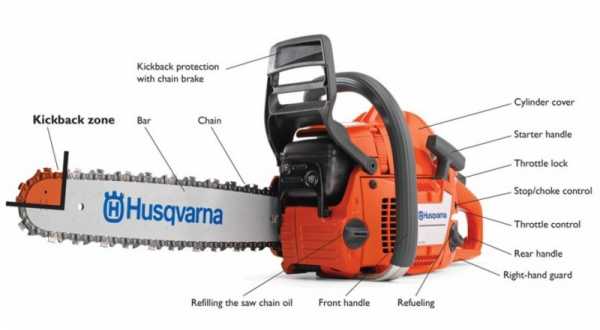

Possible malfunctions

Each saw has its own peculiarities of work, therefore it is not always possible to immediately and accurately determine why the tool is junk. However, let's consider a few of the main problems when working with such units.

Many owners are confused by the fact that the tool heats up during operation. It is impossible to completely avoid this - the working surface is heated primarily from friction, and if the unit works for a long time, then the heating can spread to the engine. Expensive instruments have a cooling system that partially compensates for the problem, while cheap ones simply need to be turned off periodically to avoid overheating as a normal phenomenon.

Chainsaws often stall when you press the gas and do not start, but this problem is not so easy to solve - there can be quite a lot of potential reasons. In some cases, the problem is solved by simply replacing gasoline with a better one - this is usually the place where it is advised to start diagnostics. Oil is also important (it is advisable to use what the manufacturer recommended), in addition, both liquids should not be stored for too long before use.

Sometimes the mixture fills the candle during operation - it is quite easy to check this, and if the suspicion is confirmed, the latter must be dried in the fresh air for about half an hour, after draining the excess fuel. If even this did not help, then the reason may lie in the absence of a spark - then either the candle does not contact the wire, or the electronic ignition unit has broken.

The breakdown may also consist in the clogging of the air filter, due to which the fuel-air mixture is not formed correctly.

In fact, the problem is so global that theoretically it could be caused by the failure of absolutely any part of the motor. Numerous reviews show that inept attempts to disassemble the engine and repair it without appropriate knowledge only make it worse, therefore, if possible, contact the service center, and do not repair the unit yourself.

For an overview of one of the saw models, see the following video.

Saw blade selection

When buying a saw blade, you need to be guided by three parameters:

- Disc diameter in millimeters.

- Bore diameter.

- Number and shape of teeth.

With the first two characteristics, everything is obvious. A disc larger than the size of the tool design can not be installed in the tool. You can put a smaller disc, but in this case, the cutting depth will be greatly reduced and you will be able to saw only thin workpieces.

The size of the bore should be equal to or slightly larger than the recommended size. In the latter case, you will have to use the insert ring.

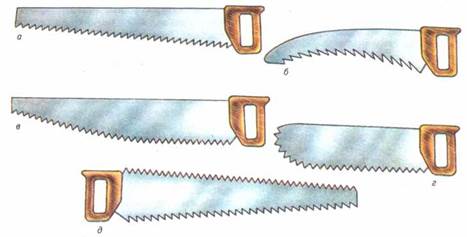

As for the selection of a saw blade according to the shape of the teeth, this is a topic for a separate large article. In general terms, you can focus on the following recommendations:

Discs with a small number of coarse teeth are designed for fast rough cuts

They are relatively cheaper but give a lot of chips.

For a fine cut, the blade must have fine, frequent teeth.

Pay attention to what kind of material the blade is intended for cutting (wood, plastic, aluminum). Some discs differ only in the shape of the teeth, but it is easy to confuse them in their size and number.

What is a segment saw

The segment saw is a cutting device and an important part of a milling and cutting machine, its main task is to process various metal workpieces. In fact, this is the Geller saw, which was mentioned above.

The segment disc is indispensable for applications such as metal cutting: about 90% of the cutting is done with this tool alone.

