Important to know when using: tips from the wizard

Every tool, regardless of brand and quality, breaks down periodically and needs to be repaired.

Causes of frequent breakdowns

Breakdowns can happen for various reasons, but basically you need to calculate the power and capabilities of your tool for the job you want to do. For example, if you want to drill a meter-long concrete wall with an ordinary hammer drill, then you need to give it a rest periodically. If the tool heats up, work must be stopped, and not wait until molten grease flows from the gearbox. And you, like the instrument, need to take a break from the constant load.

Which hammer drill do you use?

Coaxial Not coaxial

What if the tool works in only one mode of operation?

During prolonged operation of the hammer drill and under heavy loads, the gearbox may heat up, which leads to breakdown. If the gearbox breaks down, it is best to contact a repair specialist, as self-repair can lead to permanent damage and in the future to injury when working with the tool.

The device emits sounds unusual for normal operation

The reasons for such sounds can be different, ranging from the scattering of the bearing on the rotor and from the banal falling of debris into the parts and mechanisms of the instrument. To prevent such problems, periodically it is necessary to disassemble and blow out the hammer drill, as well as lubricate the rotating parts and mechanisms.

Kress history

Christian Kress

In 1928, in Tübingen-Lustnau, Christian Kress, with only 100 marks of start-up capital, founded workshops specializing in automotive electrics. The result of his fruitful activity was the invention of the SECA charging transformer for batteries.

In 1945, the representative of the second generation - Willie Kress, focused his activity on the production of electric motors and achieved particular success in attracting the attention of customers to the company's products. In 1991, the company was taken over by Dieter Kress, an adherent of global marketing. Consistently deepening his father's traditions, he multiplied the achievements of previous generations. The allocation of large funds for scientific research has led to the creation of an innovative tool that is very easy to work with. It is more economical than analogues produced by competitors, withstands high loads in harsh operating conditions, and is most useful for consumers.

Basic malfunctions and ways to eliminate them

If you have a hammer drill, it is important to have a tester available as well. It can help simplify the troubleshooting task

Otherwise, all electrical parts of the device will have to be inspected one by one. When the operator is faced with the problem of refusal to turn on the tool, he must conclude that the wire was broken. Quite often, the cord gets damaged near the handle. In this case, the cable must be replaced or shortened.

If the break occurs in the middle, then it is recommended to strip the cable from insulation and connect the parts, insulating the cord. Failure, expressed in poor contact of the elements of the trigger mechanism, sometimes occurs due to burnout or oxidation of the contacts. Items need to be cleaned or replaced.

If there is a breakdown of the extinguishing mechanism, then a large load on this part of the mechanism can lead to this. Burned parts must be replaced or, if not, the motor is connected directly. This method of troubleshooting can increase engine wear by several times. It is necessary to use this technique only in extreme cases.If you notice sparks inside, then they may be due to the fact that the brushes do not fit snugly enough to the anchor. This malfunction sometimes occurs due to wear of the brushes or when moisture gets inside the case.

If you notice that smoke has escaped from the punch, then this may also be indicated by problems with the brushes.

From time to time, it is important to carry out an inspection, since when they are abraded, wires appear on the working surface, which causes smoke to appear. Sometimes a jamming of the motor also indicates such a malfunction.

At the same time, the winding begins to heat up and smoke. It is necessary to inspect all elements, and if the problem is in the brushes, then they need to be replaced.

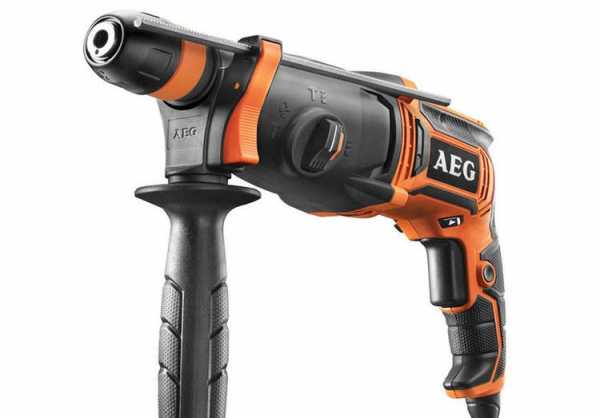

Types of rock drills, their characteristics and features

Rotary hammers are divided into several categories.

By weight, perforators are:

- Lightweight, weighing up to 3 kilograms, are the most popular devices among consumers, but with low power (up to 800 W).

