How to work correctly with a Fokin flat cutter

Some gardeners have dissatisfaction after working with the tool, since many do not know how to work correctly with the Fokin flat cutter. As a rule, the skills of working with other garden tools are also applied when using a flat cutter.

When working with a flat cutter, there is no need to bend over, you need to stand straight, holding the tool like a scythe.

Loosening the soil

Did you know?

At the beginning of the 20th century, Ivan Ovsinsky increased yields several times without the introduction of mineral fertilizers, using surface loosening and without removing straw from the ground.

Loosening and weeding is carried out with the wide side of the blade - it enters the ground at an optimal distance (about 5 cm) and with a slight movement is pulled towards itself or along the bed. In this case, the tool resembles a scythe. The soil should not rake, but remain in place, loosened.

Important!

The blade should enter the ground at a slight angle with a sharp end, almost parallel to the surface, and not from above and flat.

Thus, with the help of the Fokin flat cutter, knowing how to work with it, it is possible to process non-seeded beds, potato, tomato, cucumber and cabbage aisles.

Formation of ridges

Another function that a flat cutter can perform is the formation of beds. Moving along one side, on the other, they rake the soil and cut weeds to the garden bed. Having walked in this way along one side, they move to the other, and rake the bed from the other side.

Keep the edges of the bed parallel and straight. In wet areas, the beds are made higher, performing intermittent movements with a flat cutter, jerking movements, throwing the earth onto the bed.

The width for subsequent work with a Fokin flat cutter should remain large - 1 m.

Cutting grooves

To align the furrows, the blade is buried flat to a depth of 1-2 cm. The flat cutter is carried out like a rake, along the bed, smoothly or with slight acceleration. At the same time, the lumps are loosened, and the beds are leveled.

Important!

If this operation is carried out, moving each time along the north side (so that the slope of the bed is directed to the south), you can grow vegetables at an earlier date.

Hilling plants

The next process that will make this tool easier is hilling. How does Fokin's plane cutter work in this case? The wide part of the blade is lowered to a shallow depth into the ground. After that, they fluff the ground with gentle movements.

They work as a tool like a hoe.

Weed removal

When loosening the soil and forming beds, young weeds are almost completely destroyed (by 70-80%). If these operations are carried out at intervals of 7-10 days, then the weeds can be completely destroyed.

However, if you are late with processing, you will have to use a flat cutter to remove weeds. How to work with a Fokin flat cutter in order to correctly carry out the procedure for ridding our crops of wild relatives? It's simple: the tool blade is smoothly inserted to a depth of 1-3 cm (the soil should be moderately moist).

If the ground is dry, the grown weeds are trimmed with a sharp movement of a flat cutter or according to the principle of the scythe with a blade deepening by 1-3 cm.

After a week, the operation should be repeated to remove the weeds that have had time to take root. In any case, Fokin's plane cutter (of course, if you know how to use it) will eliminate the need to collect weeds from the garden.

Tool characteristic

The flat cutter includes several garden tools at once in its design (a small shovel, rake, scythe, and others). This versatile piece of equipment allows you to perform a wide variety of garden tasks. Working with a hoe saves physical strength and time.

