The best plunge-cut circular saws

The rating of the best circular saws necessarily includes universal tools that can start sawing from the middle of the workpiece - sawing through holes in them. If it is assumed that work of such a plan exists, then one must look in the direction of plunge-cut circular saws.

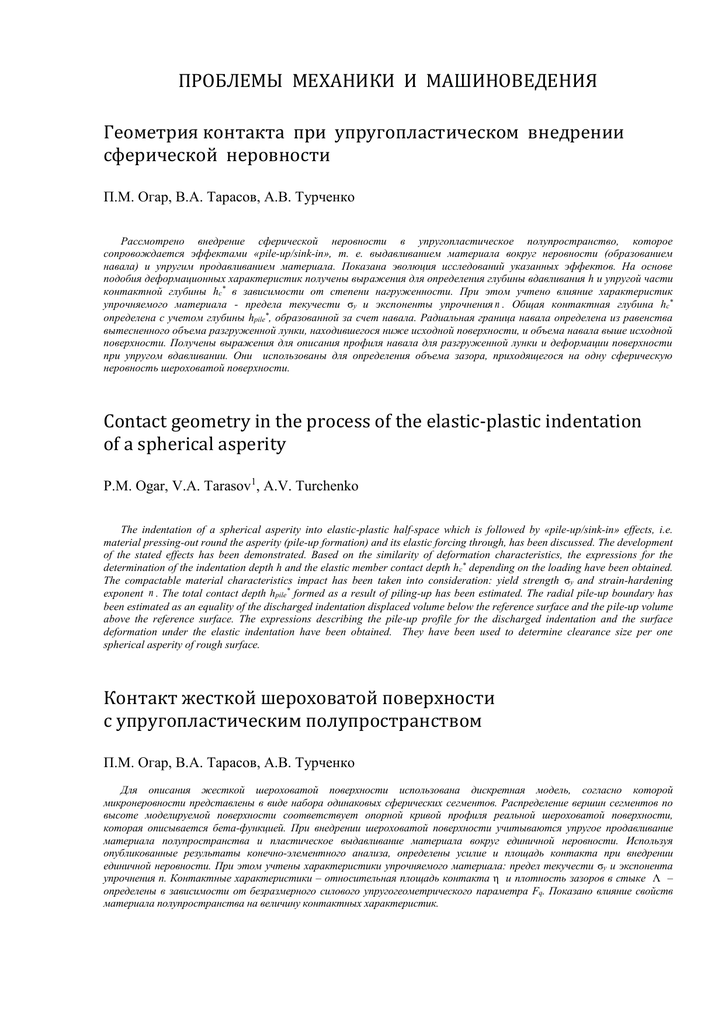

| Bosch GKT 55 GCE | Makita SP6000 Set | |

| Power, W | 1400 | 1300 |

| Number of revolutions, rpm | 3600-6250 | 2000-5200 |

| Speed control | ||

| Disc diameter, mm | 165 | 165 |

| Rim diameter, mm | 20 | 20 |

| Max depth of cut at an angle of 90 °, mm | 57 | 56 |

| Max depth of cut at an angle of 45 °, mm | 42 | 40 |

| Smooth start | ||

| Possibility to work with a guide rail | ||

| Maintaining constant speed under load | ||

| Weight, kg | 4,7 | 4,4 |

Circular saw Bosch GKT 55 GCE

A professional tool with a wide range of basic and additional functions: smooth start-up, quantity control and a system for maintaining speed under load, the ability to cut perpendicularly and at an angle.

+ Pros Bosch GKT 55 GCE

- Premium class products are manufactured at factories in Germany - only a plus to the quality of components and assembly.

- High quality "native" disc - makes a smooth and clean cut.

- Precisely aligned rulers for cutting depth and tilt.

- When registering a tool by serial number on the official Bosch website, the warranty period increases from one to three years.

- Guide tires are quite suitable from Makitov or Devolt ones - they are also cheaper than the original ones from Bosch.