- Medium (up to 1000 W) whose weight is within 5 kg. This tool is designed for more demanding work and can take a lot of stress.

- Heavy (from 1000 W) weighing from 5 kilograms. Designed for more professional work with concrete and stone.

Expert opinion

Vasily Kuznetsov

This distribution of perforators is of course conditional. There are a lot of examples among many manufacturers that do not meet these descriptions.

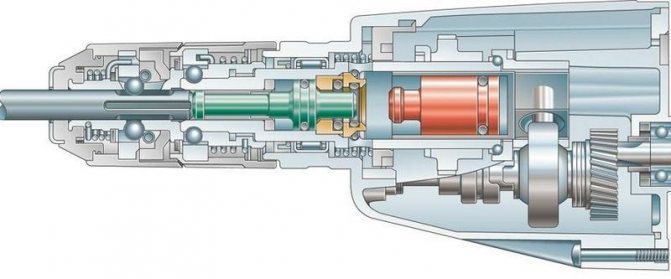

Depending on the place where the engine is installed, rock drills are divided:

- Horizontal arrangement (coaxial), which is used on a lighter tool and means that the rotor and impact mechanism are in line with the placement.

- Vertical (not coaxial) when the rotor is under the impact mechanism. This type of assembly is used on heavy professional rock drills.

1-With horizontal layout 2-With vertical layout

The effectiveness of this tool is determined by the force of the impact, which is measured in Joules. It is logical that the more power your tool has, the more difficult work you can do. This does not mean that if you buy the most powerful hammer drill in terms of impact force, you can do any amount of work, regardless of its severity. The impact force of a hammer drill, in contrast to a drill, is always the same. Therefore, do not apply too much pressure on the instrument in anticipation of the best effect, as this may damage your instrument.

The main modes of operation that each punch has:

- Drilling - this mode is aimed at performing simple drilling of holes in any material (wood, plastic, etc.). For this mode, a simple chuck is used, which is also used in drills.

- Drilling with impact - this mode is aimed at working with stronger material (brick, concrete, etc.)

- Demolition Hammer or Chiseling - This mode is for using the demolition tool.

For a long and problem-free operation of the tool, it must be periodically switched to different modes, which is necessary to lubricate the parts.

Professionals also distinguish the fourth mode of operation of the instrument, which is called pre-installation. This mode is intended for setting the chisel at the angle required for work.

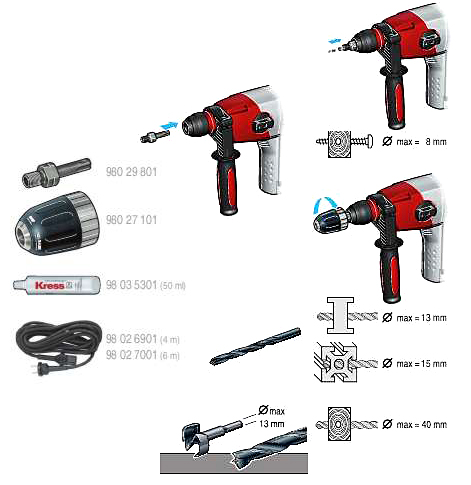

1-SDS- Plus; 2-SDS-Max; 3-SDS-Quick

There is also a separate classification of hammer cartridges, namely:

- SDS- Plus. This chuck is installed on almost every rock drill and is the most practical and convenient to use.

- SDS-Max. This chuck is installed only on professional rotary hammers.

- SDS-Quick. are a development of the BOSH company and are installed only on certain instruments of this category.

Rotary hammer repair

You can carry out the repair of the Kress perforator yourself. First, the tool should be disassembled. At the first stage, the lever is removed, which provides switching

In this case, it is important to be careful, otherwise the repair will entail the destruction of parts. For some models, the cartridge cannot be removed, so it must be disassembled. Use a flat screwdriver to remove the rubber gasket.

Use a flat screwdriver to remove the rubber gasket.

Now we should deal with the retaining ring. Perforator "Kress", which can be disassembled by you yourself, has a cover, removing which you will see that there is a fixing unit in the barrel. Disassembly must be carried out in order, starting with a metal ring. After disassembling the chuck, you may notice that the rubber gasket is worn out and dust gets inside the tool. The parts should be cleaned and the dust cover replaced. Dirt will penetrate even if the cover is deformed. This will not affect the work, but the parts will wear out faster.

