Operating tips

When using the orbital sander for works in workshops and furniture shops, users must comply with a number of rules for the operation and safety of this equipment:

- do not use power tools in hazardous areas;

- do not expose the instrument to wet conditions and rain, as water can damage the instrument itself;

- handle the power cord carefully;

- carefully attach the dust collector to the tool;

- before plugging the product into the outlet, check the "On / Off" power button, which should be in the "Off" state;

- when working with a grinder, it is necessary to securely keep balance;

- when working with the device, you must use protective goggles, a respirator, safety boots, headphones or a helmet;

- the user must have a good attitude to the tool, it is strictly forbidden to use worn out or torn sheets of sanding paper;

- for ease of use, the device has an additional handle; you need to monitor the cleanliness and dryness of the handles of the device;

- regularly clean the orbital sander every time after use;

- keep the power tool out of the reach of children and non-trained people.

In the next video you will find a review and test of the Makita BO5041K orbital sander.

Usage Tips

You can use a polishing machine for processing car bodies only after applying a special polish to the surface. In terms of chemical composition, this drug is quite complex. Getting ready for work, you need to prepare a couple of polishing wheels: one for rough, and the other for subtle effects. A small amount of paste is applied to the discs. Therefore, it is impossible to process large areas in one step.

The speed for rough processing should be minimal, and as the work approaches the logical end, it increases. An even distribution of the polish is achieved if the work is carried out using the "cross" method - initially horizontally and then vertically. The approach to wood polishing should be different. To get a good result, you should carefully study the features of a particular machine and the manufacturer's recommendations. You should also take into account the characteristics of a particular type of wood.

Eccentric Sanders Rating

Each manufacturer produces models with a specific set of characteristics that affect the performance, ergonomics, reliability and service life of the tool. Site specialists studied and analyzed data on the features of more than 20 ESM, conducted tests for the build quality, ease of use. When compiling the review, the following instrument parameters were taken into account:

- Engine power;

- Diameter and rotational speed of the disk;

- Platform stroke size;

- Dimensions;

- The weight;

- Features of sheet fastening;

- Vibration and noise level;

- Additional functions;

- Kit composition;

- Price.

The rating contains 10 models, which are divided into 2 categories according to the principle of design features. The nominees who were not included in the review were inferior in terms of comfort of use, price / quality ratio. A number of tools have a low degree of dust removal, the absence of an anti-vibration system and rubberized inserts on the handle, which negatively affected the ease of use. The doubtful reliability of units and parts also did not allow them to be selected in the top of the best units.

Best polishing machines

Peculiarities

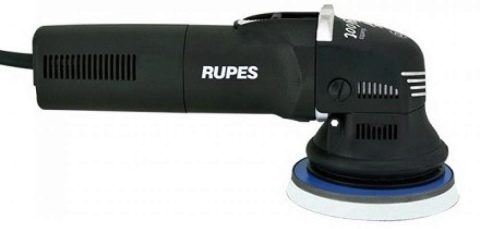

Rupes high-end polishers are relatively lightweight.Their developers were able to come up with a completely ergonomic design that does not create unnecessary noise during operation. Long mains cables dramatically increase flexibility, and carefully selected materials ensure long-term performance. The company's products are distinguished by their high power. Also important advantages of the products can be considered a well-thought-out pairing of working parts and comfortable placement of control elements.

The company began its work in 1947. All this time it has been successfully developing, constantly creating and mastering new technologies. Rupes is now firmly associated with innovative high quality manufacturing. There are 3 factories, Rupes cooperates with 160 distributors in dozens of countries around the world. Thanks to well-functioning work, it is possible to achieve an excellent result.

The group's developers always use balanced design solutions. The technical parameters are invariably aimed at achieving an optimal result. The supplied tool is initially designed for the most intensive and strenuous operation.

It is equally important that these devices create minimal noise and almost do not vibrate. Eccentric strokes are maintained at a stable frequency even under heavy load

Also provided:

- electronic control of the rate of rotation of the motor;

- temperature control;

- reliable brake for the sanding pad.

Grinding and polishing parts are manufactured using strictly patented technologies. As a result of their application, the notorious "salting" of the abrasive is significantly reduced. Therefore, the average product life is 30% longer than that of the products of competing companies. The abrasive elements are attached to the trays using a special type of velcro. Such a connection is very stable during the work itself, however, at the same time, it also makes it easy to remove the tool if necessary.

Full polish has just gotten better with the addition of Big Foot. This rotary orbital processing technology provides superior success in a single pass. As a result:

- working time is reduced;

- energy costs are reduced;

- fewer consumables required.

Thanks to careful engineering, Big Foot can operate with no more than 500 watts. Consumers note that polishers using this technology do not vibrate, and also have an impeccable balance. As a result, control over the tool is almost absolute, and the polishing part moves in the most maneuverable way. The strong point of such a system is the increase in the eccentric stroke. It helps remove holograms.

How to use the device correctly?

