Carpenter's ax

arjan

I want a good carpenter's ax, weight without an ax, 1.2-1.3 kg, where can I get it not very expensive?

Skywatcher

how much is in rubles?

arjan

Well, 2-3 tr. Something like that, I would like to, but they have expensive. Maybe there is an alternative?

Skywatcher

author's / limited-edition ax for 30 tanks? it is unlikely that you will be able to get so much pleasure for such a small budget. there is, of course, a chance to buy something of this kind on the secondary market. but it is acceleratingly small. even a decent serial in such a budget must still be looked for well ...

if it is needed precisely for work - domestic of the third quarter of the twentieth century (later they began to produce a full year ...). ZiK 50-60 years of the twentieth century. Salda plant (three cedars) or GPZ 1. They are used to sell all kinds of shops selling military junk, for example.

there is also in the local flea market

arjan

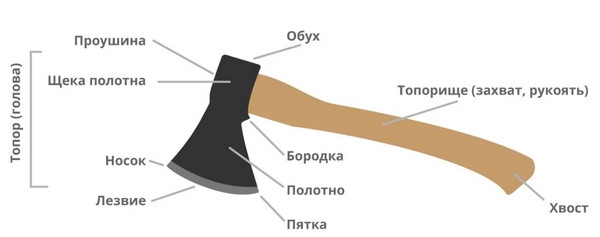

on the 3rd photo, I would not say that a carpenter's ax, it has a straight blade without a radius, but it should be.

Mr. Pterodaktel

Eh, no. In a carpenter's ax, the shape of the blade sting should be straight. A carpenter's ax is not intended for felling trees, chopping wood, or chopping nails. The carpenter's ax is designed to work neat and precise. Not everyone can do this kind of work. Therefore, the blade of such an ax is reduced thinner than that of construction axes and has a straight edge of the blade. A good carpenter's ax - you can shave.

arjan

arjan

Mr. Pterodaktel

For cups and grooves - you really better get a construction ax - as in my second photo.

Turbo4x4

If the vehicle is able to cut bowls and grooves, then he does not need advice, IMHO.

On my own I will quote the old Russian proverb-Expensive, yes, nice, cheap, but rotted ...

arjan

arjan

Lis-biker

but I can't find with a thin blade, some cleavers damn it

arjan

Lis-biker

thick cut is bad

arjan

Nix

Some kind of kindergarten))

arjan

Lis-biker

no, here the carpenter has a friend, he is thin and light.

arjan

Lis-biker

yes everything, almost instead of a chisel with a plane

arjan

Lis-biker

the problem is that the ax-cleaver is fucking, but so thin and light, no

arjan

well, where else is it thinner, weight 700 grams without an ax

Toporsib

Hello everyone . Well, it does not happen that forged and inexpensive. I still understand the sale of the Soviet past for 2 thousand can be bought, but it is impossible to make a forged from scratch for 3 thousand. Not, of course, maybe I don't understand why, and we can just bend the prices, but somehow it doesn't work out cheaper))) Although who sells to that cheap, who buys expensive. Free market, so damn it.

If you decided to do carpentry on logs, to cut logs there, then why do you need a light ax? After all, it is difficult for them to normally invest in a blow, you need to add with your hands and this knocks down accuracy. The guys for log cabins take at least a small restoration. Someone even light, they ask to make it thicker. A turbo carpenter can only do carpentry.

It's nothing that I fit. It's boring, no one writes anything in my themes)))

arjan

Toporsib

Of course there is, and in forging and in hardening and locksmiths and even in the handle and covers. If the shock head is a separate story altogether. Skaryber makes us a separate master. The price comes from it. But they also order a lot.

This is if we compare to cut a log of 30 diameter and 45, like everything is the same, the bowls are groove, but the efforts are different. And the price tag for different diameters is different.

And we have not touched prices for 1.5 years. Although all consumables have grown by 30-40%. You also need to take into account that we work officially and, accordingly, pay all taxes. So our prices are quite normal. Yes, it can be seen on orders. At the moment, everything has been paid for by the end of April.

No, I'm not convincing you of anything. If it's expensive, it's expensive. Of course, you can forge it without covers and a handle, it will be cheaper. You can make a pen yourself. But there are no other proposals for carpentry axes. Rather, there is but more expensive. Or maybe I don't know why. Now about 60% of our carpenter's axes and adzes are taken, and 40% are hunting and tourist ones.

Toporsib

arjan

arjan

Toporsib

And the adjustment of the drop at the Canadian one was not thought out at all, also twist it by hand. We do it very accurately, with a very small step and screws. The master thought over the adjustment system very well.