If you notice that the circlip is loose or worn out, it must be replaced. When the ball wears out, it is also changed, but with the condition that the diameter remains the same. Otherwise, the cartridge will fail completely. Before disassembling the Kress perforator, you need to take care of the presence of grease. At this point, the guide washers should be secured in the holes. Sometimes the guide balls wear out. If the wear is critical, then a replacement should be made. The most stable part is the conical spring. However, with prolonged use, it can deform. In this case, it must be replaced by turning the smaller vertex towards the reducer. The cartridge is assembled at the next stage, and then you can assemble it in the reverse order by lubricating the end of the drill.

General specifications

The manufacturer presents several models of equipment to choose from, differing in power - the range from 550 to 1050 watts.

The drill diameter is selected depending on the material to be processed:

- 30-50 mm - wood;

- 13-16 mm - metal;

- 20-28 mm - concrete.

The main part of modern rock drills Kress is endowed with a reverse mode, allows you to switch speeds, adjust the rotational speed.

It is important that the system has an additional function - hammer drilling

Some tool types, such as the 800 PSE QuiXs Set, are equipped with a drilling mode where the crown is involved. The hole width in this case reaches 70 mm. This unit weighs about 3 kilograms.

Punch operating modes

Modern rock drills are:

- 2-mode (drilling + drilling with impact);

- 3-mode (drilling + drilling with a blow + only blows).

Drilling is an auxiliary function of the hammer drill, and it is not recommended to activate it without blows - a drill is better suited for this purpose. If it is necessary to perform drilling without hitting with a hammer drill, it is necessary to turn off the hammering function and fix not a drill, but ordinary drills for a drill in the equipment. Drilling is allowed in wood, plastic, foam concrete, thin metal.

There are two ways to fix the snap-in:

1. Remove the SDS chuck from the hammer drill and replace it with a conventional drill chuck.

2. Put an adapter on the SDS chuck (sometimes it comes with the tool).

The first method is preferable, since the drill is fixed more reliably, the radial runout is minimal, and the accuracy of the holes is higher.

The chiseling function can be activated by deactivating the drill rotation mode. The rig will perform only reciprocating movements and, according to the principle of operation, will resemble a bump stop.

Chiseling is relevant for:

- dismantling of walls, ceilings, beams, brickwork;

- chipping off plaster;

- chipping grooves for communications and electrical wiring.

If you hammer the wall with a drill, it will become dull, so chisels are used. For small holes - grooving, for destroying stone objects - dismantling, for chipping edges or removing tiles - bran.

Impact drilling - basic mode the work of the punch. The equipment here is a drill with a victorious tip, which quickly penetrates into hard material. This mode is characterized by an increased noise level, but the process takes less time due to the high efficiency of each blow.

Models and cost

There are several popular device models.

Kress 650 PE

The price varies from 5,000 to 7,000 rubles. The instrument of this model is equipped with a strong motor (650 W). The complete set has been updated with the innovative SDS-Plus chuck, as well as operating modes: chiseling, drilling (with and without impact). The number of revolutions per minute is approximately 1,100, 4,800 / min is the impact frequency. The maximum impact energy is 1.8 J. So, in wood blanks, you can make a hole about 35 mm wide, metal - 13.

The set also includes:

- fixing spindle;

- automatic rotation control;

- reverse;

- drilling depth stop;

- safety clutch;

- switch lock;

- spare set of handles.

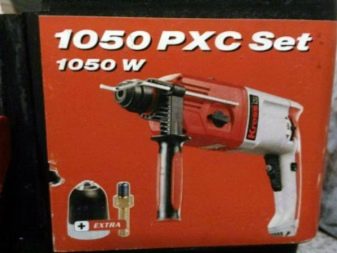

Kress 1050 PXC Set 04283503

The price of this equipment is 9,700 rubles. The main purpose of the tool is chiseling and drilling. The hammer drill is equipped with a powerful mechanism (up to 1050 W).

This feature will allow you to independently regulate, as well as maintain the number of revolutions in action.

The device operates at two speeds: the first is suitable for drilling using large drills, the second - using smaller sizes. The gearbox is made of high quality steel using the latest technology. This feature ensures reliable and long service life of the rock drill.

Model Description:

- the presence of a reverse;

- ability to turn brushes;

- 4 meter power cord;

- holes (in millimeters) - wood (50), concrete (28), brick (using a crown - 45), metal (16);

- adjustable speed;

- 4,700 strokes / min .;

- the presence of a drill chuck;

- there is no vibration protection;

- weight - 2.8 kg.

Kress 800 PE 04284301

The cost of the model is 5,900 rubles. The principle of operation of the tool is based on a motor with a power of up to 800 watts. The tool is purchased for drilling or slotting work with various types of surfaces.

