu V20D2S) are designed for water with solid particles up to 0.5%, up to 3 mm in size.

There is a MP for inclusions up to 8 mm (Koshin SERH-50B) with easy disassembly for cleaning (Koshin STR-50 EX). If the contamination is more significant (from 25 mm), then a pump without a filter with a membrane pump is used.

By the diameter of the discharge and suction branch pipes

At the outlet, the branch pipe is usually wider. Example: suction - 76.2 mm, delivery - 101 mm. You can connect two or more sleeves (MP Sprut-3).

The suction line diameter affects the water intake depth, which is 8 m as standard (Tohatsu V20D2). To increase the parameter, take a narrow intake hose. The speed and length of the jet increase, but the throughput decreases.

Connection diameters (1 inch = 25.4 mm):

- one-inch - 25.4 mm;

- two-inch - 50.8 mm;

- three-inch - 76.2 mm;

- four-inch - 101.6 mm

- according to the manufacturer's specification.

Views

There are two types of these fire extinguishing devices:

Portable:

Mounted on a rigid frame, providing, by the total weight of the assembled product, the possibility of carrying, loading and unloading by two workers, fire volunteers; for road transport inside the body, trunk, in a trailer. The handles of these motor pumps are made with a coating of heat-insulating materials.

Mobile:

Placed on the base of the trailer, in accordance with its technical characteristics in terms of carrying capacity.

Such more powerful devices make it possible to supply both water and mechanical foam generated from aqueous solutions of fire-fighting foaming agents for the elimination of fire centers.

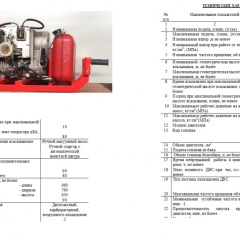

Motor pump MP-600

The number "600" means that the pump is capable of pumping 600 liters of water per minute, and the water supply pressure can reach a distance equal to the height of a five-storey building.

Main characteristics:

- the pump device is in a welded frame that has carrying handles. There are also devices that move on a trailer;

- single-cylinder two-stroke engine;

- fuel tank with a volume of 12 liters;

- the suction depth is 5 m and the suction opening is 8 centimeters wide;

- weight - about 60 kg.

You also need to mention the Deva MP600 fire pump with the following characteristics:

- Rosenbauer pump is single-stage, centrifugal. Productivity - from 500 to 1100 liters per minute with a suction head from 1.5 to 3 meters. Maximum suction height - 7.5 m;

- Briggs & Stratton two-stroke four-cylinder gasoline engine with 12 horsepower;

- fuel tank volume - 8.5 liters;

- weight - 58 kg.

Preparing the motor pump for work

The procedure for preparing a new motor pump (running in on the example of MP-600A):

- Preliminary steps:

- De-preservation, oil removal.

- Inspection.

- Checking fasteners.

- Flushing the cylinder, crankcase:

- Unscrew the candle, open the trigger cock.

- Engage the cogwheel trigger assembly.

- Vigorously moving the pedal, crank the crankshaft until it is completely cleared of oil.

- The cylinder is filled with 3 - 5 cm. Cube. fuel, turn the crankshaft, the mixture is removed through the drain cock on the crankcase.

- Candle cleaning with gasoline, drying, installation.

- Running in directly:

- The MP is started on a mixture of 1 part of oil and 16 - 18 parts of gasoline.

- The running-in duration is up to 30 hours. The working units are running-in.

- The pressure is maintained up to 0.4 MPa.

Preparing to launch:

- Fill with fuel, oil, the cooling jacket - with water.

- Check:

- Is the piston stuck (turn the flywheel).

- Are the hinges of the vacuum apparatus spread out (rotate the friction wheel).

- 50-60 cm cube of oil is poured into the vacuum unit.

- Unscrew the candle, connect it to the wire, turn the crankshaft, see if there is a spark, put it back.

- Close the faucets of the blower, cooling.

- Insert sleeves.

- The suction hose is lowered into the water source at least 200 mm.

- Open the fuel tap.

- Activate the float drowning assembly button.

- Check if the carburetor is full of fuel.

Where is used

The main advantage of a fire pump is autonomy. It can be transported to almost any place, installed where there is no electricity or running water. The source of water can be artificial or natural reservoirs. Sometimes it is connected to hydrants if the burning object is too far away and the water pressure is not enough to extinguish the fire.

The purpose of a fire engine pump is much wider than one might imagine. It is used to pump out water in case of flooding of premises, basements, wells and pits. The motor pump is purchased by fire departments and enterprises, whose buildings are located separately from the main settlements. Often a motor pump is used in rural areas, cottage and summer cottages for irrigation. On sea and river vessels, construction sites, it is indispensable as a tool for pumping water.

This is interesting: What is anaerobic sealant: explained in detail