PORTER-CABLE 7424XP

The Porter-Cable 7424XP is the most popular polishing machine and is often part of the professional workshop kit. It is a 15cm variable speed device that is relatively affordable compared to other polishers.

PORTER-CABLE 7424XP

Features of Porter-Cable 7424XP Automotive Polisher:

- Selectable orbital / dual action.

- Weighs 2.6 kg.

- 3 years warranty against defects.

- 1 year warranty for normal use.

- The ability to move the control knob in any direction.

- Speed range from 2500 to 6800 rpm.

This polishing machine is the ideal tool for removing deep coating imperfections. It comes with six speed settings and you can easily adjust the speed depending on how you want to polish your car.

Polisher advantages:

- Accessible.

- Compact and sturdy.

- Pre-installed counterweight for balance.

- Detachable handle.

- Easy to use.

- Six available speed settings.

Disadvantages:

Not detected.

The Porter-Cable is also equipped with a pre-installed counterweight to ensure balance and smooth running. Another notable feature of this tool is the removable handle, which can be fixed in two positions. If you don't want to use the handle, you can easily remove it.

Porter-Cable is one of the most popular two-speed grinding polishers available. It is also the choice of many professional craftsmen, mainly due to the value for money. For people who are worried about the look of their car, this polisher is a great choice. It will not burn paint or dent the body of your car.

Work technique

Before starting to polish a car, you need to decide on the place and time. For a small area, it will take 2-3 hours, and after that the car should stand for about an hour. The procedure is not recommended to be performed in direct sunlight or in an extremely hot room.

Before you polish the car with your own hands, you should prepare: thoroughly clean the polished area from dust, lime and insects. In addition to cleaning, it is recommended to degrease the machine coating. For this, it is best to use specialized tools.

After the preparatory stage, you can proceed to the main one. Grinding the machine before painting is carried out in 2 stages:

- abrasive;

- polishing.

Abrasive stage - removal of large paint defects requiring the application of a new coat of paint or varnish. At the same time, the hardest nozzle is inserted into the machine for grinding the car body, and the procedure is carried out with a large number of special consumables.

The protective stage is carried out after the abrasive and involves the careful application of a small amount of polishing mixture using soft nozzles.

The machine is not polished immediately, but in small patches. This is to ensure that the polishing compounds do not harden prematurely and spread evenly on the body, providing a shine. This approach also excludes overheating of the polishing machine.

In order to properly polish the car at home, you need to deal with the mixture, attachments and pressure on the tool. Before you start, you should practice on unnecessary or rough parts so as not to spoil expensive body parts.

Tips to Help When Choosing

If you have decided on the optimal type of grinder, then it remains to choose a specific model. To do this, the following tips will come in handy:

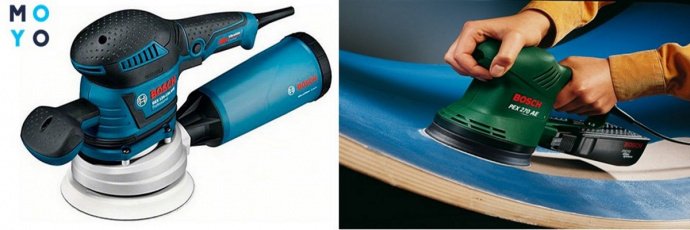

For home use, a professional expensive model is not needed. If you plan to use the grinder one-time or periodically (for surface repairs, for example), then a hobby-class tool will be the best choice. High quality models are produced by Bosch, Skil, Sparky, Black & Decker, Interskol and Fiolent (Russian manufacturers).

The weight and dimensions of the tool are of great importance. Especially if this tool is manual and you have to work with it while holding it in your hands

For small volumes, it is better to prefer a less powerful, but more compact, lighter and faster model.

Pay attention to ergonomics. You need to be comfortable with the instrument

See where the switches are located, how easy (or difficult) it is to change abrasive materials, whether the power cord will not interfere with the work.