Equipment:

- safety clutch;

- reverse;

- 4 meter cable;

- control electronics;

- impact force - up to 3 J;

- maximum hole width - 35 mm, in metal - 13;

- lack of vibration protection function, drill chuck.

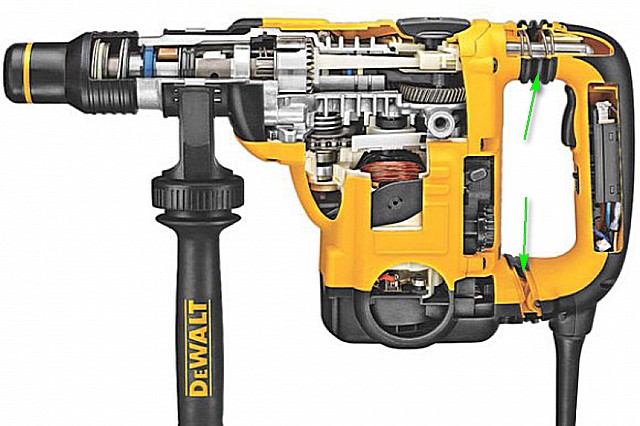

How perforators differ by the type of implementation of the percussion mechanism

Special systems are used to generate the impact force in rock drills. They differ in structure and principle of the formation of the impact force. A distinction is made between pneumatic and electromechanical percussion systems.

Pneumatic shock system

In a pneumatic percussion system, the main elements of the mechanism are:

- movable alternately working pistons;

- strikers, to which the blow from the piston is transmitted;

- air cushions that increase the pressure in the system.

These types of hammer drills do not require strong user pressure on the tool. In order to perform its functions efficiently, it is enough to make a small effort for the instrument to carry out shock effects. Strong pressure on the tool will quickly break it.

The principle of operation of this system, see the video:

Electromechanical impact system

Household and semi-professional models are equipped with an electromechanical percussion mechanism.

- the eccentric activates the spring of the lever;

- the lever moves the striking device;

- the latter transfers the impact energy to the rig.

When using these punches, pressure must be applied to the tool to create more effective hits.

The principle of operation of this system, see the video:

Advantages and disadvantages

According to the reviews of the owners of German Kress instruments, the pros and cons of this equipment can be highlighted.

First, let's look at the advantages of the devices.

- Availability of the network cable module retainer.Even with the power off, you will not worry about the device suddenly working, and you can easily change accessories and attachments.

- There are additional handles, keyless chucks, bit adapters. This configuration allows you to use the equipment as a drill, mixer, or screwdriver.

- High quality, reliability. The equipment can work for about 10 years without repair. However, frequently used parts can wear out. Most of the breakdowns occur as a result of improper use or storage of the tool. Experts advise using only original and high-quality parts from the manufacturer.

- Powerful engine, versatility. It consists in the ability to make even holes, without cracks, crumbling (even in wood and strong concrete).

- Low cost. On average, for 6,000 rubles you can buy a good German hammer drill, which will last for many years and will also provide safe, durable work.

- Convenient case. The special case contains everything you need. It is so capacious that in addition to the main device, there are additional parts here. Such storage allows you to keep the entire set safe, protect it from moisture, dirt, and other damage.

In general, all the tools of the German company Kress are excellent choices for working with various types of surfaces. You can buy equipment in official stores in Russia, where original, high-quality products from Germany are supplied, which cost little money.

The manufacturer guarantees its customers durability, safety, as well as a good result of drilling and slotting work.

For information on how to use the Kress punch, see the next video.

The difference between rotary hammers by the type of attachment fastening system used

The capabilities of the tool are largely determined by the way the tool is fixed.

There are three systems for fixing the rig:

SDS-plus.

SDS-max.

SDS-top.

SDS + is used on compact household rotary hammers. The tool shank diameter for this type of attachment is 10 mm. A device equipped with this system is capable of making a hole up to 30 mm in diameter. Tools with SDS-plus are more in demand than others, since they are cheaper than rotary hammers with other types of equipment fasteners.

Professional devices are equipped with SDS-max system. They make holes up to 52 mm, so the drill must be securely fastened. The tool shank diameter is 18 mm. If the rock drill weighs more than 8 kg, it most likely has an SDS-max mounting system.

There are models of rock drills equipped with the SDS-top system, which is built on the basis of the SDS + system, but has a 14 mm shank. Rotary hammers equipped with this system are used to produce small holes from 16 to 25 mm in diameter. These types of rock drills are reliable and durable. Some Bosch rotary hammers have this drill attachment system.