They did it along the line from Pasha, and Pasha cut down more than a dozen log cabins. And he didn’t suggest all these moments and nuances.

Of course, guys on Avito also make good features and the price is very interesting. So take it will not go wrong. The only other thing that confuses me is the double drop, damn it, it's just that you need to make your eyes on the break, with a double one my head starts to ache. With one peephole, it's much easier, keep it in the center and that's it. We also do with double, though not one order yet, all with only one take.

When ordering, do not forget to remind that you have your nickname and hansa. I will give you a discount)))

arjan

Which ax to buy

1. If you are looking for a budget solution, we recommend choosing an IZHSTAL 030904-120 ax. This is a carpenter's tool that will help both cut down a tree and chop wood. Also, buying it will allow you to support a domestic manufacturer.

2. The best carpenter's ax is the Husqvarna 5769264-01. It is made of high quality Swedish steel - even with regular work, it only needs to be straightened once a year. Also, the tool is distinguished by an excellent fit of the butt on the ergonomic handle. And only the price scares away the buyer.

3. The best choice for a carpenter should be MATRIX 21640. This ax is lightweight and has a fiberglass handle. For its price, this is the perfect tool. But for very frequent works it is better not to buy it - it is better to purchase a heavier ax, which speeds up the process.

4. If you are looking for a versatile ax, then there is nothing better than the Fiskars X10-S 1015619. It has a two-piece handle, and the blade is made of teflon-coated hardened steel. As they say, I bought it and forgot it - the ax will never need sharpening.

5. The MATRIX 21816 is an ax with a fairly long handle. Its mass is deliberately increased to make it easier to chop wood. The tool does the best for this task.

6. Tourists and ordinary lovers of hiking in the forest should buy Bison 20643-06 or STAYER "TOURIST" 2064-06. These axes are all-metal, which means they have an almost indefinite lifespan. The rubberized handle contributes to comfortable use. These tools are the best way to collect firewood.

7

If you want to combine an ax and a hammer in one tool, we recommend that you pay attention to Bahco 494-600. This hatchet is quite expensive

But it could not be otherwise, because its creators had to work hard on the design. And an item cannot be cheap if it will not need to be replaced in the next decade. Namely, this is the approximate lifespan of this ax.

Handle attachment

To figure out how to properly fit an ax on a hatchet, you need to decide on the method of attachment. There are several of them and they depend on professional skill, experience and product material. It will take a little time, some carpentry tools and wedges.

Ax attachment methods:

- Welding. This method is suitable for metal-tipped axes.

- Gluing. The butt of the ax and the hatchet are glued together with epoxy glue in a special chamber.

- Wedging - this method is most preferable for carrying out the procedure at home. The ax needs to be put on the handle and wedged.

The handle must be prepared in advance. The joint with the butt must be processed so that it tapers slightly, but at the same time ensures a tight fit. At the very end of the handle, a longitudinal cut is made for the subsequent installation of the wedge.

Having firmly planted the butt, you may be faced with the fact that part of the wooden handle will protrude beyond its limits. This is normal, the excess will need to be cut off at the end of the work. After that, a metal wedge is hammered.

Driving multiple wedges

In order for all the component parts of the tool to be securely fixed, they resort to wedging with the help of several elements. On the seat of the handle, cuts are made in the form of a lattice for five wedges. The width of the gaps should be 1 mm, and the depth should not be more than two-thirds of the butt.

Contrary to the claims of many professionals, using the same material for the handle and wedge will result in poor retention of parts of the tool. It is necessary to use denser wood, beech, oak or hornbeam are perfect. Handles are made from ash, birch or maple.

After adjusting the size of the wedges, they are driven two-thirds into the cuts and covered with gauze or a rag soaked in epoxy resin or wood glue. Then the butt is put on so that it provides the most tight connection. All the constituent elements are clogged, and the tool is left to dry.