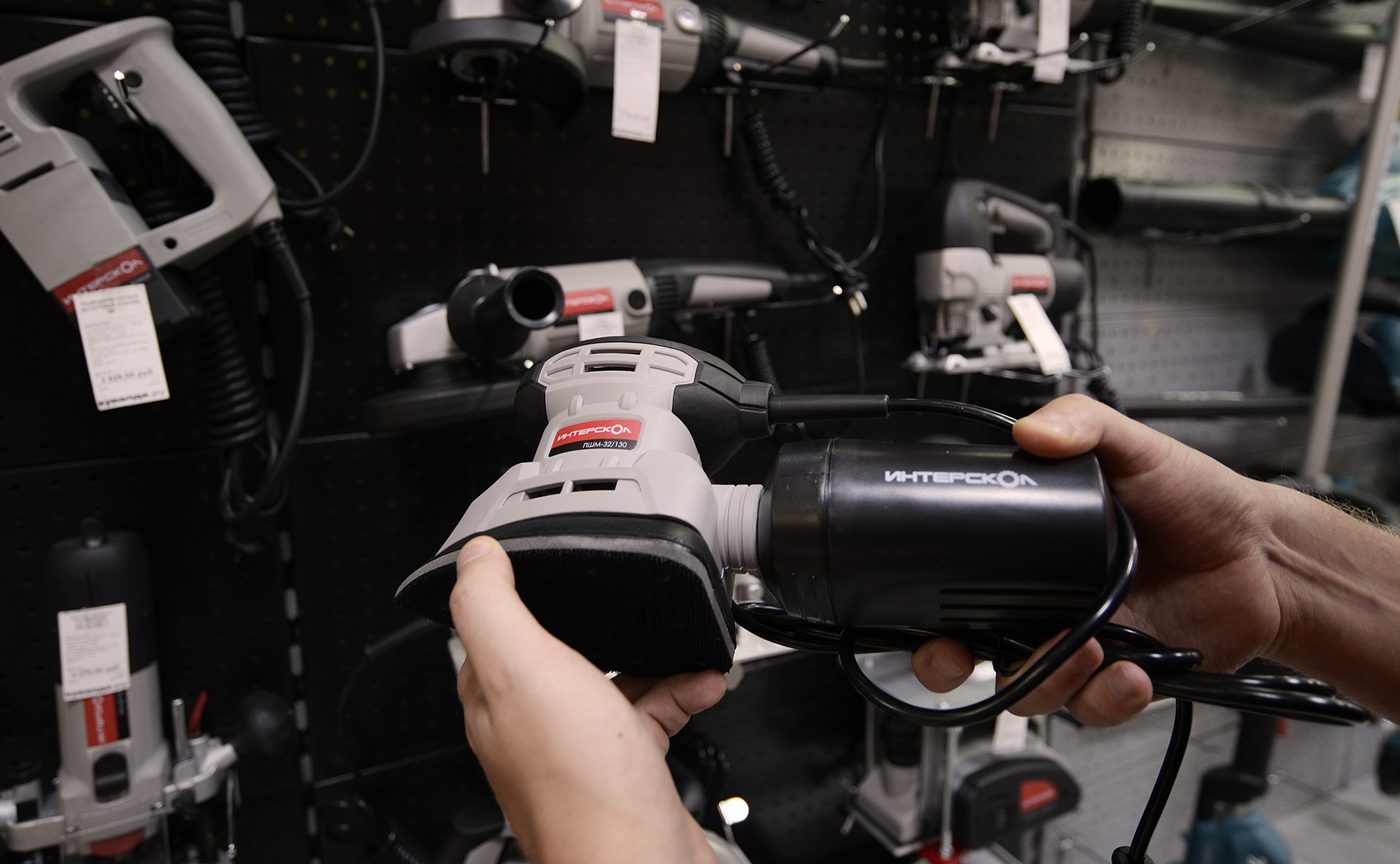

Test the machine right in the store. Turn it on, let it idle. This way you can estimate the level of the outgoing noise and vibration.

Visually inspect the machine. All body parts must fit exactly together. Eliminate the presence of backlash in the sliding elements.

Ask your dealer how easy it is to repair a particular machine.

Ask about the range and cost of consumables (abrasive).

Only after full familiarization with these points can you make the final choice.

Varieties

What kind of polishing machines are there? Structurally, the models are divided into two classes - straight and angular.

Polishers can be powered pneumatically and electrically. Of course, any car owner will prefer an electrician, since a pneumatic drive is appropriate only in a large service station or service center.

Rechargeable devices are more mobile, they can be used in any environment when there is no power source nearby, without worrying about finding an outlet and extension cord. During work, the master does not interfere with the cable, which in garage conditions can catch or knock over something.

- Corner cars are similar to an ordinary grinder. The grinding wheel and the body of the device form a right angle with each other. It is convenient to work with such a tool with vertical surfaces;

- The straight typewriter is controlled more accurately, it is more convenient to use it when working with horizontal surfaces.

1 Car polishing machine - features and principle of operation

A polishing machine can significantly speed up and greatly facilitate the process of polishing a car body. In addition, such a device can be used for other purposes, for example, for polishing various wood, plastic or metal surfaces in a house or garage. Professional devices can be of several modifications: circular, with an eccentric or orbital, angular, brush, vibrating, tape, etc.