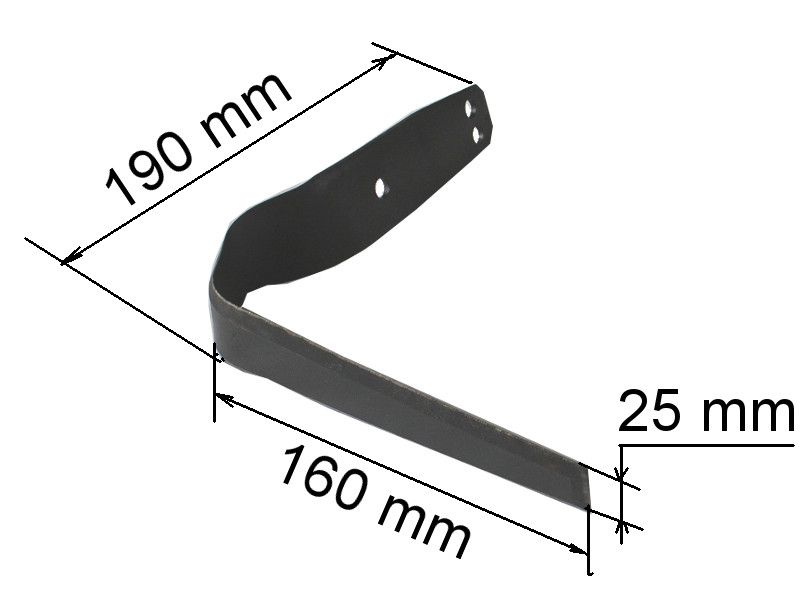

- The shape of the tool is a metal plate bent in a specific way, the three edges of which are sharpened. There is a choice on the market between a large and small flat cutter. The first is intended for forming, hilling beds, as well as for getting rid of weeds or mowing grass. The second facilitates work on weeding or shaping furrows for sowing.

- The main feature is the ability to remove weeds with a blade. The tool destroys unwanted grass without turning the ground, thus preserving the soil structure and beneficial microorganisms. Weed roots remain in the soil and rot.

- Before starting to use the equipment, you should individually adjust to your height and work style, and understand the possibility and scope of action. When assembling a flat cutter, you need to screw two fasteners to a wooden handle.

Making a Fokin flat cutter with your own hands to facilitate manual labor is a worthwhile idea. To cultivate the soil quickly and efficiently, using a flat cutter, will appeal to every gardener. Now loosening the soil and killing weeds will be a simple matter, and the yield of noble crops is much higher.

The process of making a flat cutter.

The first stage was metal tempering.

- He heated it to a cherry color in a blowtorch flame and left to cool in air.

- Grinder sharpened the edge of the blade under the cutting knife.

- Drilled holes for attachment to the handle. Difficult, but at low drill speeds, the process is easy.

- With chalk I drew the lines on which there should be bends, according to Fokin's drawing.

- He fixed the released torsion sheet in a vice slightly above the bending line and, heating the bend with a blowtorch, bent the sheet to the appropriate degree with an adjustable wrench. It is necessary to bend it easily, without force and it is necessary to ensure that no cracks or chips form. When heated, the pliability of the metal is felt.

- The next bends were made in a similar way.

- The most important point comes during hardening. The flame of the torch from the blowtorch was directed along the blade of the plane cutter and heated to a cherry color. Do not overheat.

- Holding the edge with large carpenter's tongs, he dipped the hot cloth into the car oil for one or two seconds. He held it in the air for two or three seconds and dipped it into the oil again. So until the oil stopped boiling on the canvas. Overcooked will not do good. The blade will break easily (tested).

The second Fokin plane cutter was made without heat treatment and it turned out to be no worse and just as resistant to stress

Moreover, it retained its elasticity to bending, which is important when loosening the soil

The handle to the flat knife was made flat, according to the description of the designer Fokin. Convenient in holding the plane cutter when processing and turning in the garden. Reminiscent of a hockey stick childhood feeling.

I do not know about others, but I like my flat cutter more for working in the garden. It does not strain the back and the processing speed is much higher. Fokin's flat cutter is convenient for me on small beds and I use it for weeding onions, parsley, young shoots of table greens.

Application

In other words, how to use it correctly so as not to get tired and to have time for everything. What's the main thing on the beds? So that the back was unloaded, the knees did not hurt, and the work brought aesthetic pleasure.

In other words, how to use it correctly so as not to get tired and to have time for everything. What's the main thing on the beds? So that the back was unloaded, the knees did not hurt, and the work brought aesthetic pleasure.

And for this we determine the type of soil, since clayey, hard areas cannot be easily processed even with such a tool. Before starting work, we must undermine the flat cutter.

Pliers are suitable for:

- Preparation of already dug up land for planting seeds, seedlings.

- Making holes, longitudinal grooves.

- Thinning of growing vegetable crops.

- Weeding.