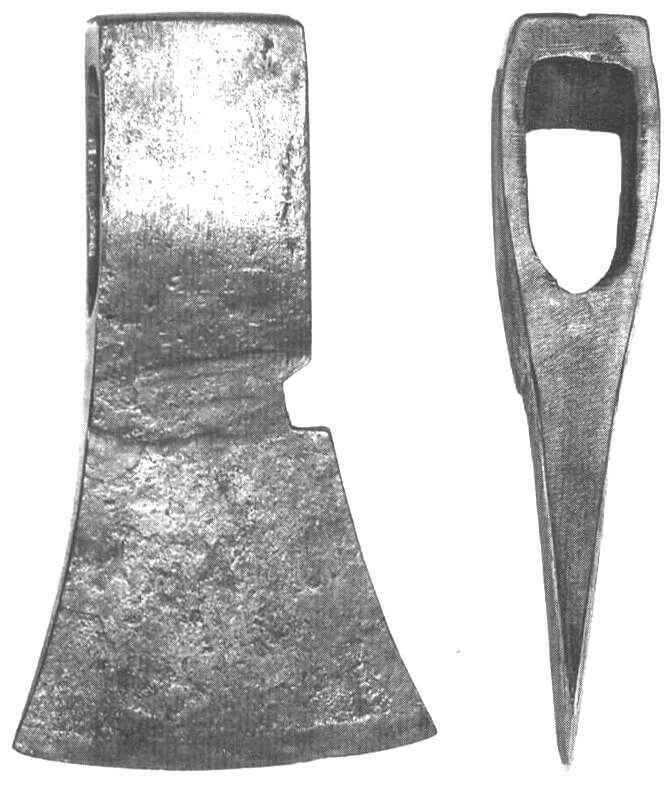

Russian ax for wooden architecture - Axes

Returned after the second week of my work. The above ax is not the most common, I have only seen two such axes. All other axes (there are about a dozen of them) look different. Probably about the second, most common model, and we must talk.

I agree about the reconstruction according to the characteristic notches. But the people who spoke these words inspire confidence. In any case, you need to check everything. This is later.

In my understanding, a carpenter should have two axes. One small gram 900 flat and straight to do fine trowelling work such as various tenon joints and other similar work. The second one should be 1600 grams and must have a rounded blade and not so flat as to be the easiest to chop. The hatchet of such an ax should also be longer. Of course, such an ax can be easily attributed to a felling ax, which it is. But it is good for them to cut. Just imagine two carpenters chopping bowls at different ends of the same log. One carpenter has a lightweight, thin and flat-bladed, short-handed ax of 900 g. And the other with a heavier, 1600 g. Rounded blade and a longer ax. The second will make the bowl faster and lighter. Then you need to make a longitudinal groove in the log. No matter how I used to be my Fiskars to make grooves, the non-rounded edge cuts into the bottom of the groove and makes unpleasant splits. I also have to wave harder and more often. On the other hand, the rounded blade with a spike-like shape easily turns up during the impact without digging into the groove with a sharp edge and makes a hewn selection. The groove is smoother and more rounded. At the felling, it is necessary to cut the bowls and make the grooved grooves. Both intellectually and in practice, I recognized that this ax is most convenient for felling log cabins. After trying a few noticed, not all are well sharpened. Everyone has a sharp edge, but the sharpening angle is different. This is due to the fact that everyone sharpens on their own and not everyone understands well how to sharpen. After all, the forged workpiece is delivered completely without a chamfer.

I will continue to study this new ax for me and to work with it in practice.

Handle material classification

Sometimes, even with an excellent blade, the ax does not do its job as well as we would like.

In this case, you should pay attention to the hatchet. It largely depends on how effective the tool will be.

Of course, first of all, one should take into account the material from which the handle is made.

Metal

The metal hatchet looks very impressive, especially on large models of blades. However, at first glance, durable material is not the best for the handle. This is due to the fact that vibration is poorly damped. Therefore, it is best to choose models of hatchets that have a special pad, preferably made of rubber. They are capable of improving this type of handle.

Plastic

Plastic ax handles are quite common. The main disadvantage, as with the metal versions, is poor vibration damping.That is why they also have to be used with a pad that can somewhat reduce vibration. Unlike other materials, plastic axes are more fragile and require certain storage conditions.

Wood

The best and most common are the wood-based axes. Such a handle is capable of completely absorbing the force of impact and resistance of the workpiece. The most common wood used to make these elements is birch. However, it should be borne in mind that such an ax will cost a lot. Pine handles cope worse with vibration, but their cost makes them more affordable.

Model rating

Unfortunately, domestically produced axes such as Taiga, Olen and Tiger cannot boast of high quality. Their axes often do not fit under the head and begin to slip almost immediately, which makes working with such a tool very dangerous. According to customer reviews, the blades of the head are so hot that they practically reach the state of cast iron, this leads to their destruction during the first frosts - the blades begin to crumble, or pieces simply break off from them, in any case, the tool becomes unusable. To protect themselves, buyers are forced to modify the newly acquired tool on their own, and given that such axes are not cheap, the demand for Russian models is low.