Criteria such as the number of teeth on the saw, the strength of the blade itself, the accuracy of the face / radial runout and bore, and the hardness of the segments determine the amount and quality of the work performed by the saw.

Is it possible to replace one instrument with another

Although these tools can in some cases replace each other without noticeable difference in the quality of work and usability, the jigsaw is still a more versatile device. A saw, on the other hand, can do much more repetitive work. Although in many respects the circular saw has long overtaken even the most modern jigsaws, it is sometimes quite laborious to use it, and frequent replacement of the blade when working with various materials will not add convenience. You can change the file at the jigsaw in just a couple of minutes.

Having decided more precisely which of the types of instrument you need, you can proceed to market research. You should not buy the cheapest option: such a tool will be much more noisy and, most likely, will heat up, which will negatively affect its service life. And vice versa, it is not at all necessary to buy a tool for your needs with a whole set of different bells and whistles and capabilities, most of which you will definitely not use in your household. The best option would be to opt for a mid-priced tool that will contain a set of essential features and will not hit your budget.

Main technical characteristics

These are a number of criteria that fully describe the performance and scope of the tool:

Electric motor power

The first parameter to pay attention to. The productivity and maximum thickness of the material to be cut directly depends on it:

- 8-1.2 kW - entry-level saw. A budget version of hand tools with a saw blade diameter of 130–160 mm. Maximum cutting depth - 45 mm;

- 1.2–1.8 kW is a medium-level tool. The diameter of the disc is 160-200 mm. The maximum cutting depth is 60 mm. Suitable for housework and cottage work. You can dissolve boards, cut plastic and profiled sheet. There are models with fixtures for stationary installation;

- From 2 kW - powerful saws, mainly with a stationary attachment. Circle diameter 200–350 mm. It is practically impossible to work "on weight", it is very dangerous. It can be used to equip a small sawmill for sawing boards;

- Disk rotation speed. Directly depends on the power of the electric motor. The higher the power, the more revolutions it makes in one minute. At low speeds, the quality of the cut deteriorates, burrs and uneven edges appear. At high speeds, the cut edges are smooth, without chipping, which is good when cutting wood. Sawing plastic at high speeds will melt the edges. The professional tool runs at 5000–6000 rpm;

- Cutting depth. Inexpensive models do not exceed 45 mm. The professional tool “bites in” at 85 mm;

- Saw blade tilt. Required parameter in a modern instrument;

- Additional options:

- Smooth start. Extends engine life;

- Automatic power increase when working with dense material;

- Anti-jamming protection. Weakens kickback when stopping abruptly;

- Overload protection of the electric motor;

- Momentary stopper. Increases work safety. As soon as the power button is pushed out, the engine instantly stops;

- Speed control;

- Cutting depth adjustment;

- Connecting a vacuum cleaner. A convenient option that allows you to remove all suspension and dust in a special bag;

- Work surface lighting.

What it is?

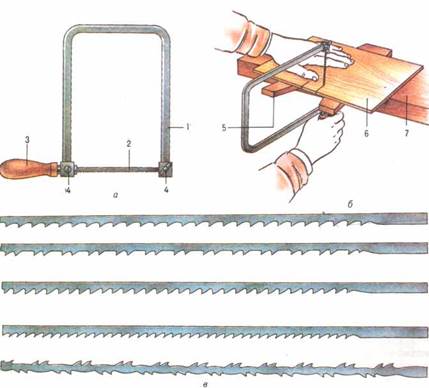

A hand tool, whose blade was originally made of flint, first appeared in the 7th millennium BC. With the development of metal smelting, that version of the hand saw appeared, which everyone has probably seen - it does not need an introduction. However, today there are quite a few varieties of this tool with a specific structure, and they are united only by the fact that, unlike a knife and most other cutting devices, they usually do not have a solid point, but consist of numerous teeth or cutters of a different type. Usually their shape resembles an elongated classic saw, but the same circular pattern assumes their circular arrangement on a special replaceable disc.

True, there are also toothless models that use diamond sputtering on a standard "knife" point.