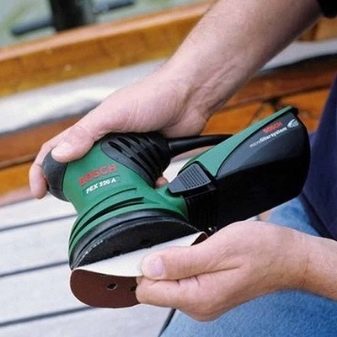

It is very important to take care of effective dust extraction during operation. If it is not possible to connect an external vacuum cleaner, and the model has a built-in dust extraction function, you must make sure that the holes on the sanding sheet completely coincide with the holes on the sole.

Failure to comply with this requirement significantly reduces the efficiency of dust removal, as a result of which a situation may arise when even a powerful vacuum cleaner will not help.

The operating mode must be selected correctly, depending on the material to be processed, surface characteristics. For example, it is absolutely impossible to use the machine at high speeds when processing plastic or varnished surfaces. During work, do not apply strong pressure on the typewriter. Insufficient performance may be due to wear on consumables or a lack of model power. Strong pressure on the tool will not improve performance in these cases.

In order for the tool to serve for many years and to perfectly cope with the tasks assigned to it, it needs regular maintenance.

This is especially important with frequent use of the machine.

Be sure to pay attention to any changes in work. For example, the appearance of extraneous sounds indicates that the bearings are clogged with dust and must be cleaned with a stiff brush.

The sole of the machine has to be changed over time. The replacement period will depend on the frequency of use of the tool. With active work, replacement may be required in the next six months, and if the machine is used from time to time, the service life of the sole can be several years. A sign that the sole is out of order will be the flying off of the abrasive wheel during the rotational movements of the eccentric.

Extend the service life of the velcro soles for gentle use of the tool. When installing the abrasive wheel, you must carefully ensure that it completely covers the Velcro, does not move from its place even by a few millimeters. Otherwise, the edges of the Velcro begin to grind off and cease to function. It is impossible to fix this problem, you have to completely replace the plate.

Models

There are only two models of polishing machines from the manufacturer on the market.

ZPM-1300E

This model is used for solving household tasks, has a power of 1400 W, while the manufacturer has provided a six-step adjustment, in 1 minute the nozzle is capable of making from 600 to 3000 revolutions. One of the main advantages of the described unit is the ability to use attachments that are not included in the kit, sometimes you will need to additionally purchase an adapter or adapter. Attachments are attached with Velcro, there is a spindle lock.

ZPM-240

This model is ideal for polishing wood surfaces. The manufacturer has equipped its product with a powerful motor, the power of which is designed for 140 watts. The nozzle makes 3200 revolutions per minute, while the design provides for an eccentric mechanism. The unit operates from a 220 V network, the total weight is less than that of the previous model and is 2.2 kg. The unit is delivered for sale with a polishing disc, on the surface of which a water-repellent layer is applied.

There are two handles and the same number of attachments in the package, thanks to which the tool can be used to polish plywood and other wood products that have been painted.

Appointment

When choosing an ESM, you should know exactly its purpose, as well as how often it will be used. If the device is used once a month (or even less often), then it is wise to purchase an inexpensive sander. In the case of professional use of ESM (for example, for construction), it is recommended to look at more expensive models.

The quality of the machine tool depends on the following indicators:

- power;

- amplitude;

- torque speed;

- machine weight;

- power supply;

- diameter of the nozzle circle;

- frequency of revolutions;

- current adjustment, etc.

ESM power is one of the main indicators. Power fluctuates from 165 watts to 950 watts. In everyday life, units are used that have a power of 300 to 600 watts. The machine can be powered from a power plant or from a 220 volt network. If you have to work at a distance from stationary energy sources, then it is better to use the battery option.

At production sites (for walls and ceilings, for plastering), a pneumatic eccentric machine is most often used. Such units are easy to use: they have a minimum of dynamic units, do not need power from an electric motor or a battery device. One of the best manufacturers of such equipment is Dynabrade, which manufactures Dynorbital machines.

An important point to remember when choosing an ESM is that the rotation speed decreases with an increase in the power of the unit. The vibration amplitude is responsible for the quality of the surface finish. There are models with an amplitude of vibration from 2 to 5 millimeters.On some models, additional attachments can be installed that will correct the reciprocating movement. Such additional devices change the dimensions of the "orbit" required for grinding.

It is also important to take into account the diameter of the sanding "pad" itself: the larger the size, the larger the area can be processed in one pass. Usually this indicator varies in the range from 120 to 155 mm, however, there are other sizes: 75 mm, 95 mm

Small diameters of "plates" make it possible to work with corner joints.

Devices with small diameters are exclusive products. Such units are produced by only a few companies: Rupes, Metabo.

There are special ESM with a horizontal layout of the engine, which has forced rotation.

Interesting: Hinge cutter and lock inserts - setup, operation

Model LH 18ENS

This design has excellent power - 1100 W

Importantly, the excellent technical characteristics did not prevent the polishing machine from being lightweight. Due to the maintenance of uniform power, work is as convenient as possible

Users can adjust the RPM in the range of 750-1800 revolutions per minute. It is noted that the product is quite light, and also does not create excessive noise.

From other reviews, the LH 18ENS has worked well for a long time. In addition to the stability of the equipment itself to long-term operation, its positive side is the minimum operator fatigue. In the production of the polishing machine, high-quality plastic is used that does not emit an unpleasant odor. An important positive feature is the zero risk of hand slipping. It is also worth noting the long (5 m) power cord.