High quality taiga axes were produced in Soviet times during the Stalin era, now the technology has been lost, and products of the 1950s model can only be bought on the Internet, and their cost starts from 4-5 thousand rubles. In those years, steel grade U7 was used.

Nowadays, high-quality taiga axes can be bought only from foreign manufacturers. Products of the brands Gransfors Bruks, Husqvarna, as well as Fiskars and Hultafors are in the greatest demand.

Making an ax with your own hands

If you are interested in the question of how to make an ax, then remember that you will not be able to make a blade yourself from scratch. You can only give a regular blade the desired shape by processing with a grinder or emery wheel.

But the hatchet is quite capable of making. For this you need:

- pick up a workpiece with a diameter of more than 120 mm and a length of 200 mm more than the planned handle;

- dry for several months at a temperature of 22-24 degrees and a humidity of 15%;

- using an ax or a large knife, remove the excess part of the wood in accordance with the outlined contour;

- carry out processing with a chisel and a hammer.

Now it is important to learn how to plant the ax correctly. Do this with gauze and epoxy resin.

The wedge provides the best strength. After that, polishing is performed, the handle is varnished. Sharpening is done on a machine or manually.

The ax is a useful helper in the country, and in the hike and when working in the forest. It is only necessary to choose the right model, focusing on the required characteristics and quality of manufacture of a particular specimen.

Ax photo

Hello everyone, today we will be doing such a useful thing for the kitchen as a kitchen hatchet. With the help of homemade products, you can chop or cut vegetables, meat, bones and other products. The author used an old thick steel saw blade as material. As a result, the hatchet has become weighty, which makes it comfortable. Also, the product was hardened and tempered, which made the steel strong. The handle covers are made of wood, which is impregnated with epoxy resin, as a result, such a handle will not be afraid of water. The only drawback of the steel chosen is that it rusts, but if the ax is used frequently, the steel will become patinated over time. You can make a patina yourself using etching and so on. If you are interested in the homemade product, I suggest studying the project in more detail!

Materials and tools used

List of materials:

- old saw blade (made of good steel); - wood for lining; - brass rods for pins; - epoxy and paint; - oil for wood.

Tool list:

-; - drilling machine; -; - files; - sandpaper; - oven, oil, oven (for heat treatment); - marker; - orbital sander.

Hatchet making process:

Step one. Ax profile

Before cutting the ax, it is advisable to check the steel for hardening. Otherwise, then it can be very offensive when the product suddenly refuses to be tempered. Some modern saw blades are made of poor metal to save steel, such “steel” cannot be hardened.

The author uses an old thick saw blade as a starting material. To begin with, draw the desired hatchet profile on it with a pencil, and then point it with a marker. That's all, you can start cutting, the author works with a grinder. Our metal is quite thick, so it will take a long time to cut. As for the problem areas, which cannot be cut out with a grinder, we cut them out in pieces.

Step two. Slopes

Step three. Heat treatment

Then be sure to take a vacation, otherwise the steel will be very fragile, the blade may chip. For holidays we use an oven, the temperature is classically set around 200 ° C. If the steel has been previously sanded, it will turn straw-colored after tempering.

Step four. Grinding

grinder

Step five. Overlays

When the epoxy is dry, we need to cut the workpiece lengthwise to make two halves, which will become overlays. For cutting, the author uses a band saw, but you can also do it with a hacksaw. We grind the workpieces well and you can cut the primary profile.

Step six. Installation of overlays and completion

Well, when the glue dries, we set the desired handle profile, the author does this work manually, so as not to remove unnecessary things. First, we work with files, and then we go to sandpaper and grind the handle to a perfectly smooth state. At the end, we cover the handle with oil or varnish, while the epoxy resin will return to its former transparency, and the handle will look like a masterpiece.

What to look for when choosing any ax:

Steel. Hang up the ax and hit the canvas with a small hammer - the louder and longer the sound, the better. This indicates the density of the steel used for the web.

The handle should be comfortable enough. If it is made of wood, then it is carefully processed, without knots and chips.

If made of fiberglass, pay attention to the coating of the handle. It should not scratch or injure your hand.

If the handle is made of wood, then the wedge should not be metal.

The presence of a cover. Decide if you need it.

Do not use the hole in the handle (some axes have one) for the lanyard. The ax swings strongly when walking and it will be not only inconvenient, but also dangerous to carry it on the hand.

Although, we have not considered all types of axes, we talked about all the nuances of their design. I think, knowing this classification of axes, you can easily choose the right one for yourself.

Collectible axes

For those who are anxious about their tool, and who are allowed financial means, below are examples of cleavers from Scandinavian manufacturers who really "live" not in China, with a centuries-old history of producing tools and hand tools.