- Hilling.

- Cutting tall weeds.

- Cleaning the trunks of garden plantings for whitewashing.

Where can you buy the original Fokin flat cutter?

Only a flat cutter made according to the inventor's patterns will be able to give you genuine pleasure in summer cottage work. No other options, even home-made and made exactly according to the drawings, can boast of durability and reliability simply because the technologies for processing steel and applying an anti-corrosion coating are constantly being improved.

Real flat cutters "from Fokin" are necessarily sold with the inventor's brochure "Towards the Earth with Science", with a color cover and a photograph by V.V. Fokine. The set includes 2 attachments (large - for soil cultivation and difficult work, small - for quick and easy weeding), a set of fasteners and 2 shanks. Cuttings for flat cutters can be made independently, at the end of the brochure there is an instruction on how to do this.

You can contact one of the leading manufacturers, which preserves and enhances the traditions laid down by the inventor Fokin, in the following ways:

Mailing address:

601384, Vladimir region, Sudogodsky district, p. Muromtsevo, st. Shkurina, 8, apt. 6.Fokin Vladislav Olegovich.

+7 (4922) 46-29-46,

+7 (4922) 60-10-81.

Detailed information for online ordering of Fokin flat cutters is here.

What it is?

The plane cutter was invented and patented by an outstanding and versatile person, a talented journalist, engineer and gardener Vladimir Vasilyevich Fokin from the city of Sudogda, Vladimir region. The idea of creating a tool came to him after a heart attack, as a result of which full-fledged work in the garden was out of the question. The author began to study the behavior of hand-held agricultural tools in various conditions, and analyze their strengths and weaknesses. After a series of experiments with various variations, Vladimir Vasilyevich approached the creation of a device that was completely unique in its simplicity and efficiency, which was later called a flat cutter, and was successfully tested on his own personal plot. Today, the production of flat cutters is carried out by a workshop founded by Vladimir Vasilyevich, which is located in his homeland - in the city of Sudogda, and produces the best tool in Russia.

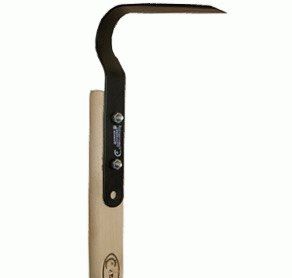

Structurally, the flat cutter is a curved metal bracket, fixed on a long handle, and outwardly resembles a poker. Each side is sharply sharpened, which significantly reduces soil resistance during operation and greatly facilitates manual labor. There are also combined models, consisting of two blades of different lengths. The secret of the tool's effectiveness lies in the combination of its geometric shapes with the angles on the bends of the structure. This allows for flat cutting of the soil without sinking particularly deep into it. From the side, the work with a flat cutter looks like a broom sweeping snow in both directions, which is due to the double-edged blade of the tool and the ability to perform manipulations in either direction.

Types of flat cutters and their application

All work in the garden and vegetable garden can be done with one of the ones on the list. But then the principle of using this tool will be violated - easily and efficiently.

A flat cutter will help, but on condition that each model will be used for its intended purpose.

- Small plane cutter - for working on light soil, when forming furrows and small beds, for sowing vegetable seeds, weeding and shallow loosening.

- Large - Formation of large ridges and seed furrows in heavy soils. Planting crops in seedlings. Loosening to a depth of more than ten centimeters. Formation of near-stem circles, the first hilling of plants in the early phases of growth.

- Small cloth - fast processing of narrow row spacings. The working part of the tool is narrow, sharply sharpened.

- Large cloth - a tool with a strong, sharp blade, for weeding crops that take up large areas.

- The mighty man - has the widest blade, convenient for hilling vegetable crops.

- Strong - wide but short blade allows for tilling heavy, stony soils.

For processing one crop, in different phases of growth, it is possible to use different models. If, when planting carrot or beet seeds, the Small Plane Cutter is suitable, then in the future, for weeding and loosening the row spacing of the same crops, you will need a large or small cloth.

Points to consider:

The stalk should be rectangular with rounded edges.