The drill is fixed using oval grooves. Each system has two of them, but the diameter of the attached shank is different: plus - 10 mm, top - 14 mm, max - 18 mm.

The torque is transmitted by means of long splines. The plus system has two of them, both are symmetrical, the top has two asymmetrical, and the max has three asymmetric slots.

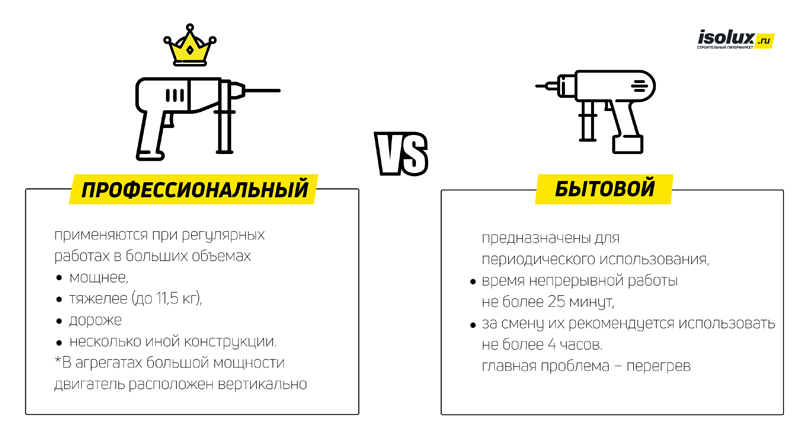

Rotary hammers by shape and engine location

In terms of appearance and shape, existing rock drills can be divided into L-shaped (vertical engine) and straight (horizontal). The design of the first type is good in that it allows you to reduce the length of the device and increase the cooling area of the engine. The rotary hammer with a vertical engine works longer without interruptions, since it does not overheat, and at the same time has an increased resource.

However, this tool is generally bulky, which reduces its maneuverability in confined spaces.For domestic purposes, devices with a horizontal engine are preferred. They are compact, lightweight and comfortable. In addition, during repairs, it is rarely necessary to operate the hammer drill for several hours without interruption.

Types of rock drills by weight and purpose

By weight and purpose, the following groups of devices are distinguished:

Lightweight (household) perforators - 2-4 kg.

Medium (semi-professional) perforators - 5-8 kg.

Heavy (professional) perforators - 8-10 kg.

Household rotary hammers

Perforators weighing less than 4 kg are considered light. They are bought for periodic repair work at home or in a garage. Better known as household rock drills.

Semi-professional rotary hammers

The middle class includes semi-professional instruments weighing from 5 to 8 kg, they are distinguished by increased power and impact force (5-7 J). The tool can even cut through a steel grate, not to mention making an opening in a concrete wall.

Professional rotary hammers

The heavy class includes hammer drills weighing more than 8 kg and an impact force of more than 8 J. The tool is designed for long, continuous work. It is usually used by repair crews, therefore it is called professional. Buying a heavy-duty hammer drill for domestic conditions is an unjustified investment.

Type of food

When deciding which perforator to choose for the home, you need to have a clear idea of what types of repair work will be performed and in what conditions.

Rotary hammers by type of power supply can be:

- electric;

- pneumatic;

- gasoline.

In a domestic environment, electric rock drills are used in most cases, which are:

- network;

- rechargeable.

The mains tool is powered by a regular electrical network, the rechargeable tool is powered by batteries (lithium-ion, nickel-cadmium or nickel-metal hydride)

If it is possible to connect to an outlet, choose a power drill, paying attention to the length of the power cord (the longer, the better). And if there is no network connectivity, then a self-contained cordless rotary hammer is the best solution, but it costs much more and is used much less often.

Conclusion

Drawing conclusions from the above article, there are several main reasons for buying a hammer drill as a home tool:

- Versatility in work. This tool can be used as a drill, screwdriver, mixer, etc.

- Power. For chiselling concrete walls, removing unnecessary plaster and putty, for creating ditches in hard rocks, a puncher will come in handy in all this.

- Wide choose. Depending on your financial capabilities, you can purchase a quality tool that will serve you for a long time.

Happy choice!

- Cordless screwdrivers: model rating, tips for choosing

- Jigsaw: how to choose, characteristics, rating of models

- LBM with speed control and smooth start. Model rating

- Rechargeable reciprocating saw. How to choose a rating of the best models