- Cons Bosch GKT 55 GCE

- Guide bars, without which it is very inconvenient to work with a saw of this class, must be purchased separately. It should be borne in mind that the old ones - for 700 and 1400, most likely will not work - it is better to look for new ones, with sizes 800, 1100 and 1600.

- Convenience of tilt angle adjustment leaves much to be desired, however, this applies to most circular saws.

Circular Saw Makita SP6000 Set

Professional circular saw with the ability to adjust the cutting depth and angle. Suitable for floor or wall work. A disc of 165x20 mm is used. The standard cutting depth is 56 mm, and when the blade is tilted by 45 ° - 40 mm.

+ Pros of Makita SP6000 Set

- The design of the blade allows you to cut already at a distance of 18 mm from the wall or other stop.

- A good set of electronic filling: soft start, speed control, engine braking function and overheating protection.

- High accuracy and quality of cut - according to these parameters, the tool is quite suitable for furniture installers.

- One of the best ratios of performance, workmanship and cost.

- The engine power of 1.3 kW plus 5200 blade revolutions per minute is fully sufficient for confident saw operation, even despite the absence of a riving knife.

- Cons of Makita SP6000 Set

A frankly weak sole design - if handled carefully, it will “live”, but if you drop the saw or otherwise hook it strongly, an out-of-warranty case may happen, because the sole is fastened to the tool with four self-tapping screws in plastic

Tires of suitable quality still need to be looked for - ideally, you should buy everything together and pay attention to the evenness of the ride

disadvantages

A significant disadvantage can be attributed to the fact that such segmental cutting discs are a consumable item that requires regular replacement. It was mentioned above as an advantage, but this is not always the case, because it is not very convenient.

Regular replacement implies care and caution when purchasing such material - there is a high probability of purchasing a low-quality product.In addition, it is imperative to purchase only those segments that will fit the body of the saw.

For an overview of the Geller saw, see the video below.

Band-saw

The logical development of the jigsaw design has become a compact band saw. Its working body is a closed steel belt with teeth, which is rotated by an electric motor.

Band-saw

Sawing with its help is easier than working with a jigsaw, which vibrates strongly and strives to get out of your hands. The cleanliness and precision of the band saw is ideal. This not only reduces waste, but also produces a cut surface that does not require sanding.

The workpiece can be held here with two hands, which increases the accuracy of operations when cutting curved elements.

The main indicator of band saws for wood is the cutting depth, which can be from 8 to 50 cm. The jigsaw and circular saw are not able to cut such a thick material.

The rest of the characteristics apply to cutting blades.

There are two categories here:

- Carbon saws (made of steel S75 and analogs);

- Alloy saw blades made of D6A steel (have increased wear resistance and resistance to alternating loads).

Depending on the manufacturing technology and hardening of the cutting teeth, the blades are divided into two types:

- Saw blades with serrated unhardened teeth;

- Sliced hardened tooth blades.

The advantages of the saws of the first type are low cost and the ability to cut wood with foreign inclusions: nails, stones, splinters. They work with such a blade at small sawing volumes (2-4 m3 per day) and at a minimum feed speed (6-10 meters per minute).

The main advantage of a saw blade with a hardened tooth is its high wear resistance (2 times higher than that of saws with unhardened cutters). Disadvantages - high cost and sensitivity to foreign inclusions.

The rest of the parameters of the band saws are summarized in a simple list:

- Web width;

- Teeth Per Inch Length (TPI).

For standard sawing jobs, a 1/2 ″ band is ideal. Narrower blades (3/8 ") are used for shape cutting.

The number of teeth of the cutting strip directly affects the evenness of the cut (the more there are, the smoother the cut). Coarse saw blades (2.3 TPI) are used for cutting wood and logs up to 200 mm thick. For cleaner work, saws with 6 TPI are used, and for precise cutting, the size 10-14 TPI is used. The optimum size for high productivity and good cut quality is 8 TPI.