The handle should "lie" in the hand. When gripping, fingers should "point" up. If the diameter of the shank is large, it will be difficult to work with such a tool.

The length of the handle is selected according to the height of the person. A short handle will force you to work, tilting strongly, and a long one will not allow you to hold the tool at the required angle.

The metal part is attached to the handle at an angle of 45 °. Industrial models have ready-made technical holes

It is important to take this point into account when making a flat cutter yourself.

The tool must be well sharpened. It is easier to work with a sharp instrument.

The main principle is the horizontal direction of the tool movement at a given depth. At the same time, both rules will be observed: it will be easy to work, and the quality and speed of work will be high.

How to work with a Fokin flat cutter correctly

Fokin's plane cutter can rightfully be considered a replacement for many country tools, for example:

- hoe;

- cultivator;

- plow;

- hoe;

- hiller.

In part, this device replaces a scythe, rake, shovel and pitchfork. The tool is suitable for carrying out the following works on the site:

- Formation of beds. This type of work is the most important stage. Fokin's flat cutter perfectly forms the beds. First, the reverse side of the device should rake the earth between the rows onto the main ridge, alternately, first from one row-spacing, then from the other. The edge of the blade should be perpendicular to the surface of the bed, looking down. The plane cutter should be moved smoothly towards you, raking the earth into one place.

- Leveling the surface of the beds. For such work, the Fokin double plane cutter is perfect. The edges of the tool need to be buried 1-2 cm into the ground and drive the tool like a rake. Additionally, lumps of soil are loosened.

- Loosening and weeding. The sharp cutting edge of the tool allows for easy weed control. The flat cutter should be directed "towards yourself", smoothly deepening it into the ground. By performing these actions, you can easily remove weeds, especially in the early stages of their growth and development. You can get rid of various types of weeds using the method of simple mowing of the top layer of the earth;

- Clay soil processing. If it becomes necessary to process heavy, clayey soil, you need to use the tool in the same way as a pickaxe or catman. A sharp blade is buried in the ground with a narrowed end and parts of the lump are chipped off. Experienced summer residents often note that it is not necessary to dig a site to a great depth. The required depth should not be more than a few centimeters. This requires striking the soil with the narrow cutting edge. Such work can be carried out with any plane cutter, but it is best to use "Strong" and "Mighty";

- Hilling. It is best to carry out hilling with the help of the “Mighty” model. The soil between the rows is poured with an inverted tool on each side of the plants;

- Cracking the soil. With this tool, you can easily loosen the soil and saturate the soil with oxygen. To carry out this procedure, the narrow edge of the tool should be plunged into the ground, as far as the length of the plane cutter allows and carried along the ridge. In this way, you can cut the grooves for sowing seeds.

Summer cottage work in the garden using a flat cutter is clearly demonstrated in the video at the end of the article.

Watch the video! Fokin's plane cutter, techniques for working with a plane cutter

The main principle of working with a flat cutter is that it must be directed parallel to the surface of the ground, this rule is often not followed.

When working with the device invented by Fokin, the following conditions must be met:

The back should be kept straight, the body should be slightly tilted;

When the handle is in the hands, the thumbs should "look" up;

The instrument must be properly tuned. The holes in the handle of the Large Tool are used to adjust it to the user's height. If the adjustment is carried out correctly, the working person does not have to bend specially, and the device does not get stuck in the ground;

Ordinary, round handle does not fit the blade of this device

A special, flat handle is required, on which a certain place for attaching the blade is provided, offset by 45 degrees;

It is important to correctly position the beds. They should not be wide, the rows should be separated by paths.

1 Fokine's invention

The most famous and used by summer residents and gardeners, for sure, can be considered a cultivator invented by an inventor from the Vladimir region Fokin Vladimir Vasilyevich. The invention received the name of the author.

Fokin flat cutters

Fokin's invention successfully solves the following problems:

- loosening of the arable layer with penetration to different depths;

- weed removal;

- hilling of cultivated plants;

- processing of inter-row spaces;

- decoration of beds, etc.