Such axes are not cheap, as such tools can be called collectible.

Carpenter's ax Husqvarna (5769265-01)

This ax, like the previous model, is designed for carpentry work. The whole structure allows you to easily carry out woodwork. The thin, straight edge of the blade removes chips and does other woodworking work. At the same time, for the most convenient use, the hand can be placed near the blade itself, which is facilitated by a notch near the hatchet.Hand-forged Swedish steel makes the construction tool durable and reliable.

American hazel wood handle. It has a through hole at the bottom, which makes it possible to conveniently carry the instrument with you. The package includes a leather case.

The weight of 1.5 kg and the length of 50 cm also contribute to comfortable and high-quality work.

Country of origin: Sweden.

The average price is 4500 rubles.

Carpenter's ax Husqvarna (5769265-01)

Advantages:

- quality materials;

- includes a leather case for the blade;

- reliability.

Disadvantages:

not identified.

Splitting Maul forged ax-splitting ax from the Swedish manufacturer "Granfors Bruks"

A real Swedish cleaver. Reliability is evident at first glance. Any log lends itself to a weight of more than 3 kg. The working part is forged high carbon steel blacksmiths by hand using technologies that have stood the test of time. A massive hammer-shaped butt will hammer in any wedge made of any material.

The 81 cm handle is made of hickory wood, a variety of hazel, and is impregnated with wax and linseed oil for long-lasting protection. On top of the handles there is a metal cover for protection.

This tool, the price of which starts at 19,000 rubles, is a real work of art.

The leather protective cover makes the transfer safe, protecting against injuries during careless movements.

Splitting Maul "Granfors Bruks"

Advantages:

- the highest quality materials and workmanship;

- high performance;

- handmade.

Disadvantages:

high price.

Sledgehammer "Wetterlings" Splitting maul №146

Another Scandinavian specimen in our market.

The long and narrow blade handles very large logs. The working part is made of steel alloyed with silicon, manganese and vanadium. After that, it was hardened and brought to a hardness of 58-59 HRc.

The 800 mm long handle gives the tool a powerful impact force, and the narrow blade easily splits any tree, and the impact butt effortlessly drives wedges.

Hickory wood handles protect the flax oil from the environment.

All parts are securely held together with metal and wood wedges.

The weight of 2.5 kg confirms the strength and reliability of this sledgehammer ax.

A leather protective case is included with the instrument. Average cost: 8,300 rubles.

Sledgehammer "Wetterlings" Splitting maul №146

Advantages:

- reliability and quality;

- manufacturer with many years of experience;

- excellent performance.

Disadvantages:

not identified.

How to choose?

Carpentry is closely related to both tree felling and construction. Choose carpentry axes with medium-width blades. This will allow you to efficiently chop off branches, process logs. Modern products on sale are called tourist or garden products.

In carpentry work, sometimes it is necessary not only to cut, but also to cut. The rounded edge of the blade is very convenient for this.

It is important that it is not too sharp, otherwise the instrument will be very fragile.

The quality of the blade steel is selected by sound. Craftsmen advise to knock on the ax when buying it. A sonorous sound indicates the strength and durability of the selected specimen.

The classic carpentry tool handle is made of wood. The handle will be resilient if it is made of dense rock. The fibers of the wood should run along. Good wood for an ax is free of knots and cracks. Such a product will not break from strong impacts.

Wooden handles darken and dry out over time. Therefore, experts advise treating purchased axes with paint.

Metal handles are not affected by a harmful environment. All-metal structures are highly reliable. For convenience, they are usually supplemented with rubber pads. This addition prevents hands from slipping off the product during work.

Modern versions of the hatchet are made of fiberglass (fiberglass).The material is based on polyester resins. When they harden, they acquire the strength of a metal. Unlike wood, they do not rot, do not change their original properties, regardless of any impact.

Thanks to modern material, the performance of conventional axes is significantly improved. Experts believe that the impact of vibration that occurs upon impact is reduced. The grips are equipped with grooved inserts to reduce slipping.

The convenience of the handle is due to its shape. Most of the tools are made with a bend, this ensures a secure grip. The end of the ax is usually widened. This prevents accidental slipping.

For the carpenter, the weight of the tool is also of great importance. Carpentry models are often made light. This is necessary so that the hands get tired less, since such works are lengthy.

An important addition to the ax is the presence of a rubberized pad on the blade. It will cover the sharp edge and ensure safety when carrying the tool

A canvas cover is also required.

For more on carpentry axes, see the video below.