Metal band saw

The metal table saw is similar in design to a wood cutter. However, its capabilities are more modest. This tool can only perform cross-cutting of rolled steel (pipes, angle bars, fittings, channel bars) at different angles.

About Geller's Saw

The Geller saw is used to cut ferrous and non-ferrous metal with circular saws. This part is a disc with teeth fixed along the edge, which are called segments. The cutting process takes place at the right angle of the disc to the workpiece itself. Blanks can have a round, rectangular or shaped cross-section. This is specialized equipment used only in workshops, factories or other manufacturing facilities.

The ability to process metal molds of all sizes is possible thanks to certain segments with different characteristics. The workpieces are fastened and moved using hydraulic mechanisms.

What are they?

All electric pendulum saws can be divided into products according to the type of material being processed:

for metal;

Power saws in the first category are capable of working with aluminum and other softer and harder materials. Some models are available with a carbide disc and even a turntable, making the task much easier. You can buy a product for cutting with a long feed.The tool for metal eliminates the thermal effect on this material, thus, mechanical cutting does not affect the composition of the alloy, therefore, the characteristics of the metal do not change.

The power of the pendulum saw and the type of disc that stands on it determines what kind of metal the tool can work with. Non-ferrous and ferrous metals can be processed. If we talk about the scope of application, then metal saws are used when cutting:

- corners;

- rods;

- fittings.

There are lower power pendulum saws on the market that are used to cut wood. Such units belong to one of the varieties of circular saws. They are used for trimming a bar or cutting a tree at right angles. During operation, such a tool swings like a pendulum, hence the name.

During work, the operator has the opportunity to follow the cutting line, which is very important if no preliminary marking has been applied. Among the disadvantages are the limited cutting width and the need to apply additional efforts to the operator.

The design uses cutting elements with a diameter of 50 to 65 cm.

Segment saw characteristics

The segment saw is suitable for all types of metal objects: from relatively soft metals like aluminum and its alloys to cast iron and steel.

Such models have the following distinctive characteristics.

- One of the most important characteristics is size. The dimensions of the saw body are made with the following values: in width - from 0.05 to 0.15 cm; in length - from 0.3 to 200 cm.

- The shape of the teeth on the segment. Different types of metal correspond to different forms of teeth.

- The frequency of the teeth on each segment. This characteristic depends on the dimensions of the device itself and the size of the teeth (the smaller they are, the more there are).

Basic rules for the use and storage of measuring instruments

We will tell you how to properly use and store measuring tools used by locksmiths, repairmen and craftsmen of other profiles.

Operation of instrumentation

1. All measuring instruments have operating instructions. Be sure to study them before using the fixtures and storing them.

2. When fixing the instruments, do not use too much force. This is fraught not only with a deterioration in the accuracy of the readings, but also with breakdowns of devices.

3. The part or its parts must be cleaned of various kinds of dirt and burrs before measurements.

4. Measuring instruments should be lubricated if necessary.

5. After finishing the work, the fixtures should be cleaned, lubricated and put into the cases.

6. Protect products from moisture, drops and shocks.

7. The measured parts and products must have a temperature from +15 to +20 ° С. In this case, the measurements will be as accurate as possible.

8. Measurements of the workpieces are carried out with the machines turned off.

9. In the intervals between measurements, the fixtures must be placed on dry and clean surfaces.

10. Operation of measuring instruments requires regular verification.

Storage of measuring instruments

-

It is necessary to store measuring instruments in dry and heated rooms.

-

To protect against negative factors, it is advisable to place the devices in individual cases and tubes.

-

The recommended storage temperature is from +10 to +35 ° С.

-

The air should not contain aggressive impurities.

-

Before sending for storage, the measuring surfaces are disconnected, and the clamps are loosened.

Photo # 22: storage of measuring instruments

Compliance with the above rules helps to obtain the most accurate measurement results and prolongs the life of the test fixtures.