1.1 What is it, what is it for and how does it work?

The device of the cultivator is very simple: it is a metal plate 3-4 mm thick, bent at the desired angle. The tool must be properly sharpened on both sides. The handle can be a regular wooden grip purchased from any hardware store.

Outwardly, it looks like an ordinary hoe or hoe. The Fokin hand cultivator, according to the principle of operation, is visually associated with the process of sweeping with an ordinary broom. The working plate is inserted into the ground parallel to the surface to a depth of 4 cm and the "sweep" begins from side to side.

When the operating rules are followed, the double-sided working plate is self-sharpening and does not become blunt. Therefore, the question - how to sharpen a flat cutter - is usually not relevant. If such a need arises, it is better to use a sander.

1.2 Varieties of Fokine cultivators

According to their characteristics, purpose and method of application, these tools are divided into five main types:

Plane cutter "Krepysh" without handle

- cultivator "Krepysh", used in the processing of heavy clay soils;

- flat cutters "Moguschnik" are applicable for high hilling of crops;

- small flat cutter, indispensable for high-speed working out of the row spacing of onions, carrots, garlic, etc.

- large cultivator, ideal for weeding, hilling, preparing the site for sowing seeds, mowing grass around trees, etc.

- large blade, used for processing large areas

Necessary materials

In order to be able to independently make all sorts of products useful for cultivating a vegetable garden, it is advisable to have the most necessary and frequently used materials at hand. Such materials, which should be in any workshop, are, first of all, steel.

The more profiles, strips, bars and pipes made of steel will be on the farm, the easier it will be to carry out a variety of work, carry out repairs and produce useful equipment.

Also, you definitely need a welding machine, with the help of which it will be possible to quickly and reliably connect all metal parts.

This can be done with self-tapping screws for metal, but their scope and reliability are not comparable to welding.

How to sharpen the Fokin flat cutter correctly?

Any gardener knows that all gardening tools must be sharp.

And Fokin's plane cutter is no exception. The sharper the better - these are the generally accepted concepts of sharpening tools. However, a lot of work is performed with a manual Fokin flat cutter, and sharp sharpening is not needed for every one. For example:

during the first weeding, when the weeds are still very small, and are still in the "thread" stage, it is better not to sharpen the plane cutter. He will simply pull them out of the ground, just have time to clear the blade from adhered thin roots

a blunt plane cutter can only remove small weeds in the aisles

Slightly less sharpness of the blade is needed when cutting grooves for sowing seeds, slotting, thinning densely sown carrots, parsley, dill

if the weeds have already grown stronger, then a blunt plane cutter cannot cope with them

The blade will have to be sharpened well, and then you will see the result;

mowing weeds, cultivating the soil to a depth of 5 cm (in Ovsinsky) and deeper (especially for the entire length of the knife) is more convenient with a sharper plane cutter;

a sharp blade is needed when the weeds are already large enough;

thin out raspberries, trim the whiskers on strawberries, form ridges, huddle, of course, better with a sharp blade;

for all other work, the blade must be well sharpened, since most often the plane cutter is used when weeding

.Attention! One of the main reasons for the inconvenience when working with this tool lies in its improper sharpening, since many try to sharpen the plane cutter's blade in the same way as the rest of the tool, which is strictly prohibited.

Sharpening technology

First, a little theory from Fokine:

A flat cutter is not a knife, its cutting edge (chamfer-bevel) should be at an angle of 40-45 °, not sharper. Moreover, working on harder soil requires a more obtuse angle.

In practice, to sharpen a flat cutter, you can use any sharpening tool: a file, a touchstone, an electric sharpener, a sharpener-scraper.

If the garden tool is original from Fokin, not a fake, then it is advisable to sharpen it without overheating the metal.

Note! If the blade is made too sharp, it will easily sink into the ground, but it will be much more difficult to pull it out of there. And one more important point: which side to sharpen?

And one more important point: which side to sharpen?

Take a close look at the Fokine Plane Cutter, it has:

the main cutting edge (the ground "creeps" along it when the tool moves in the soil

and a chamfer-bevel (the back surface, which is turned towards the ground (during operation, it faces a fixed monolith of the earth).

You only need to grind the chamfer-bevel, which sharpens the cutting edge, and from the top, you just need to remove the burrs with a file.

The plane cutter is stitched along the entire length of the blade, while maintaining the above specified angle.

If, contrary to common sense, grind the front surface of the cutting edge, then the angle of sharpness of the blade becomes larger, and therefore dumber.

Most of the wear is on the tip formed by the intersection of the main cutting edge (longest) and the secondary cutting edge at the tip of the blade, especially if the soil is heavy, stony.

And so we repeat once again that the plane cutter can only be damaged by the wrong sharpening, therefore:

- we sharpen the chamfer located on the back surface of the blade. If you do the opposite and grind off the front of the blade, then it will become even more dull;

- the tip of the flat cutter is always the most worn out. He is sharpened in the first place;

- when sharpening, the cutting edge should not be heated. Otherwise, wear resistance is reduced;

- the plane cutter is sharpened at an angle of 45 degrees;

- for a season, the tool is sharpened according to all the rules of times 2. For this operation, you need an emery wheel, a file, a sharpening bar or a sharpener-scraper;

- there should always be a universal sharpener at hand, for example "Sharpener-scraper", suddenly you will have to run it several times over the blade to make it sharper.

- It is necessary to sharpen the blade regularly, avoiding its final bluntness.

- For winter storage, the tool must be lubricated with something, this will protect the metal from rust. Then next spring the work will go quickly and easily.

See how to sharpen a Fokin flat cutter, a sharpener-scraper, a video - better than any story:

See how to sharpen Fokin's flat cutter with an emery wheel video - better than any story:

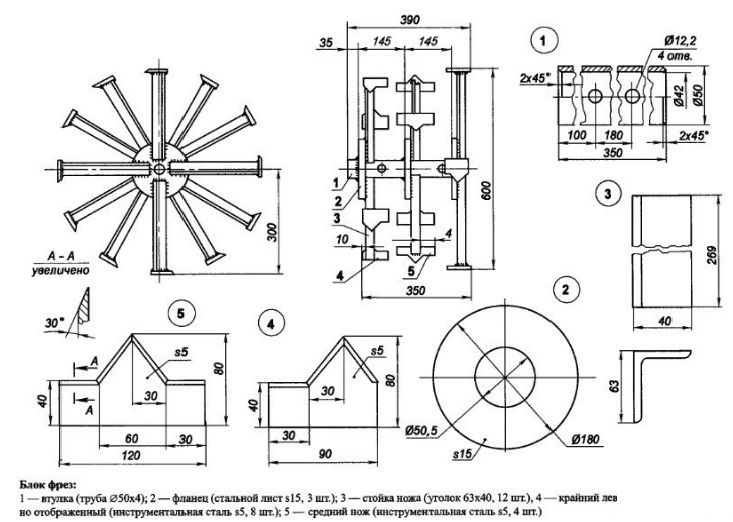

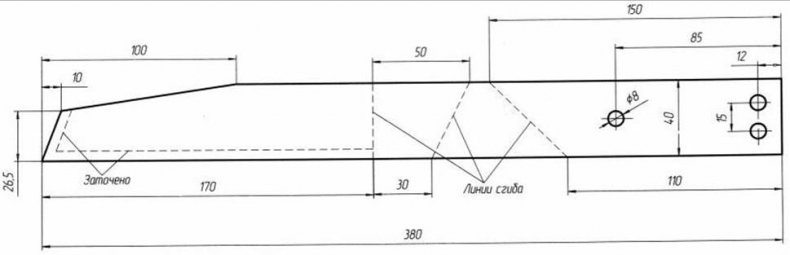

Do-it-yourself Fokin plane cutter: step-by-step instructions with drawings

When making a Fokin flat cutter with your own hands, you should adhere to the drawings and instructions as much as possible - this will help preserve the ergonomic properties and technological qualities of the product.

In addition to metal and wood, for the manufacture of a flat cutter you will need:

- electric drill;

- hammer;

- blowtorch;

- machine oil - working off (for hardening and anti-corrosion treatment);

- vice;

- pliers and two keys 10 x 12;

- Bulgarian;

- grinder;

- whetstone;

- sandpaper;

- plane;

- bolts, washers and nuts.

Workpiece manufacturing process

A workpiece made of ordinary iron is cut to the required size. When using high-alloy steel, it should be borne in mind that the workpiece will be both hard and brittle.

Before further processing, the steel must be "released". For this you need:

evenly heat the workpiece with a blowtorch (gasoline or gas) along its entire length until it acquires the color of a cherry (it is important not to overheat, if it starts to turn orange, it is already overheating);

making sure that the workpiece is cherry-colored, leave it to cool. It is better to carry out such processing in the summer or in a warm room - the cooling will be more even .. After the workpiece has completely cooled down, you can already make a flat cutter with your own hands

Having cut off the desired length with a grinder, you can proceed to the next stage - marking according to the drawing (where to drill holes, where to bend)

After the workpiece has completely cooled down, you can already make a flat cutter with your own hands. Having cut off the required length with a grinder, you can proceed to the next stage - marking according to the drawing (where to drill holes, where to bend).

Workpiece deformation

The stage of deformation of the workpiece is important in that it is necessary to give the desired shape and maintain the angles. The workpiece should be clamped in a vice and with a hammer bend the metal according to the marks (the folds can be preheated with a blowtorch):

- the first bend should have an angle of 95-105 degrees;

- the second - 110-130 degrees;

- the third bend is similar to the second;

- the last, fourth bend is done within the same limits, adjusting the workpiece under the handle.

The deformation sequence cannot be changed (otherwise the last fold will fail). Thus, we get a workpiece for the so-called large Fokin plane cutter, in which the blade dimensions are 170 mm.

Workpiece transformation and plane cutter sharpening

The last step is drilling the holes, shaping, sharpening and hardening. Drilling holes does not cause any particular problems.

The final shape is given according to the drawing using a grinder and grinder. The grinder cuts off at an angle of 45 degrees the edge of the working part of the plane cutter, including the end. The further efficiency of his work depends on how to sharpen the Fokin plane cutter - right or wrong.

Double-edged sharpening (both edges are sharpened, including the end of the blade). It is best to sharpen on a sharpening machine, you can trim it with a hand sharpener. Sharpening should start from the tip of the flat cutter. After that, it is hardened (you can do without it, but the plane cutter will become blunt faster).

Double-edged sharpening (both edges are sharpened, including the end of the blade). It is best to sharpen on a sharpening machine, you can trim it with a hand sharpener. Sharpening should start from the tip of the flat cutter. After that, it is hardened (you can do without it, but the plane cutter will become blunt faster).

Quenching is done as follows:

- pour oil into the container - working off (so that when immersed, the workpiece is covered with it);

- heat the workpiece evenly with a blowtorch (until cherry color);

- quickly immerse it in oil for 2-3 seconds, take it out and immerse it again after 5 seconds, then take it out again and immerse it again (repeat until the oil stops boiling on contact with metal);

- hang to cool. The surface of the workpiece should turn black (protection against corrosion), the metal acquires greater strength.

Making a cutting

Before making a stalk with your own hands, you need to decide on the material (we have already done this) and the workpiece. The blank for the cutting should be in the form of a rectangular strip 45 mm wide and 20 mm thick.

Before making a stalk with your own hands, you need to decide on the material (we have already done this) and the workpiece. The blank for the cutting should be in the form of a rectangular strip 45 mm wide and 20 mm thick.

Initially, you need to give it the necessary shape (it is somewhat reminiscent of a hockey stick):

The assembled handle for the Fokin plane cutter, if placed vertically, should be 20 cm below the shoulder, so the size of the handle for each will be different, individual.

How to make a Fokin flat cutter at home

It will not be difficult to make it yourself.

Before starting work, you need to decide:

- what types of work, in what volumes and on what soils it is planned to be carried out;

- what material is available for work;

- what tool the master has;

- how many flat cutters need to be made.

After preparing everything you need, you can get to work. By doing everything in stages, you can achieve good results and get hold of a simple but useful tool.

Choosing a metal for a flat cutter

The main part of the flat cutter is the metal part. As far as it is possible to select the right metal, the tool will turn out to be so durable. For manufacturing, you need a strip 4 - 4.5 cm wide and 40 - 45 cm long.

What will fit the metal part:

- steel corner, sawn lengthwise;

- spring of a passenger car, 5 -7 mm thick.

High alloy steel is the best option; tools made from this material are durable, corrosion resistant and do not require frequent sharpening.

It is advisable to choose a stronger metal. In order for it to be more pliable in processing, it is "released". After heating the plate on a blowtorch to the color of a ripe cherry, it is allowed to cool slowly. This “tempering” procedure will allow you to bend, drill and sharpen the workpiece in accordance with the product diagram.

Production of a flat cutter workpiece

If the steel is high-alloyed, for the convenience of working with it, it must first be “released”. After this procedure, the metal will be more malleable, and it will be easier to work with it.

The whole process of making a flat cutter can be divided into several stages:

- We give the blank the required shape in accordance with the dimensions.

- We mark the detail.

- We mark the places of technical holes and places of bends of the plate.

It is convenient to bend the plate by holding it in a vice. It is better to preheat the sections of the plate where the folds are planned.

With verified hammer blows, give the plate the required angles:

- The first fold should be 90 - 100 degrees;

- the second - 110˚ - 120 ˚;

- the third - 110˚ - 120 ˚;

- the fourth fold is adjusted to the junction with the handle.

It is better to bend the plate in this sequence, otherwise it will be very difficult to make the fourth fold. This is how all models of flat cutters are made, the only difference is in the width and length of the segments between the folds of the product. It is necessary to bend the metal slowly, periodically checking the angle with the one indicated in the drawing. Avoid kinks and reverse actions - this can break the fold and the workpiece will have to be thrown away.

In accordance with the diagram, technical holes are outlined and drilled. They should be located at a distance of 5 - 7 mm from the edge of the workpiece. The diameter of the holes depends on the width of the plate, the number of fixing bolts and the model of the plane cutter.

Flat cutter assembly diagram

For the manufacture and assembly of a flat cutter, you will need tools:

- electric rain gear with replaceable circles;

- drill with a set of drills;

- vice;

- large and medium hammer;

- blowtorch;

- plane;

- sandpaper.

Do not make the handle for a flat cutter round. A rectangular blank with rounded edges is easier to hold in the hand and makes the fastener for the metal part strong and reliable.

If you have the material, a detailed drawing and the necessary tools, it will take 3-4 hours to make the tool. It will be possible to use it for more than one season. Self-made flat cutter, will facilitate all work in the garden and will be the pride of the master.

Sharpening

When heating metal for hardening, you need to monitor the color. An orange glow is a sign of overheating.

Such a tool will be fragile and may chip on the blade when hitting a hard object.

- Coarse sharpening is best done on a machine. It is necessary to give a certain angle, which should be equal to 35˚ - 45˚, relative to the main plane of the plate. A smaller sharpening angle leads to a quick blunting of the tool, and a larger angle will impede the ease of movement of the plane cutter in the soil.

- After coarse sharpening, finer, longer grinding of the tool tip follows. The finer the sharpening point is, the longer the tool stays sharp. The tip is sharpened first, then the main blade of the plane cutter is made double-edged.

After sharpening, metal hardening follows. This procedure will give the metal strength and protect against corrosion. Heat the sharpened workpiece of the plane cutter to the color of a ripe cherry, and immerse it in machine oil for a couple of seconds at intervals of 5 - 7 seconds. There can be up to ten such dives until the part cools down.

The benefits of its use will be expressed in additional kilograms of fresh, vitamin products from our own garden.