The angle type of polishing tool is actually similar to a conventional grinder. The body and the grinding wheel form a clear right angle to each other. These machines are especially useful for polishing vertical surfaces. Unlike an angle grinder or grinder, the shaft of a circular or orbital polishing machine can produce not only circular movements, but also move in different directions by several millimeters. This improves the quality of polishing and prevents excessive overheating of the surface due to high friction. According to the type of power supply, there are two types of polishing machines:

- compressor or pneumatic;

- network or battery.

The first type of grinding devices in home or garage conditions is used extremely rarely due to its high cost and high productivity.Such machines are most often used in car washes and related services, since a special compressor and a receiver are needed to work with them. Network devices are powered from a regular home 220V network, while they can be equipped with a small capacity battery 12-13V, which can be charged from a car network. They are great for polishing both individual parts and the entire car body.

Photos of the best polishing machines

We also recommend viewing:

- The best woodworking machines for home use

- Review of the best types of drilling machines

- Knitting gun for fittings

- How to choose a soldering iron for polypropylene pipes

- TOP best miter saws

- How to choose a good circular saw

- Review of the best electric planers

- How to choose an electric riveter

- An overview of the most reliable chain saws

- The best handheld wood milling cutters

- Electric type construction stapler

- Best electric spray guns

- The best grinders

- Which cordless screwdriver is better to choose

- Rating of the best blowers

- How to choose a renovator

- How to choose electric metal shears

- Which building hair dryer is better to choose

- Review of the best glue guns

- Rating of the best impact drills

- How to choose a mini drill

- TOP-best jigsaws of 2018

- Review of the best drills of 2018

- TOP best engravers

- Best cordless screwdrivers

- The best grinders

- How to choose a good electric hawk

- Review of the best models of electric trimmers

- Which construction vacuum cleaner to choose

- DIY power tool repair

- Review of the best soldering irons for home

- Review of the best rock drills in terms of reliability

- Best Reciprocating Saws

- How to choose a good jackhammer

- Best screwdrivers of 2018

- Review of the best wall chasers

- How to choose a good impact wrench

Help the site, share on social networks

Vibrating grinders

The vibrating sander is a compact universal tool used for rough and fine sanding of various wood surfaces, including parquet. In the process of operation, the rectangular sole of the machine vibrates, making reciprocating movements of small amplitude at high speed. With an increase in the stroke amplitude, the grinding speed also increases, but the processing quality decreases.

Sandpaper or abrasive mesh of varying grain size is fixed on the sole of the vibrating sander. The paper can be secured with Velcro or with side clips. Metal clips are used in most designs, as they allow you to securely fix sanding paper (mesh) of any manufacturer on the sole.

The sole - the working element of vibrating grinders - can be of different sizes. The most popular machines with traditional sole dimensions ("standard") are about 100x200 mm. But for narrow, hard-to-reach places, units of the "mini" class with dimensions of about 10x10 mm are more suitable.

Most sander platforms are rectangular or square. A separate class includes devices with a triangular sole. They are designed for processing corners, elements of stairs, surfaces of complex shapes. Triangular platforms of some models are rotary and removable (for the possibility of installing another platform).

The base of the sole of budget models is most often steel or plastic, and for more expensive analogs it is made of aluminum or magnesium alloys. In any case, a high-quality sole is characterized by a low vibration amplitude when idling (no load). A soft rubber or fine-pored polymer pad is attached to the working surface of the sole. The polymer is denser than rubber, so it "holds" the plane better.

Most models of this type of grinders have a motor with a power of 150-300 watts. They are lightweight, manoeuvrable, but at the same time do an excellent job of their grinding function. There are also more powerful machines, such as the Makita 9046 (600W).They are larger and heavier, making them more difficult to handle. However, such machines have a significant advantage: they are able to work without interruption (and overheating!) At low speeds and get a better processing result.

The amplitude of the sole stroke in vibration machines is always small, in the range of 1-6 mm. 5-6 mm is the largest amplitude for quick sanding of the surface. But the processing will be quite rough. The smaller the amplitude, the better the grinding will be.

Another important characteristic is travel speed. At high speed, the machine is able to quickly remove a thick layer of wood. This corresponds to rough grinding. Finishing fine sanding is possible when using the machine at low travel speeds. Many well-known manufacturers produce models with adjustable speed, which makes it possible to customize the tool for different processing purposes and for different materials.

A small overview to understand what to look for when choosing vibratory grinders: